Control method of electrical discharge machining power supply capable of realizing automatic boosting

A technology of automatic boosting and control method, which is applied in the field of power processing, can solve the problems of not meeting the requirements and accuracy of processing size, and achieve the effect of improving processing efficiency and processing size accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Embodiment: A control method of an electric discharge machining power supply that can automatically boost voltage.

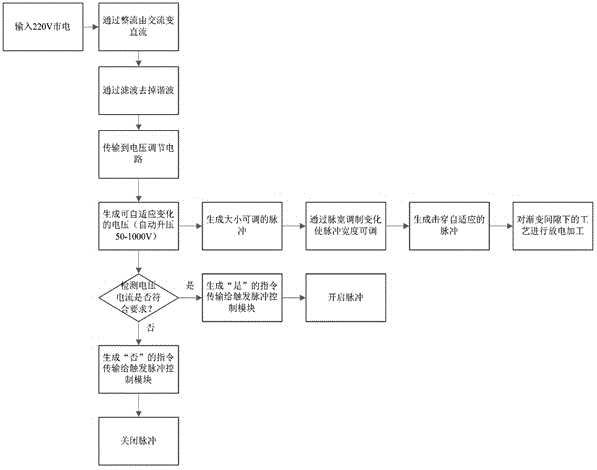

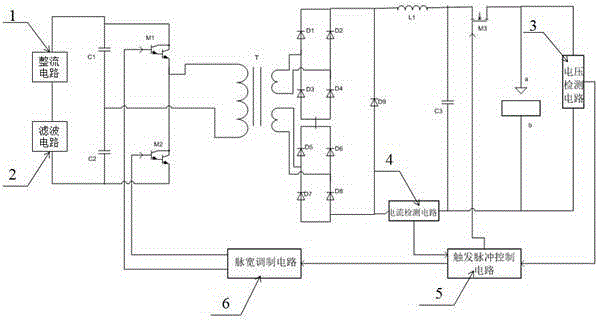

[0024] refer to figure 1 As shown, a control method of an EDM power supply that can automatically boost voltage includes the following steps:

[0025] S1. Rectification; input 220V AC mains power into rectification circuit 1, after being rectified by rectification circuit 1, 220V AC mains power becomes 220V DC power;

[0026] S2. Filtering; after step S1, input the 220V direct current into the filter circuit 2, and remove the harmonics through the filter circuit 2;

[0027] S3. Voltage adjustment: input the DC power after harmonic removal to the voltage adjustment circuit, and the voltage adjustment circuit adjusts the DC voltage, so that the voltage can be adaptively changed, and the voltage can be automatically boosted to 50-1000V;

[0028] S4. Generate pulses; input the regulated voltage to the pulse forming circuit, and the pulse forming circuit gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com