Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Won't lift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing organic electroluminescent display mask plate

InactiveCN101250685AGuaranteed tensionReduce tensionVacuum evaporation coatingSputtering coatingWire gauzeSheet steel

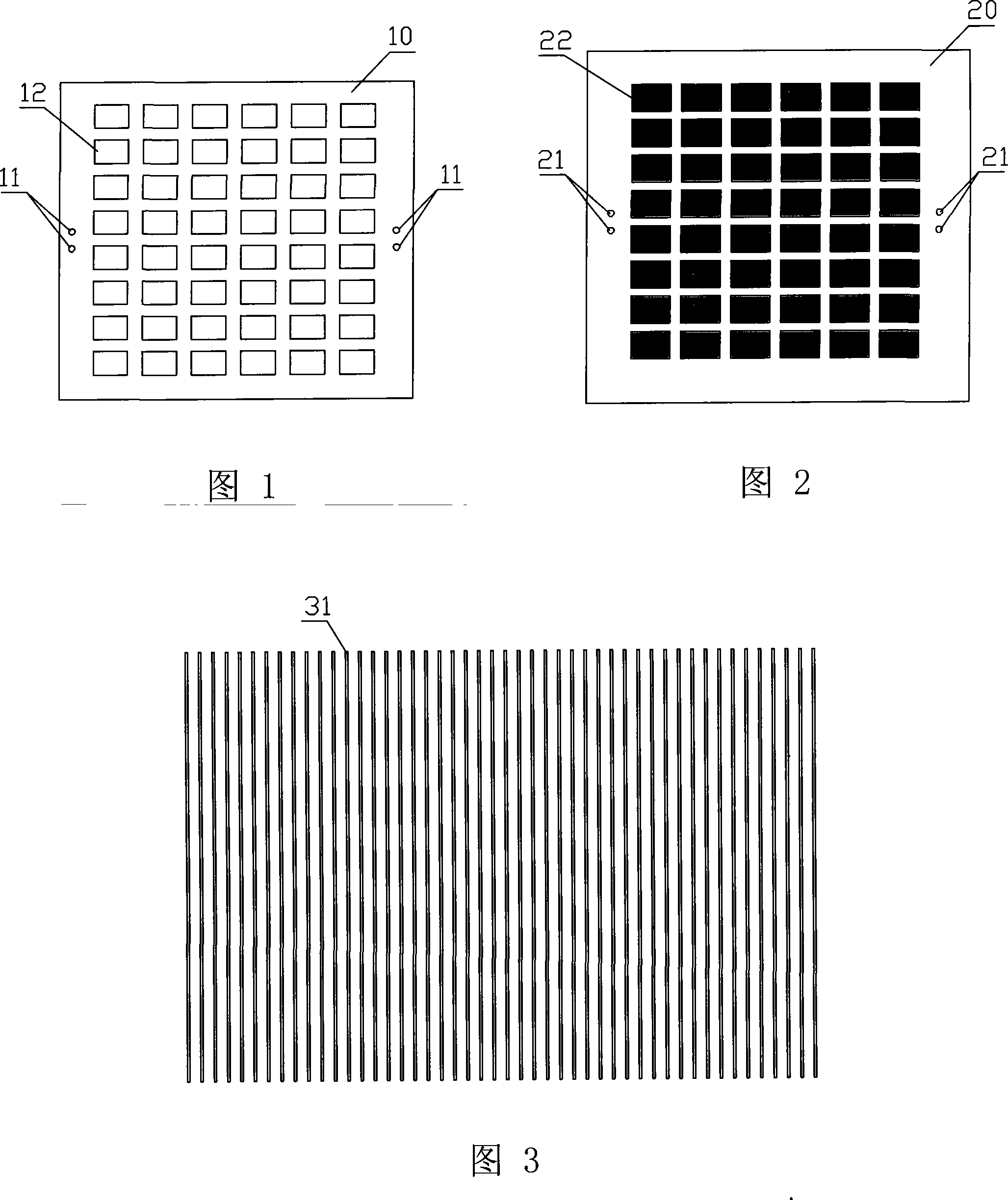

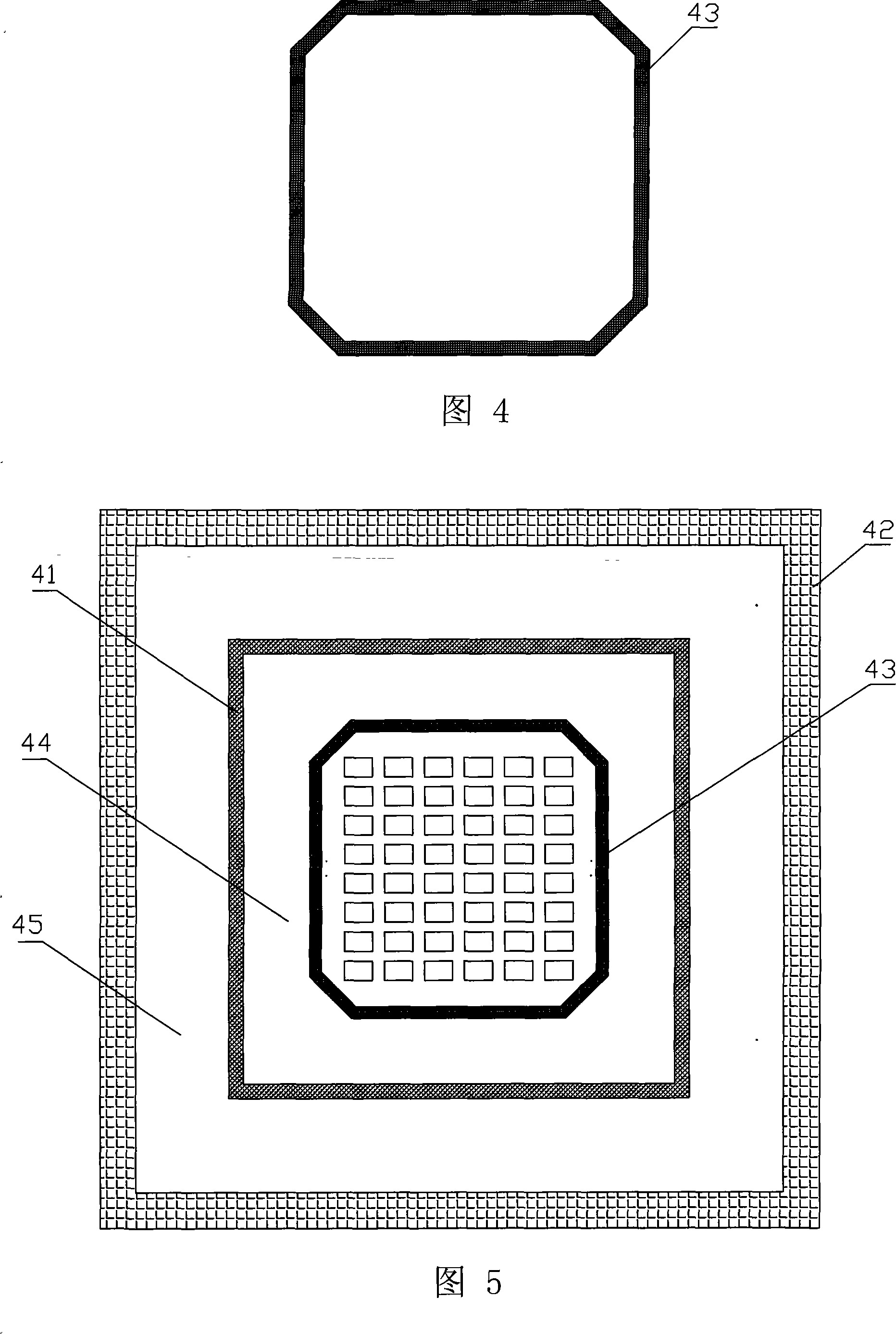

The invention discloses a method for producing mask plates of organic electroluminescent displays, which comprises following steps: taking a sheet of magnetic conductive thin sheet steel, utilizing stainless steel etching or laser cutting to open holes on the thin sheet steel to form patterns, flatly spreading a silk screen on the thin sheet steel with the patterns, coating mucilage which is used to stretch the silk screen on the edge of the thin sheet steel, then, removing the silk screen on the region of thin sheet steel patterns, then, stretching the silk screen, taking a frame body, clinging the frame body on the stretched silk screen to form a net frame, tailoring along the outer margin of the net frame after bonding stably, cutting another magnetic conductive sheet steel into an outer frame of the mask plate which is needed, then, connecting the outer frame of the mask plate and the magnetic conductive thin sheet steel in the net frame, then, cutting off the silk screen, shedding the net frame, lastly, cutting off excess sheet steel along the outer margin of the outer frame of the mask plate, and finishing producing the mask plate. The method of the invention utilizes the silk screen to stretch the thin sheet steel, which lowers the production cost and simplifies the technological process, the net frame is more stably connected with the outer frame, the operation is comparatively simpler, and the precision is greatly increased.

Owner:TRULY SEMICON

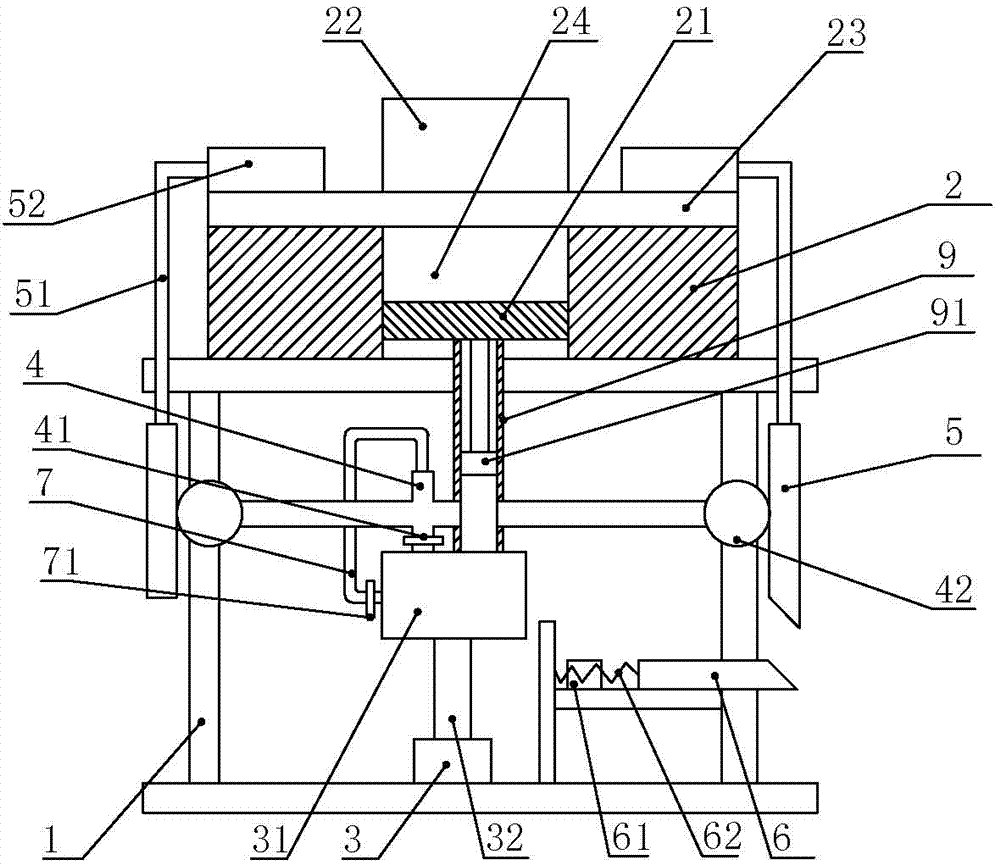

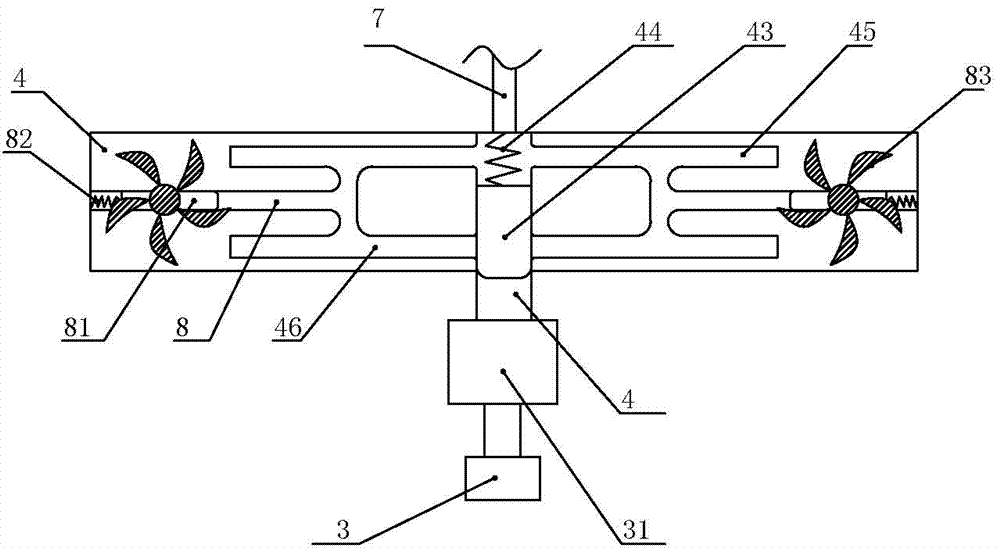

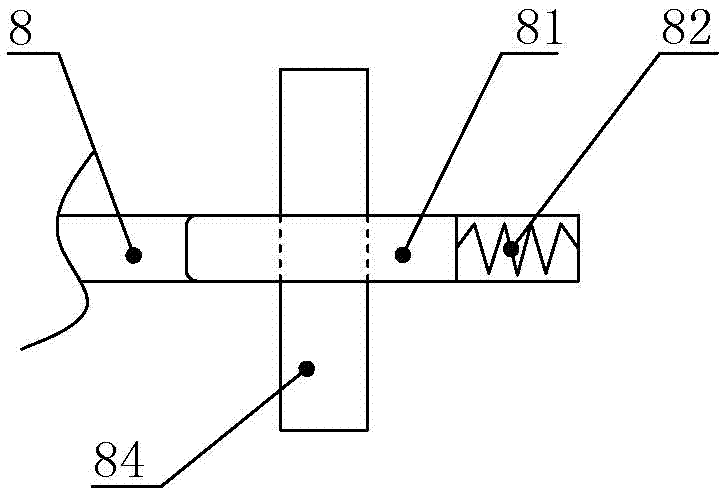

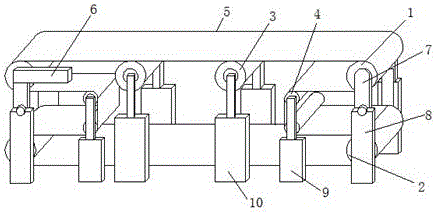

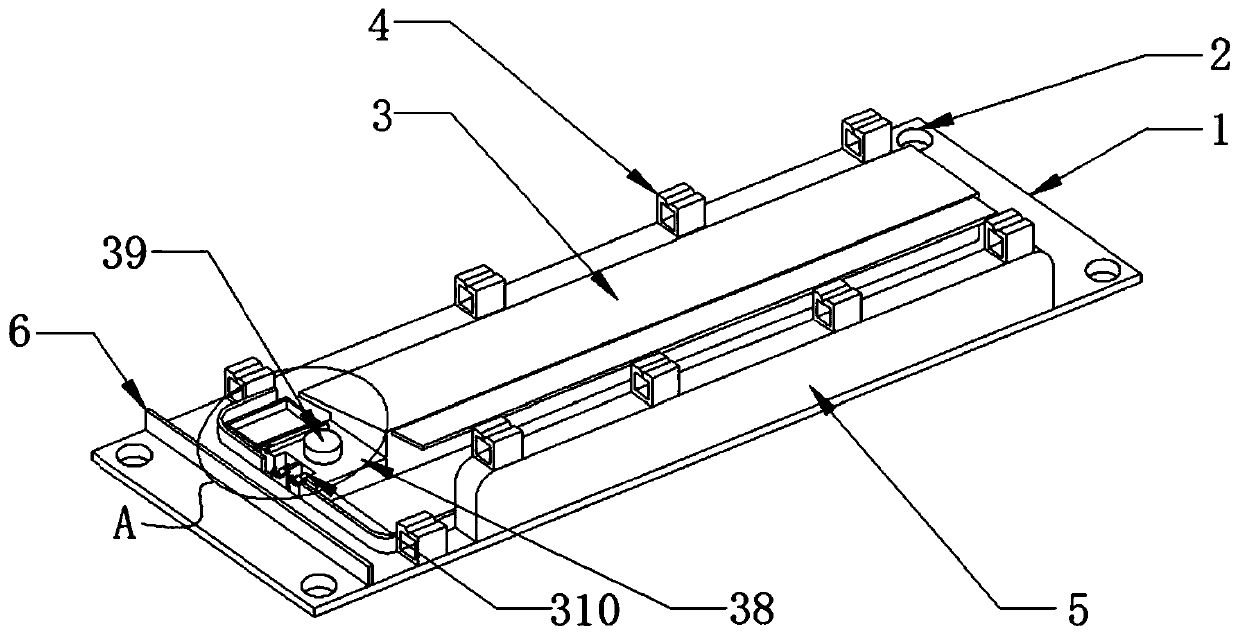

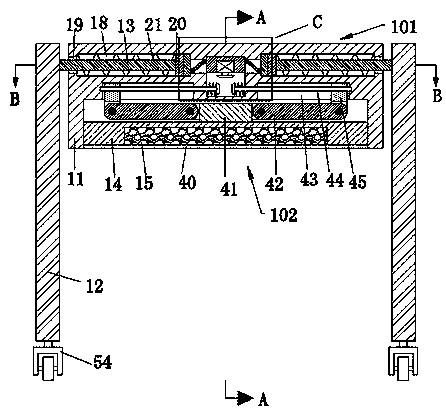

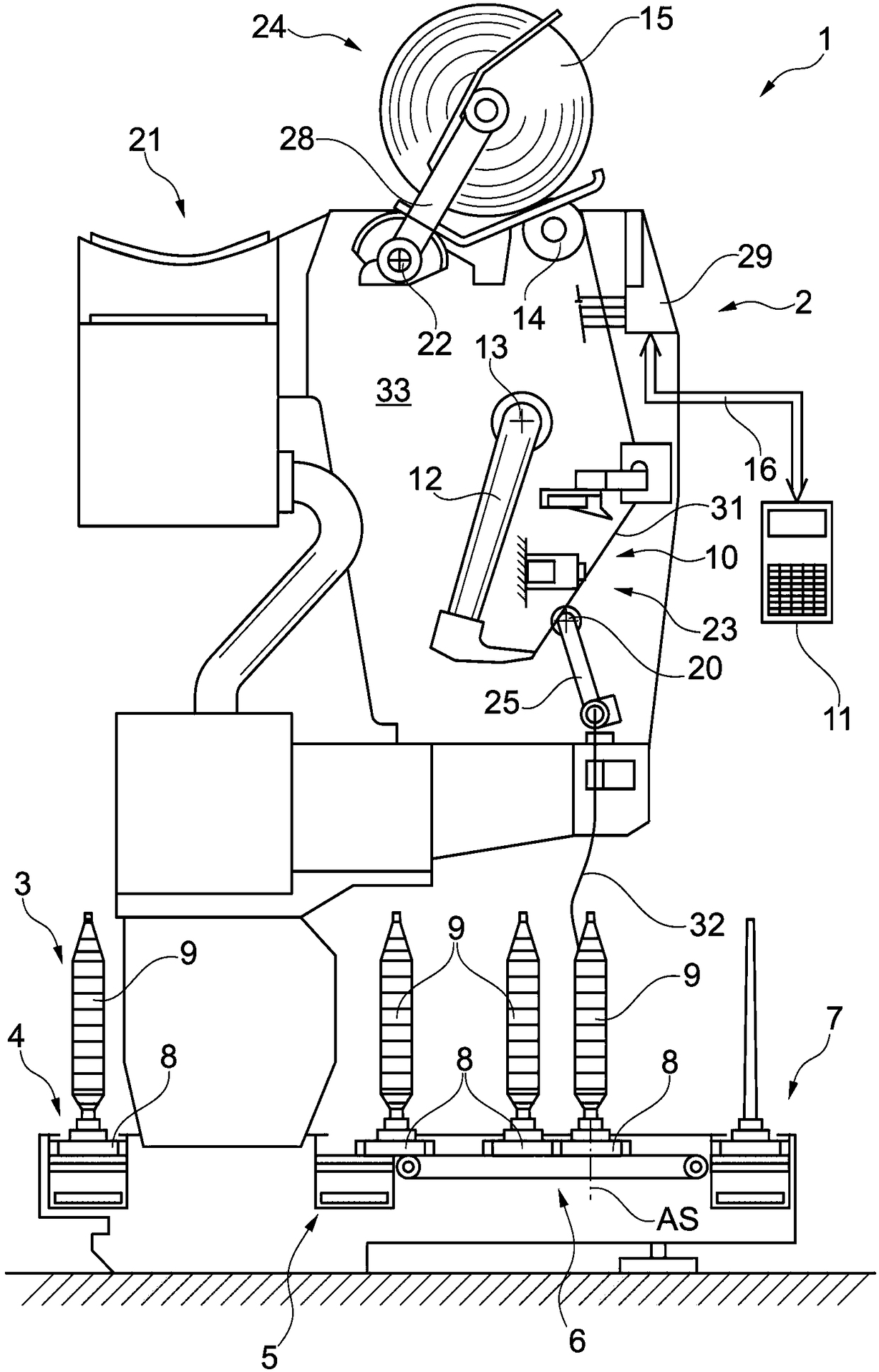

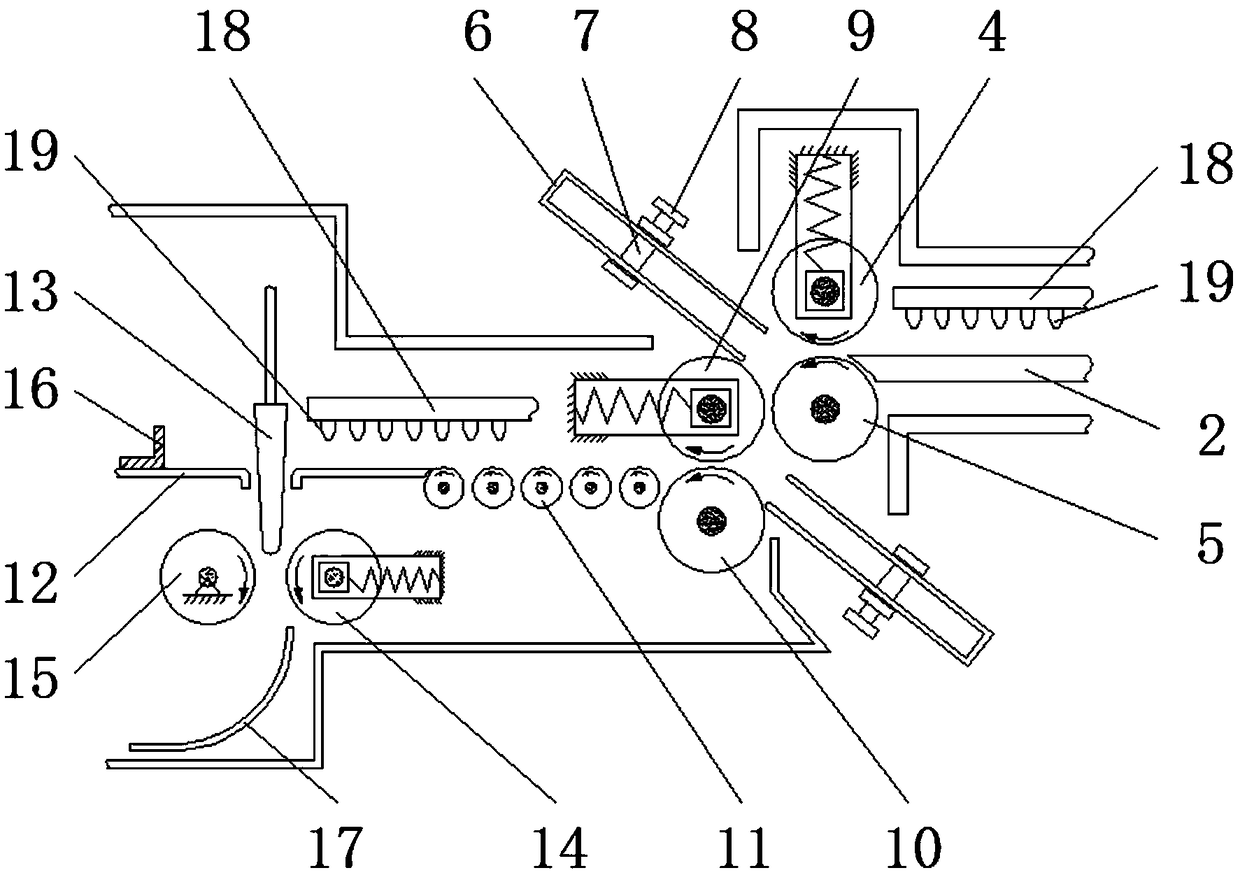

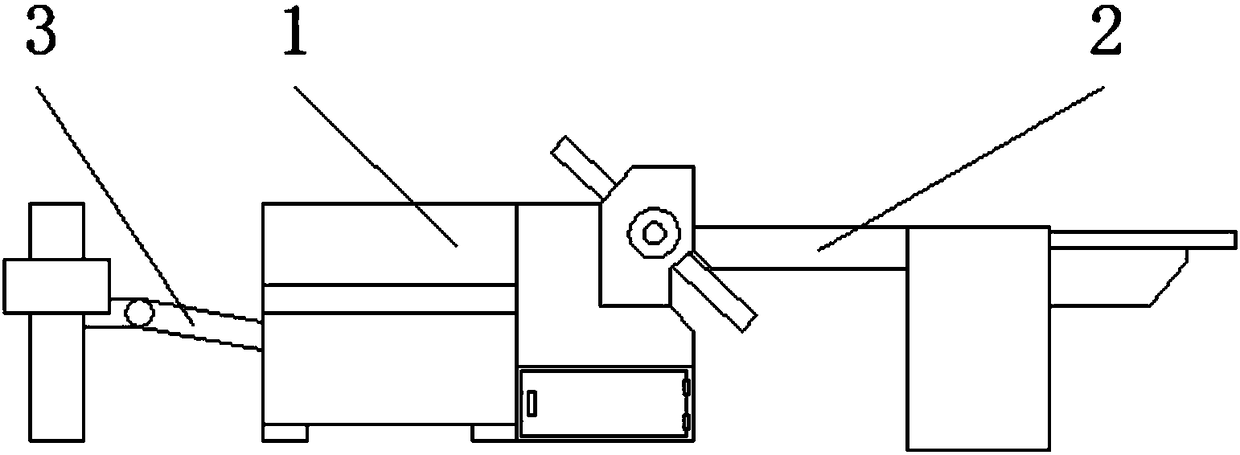

Handwork imitation full-automatic egg-biscuit-roll machine

InactiveCN102640941AGuaranteed to be rolled upImprove the success rate of windingFood preparationManipulatorImitation

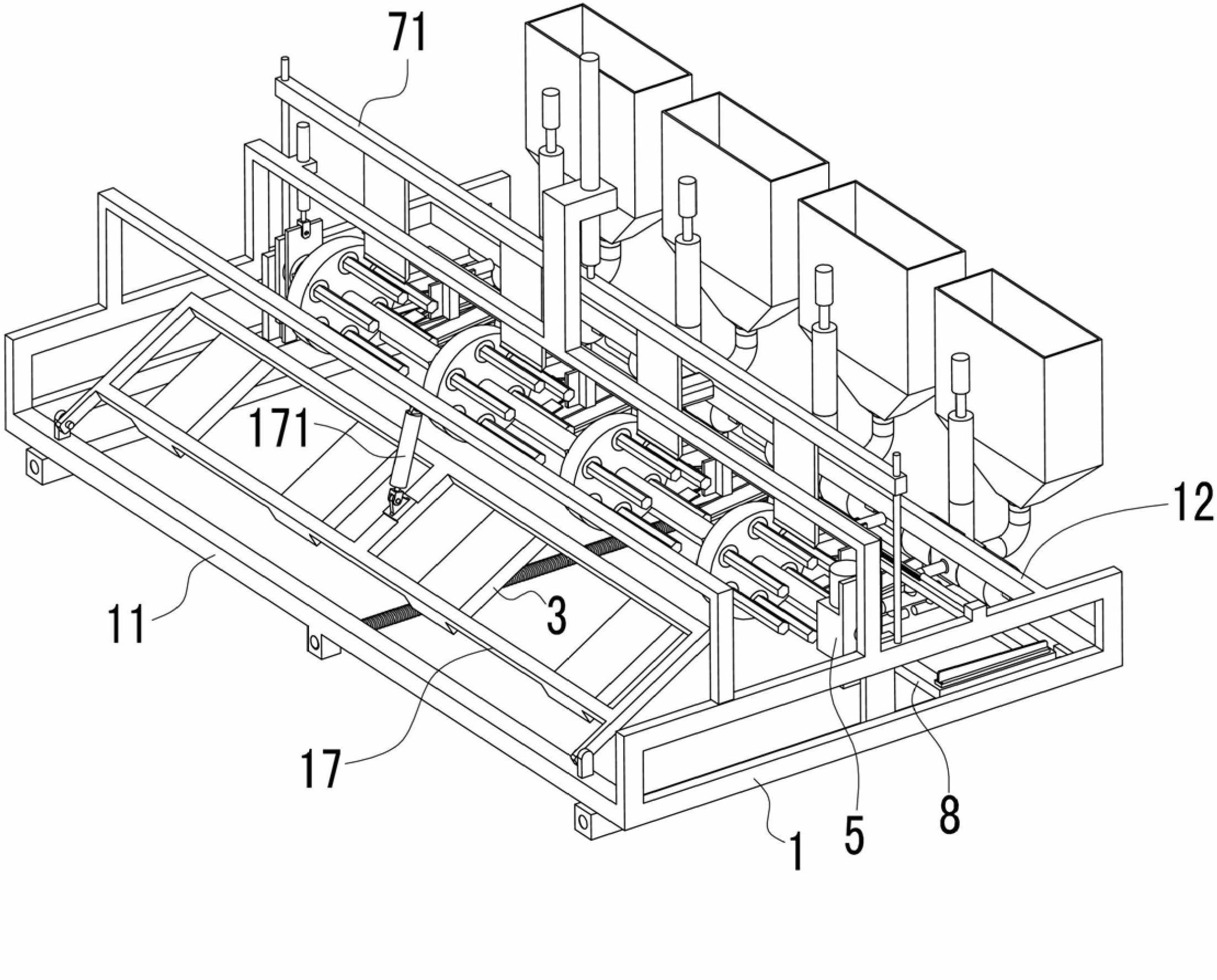

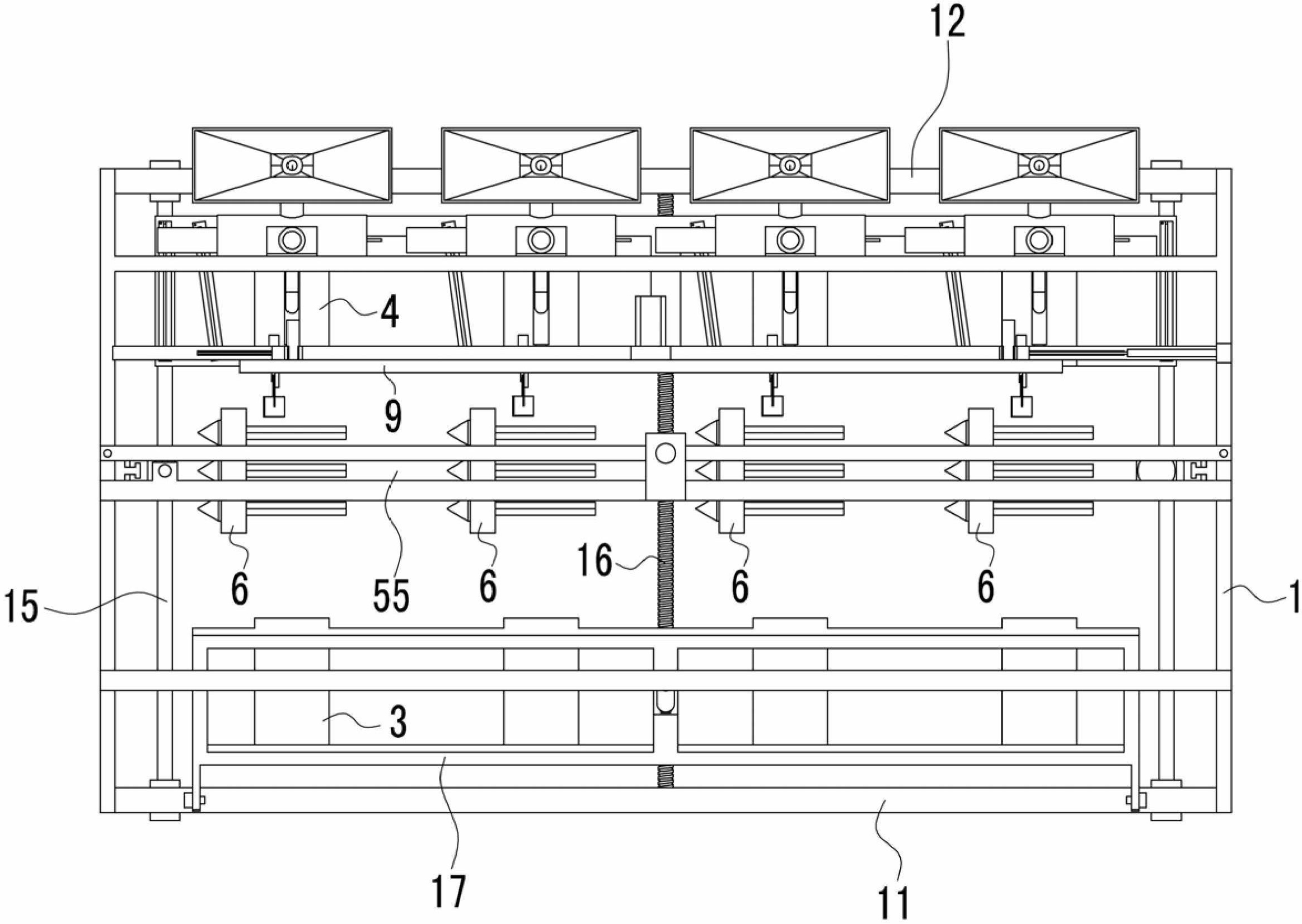

The invention relates to an egg-biscuit-roll machine which comprises a rack, a controller and a plurality of egg-biscuit-roll processing units arranged on the rack, wherein each egg-biscuit-roll processing unit comprises a material discharge device, a heating device, a material rolling device and a manipulator material unloading device; the material discharge device is installed at the tail end of the rack; the heating device comprises an upper mold board and a lower mold board; the lower mold board is installed on the bottom of the rack in a sliding manner; the material rolling device comprises a lifting frame, a rotary plate, a material shoveling mechanism and a plurality of rolling cylinders; the lifting frame is installed in the middle of the rack; the rotary plate is installed on the lifting frame; the rolling cylinders are pivoted on the periphery of the rotary plate; the material shoveling mechanism comprises a cross beam and a shoveling plate; the shoveling plate is installed on the cross beam; and after egg-biscuit-roll shells are rolled, the egg-biscuit-roll shells are taken out by the manipulator material unloading device. According to the invention, the egg-biscuit-roll shells can be ensured to be rolled on the rolling cylinders, the rolling success rate of the egg-biscuit-roll shells is improved, the production efficiency is improved, meanwhile, the storage space of the egg-biscuit-roll machine is saved, the amount of driving mechanisms of each egg-biscuit-roll processing unit is reduced, and the manufacturing cost is saved.

Owner:中山市万利园食品有限公司

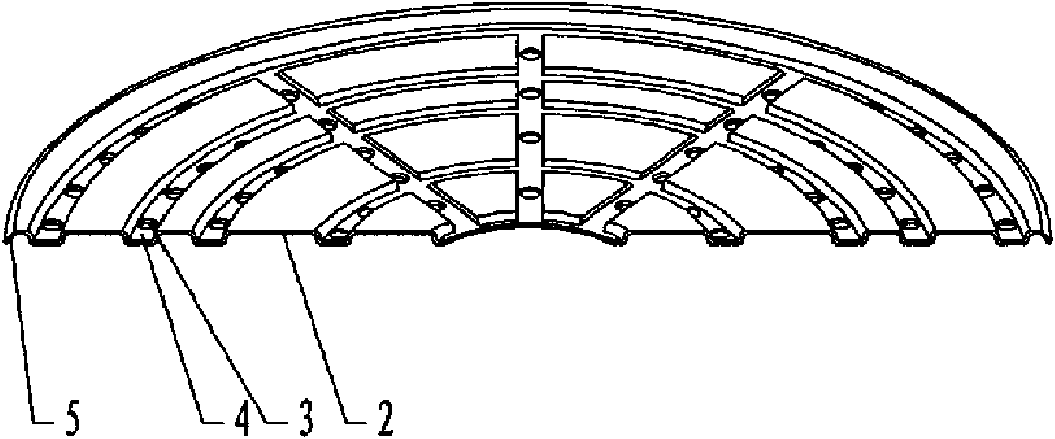

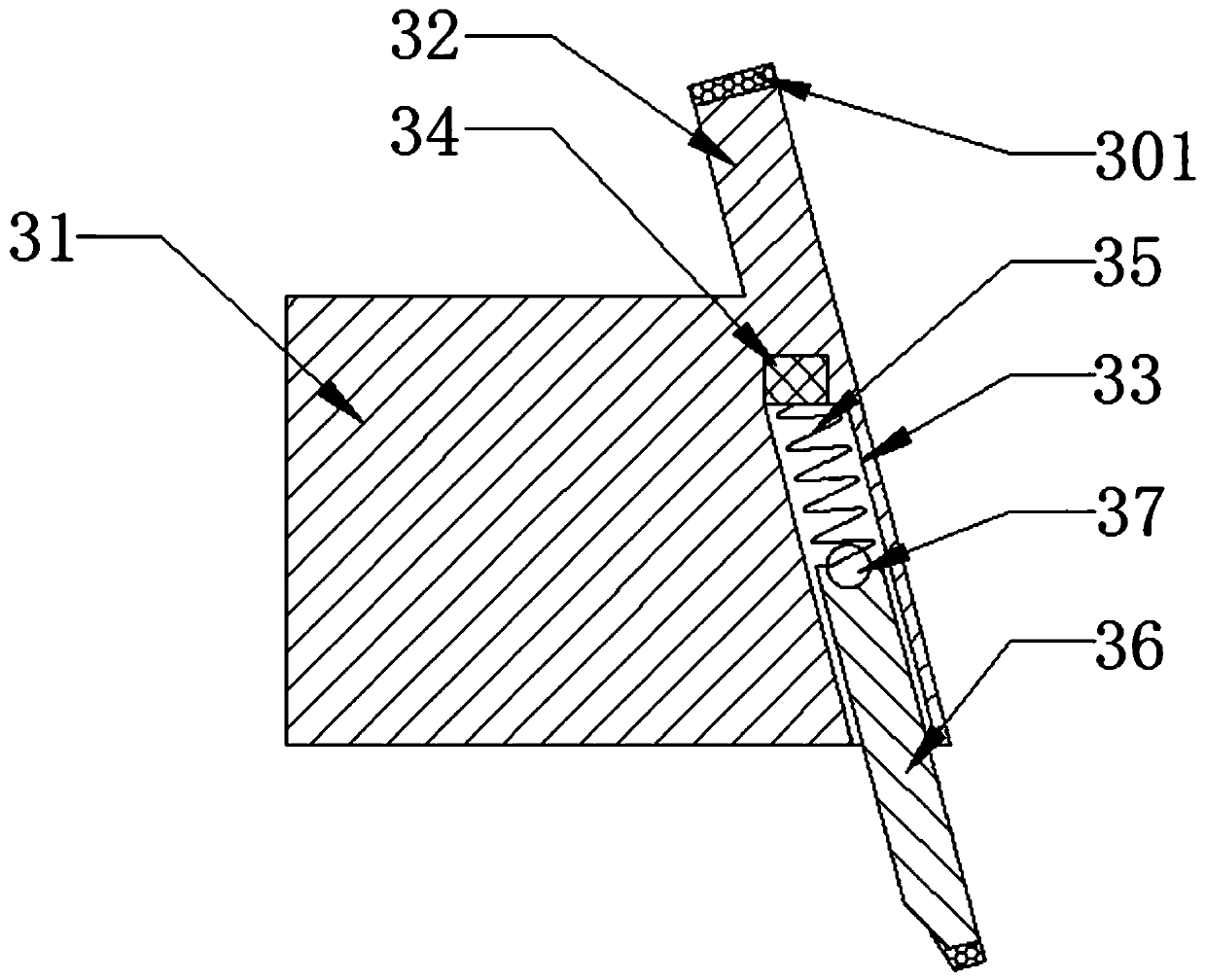

Novel self reset shock insulation support seat

ActiveCN104775358ASelf-resetting function guaranteeReduce overdependenceBridge structural detailsShock proofingSelf recoveryEngineering

The invention discloses a novel self reset shock insulation support seat, comprising an upper connection plate and a lower connection plate. The novel self reset shock insulation support seat is characterized in that corresponding grooves are formed in middles of the upper connection plate and the lower connection plate; bulges are correspondingly formed at the middles of the grooves; elastic cushion layers are cemented at the surfaces of the grooves; an oval rolling body is movably connected between the elastic cushion layers; two trenches are symmetrically formed in the spherical surface of the rolling body; a steel plate laminating rubber drum connected with the upper connection plate and the lower connection plate is arranged at the outside of the rolling body; a clearance is reserved between the rolling body and the steel plate laminating rubber drum; lead cores are arranged at the inner peripheral direction of the steel plate laminating rubber drum at equal intervals. The support seat can absorb high vibration energy, is high in self recovery capacity, and has the advantages of simple structure, convenience in use, high safety and the like, and excessive lateral displacement of the support seat is avoided without lifting a structure body.

Owner:TIANJIN UNIV

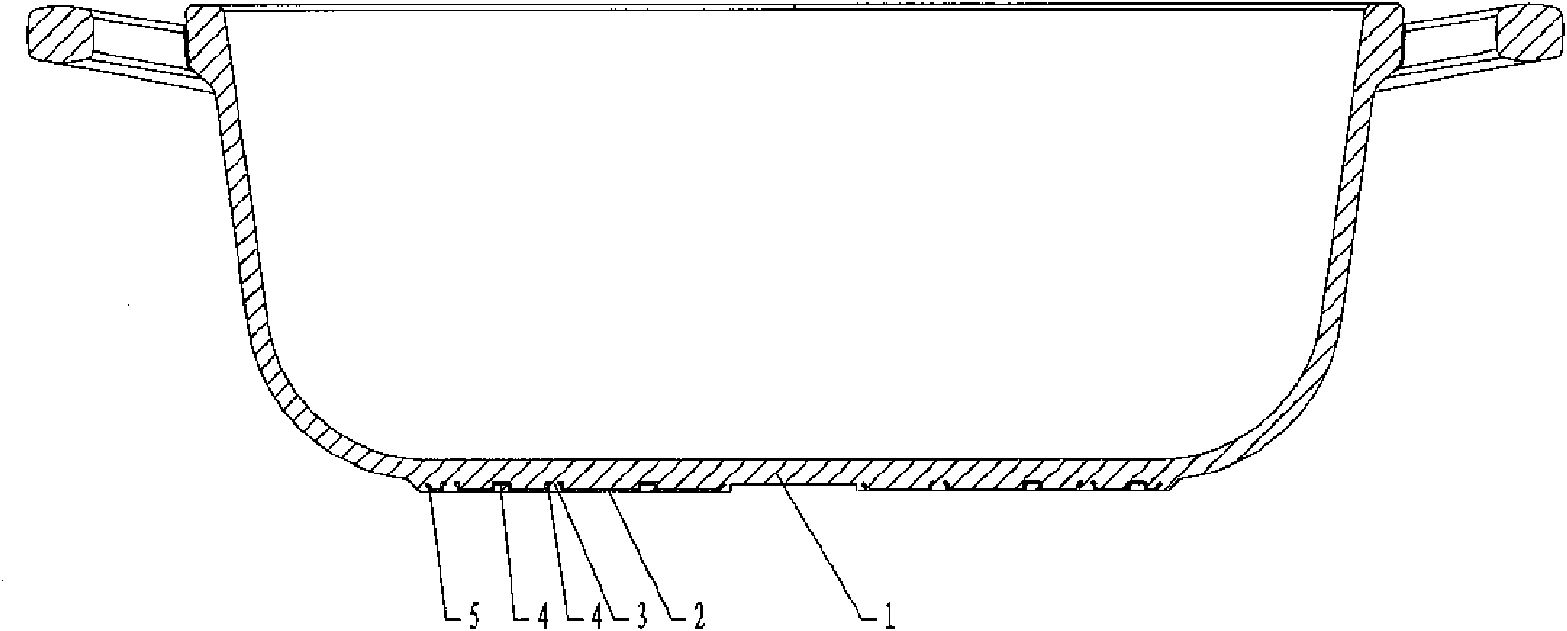

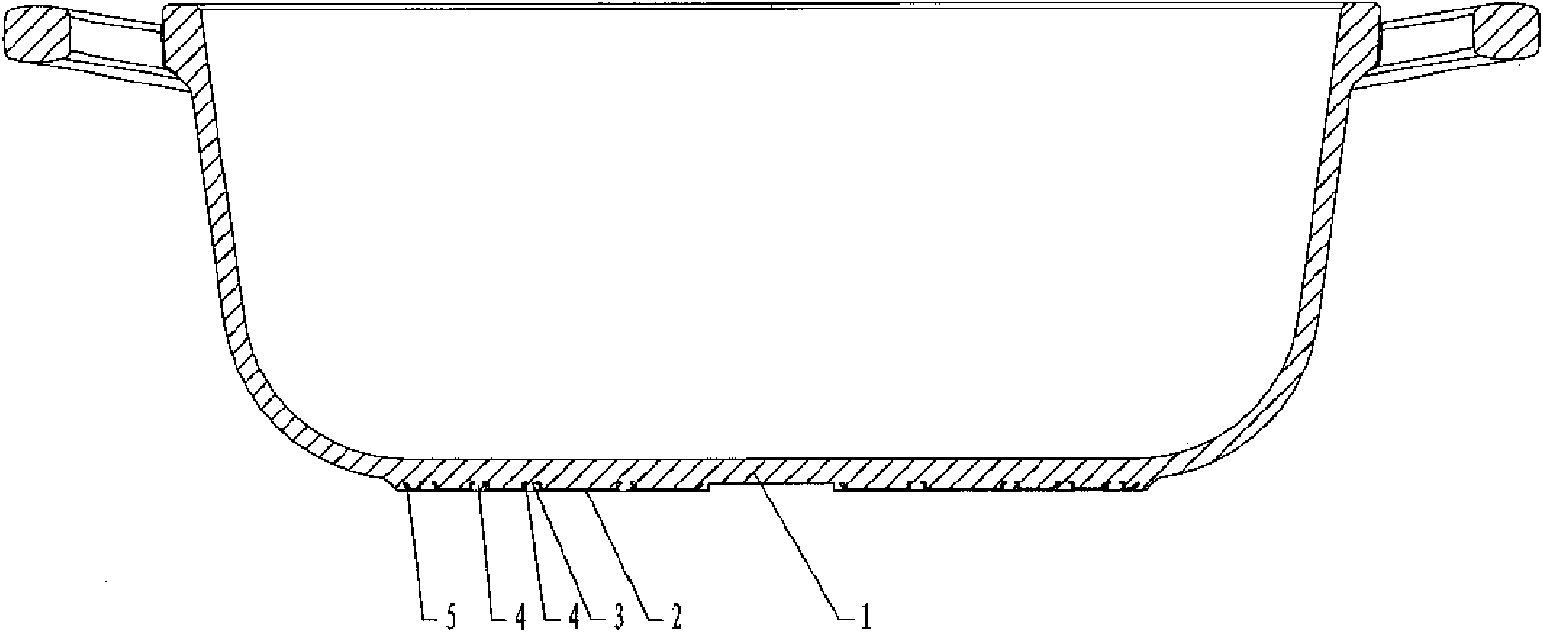

Aluminium pot with compound bottom and manufacturing method thereof

The invention relates to an aluminium pot with a compound bottom. The pot bottom is fixed with a metal magnetic conductive sheet which is provided with a plurality of holes and grooves, wherein the holes are arranged on the bottoms of the grooves; the groves communicate at least two holes; the spot bottom and the metal magnetic conductive sheet are cast into an integer in a pressing way through a press-casting machine; the grooves are filled with aluminium alloy, and the aluminium alloy inside the grooves is connected with aluminium alloy positioned on the spot bottom through the holes. The grooves are filled with the aluminium alloy, and the aluminium alloy inside the grooves is connected with the aluminium alloy positioned on the spot bottom through the holes, thereby the metal magnetic conductive sheet and the spot bottom of the aluminium pot are reliably fixed; the holes are arranged on the bottoms of the grooves, and the groves communicate at least two holes, thereby the peripheries of the holes of the metal magnetic conductive sheet are wrapped by the aluminium alloys; and the peripheries of the holes of the metal magnetic conductive sheet can not be tilted in the using process of the aluminium pot, thereby effectively preventing an electromagnetic range from being scratched.

Owner:胡程韶

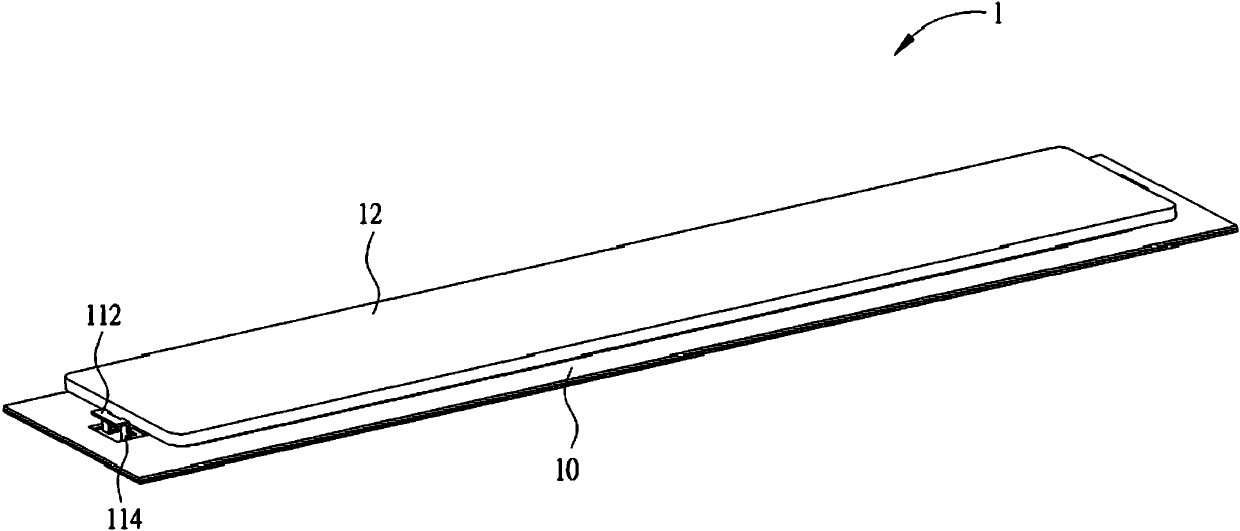

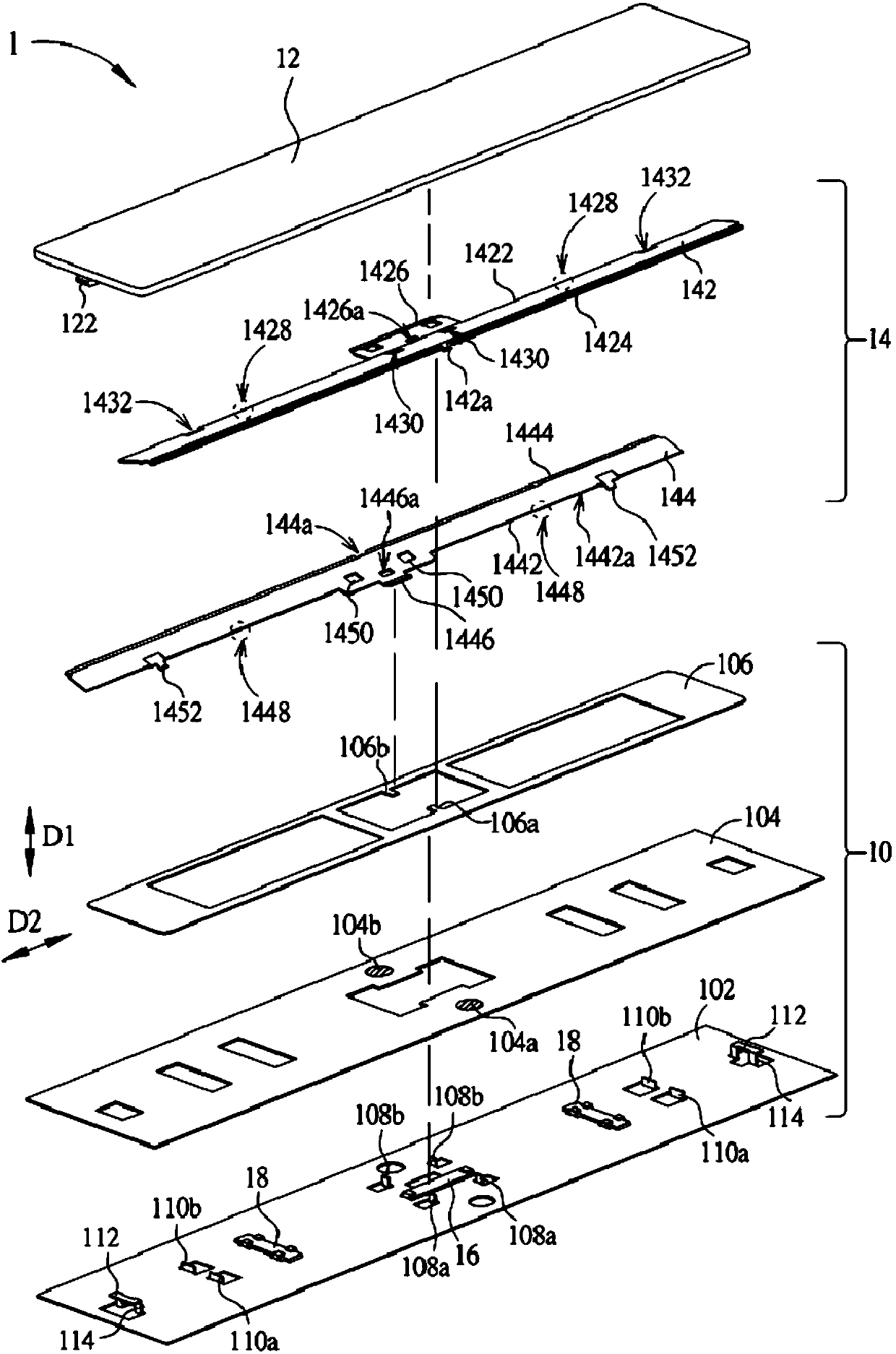

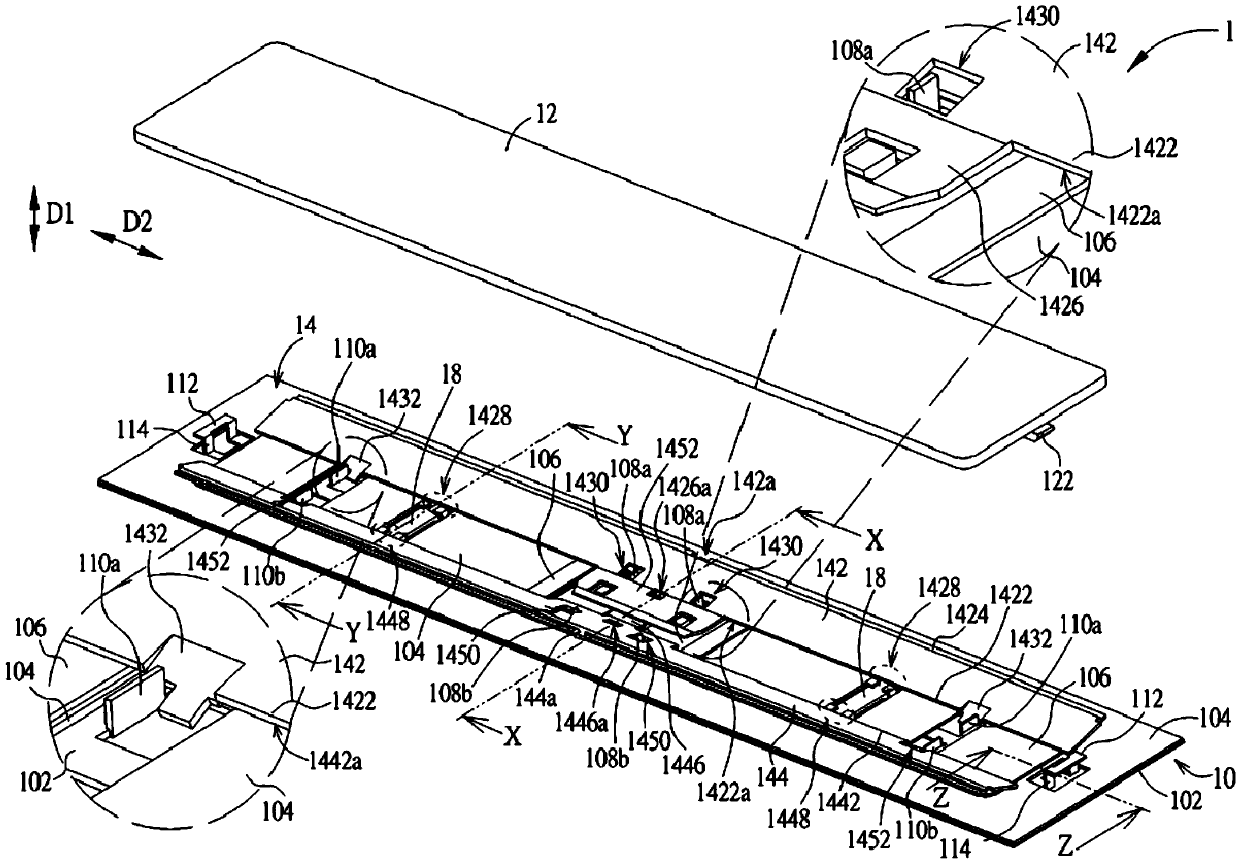

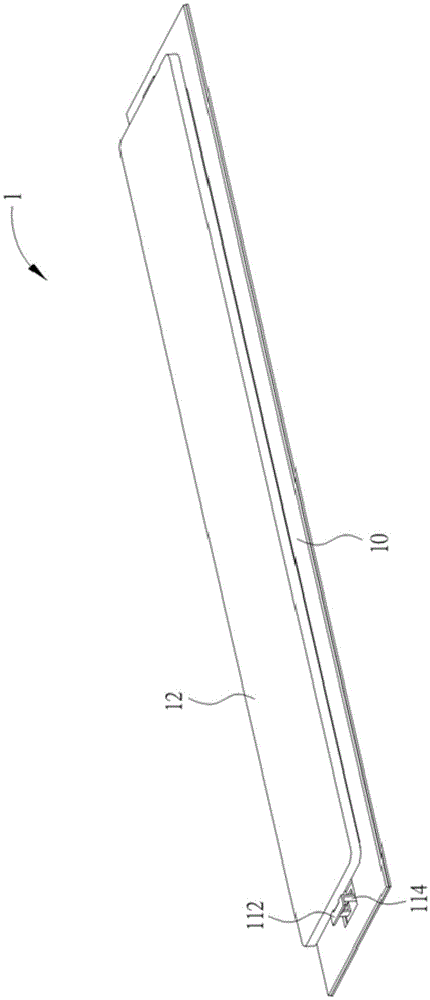

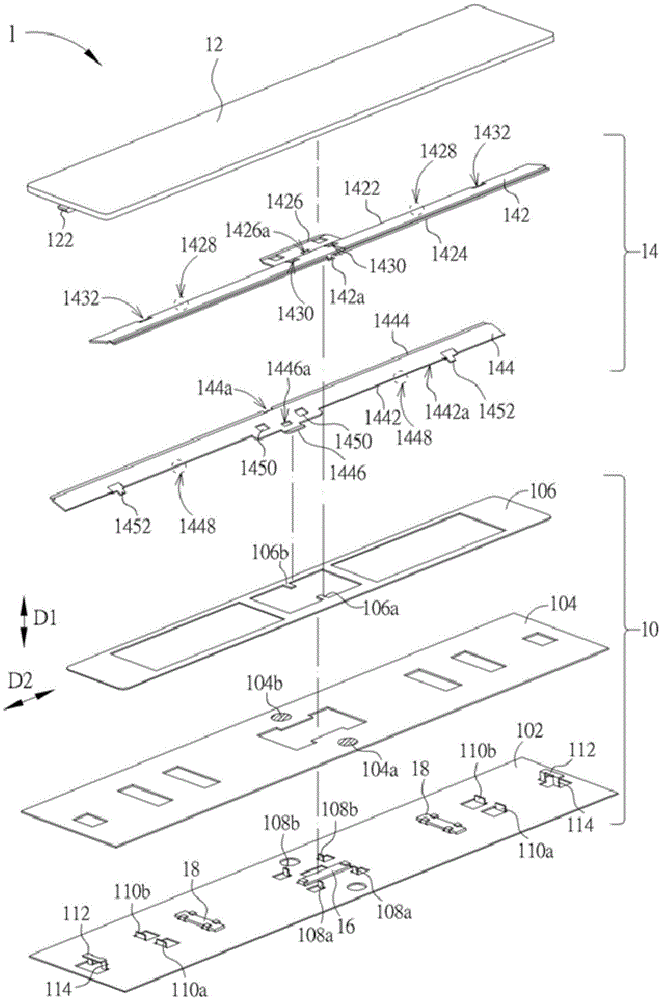

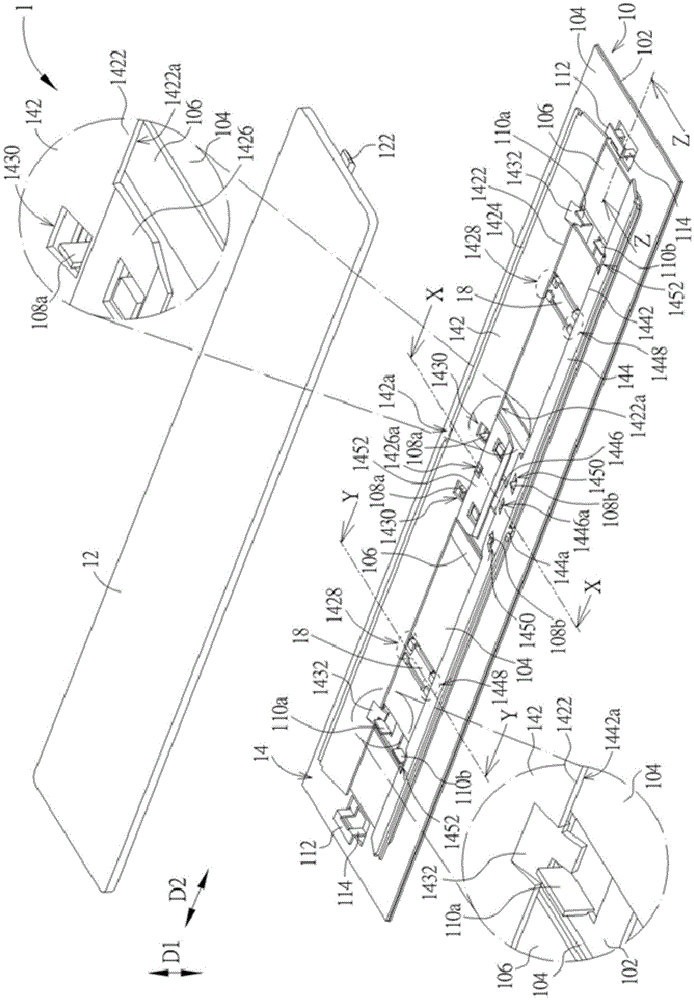

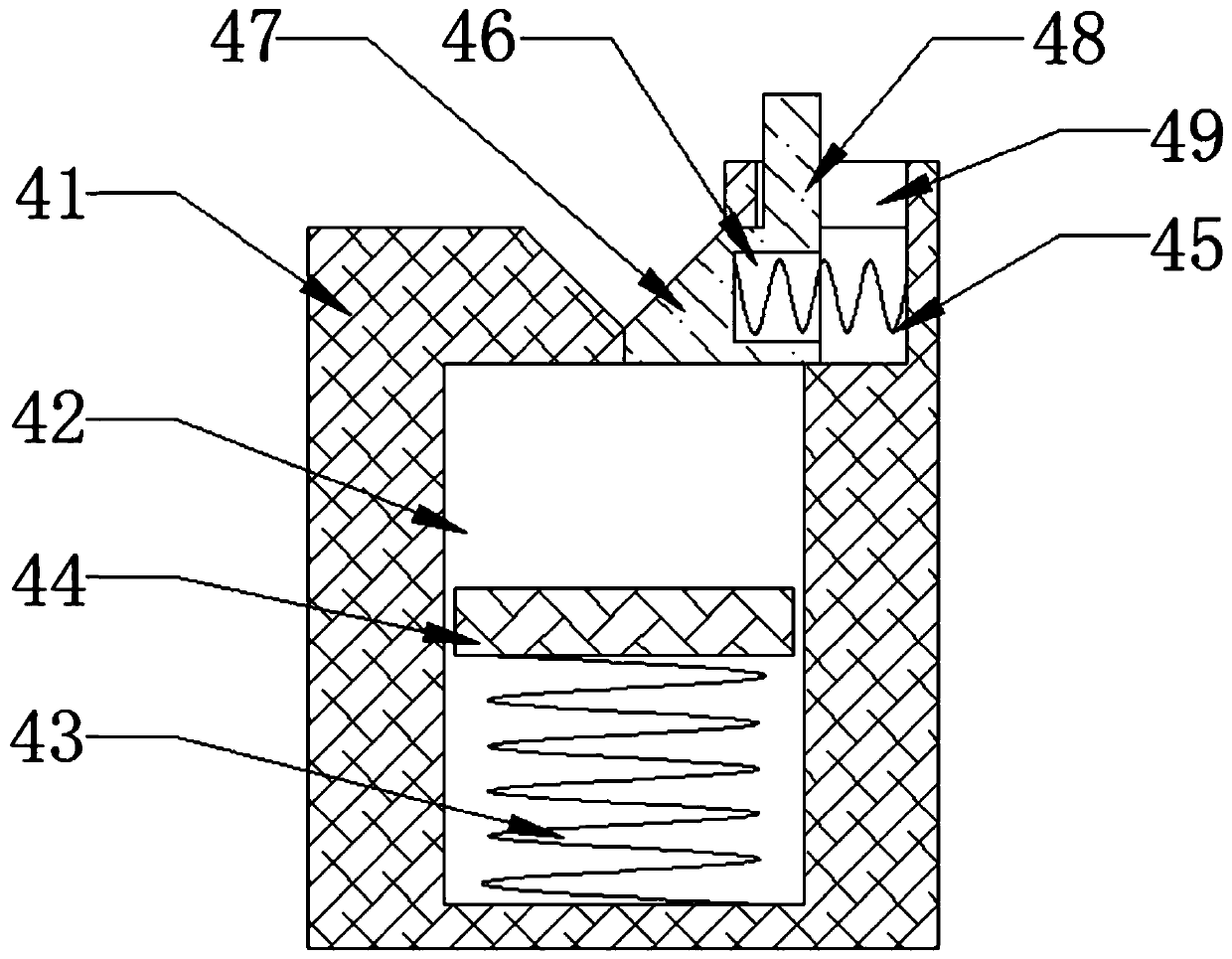

Key structure

ActiveCN104201029ALower the altitudeApproach steadilyElectric switchesTactile feedbackKey pressingSuction force

The invention relates to a key structure. The key structure comprises a base, a keycap, a lifting mechanism and a magnetic part; the keycap can move vertically relative to the base through the lifting mechanism; the lifting mechanism comprises a support; one lateral side portion of the support comprises a magnetic portion; the lateral side portion is in abutting joint with the base through a sharp edge; the magnetic portion extends outward from the lateral side portion; the support is flexibly connected with the keycap through an opposite lateral side portion; the magnetic part is arranged on the base corresponding to the magnetic portion; the magnetic suction force is produced between the magnetic part and the magnetic portion; when the keycap is pressed by the external force, the support rotates relative to the base through the sharp edge to enable the magnetic portion to be far away from the magnetic part and the keycap to be close to the base; when the external force is released, the support is driven by the magnetic suction force to rotate relative to the base through the sharp edge to enable the keycap to be far away from the base; the base can be provided with a magnetic part, wherein the magnetic suction force can be applied to the other magnetic portion of the support to drive the lateral side portion to be in abutting joint with the base.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

Multilayer sheet comprising a protective polyurethane layer

InactiveCN1602251AImprove wear resistanceImprove scratch resistanceFilm/foil adhesivesSynthetic resin layered productsTectorial membraneIonomer

The invention relates to a multi-layer sheet for use as a decorative protective film on a door or window post of a vehicle. The multi-layer sheet comprises (i) a polymeric film having a thickness of not more than 150mu and that is formed from an ionomer of an olefin-vinyl carboxylic acid copolymer, (ii) on a first side of the polymeric film a cross-linked polyurethane layer comprising the crosslinking reaction product of a polyurethane containing acid groups and a crosslinker and (iii) on a second side of the polymeric film opposite to the first side, an adhesive layer.

Owner:3M INNOVATIVE PROPERTIES CO

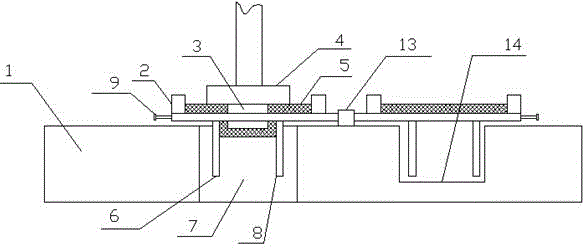

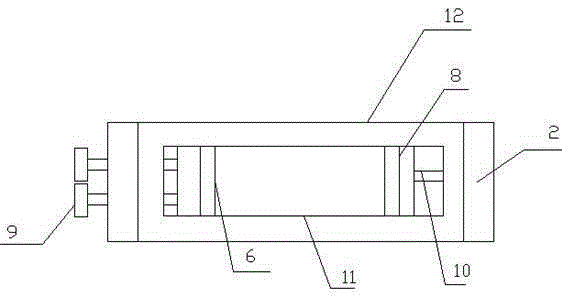

Stamping die

ActiveCN107344198AWon't liftGood stamping effectPerforating toolsMetal-working feeding devicesGear wheelEngineering

The invention relates to the technical field of metal forging, in particular to a stamping die. The stamping die comprises an upper die body. A lower die body is arranged in a die cavity. A steam generator and a booster pump are arranged below the lower die body. The booster pump communicates with a main pipe. The main pipe communicates with a branched pipe, and the branched pipe communicates with the booster pump. A sliding plate is slidably arranged in the main pipe. A first spring is connected between the sliding plate and the wall of the main pipe. A turbine is arranged in the main pipe. A first air duct and a second air duct are formed in the main pipe, and an air outlet of the first air duct and an air outlet of the second air duct face two symmetrical sides of the turbine correspondingly. A third air duct is formed between the first air duct and the second air duct in a communicating mode. A plug pin is slidably arranged in the third air duct, a second spring is connected between the plug pin and the wall of the third air duct, and the plug pin is slidably arranged on a turbine shaft of the turbine. The turbine is coaxially connected with gears, the gears are engaged with racks, the racks are connected with connecting rods, and the connecting rods are connected with pressing blocks used for pressing the two ends of a workpiece. By adoption of the stamping die, the problem that the two ends of the workpiece warp upwards in the stamping process is solved.

Owner:常熟市明光冲压件有限公司

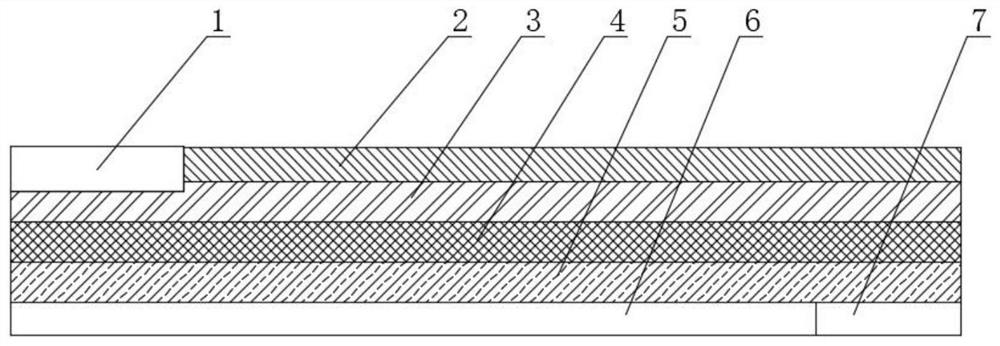

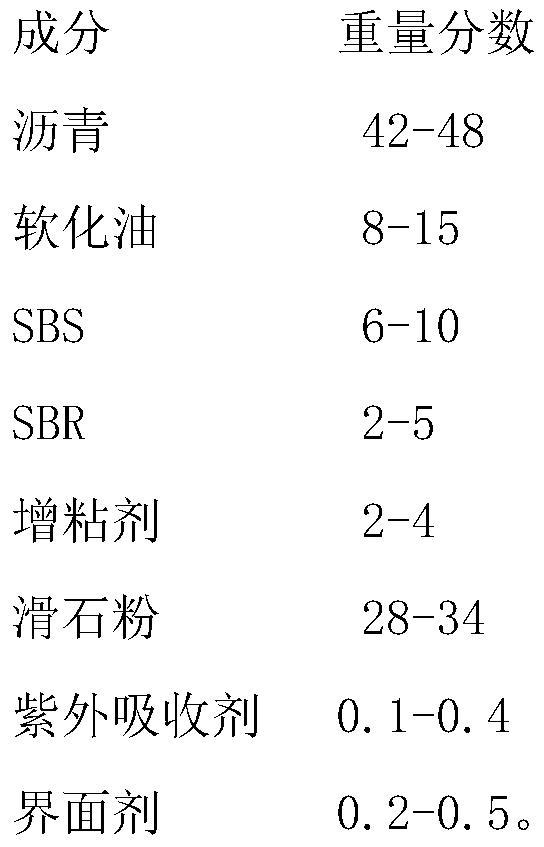

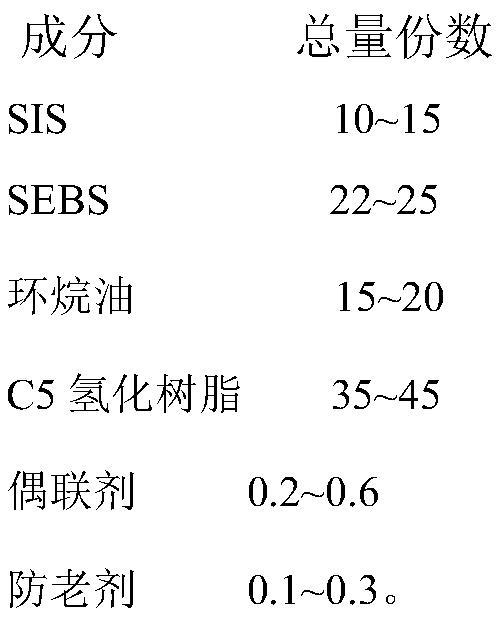

Super strong cross laminated film self-adhesive waterproof coiled material and preparation process thereof

ActiveCN111805994AImprove physical performanceHigh tensile strengthNon-macromolecular adhesive additivesSynthetic resin layered productsPolymer scienceAdhesive

The invention relates to a super strong cross laminated film self-adhesive waterproof coiled material which sequentially comprises an isolation protection layer, a non-asphalt-based self-adhesive layer, a strong cross laminated film, an asphalt self-adhesive layer and a PE isolation film from top to bottom, one side of the upper surface of the coiled material is a lap joint edge, and the other side of the lower surface of the coiled material is also provided with a lap joint edge. The bonding performance of the waterproof coiled material provided by the invention and post-cast concrete is better than that of an asphalt-based coiled material; the waterproof coiled material can be better bonded with a main body structure (namely a pre-laid reverse-bonding coiled material), the strong cross laminated film in the middle of the coiled material has good ductility, the coiled material can still be well bonded with the main body structure when a base layer slightly sinks or the main body structure slightly deforms, the coiled material cannot be separated, and a good waterproof effect can be achieved.

Owner:TIANJIN JOABOA TECH CO LTD

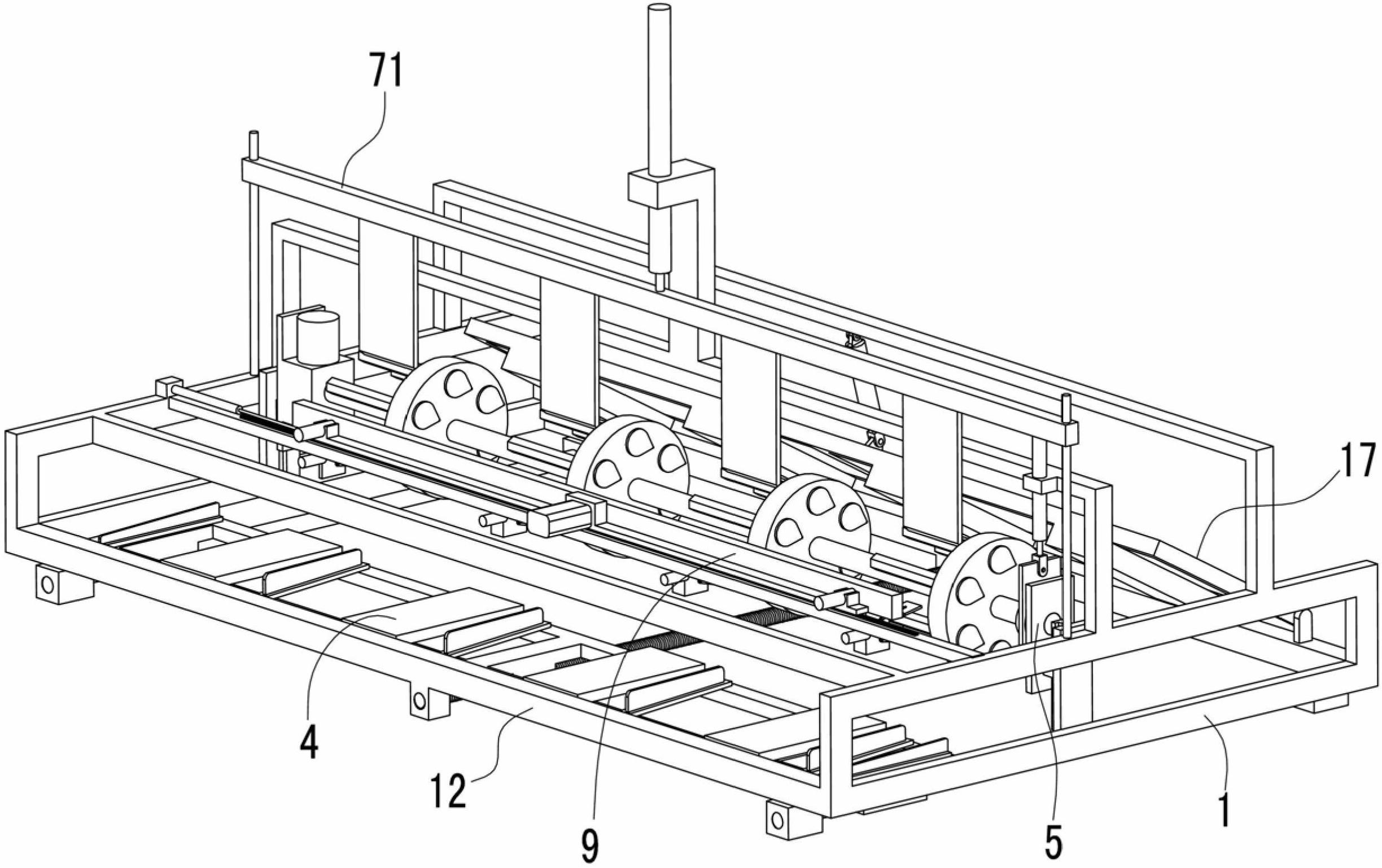

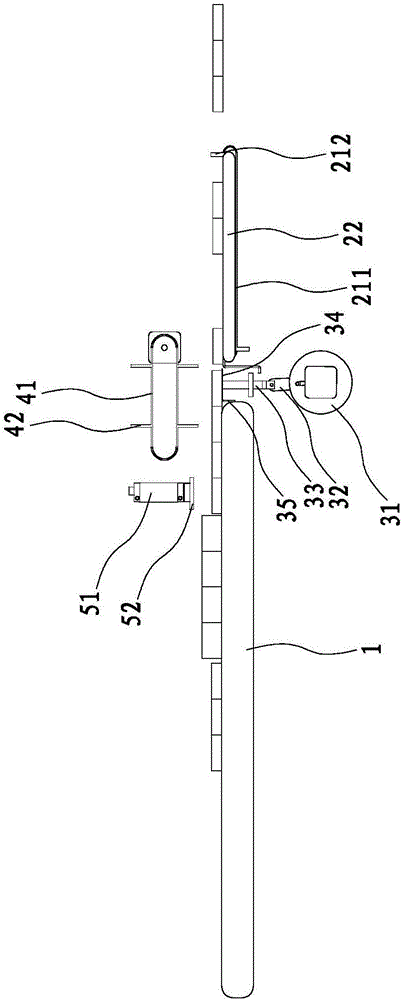

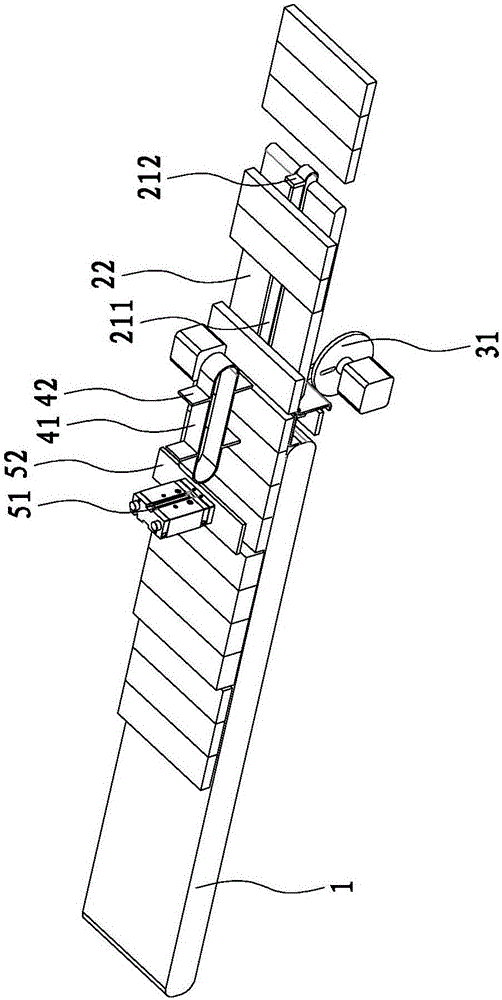

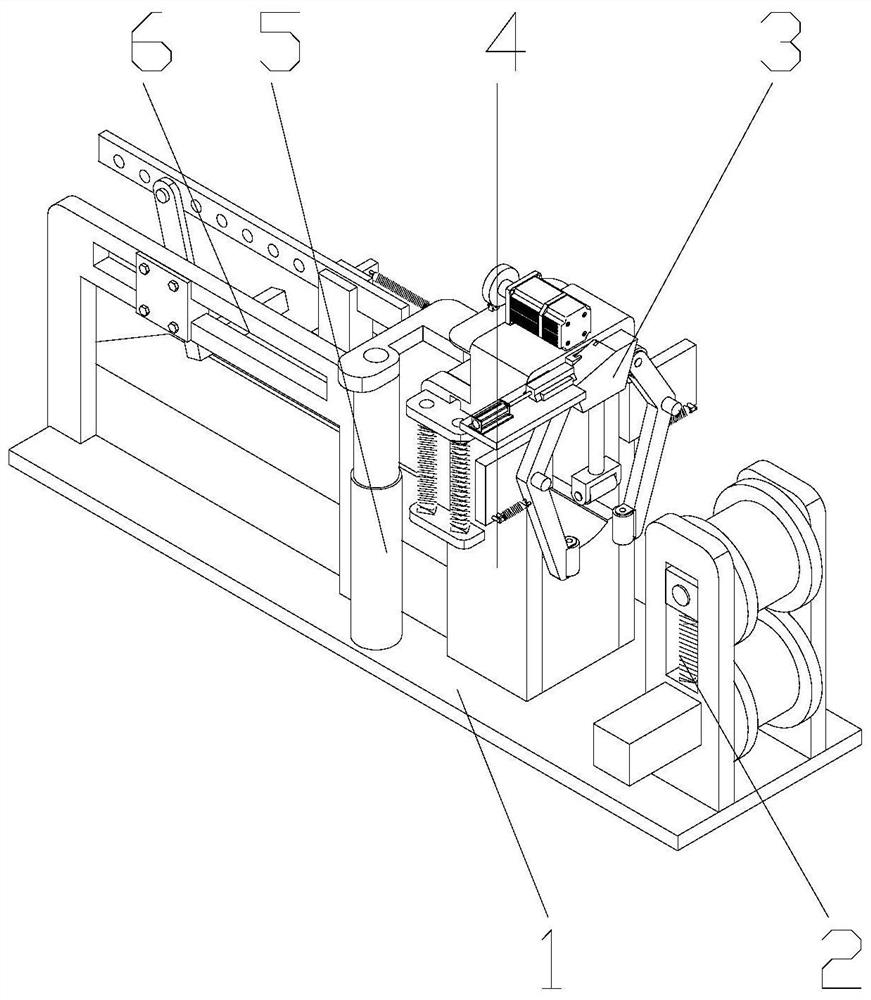

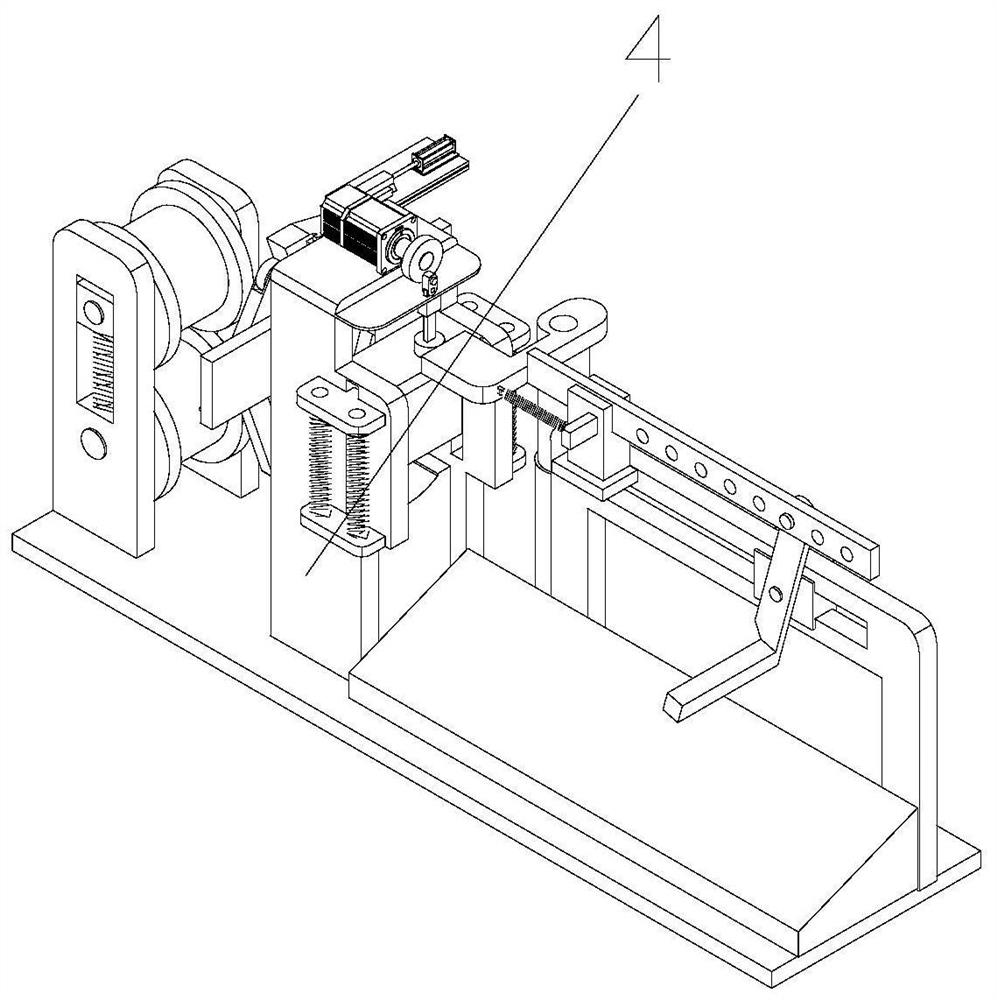

Combination and output device for cigarette cartons

The invention relates to a combination and output device for cigarette cartons. The device comprises a rack as well as an input conveying belt and an output device which are arranged on the rack along an assembly line, a jacking device for jacking the cigarette cartons is arranged on the rack and located between the input conveying belt and the output device, and a shifting device for pushing the jacked cigarette cartons into the output device is arranged on the rack and located above the jacking device.

Owner:QUANZHOU KESHENG PACKAGING MACHINERY

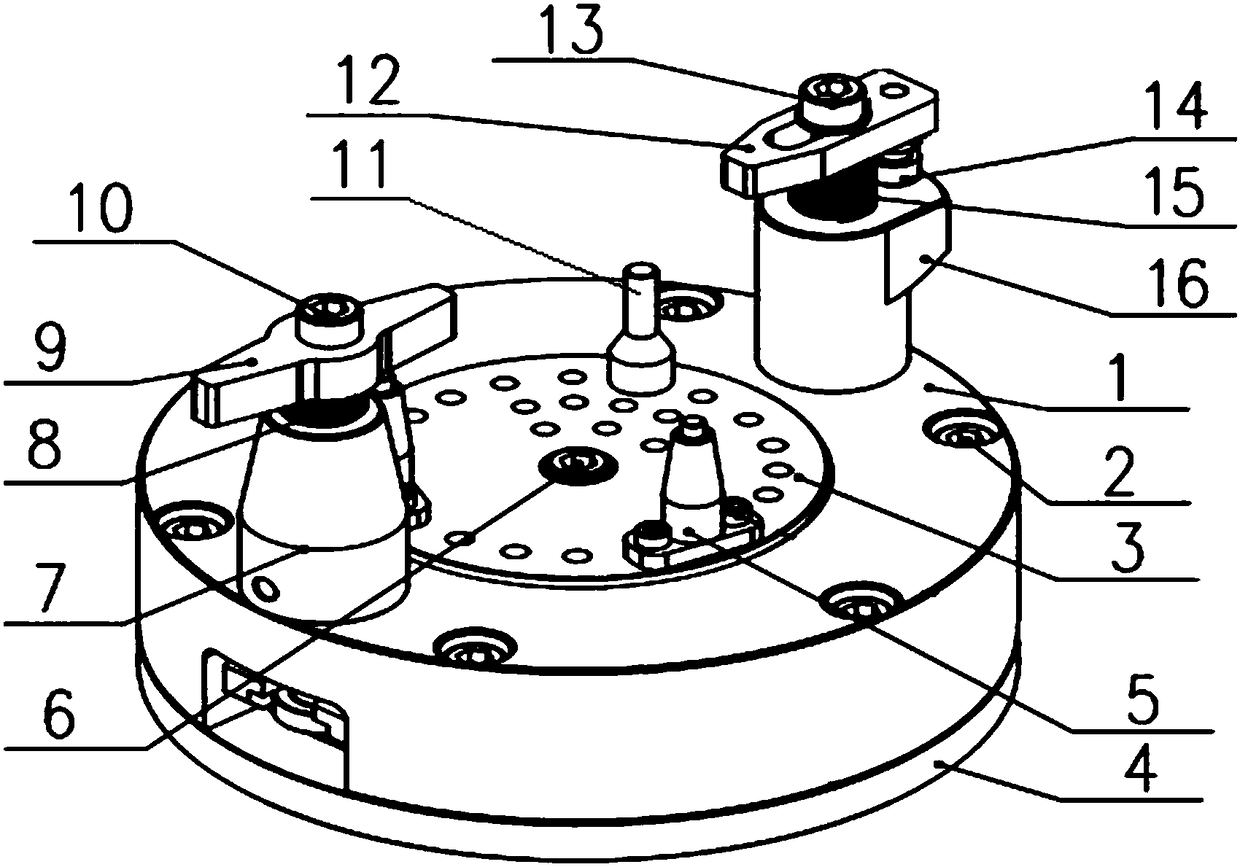

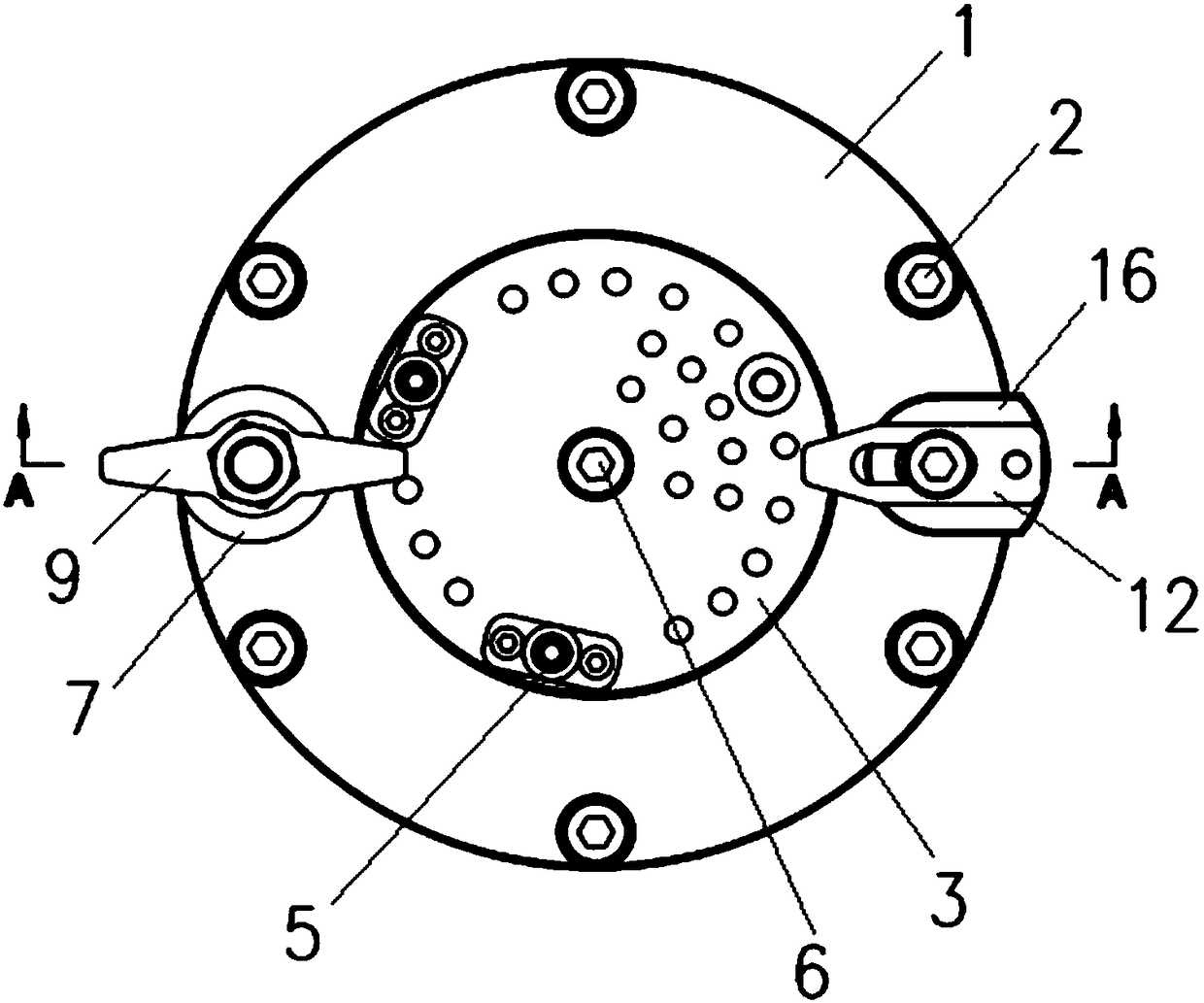

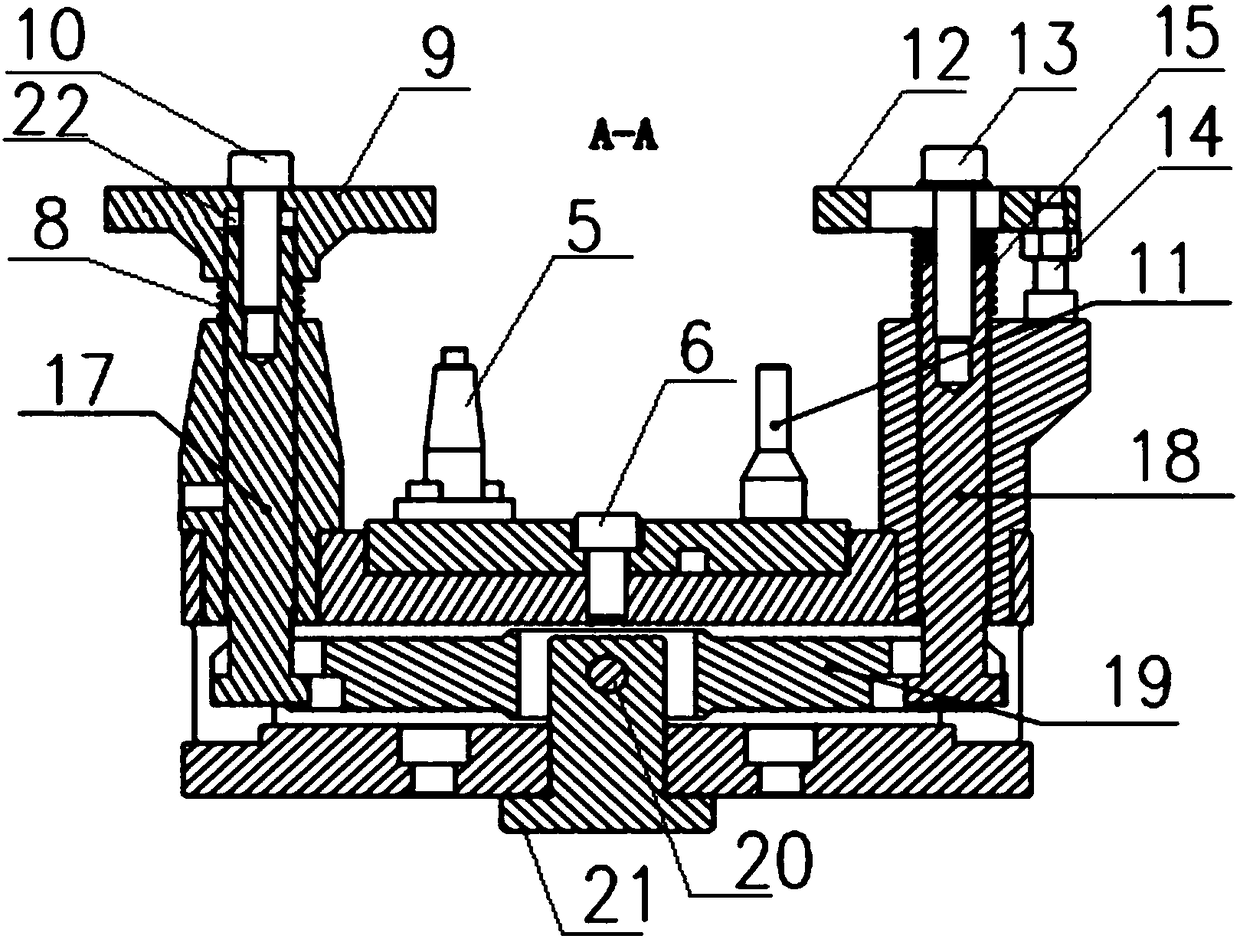

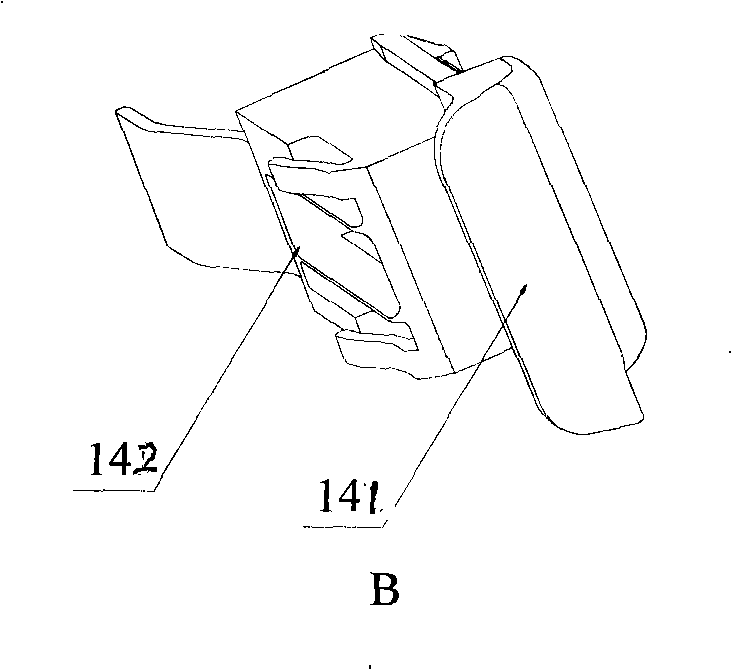

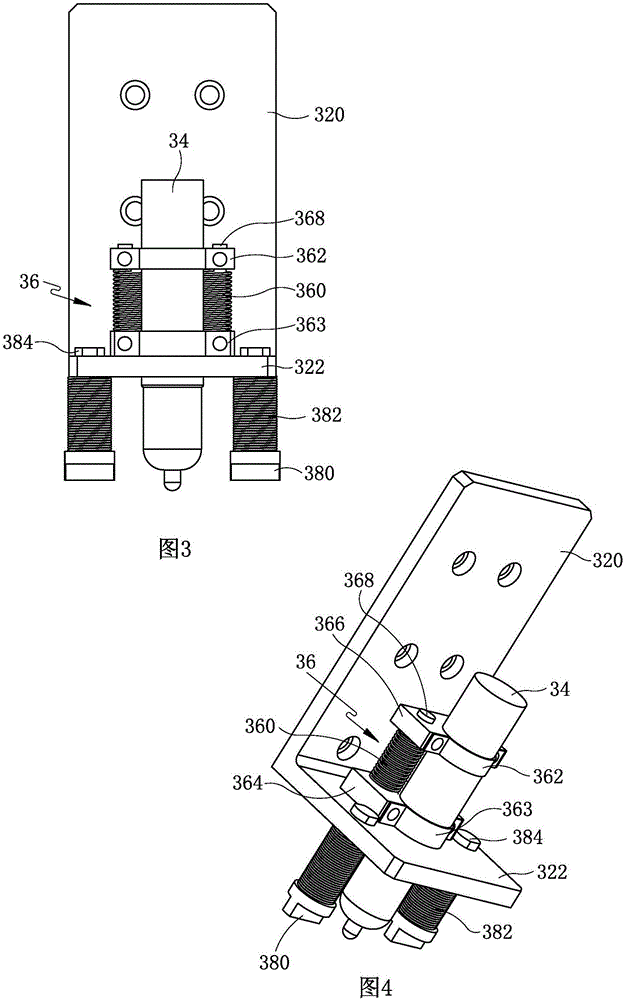

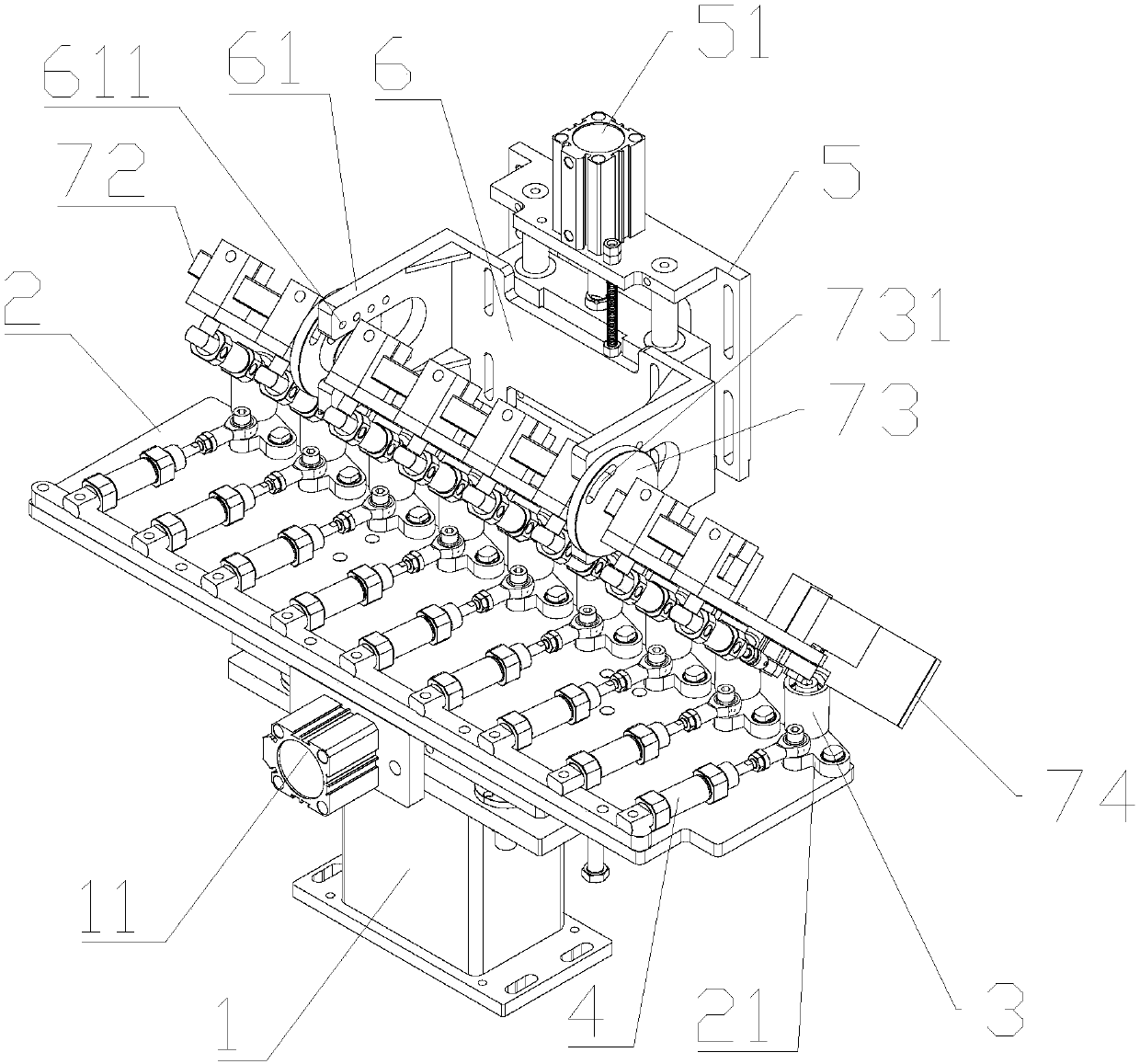

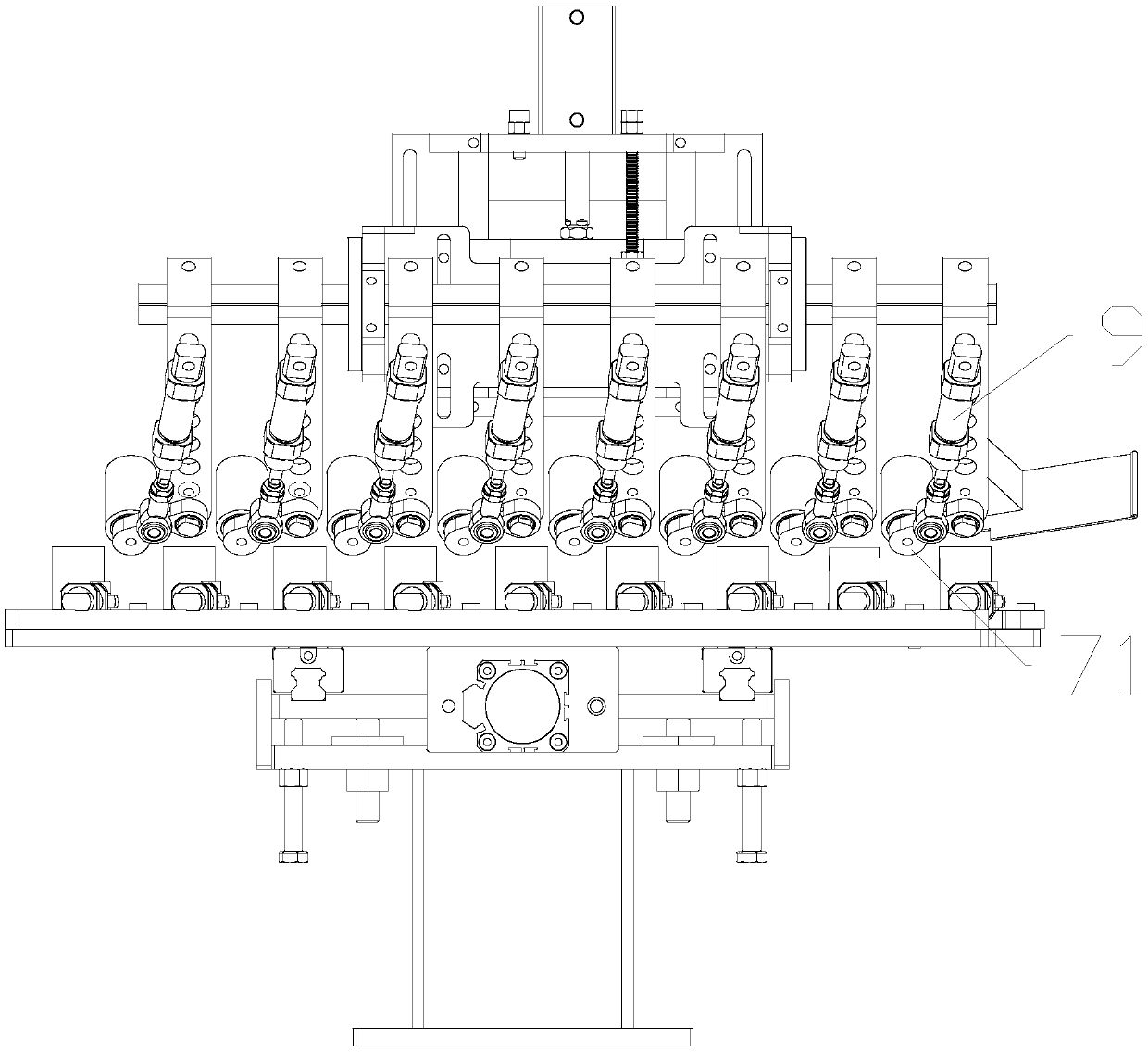

Clamp for machining rear cover of automobile air conditioning compressor

PendingCN108296829AEven by forceWon't liftPositioning apparatusMetal-working holdersAutomobile air conditioningEngineering

The invention discloses a clamp for machining a rear cover of an automobile air conditioning compressor. The clamp comprises a connecting seat fixedly arranged on a connecting flange, a positioning disc is arranged in the middle of the top end of the connecting seat, and the positioning disc is correspondingly and fixedly provided with a limiting pin and a supporting column, wherein the limiting pin and the supporting column are used for positioning a rear cover workpiece; and pressing devices for pressing the rear cover workpiece are arranged in the positions, located on the outer side of thepositioning disc, of the connecting seat. According to the clamp for machining the rear cover of the automobile air conditioning compressor, the pressing devices on the left side and the right side clamp the rear cover workpiece at the same time, stress is uniform, and the pressing point positions can be freely adjusted; the clamp is adaptive to the rear cover workpieces of different sizes, so that universality is high; and furthermore, the functions of further improving repeated positioning precision, improving production efficiency, reducing clamping time and the number of times, reducing labor intensity of workers and reducing machining procedures and personnel are achieved.

Owner:合肥达因汽车空调有限公司

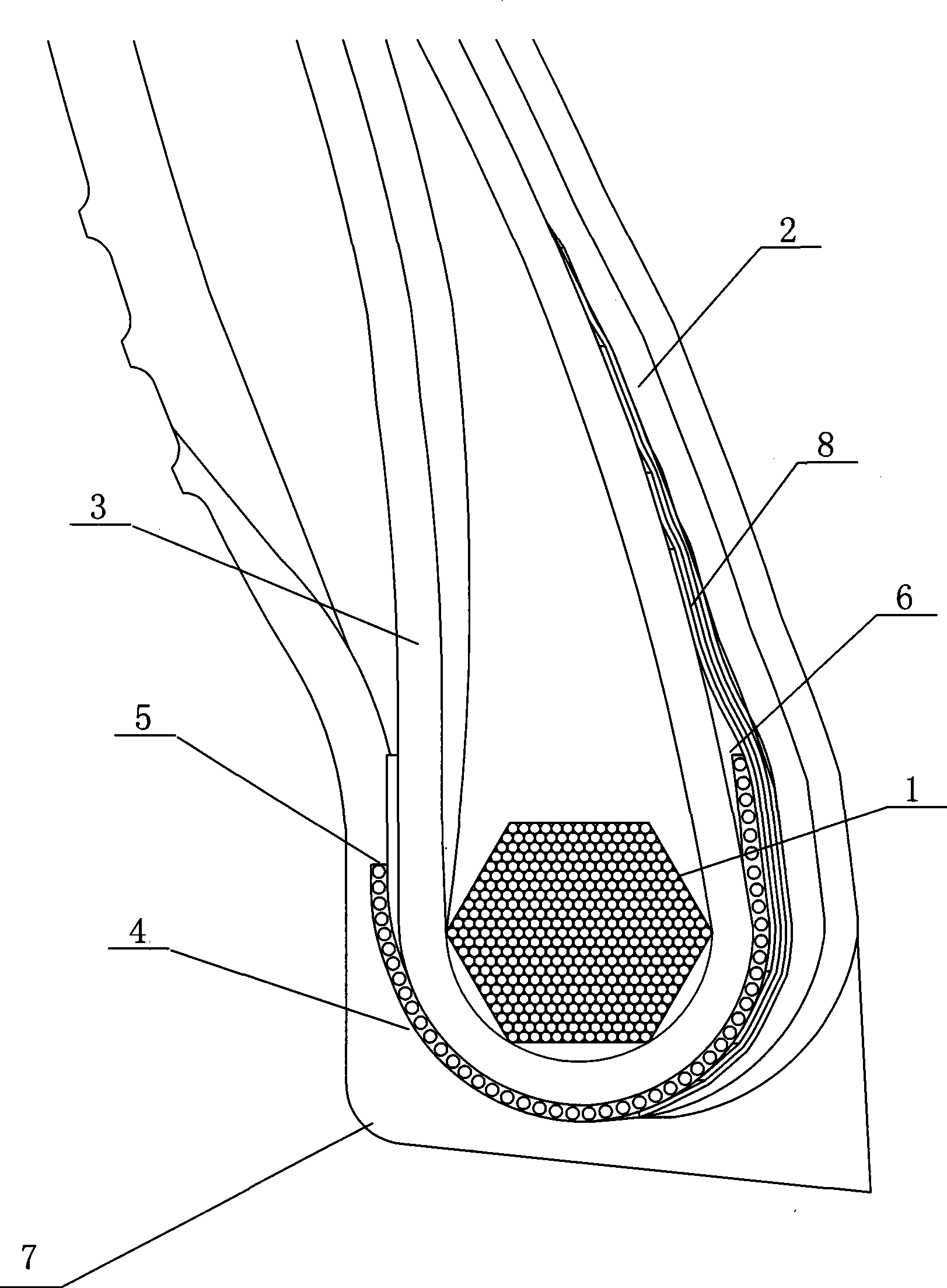

All-steel transverse-cord tyre with reinforced layer at tyre bead

InactiveCN101428537AImprove stability and securityExtended service lifeTyre beadsCarrying capacityEngineering

The invention relates to an all-steel meridian giant embryo which has a reinforced layer,wherein, a steel wire cord reinforced layer is coated on a tire casing cord layer and a tire casing cord revised coating layer. the steel wire cord reinforced layer has is U-shaped and the outer endpoint thereof is not higher than the height of a wheel felloe flange; and a fiber cord reinforced layer is arranged outside the inner endpoint of the steel wire cord reinforced layer. The invention strengthens the rigidity of the tyre bead, reduces deformation, decreases the shearing force of the tire casing cord layer and the tire casing cord revised coating layer to tyre rubber, and improves the carrying capacity of the bead part of the tyre in a large scale. Due to the fact that the steel wire cord reinforced layer reinforces the main weak part of the bead, the security and stability of running are increased and the service life of the tyre is prolonged. In addition, the outer endpoint of the steel wire cord reinforced layer is not higher than the height of the wheel felloe flange, so that when being forced, the outer endpoint of the steel wire cord reinforced layer can not be tilted without the support of the wheel felloe.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

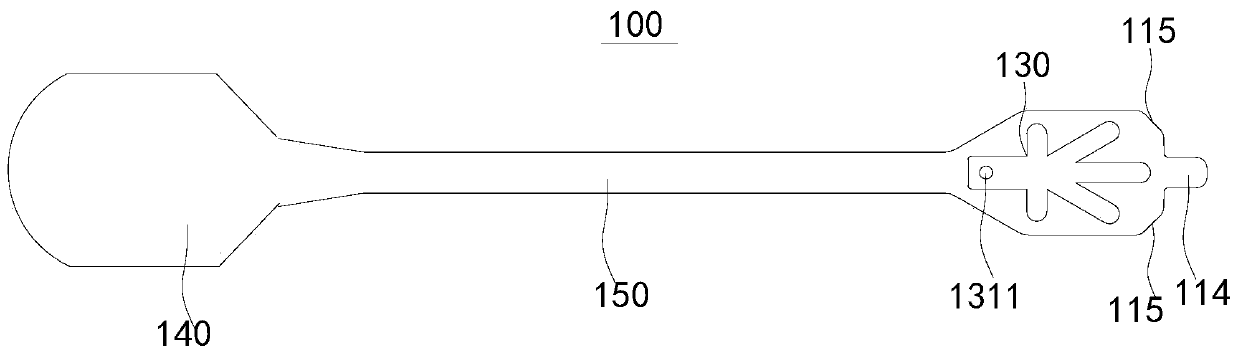

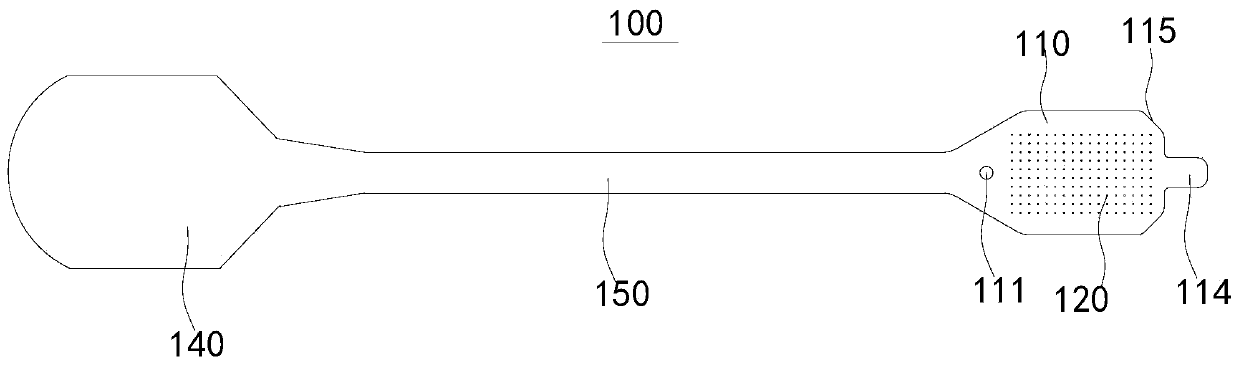

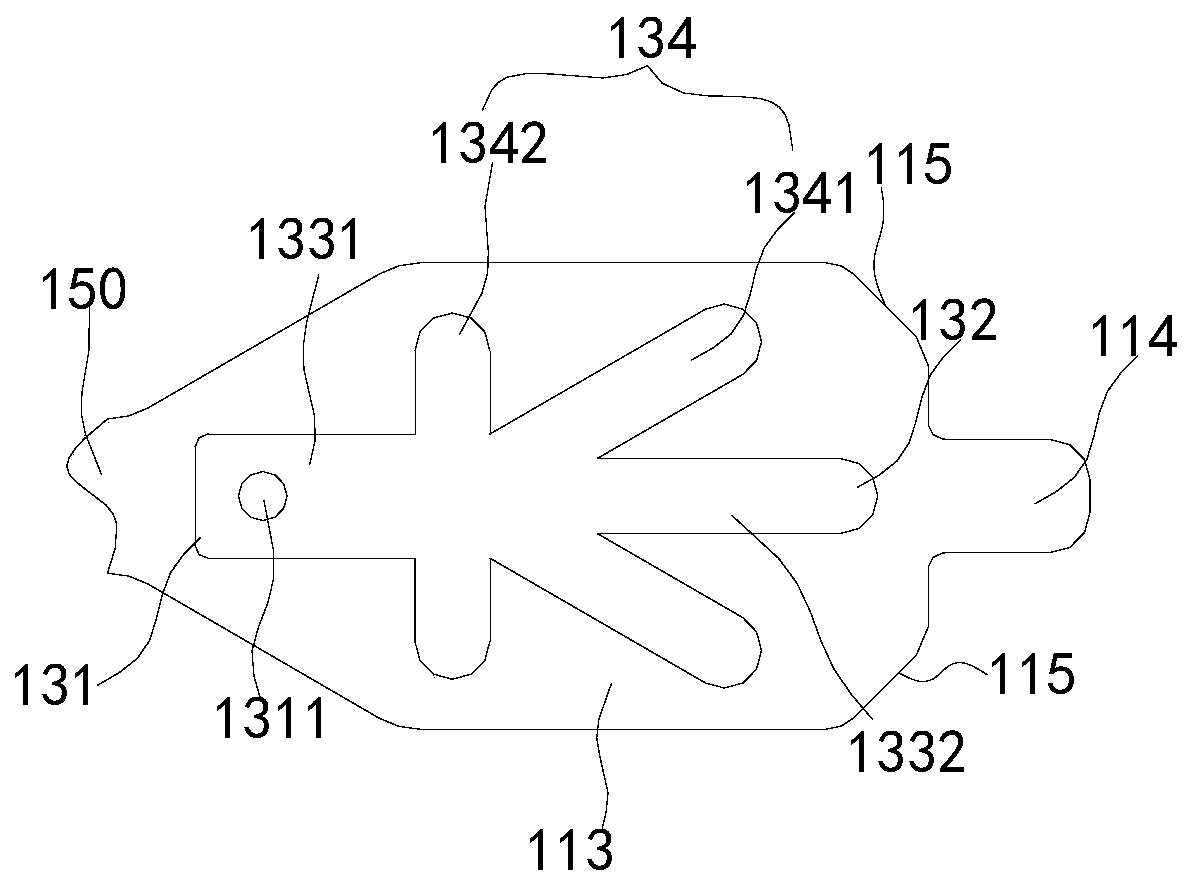

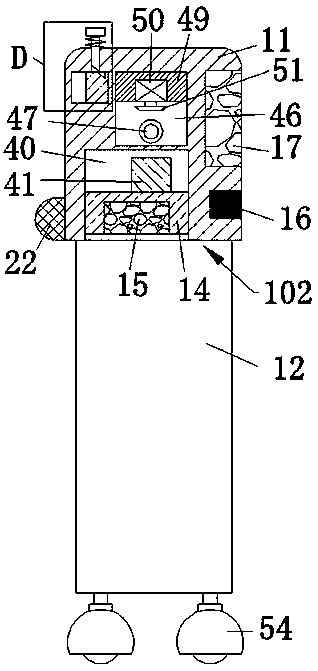

Retinal prosthesis, implant device and flexible cable

PendingCN109821149AEven by forceWon't liftEye implantsInternal electrodesRetinal implantImplanted device

The invention discloses a flexible cable of a retinal prosthesis, which comprises a microelectrode, a plurality of stimulation electrodes, an abutting piece, a leading-in part and a connecting part, wherein the microelectrode is provided with a first mounting hole and an electrode region;the stimulation electrodes are arranged in the electrode region, and the end parts of the stimulation electrodes are exposed on one side surface of the microelectrode; the abutting piece is provided with a second mounting hole corresponding to the first mounting hole and extends to the back surfaces of the stimulation electrodes from the second mounting hole; the abutting piece is arranged on the other side surface of the microelectrode; force distribution obtained at the second mounting hole is transmitted to the back surfaces of the stimulation electrodes through elastic force generated by elastic denaturation, so that the electrodes are uniformly stressed, a better sticking effect is achieved, and the phenomena of inclination and warping of the electrodes caused by uneven stress are avoided.According to the flexible cable, the microelectrode can be uniformly stressed and can be better attached to the retina so as to obtain a more effective stimulation effect.The invention further discloses a retinal implant device and the retinal prosthesis.

Owner:INTELLIMICRO MEDICAL CO LTD

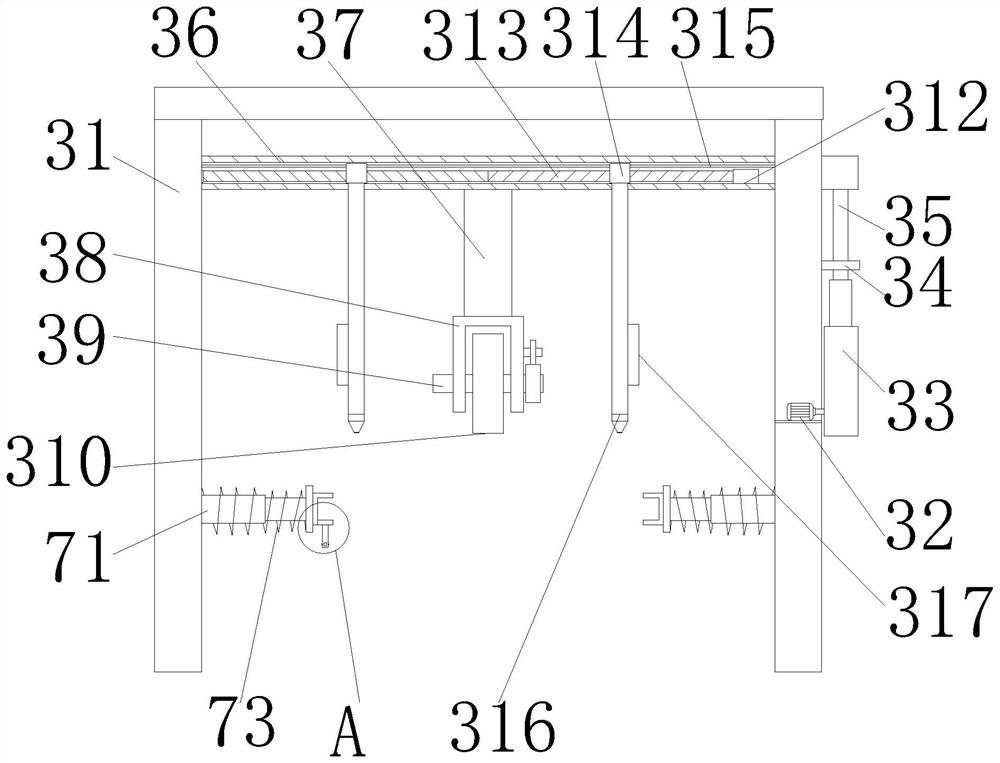

Power tube cutting device for power construction

ActiveCN112476014AGuaranteed smoothQuality assuranceMetal working apparatusPositioning apparatusStructural engineeringMechanical engineering

The invention discloses a power tube cutting device for power construction. The power tube cutting device comprises a bottom plate, wherein a conveying mechanism, a cutting mechanism, a limiting mechanism and an adjusting mechanism are mounted on the bottom plate; the conveying mechanism is mounted at one end of the bottom plate; the cutting mechanism is mounted on the bottom plate and on one sideof the conveying mechanism; a fixing mechanism is mounted on the cutting mechanism; the adjusting mechanism is mounted at the other end of the bottom plate and matched with the limiting mechanism; and the limiting mechanism is mounted on the bottom plate and between the adjusting mechanism and the cutting mechanism and matched with the cutting mechanism. The power tube cutting device can guarantee the flatness of a notch of a power tube and the quality of the power tube, can guarantee the cutting of the power tube with the same length, can adjust the length of the power tube as required, guarantees the cutting quality of the power tube, guarantees the normal use of the power tube, reduces the production cost and improves the working efficiency.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO TAOXIAN POWER SUPPLY CO

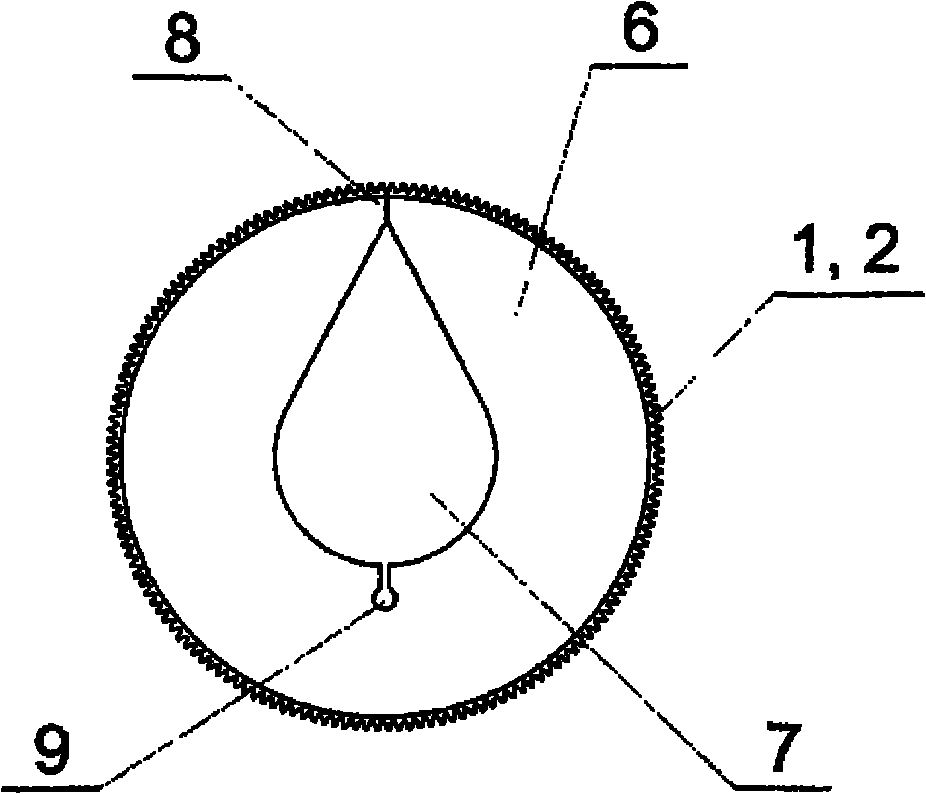

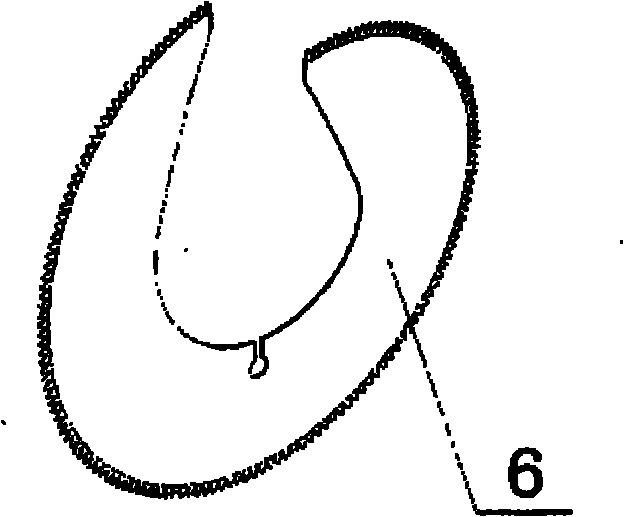

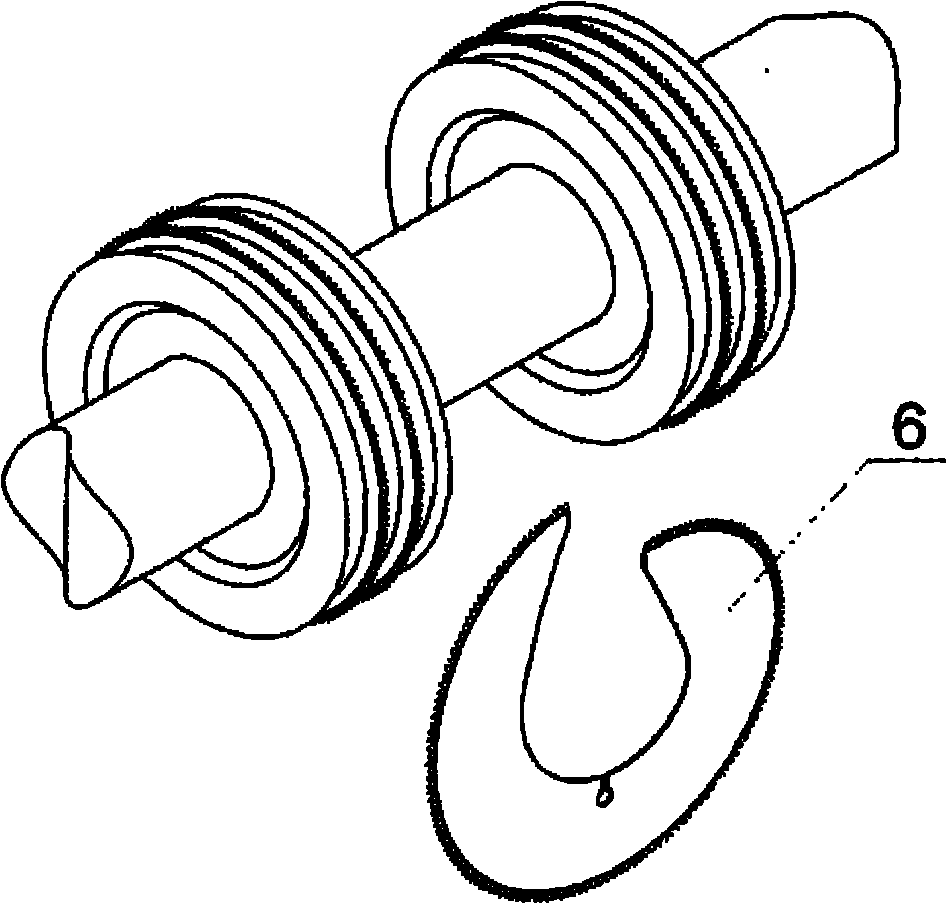

Rotating disc knife, method of mounting the rotating disc knife and method of dismounting the rotating disc knife

InactiveCN101828767AEasy to removeShorten the timeCigarette manufactureMetal sawing toolsEngineeringRotating disc

The present invention provides a rotating disc knife, in particular for cutting the paper cover of cigarettes, provided with a mounting opening for mounting the knife onto a cutting assembly shaft and with a plurality of cutting teeth (1, 2) located around the circumference of the disc (6), wherein the mounting opening (7) in the disc (6) of the knife connects with the cutting edge (5) of the disc at a point (8) where the edge (5) of the knife is discontinuous. A method of mounting / dismounting a rotating disc knife provided with a mounting opening onto / from a cutting assembly shaft provided with a plurality of such disc knives.

Owner:INT TOBACCO MACHINERY POLAND

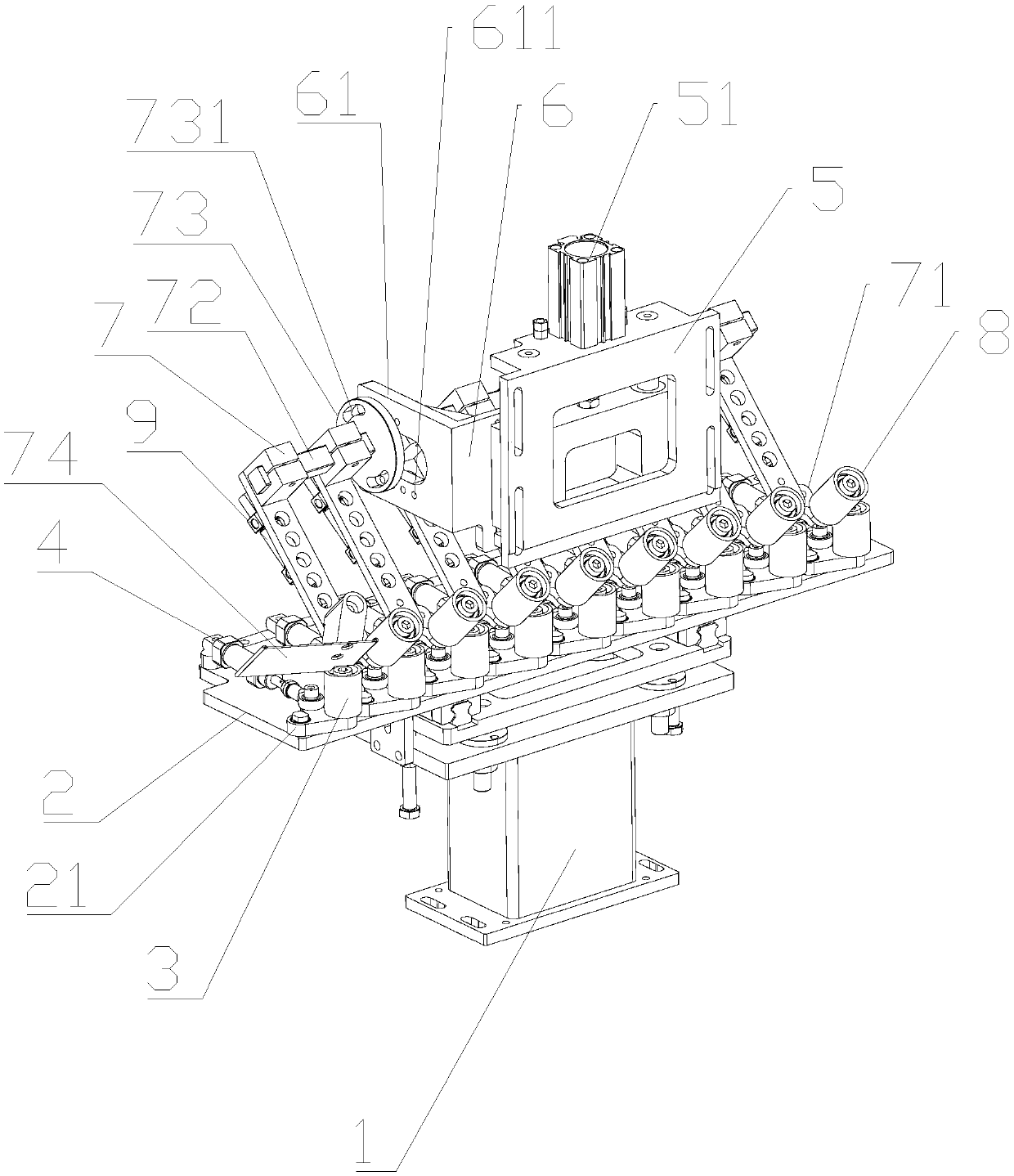

Angle adjusting device of conveyer for engineering machine production

ActiveCN106542255AAdjust the horizontal conveying lengthAdjustable angleConveyorsRollersEngineeringPulley

The invention discloses an angle adjusting device of a conveyer for engineering machine production. The angle adjusting device comprises a first driving roller, a second driving roller, a first driven roller, a second driven roller, a locating roller, a locating pulley and a driving belt; each of the first driving roller and the second driving roller is connected with a driving device; the first driving roller is connected with the first driven roller through a first connecting rod; the outer wall at the side, far away from the driving roller, of the first connecting rod is provided with a cylindrical raised structure; a first lifting device is arranged below the raised structure; a first groove is formed in the top of the first lifting device; the outer wall of the locating pulley is slidably connected with the outer wall of the driving belt; each of two sides of the locating pulley is connected with a second lifting device; each of two sides of the locating roller is connected with a third lifting device; and the first lifting device, the second lifting devices and the third lifting devices are sequentially connected through telescopic rods. By using the angle adjusting device, the conveying length and angle of the conveyer can be adjusted.

Owner:芜湖光荣网络科技有限公司

Key structure

ActiveCN105551866ALower the altitudeApproach steadilyElectric switchesTactile feedbackKey pressingEngineering

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

Efficient stamping die

ActiveCN105268860AAvoid extrusion deformationWon't liftShaping toolsMetal-working feeding devicesEngineeringStamping process

The invention discloses an efficient stamping die. The efficient stamping die comprises an upper die plate and a stamping head assembly arranged at the upper end of the upper die plate. The stamping head assembly comprises a stamping rod, a backing plate and a stamping head. The backing plate is arranged at the lower end of the stamping rod. A cavity is formed in the portion, right facing the stamping head assembly, of the middle of the upper die plate. A receding groove is formed in the portion, located on one side of the cavity, of the upper die plate. A rotating shaft is arranged on the upper end face of the portion between the cavity and the receding groove. Two fixing plates are arranged at the two ends of the rotating shaft respectively. Two pressing blocks are arranged at the upper end of each fixing plate. According to the efficient stamping die, a workpiece is continuously clamped through the fixing plates capable of rotating, and the outer side wall of the workpiece to be stamped is limited through movable baffles and fixed baffles in the stamping process, so that the situation that after the workpiece is stamped, extrusion deformation of the outer side face of the workpiece is caused by the overhigh stamping speed of the stamping head is avoided, the outer wall of the stamped workpiece is more attractive, the upper end face of the workpiece is prevented from cocking, and efficiency is higher.

Owner:东莞市万鑫隆制罐有限公司

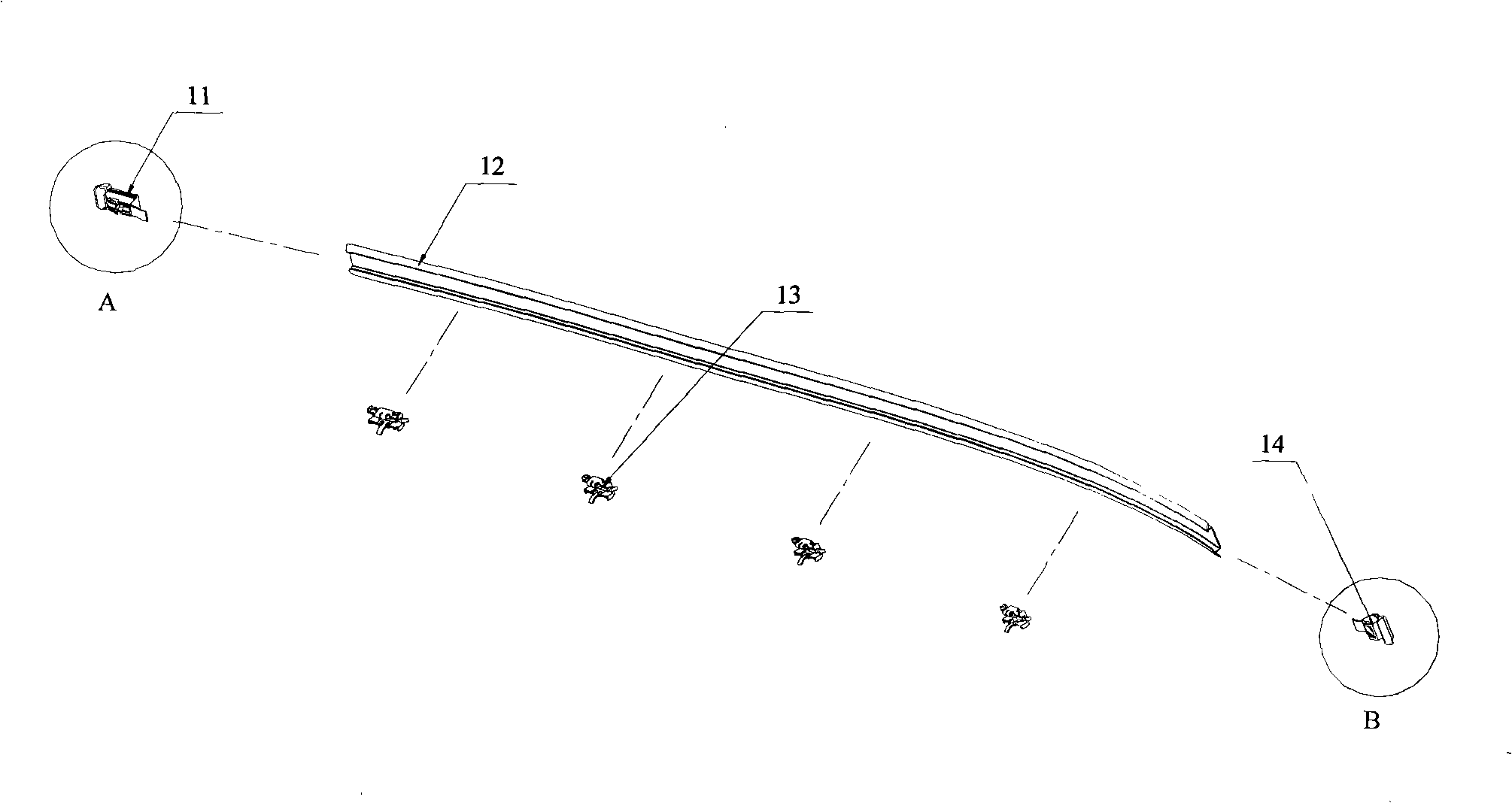

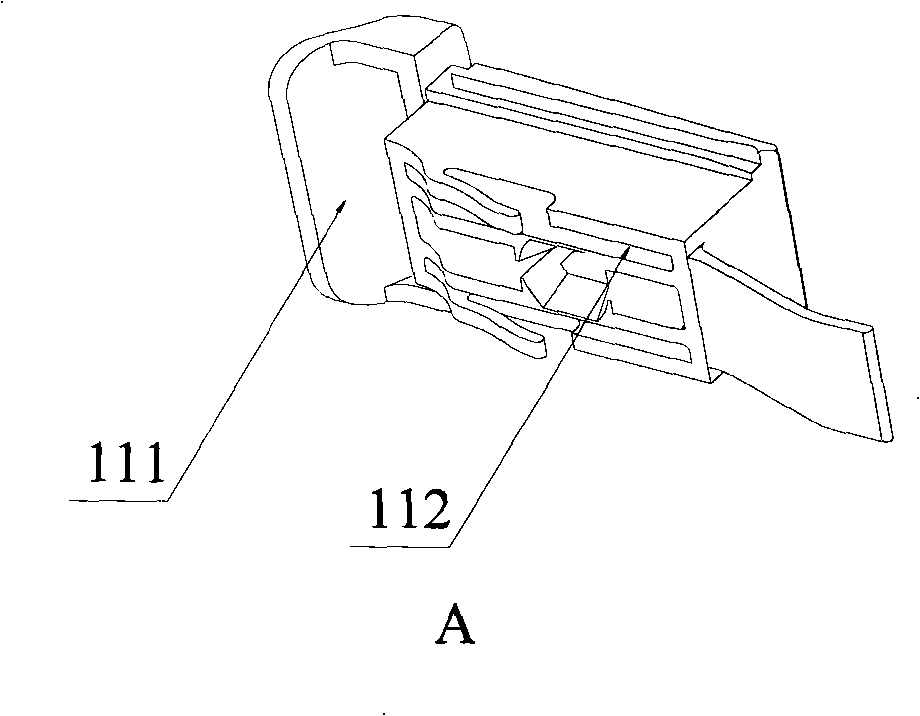

Decorative strip for sedan top cover

The invention relates to a sedan roof decorative strip, which comprises a decorative strip body and a clamp arranged in the middle of the body and matching with the flange of the roof; wherein a front positioning fastener is spliced in the front end of the decorative strip body, and a back positioning card is spliced in the back end; the front positioning card is clamped with the front rivet welded on the roof, thus realizing effective positioning of the roof decorative strips and eliminating the up-wrapping of the front end part; the back positioning card is clamped with the back rivet welded on the roof, thus eliminating the up-wrapping of the back end part of the roof. The decorative strip has reasonable positioning and stable installation, and eliminates the up-wrapping of the front and the back ends, and at the same time, simplifies the manufacture and assembly processes.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

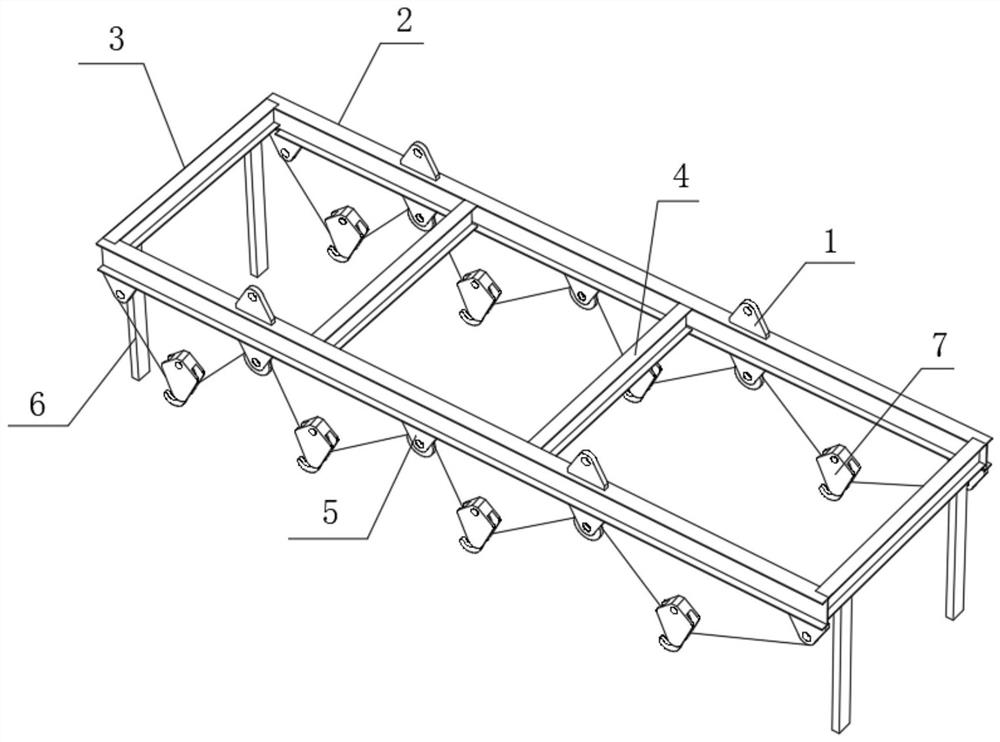

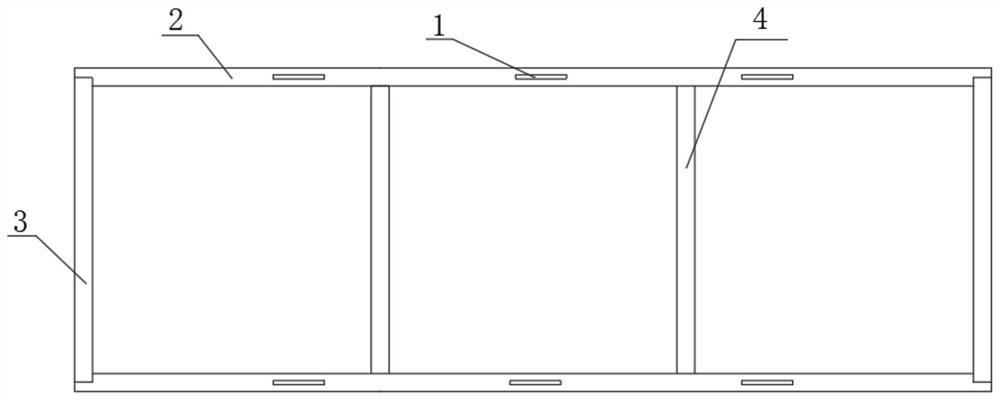

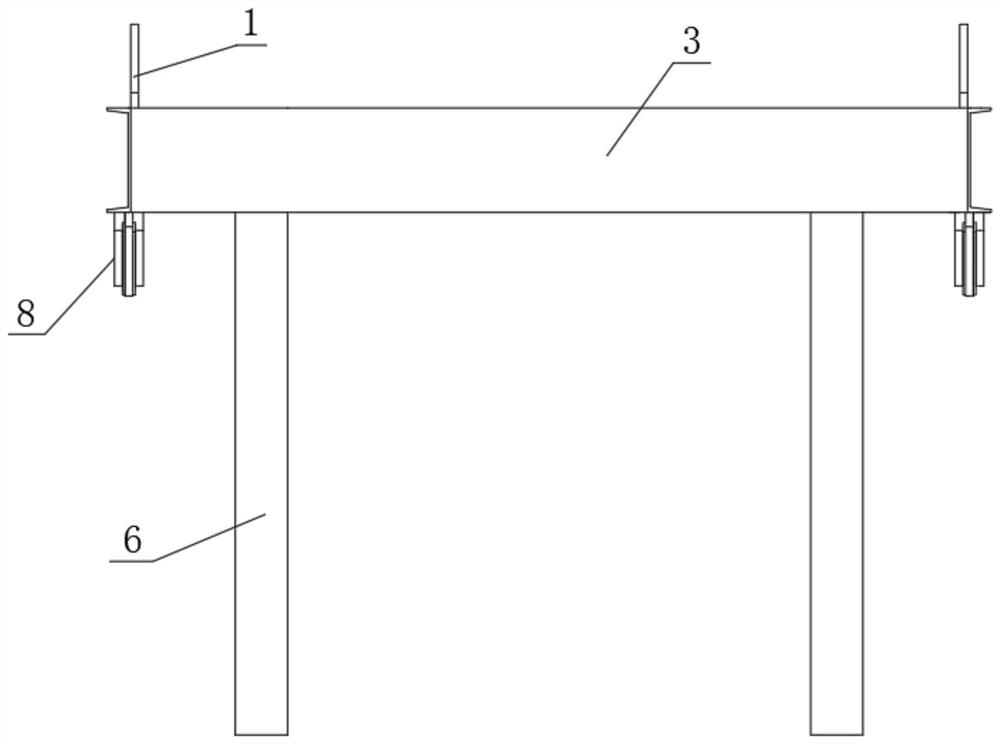

Laminated plate lifting appliance and steel beam

PendingCN111960249ASame lifting heightHighly consistentLoad-engaging elementsBlock and tackleIndustrial engineering

The invention discloses a laminated plate lifting appliance and a steel beam, and relates to the technical field of lifting appliances and steel beams. The stability problem of lifting of the liftingappliance is solved, the laminated plate lifting appliance specially comprises two first I-shaped steels and two second I-shaped steels, wherein the two ends of the two first I-shaped steels are provided with welding grooves, the two ends of the two second I-shaped steels are welded with the welding grooves of the two first I-shaped steels correspondingly, the two first I-shaped steels and the twosecond I-shaped steels form a rectangular frame structure, the top outer walls of the two first I-shaped steels are each provided with two welding holes, and a lifting plate is welded on the inner wall of each welding hole; and the outer wall of one side of each lifting plate is provided with a lifting hole, and triangular supporting plates are fixed on the outer walls of the bottoms of the two ends of the two first I-shaped steels through bolts. The problem of translational shaking of a laminated plate caused by less hoisting points of a traditional lifting appliance is solved, and the lifting stability of the laminated plate is effectively ensured through a fixed pulley assembly and a movable pulley hook assembly.

Owner:CHINA CONSTR SCI & TECH CO LTD

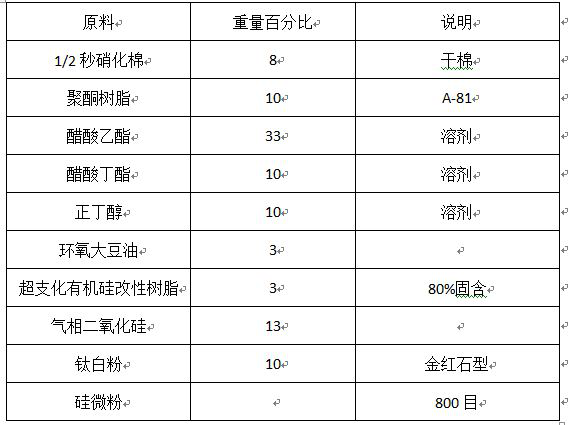

Light-smell self-volatilizing crackle paint coating and preparation method thereof

The invention relates to a light-smell self-volatilizing white crackle paint coating and a preparation method thereof, and in particular, relates to a preparation method of a low-smell coating capableof generating cracks on any primer. The method is mainly realized by adopting the following technical formula and process. 5% of hyperbranched organic silicon modified alkyd resin, 8% of 1 / 2 second digested cotton, 10% of polyketone resin, 3% of epoxidized soybean oil, 13% of fumed silica, 3% of magnesium silicate and 10% of titanium dioxide are adopted and finally a butyl acetate solvent is added. The crackle paint prepared by the method has the advantages that no matter the crackle paint is sprayed or brushed on any base material, a regular crackle effect can be generated; the product is free of triphenyl and DOP addition, and is environment-friendly and healthy. The invention also discloses the preparation method of the crackle paint.

Owner:广东顺德三和化工有限公司

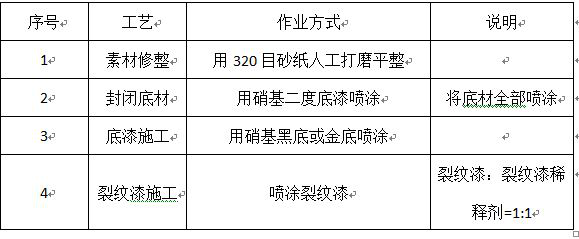

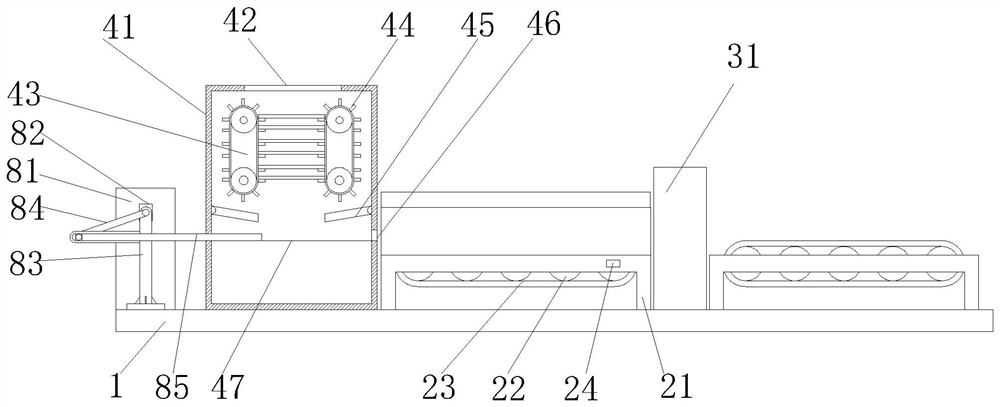

Automobile cold-rolled strip steel material processing system

InactiveCN112077147AGood welding effectReduce frictionWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryStructural engineering

The invention relates to an automobile cold-rolled strip steel material processing system. The automobile cold-rolled strip steel material processing system comprises a base, conveying devices, welding devices and a plate pushing device, wherein the conveying devices are symmetrically installed in the middle of the upper surface of the base; the welding devices fixedly connected with the base arearranged on the inner sides of the two conveying devices; a plate pushing mechanism is fixedly installed at the left end of the upper surface of the base; each conveying device comprises a conveying frame, conveying rollers, a conveying belt, a conveying motor, a limiting plate and a plate pressing mechanism; the conveying frame is fixedly installed on the upper surface of the base; and a plurality of conveying rollers are sequentially installed on the inner side of the conveying frame from left to right. According to the automobile cold-rolled strip steel material processing system, the conveying devices are arranged, a limiting shaft drives two limiting wheels to rotate in the same direction, two sections of strip steel are closely attached to each other during welding, and the welding effect is better; through the plate pressing mechanisms, friction force can be reduced when the strip steel on the conveying belts is conveyed; and through the plate pushing mechanism, the strip steelon supporting blocks regularly falls onto a pushing table.

Owner:郭亚亚

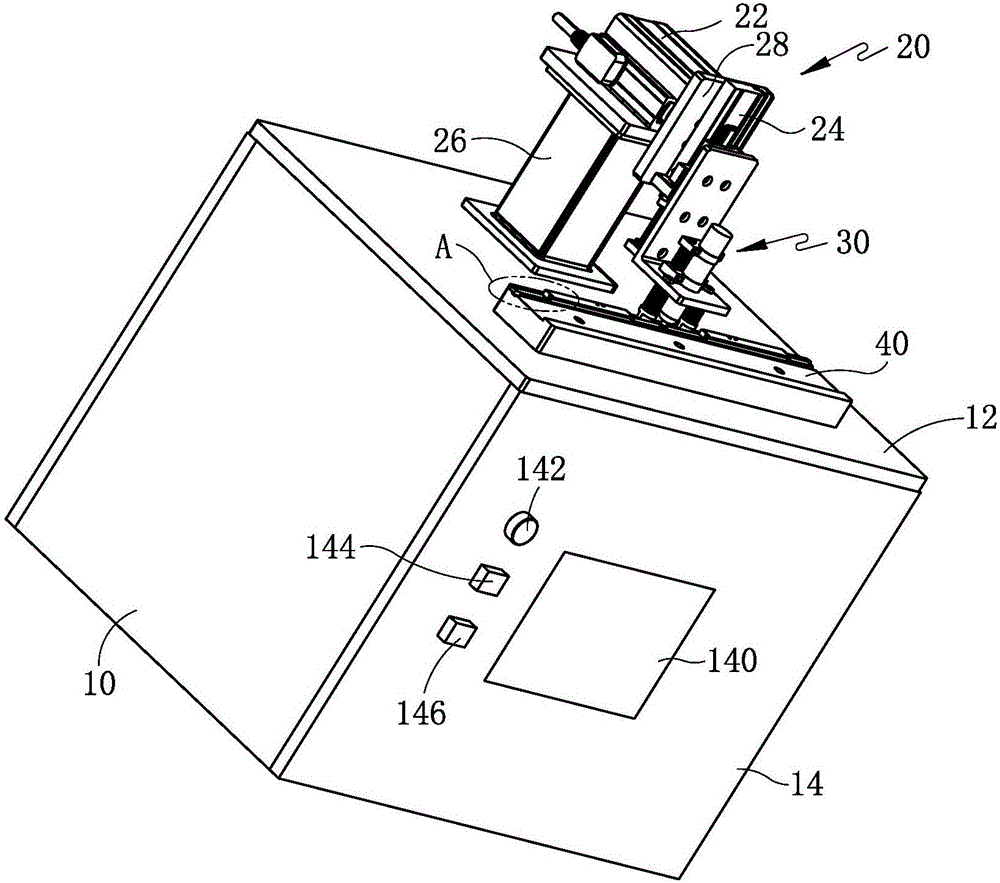

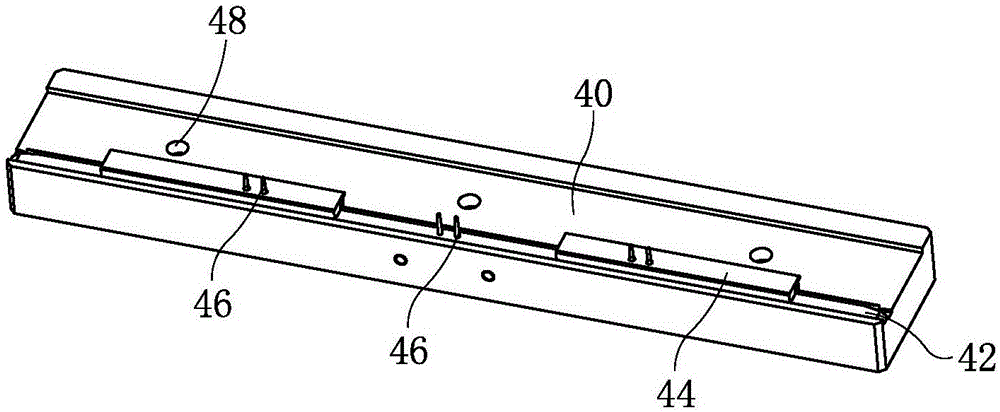

Connecting device for material belts

ActiveCN106735682AReduce the number of stopsLow failure rateSoldering bitsSoldering ironProcess equipmentStop time

The invention discloses a connecting device for material belts, and relates to the technical field of processing equipment of injection molding inserts. The connecting device comprises moving mechanisms, a welding device and a material belt locating plate, wherein the moving mechanisms comprise a longitudinal moving mechanism and a vertical moving mechanism; the vertical moving mechanism is mounted on a stress part of the longitudinal moving mechanism; the welding device is mounted on a stress part of the vertical moving mechanism; the welding device comprises vertically arranged soldering iron; and a plurality of locating pins matched with locating holes in the material belts are formed in the material belt locating plate. According to the connecting device for the material belts, the technical problems that in the prior art, the material belt processing efficiency is low and lots of waste materials are generated are solved, connectors of two rolls of material belts or small sections of material belts can be connected, the stopping time of a cutting feeding machine is decreased, the production efficiency of the cutting feeding machine is improved, waste of the material belts is avoided as well, and the production cost of enterprises is reduced.

Owner:GEER TECH CO LTD

Fixed device of power distribution device for power distribution cabinet

InactiveCN109768482AEasy to installImprove installation efficiencySubstation/switching arrangement detailsEngineeringOblique angle

The invention discloses a fixed device of a power distribution device for a power distribution cabinet. The fixed device comprises a bottom plate, a rapid installation assembly and a storage and arrangement part, wherein installation holes are formed in four corners of an upper surface of the bottom plate, the rapid installation assembly is arranged at a middle part of the upper surface of the bottom plate, a plastic buckle is arranged at a connection position of a wire groove and a power connection piece, a transparent plastic insulation covers are arranged on both of the power connection piece and a button, the rapid installation assembly is in an inclination shape, and an oblique angle of a fixed clamping rail is 15 degrees. By the rapid installation assembly of the fixed device of thepower distribution device for the power distribution cabinet, a movable clamping rail can be contracted, and installation of the power distribution device is facilitated; a force is not needed duringinstallation, a groove mouth above the power distribution device is only needed to be placed on the fixed clamping rail, and force is not needed; and moreover, a plurality of power distribution devices can be simultaneously placed, the installation time is greatly saved, the fixed device is stable, reliable, rapid and convenient, time and labor are saved, and the installation efficiency of the power distribution device is greatly improved.

Owner:海安美物菲斯物联网科技有限公司

Pressing sticking structure of edge bonding machine

ActiveCN109571705AWon't liftImprove automationWood working apparatusDomestic articlesEngineeringAutomation

The invention discloses a pressing sticking structure of an edge bonding machine. The pressing sticking structure comprises a base, a longitudinal sliding frame, vertical drums, a vertical drum cylinder, a mounting plate, a vertical sliding frame, an adapter plate, tilt drums and a tilt drum cylinder. According to the pressing sticking structure, a row of vertical drums and a row of tilt rollers staggered with the vertical drums are arranged, and the wood can be pressed by the tilt drums and then pressed the side face by the vertical drums, so that the fact that an edge binding belt can be pressed by the vertical drums, and meanwhile, the wood cannot cock is ensured; and meanwhile, the tilt drums and the vertical drums are arranged in a split mode, the complex structure of the all-in-one design is avoided, finally, the cylinder is adopted, the fact that an original spring is used as a power source is replaced, the compaction action is controlled, and the automation of the machine is improved.

Owner:广东颐迈速派智能装备有限公司

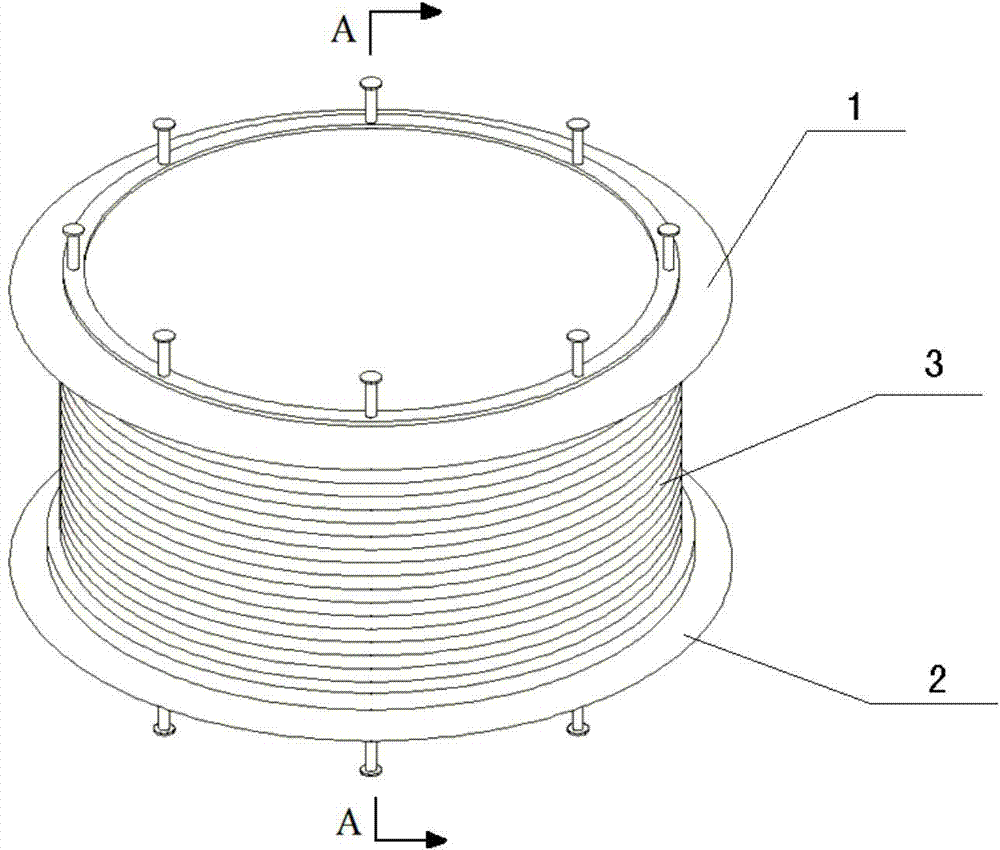

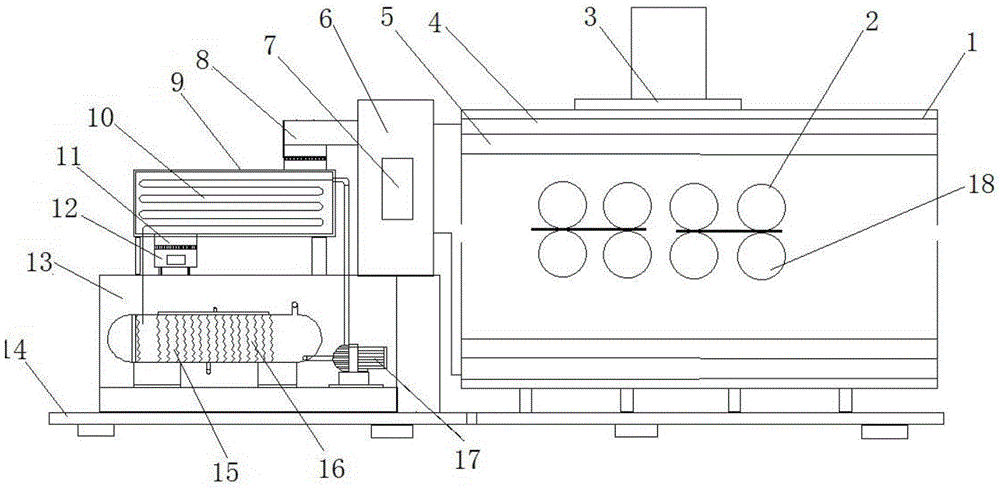

Electromagnetic heat-conduction oil type single wood plate drying machine

InactiveCN104019648AEasy to moveImprove efficiencyDrying gas arrangementsDrying machines with progressive movementsCirculating pumpMoisture

The invention provides an electromagnetic heat-conduction oil type single wood plate drying machine. The electromagnetic heat-conduction oil type single wood plate drying machine comprises a hot air device and a drying box which are arranged on a rack, wherein a feeding opening is formed in one end of the drying box and a discharging opening is formed in the other end of the drying box; a moisture discharging opening is formed in the top of the drying box; the drying box is internally and horizontally provided with a plurality of roller sets; the hot air device comprises a hot oil tank which is arranged at the lower end of an engine body and a heat exchanger arranged at the upper end of the engine body; the hot oil tank is internally provided with a plurality of sets of electromagnetic heating coils; a high-temperature circulating pump is arranged at one side of the hot oil tank; the heat exchanger is internally provided with a heat exchanging coiled pipe; a hot air outlet pipe and a lower-end pipeline of a roller drying machine body are communicated with an air storage chamber; the air storage chamber is provided with a pressurizing machine; the air storage chamber is connected with a hot air pipe through a pipeline. Compared with the prior art, the drying machine can be used for uniformly drying; a wood plate is not raised in a drying process; the drying efficiency is high; the electromagnetic heat-conduction oil type single wood plate drying machine is convenient to control and free from pollution.

Owner:SUZHOU CHUANGWEISHENG AUTOMATION SCI & TECH

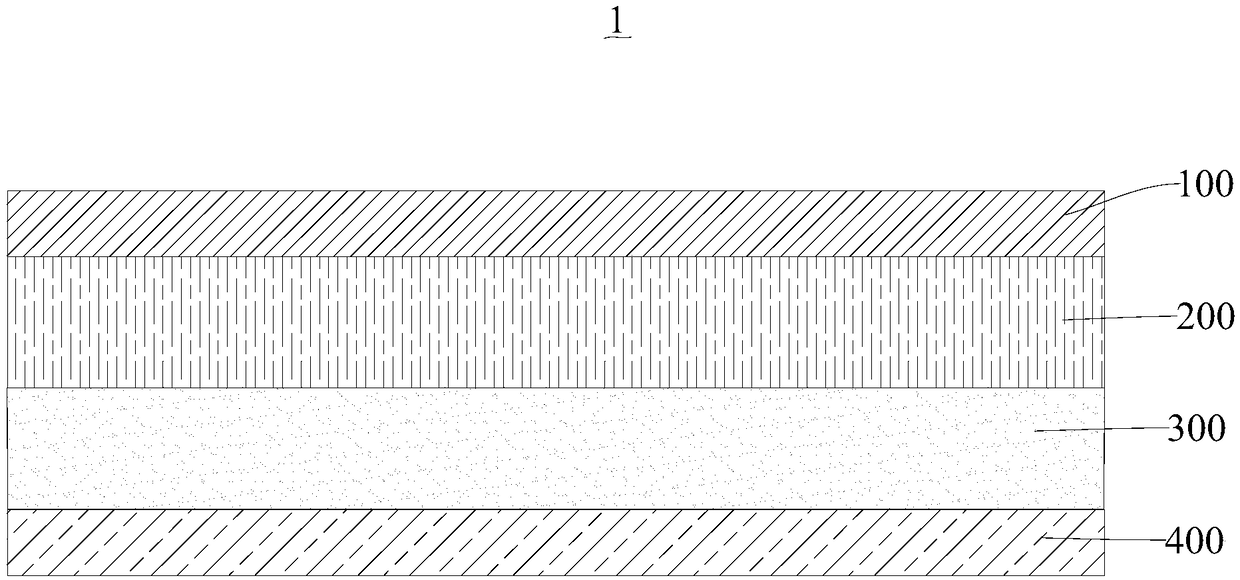

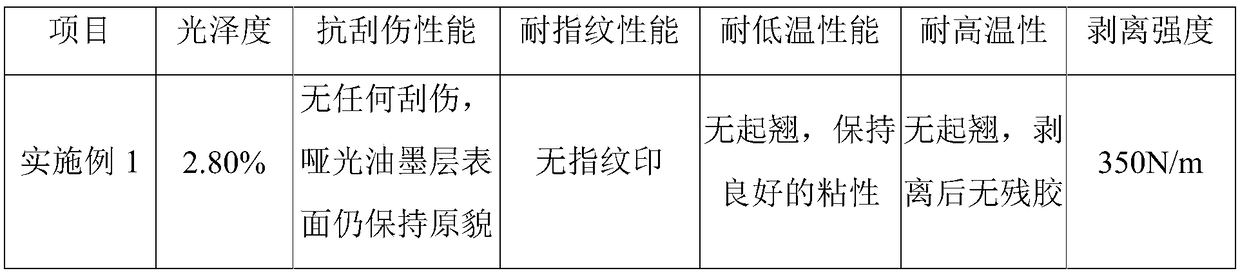

Matte printing ink, preparation method thereof and shading adhesive tape

InactiveCN109354923AGood matte effectExcellent fingerprint resistanceInksPressure sensitive film/foil adhesivesWaxFingerprint

The invention discloses matte printing ink, a preparation method thereof and a shading adhesive tape. The preparation method of the matte printing ink includes: grinding 92.8-98.8 parts of polyurethane modified acrylate resin, 0.5-3 parts of matting powder and 0.5-2 parts of wax powder after being mixed, adding 0.5-2.2 parts of first curing agent, and well mixing to obtain the matte printing ink.The matte printing ink is obtained by grinding the polyurethane modified acrylate resin, the matting powder and the wax powder after being mixed and adding the first curing agent. The matte printing ink is used for the shading adhesive tape of a liquid crystal display screen and has good matte effect, excellent fingerprint-resistant performance and good anti-scratching performance.

Owner:新丰杰力电工材料有限公司

Mailing scanning and logistics information timely updating system

ActiveCN110795953AImprove loading efficiencyReduce work intensitySensing by electromagnetic radiationLogistics managementBarcode

The invention discloses a mailing scanning and logistics information timely updating system. The system comprises a transverse rod. Supporting plates are arranged on the left side and the right side of the transverse rod. Telescopic devices are arranged on the upper side in the transverse rod in a bilateral symmetry manner; telescopic rods which are symmetrical left and right are arranged in the telescopic devices. Supporting plates are fixedly arranged at the end, away from the symmetric center, of the telescopic rods. The supporting plates are pulled to be away from each other, and the distance between the supporting plates is larger than the width of a conveying belt for conveying expresses. The supporting plates are started to the two sides of the conveying belt; the transverse rod istransversely arranged above the conveying belt. A scanner is suspended above the conveying belt. Delivery of express items is achieved while, the logistics information is updated in time while bar code scanning is conducted, manual scanning is not needed, the work intensity of workers is reduced while the express loading efficiency is greatly improved, the height of the scanner can be automatically adjusted according to the size of logistics, scanning is more accurate, the success rate is higher, and high reliability is achieved.

Owner:浙江华眼视觉科技有限公司

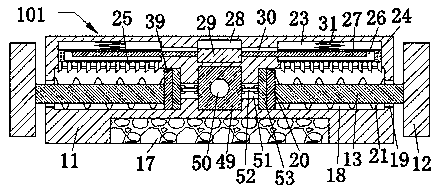

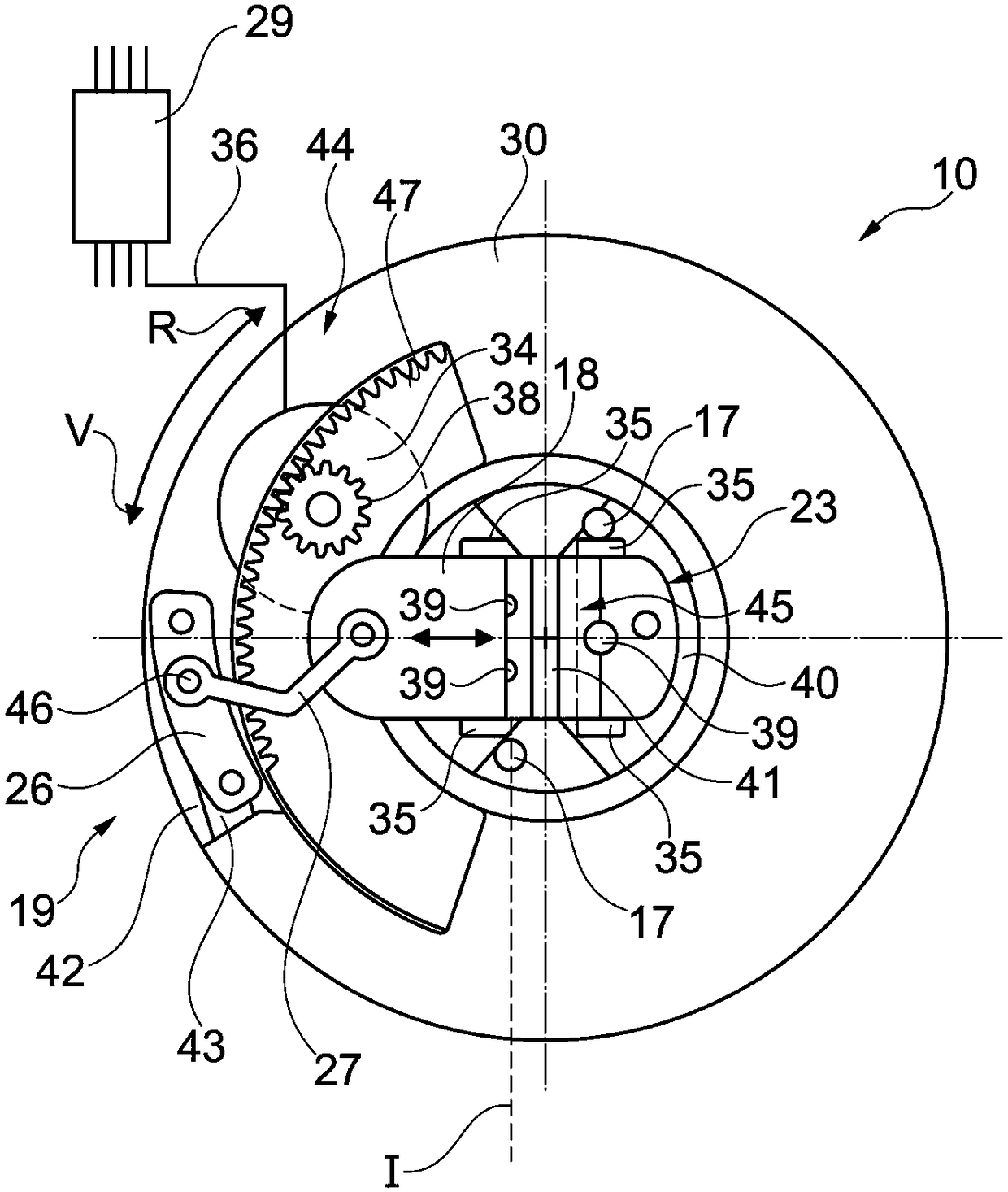

Yarn splicing device

InactiveCN108147222ACompact structureEasy to usePiercing arrangementsFilament handlingYarnEngineering

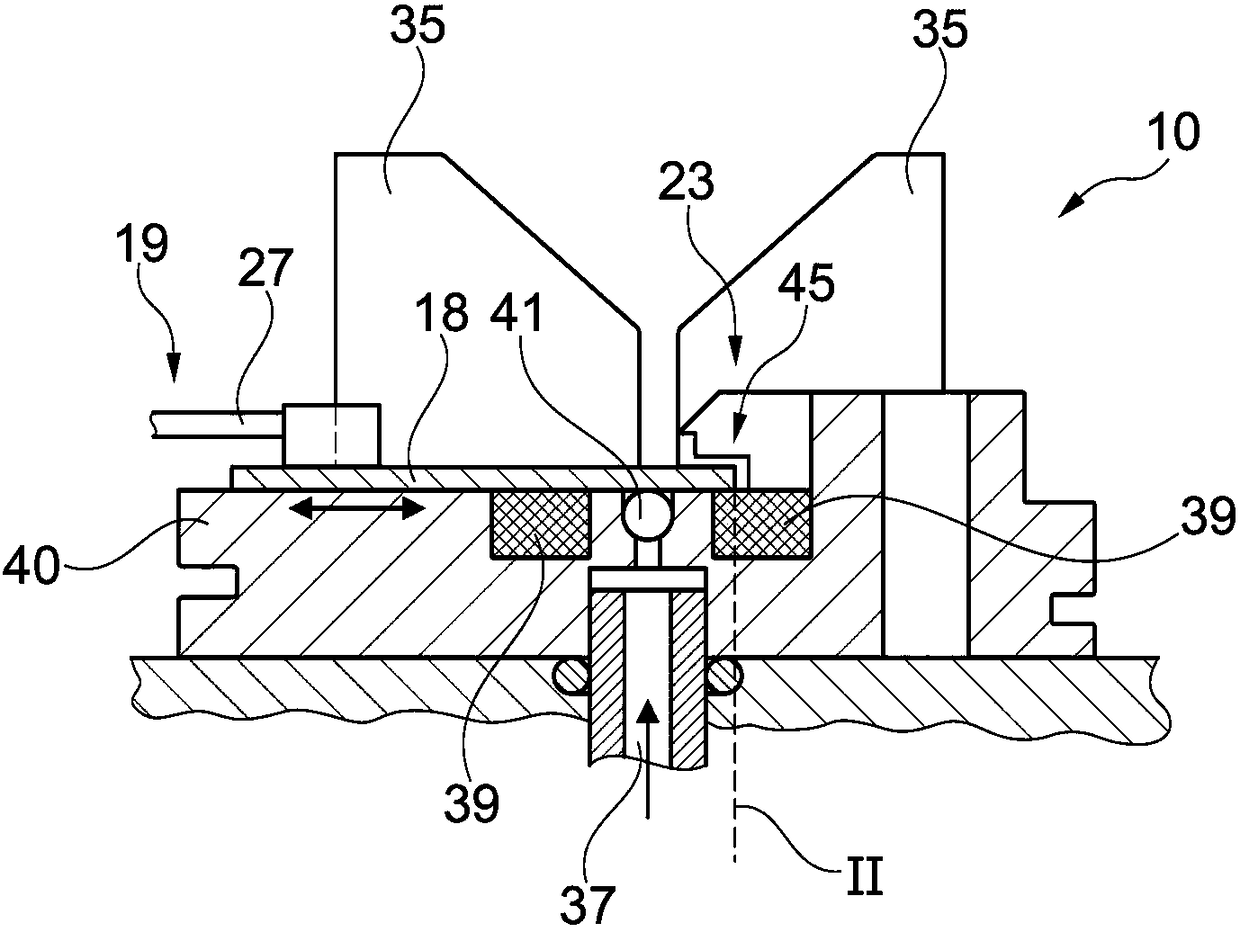

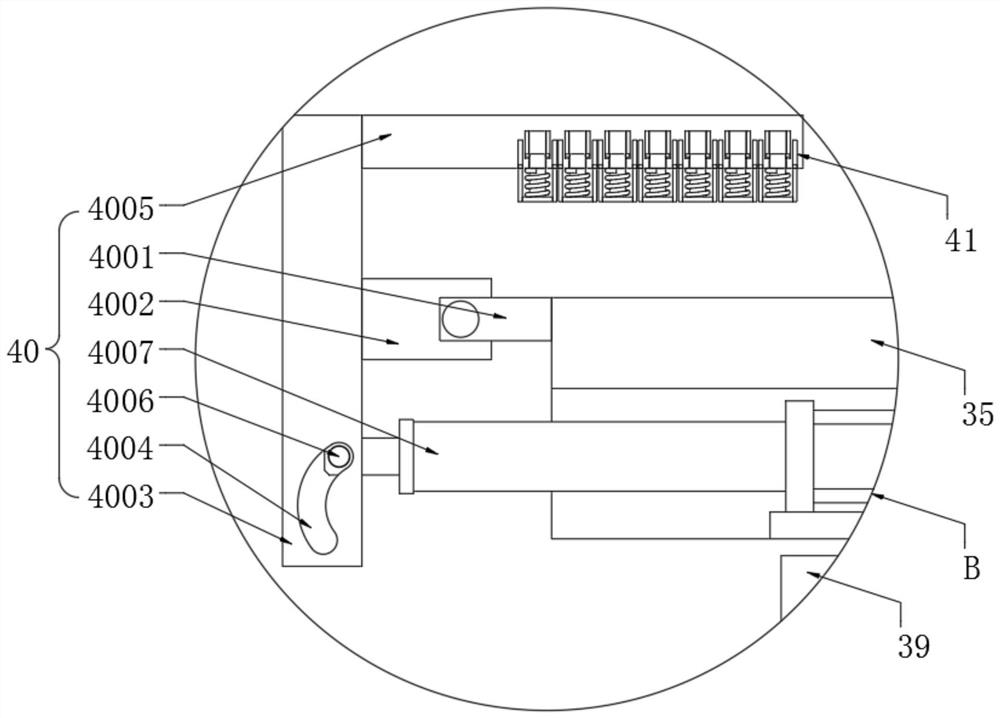

The invention relates to a yarn splicing device (10) which is used for pneumatically for splicing two yarn ends. The yarn splicing device comprises a splicing prism (23) which has a splicing channel (41). Compressed air can be added into the splicing channel (41). The splicing channel (41) can be closed by a cover (18) in a splicing operation period. According to the yarn splicing device, the cover (18) is slidably mounted and can be arranged, through a driving device (44), in a manner that the cover (18) is fixed to a position (I) which is open in an upward direction in the splicing channel (41) of the splicing prism (23) or a position that is closed in the upward direction in the splicing channel (41).

Owner:SAURER GERMANY GMBH & CO KG

Insulating frame cutting and splicing device for washing machine and processing method of insulating frame cutting and splicing device

InactiveCN114734499AImprove processing efficiencyMoving doesn't affectMetal working apparatusHome appliance efficiency improvementLaundry washing machineGear wheel

The invention discloses an insulating frame cutting and splicing device for a washing machine and a processing method thereof, and relates to the technical field of washing machine frameworks, the insulating frame cutting and splicing device comprises a chassis and a fixing assembly, a conveying motor is fixedly connected to the upper left of the chassis, a full gear is arranged on the left of a half gear, and a push block is fixedly connected to the surface of a conveying belt; through openings are symmetrically formed in the left side and the right side of the storage bin, a limiting groove is formed in the left portion of the cross beam, a bottom frame is fixedly connected to the lower portion of the hydraulic rod, a mold cavity is formed in the lower portion of the bottom frame, a mold plate is connected into the mold cavity in an embedded mode, and the fixing assemblies used for fixing the mold plate are arranged on the left side and the right side of the front portion of the bottom frame. An anti-scalding grip is fixedly connected to the front portion of the template, and a material guide plate is fixedly connected to the upper portion of the middle of the base plate. According to the cutting and splicing device for the insulating frame for the washing machine and the processing method of the cutting and splicing device, compared with an existing common cutting and splicing device, different faces of the frame can be sequentially cut and spliced, and the processing efficiency is improved.

Owner:盐城立德塑业有限公司

Mixed folding machine

PendingCN108382917AWon't liftThose who don't know foldFolding thin materialsArticle deliveryPulp and paper industryPaper sheet

The invention discloses a mixed folding machine which comprises a folding device, a first horizontal folding roll, fences, a folding knife and air pipes. A paper feed device is arranged on the right side of the folding device, and a paper collection device is fixed to the left side of the folding device. A second horizontal folding roll is arranged below the first horizontal folding roll. First baffles are mounted on the fences. Transfer rollers are mounted on the left side of a fourth horizontal folding roll. A first vertical folding roll and a second vertical folding roll are mounted below the folding knife. The air pipes are arranged on the right side of the folding knife and the right side of the first horizontal folding roll, and air nozzles are fixed to the lower end face of each airpipe. According to the mixed folding machine, the air pipes cooperate with the air nozzles, paper in the transfer process bears pressure of air blown out from the upper air nozzles, the paper is attached to a transfer device, and it is guaranteed that the paper cannot upwarp or be folded in the transfer process; and the two movable baffles are arranged, and adaptability of the device to differentfolding requirements is increased.

Owner:宜春市同茂印务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com