Handwork imitation full-automatic egg-biscuit-roll machine

A fully automatic, hand-imitating technology, applied in applications, food preparation, food science, etc., can solve the problems of lower production efficiency, high cost, and large storage space in automatic egg roll processing devices, and achieve the goal of improving the success rate of winding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

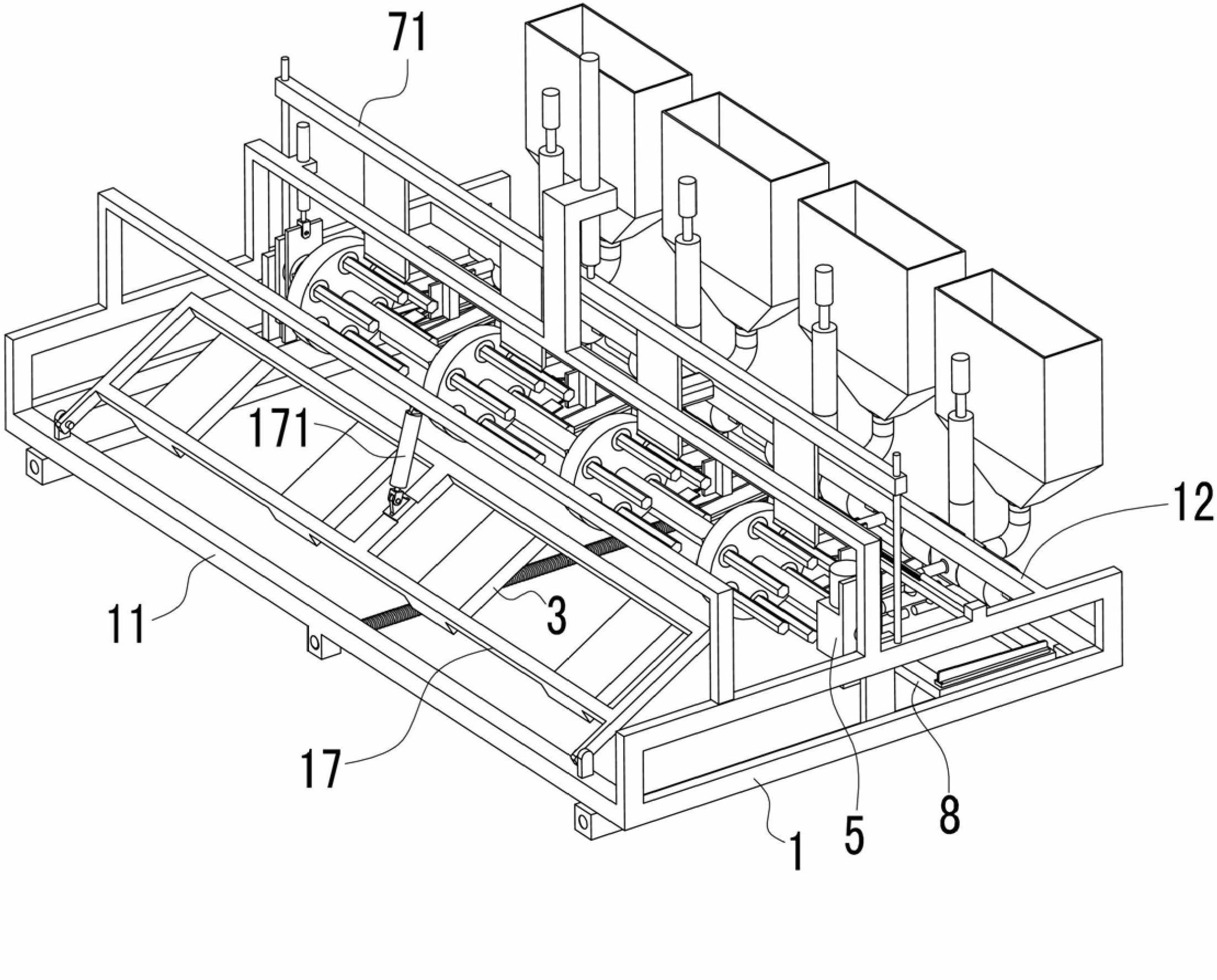

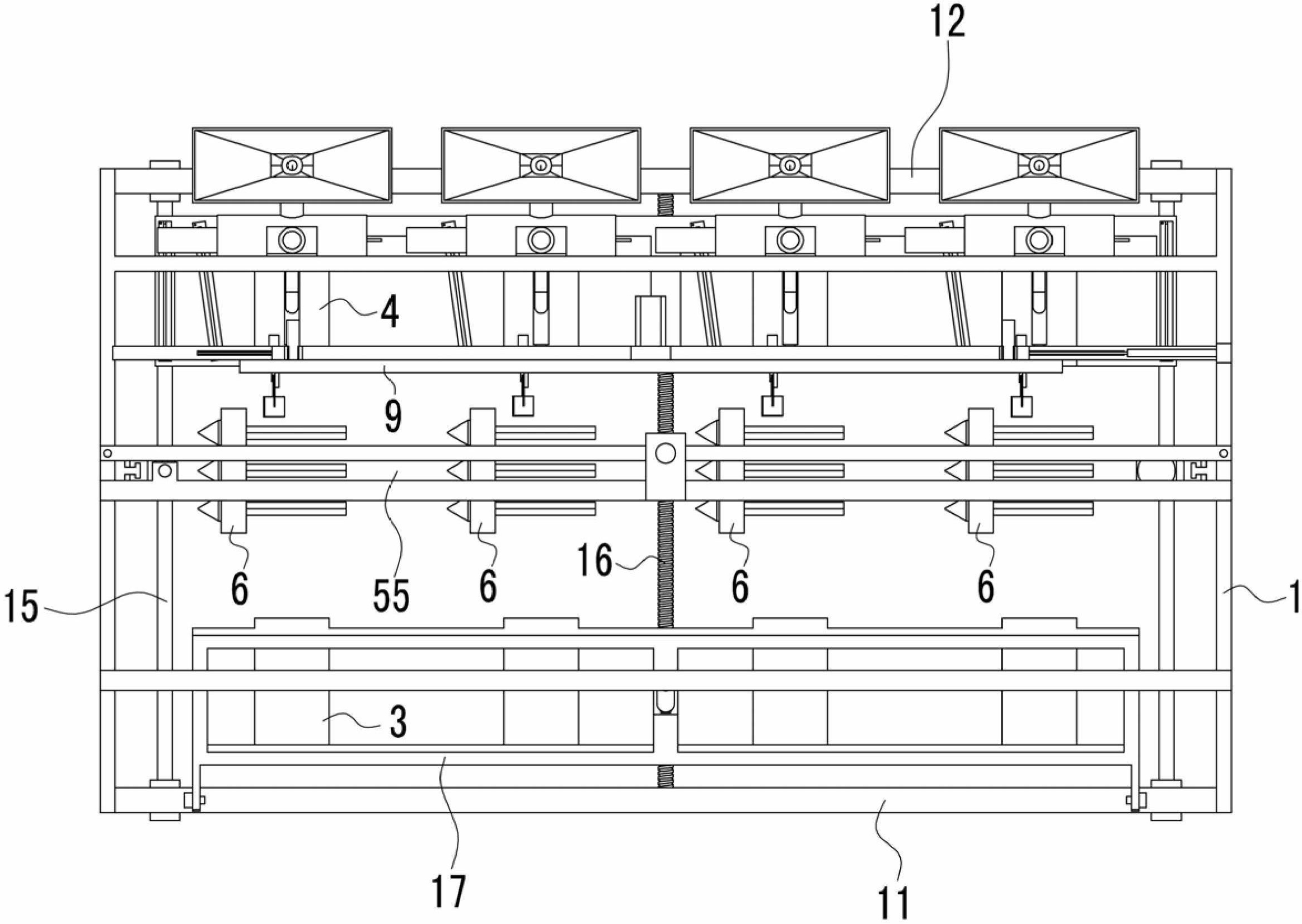

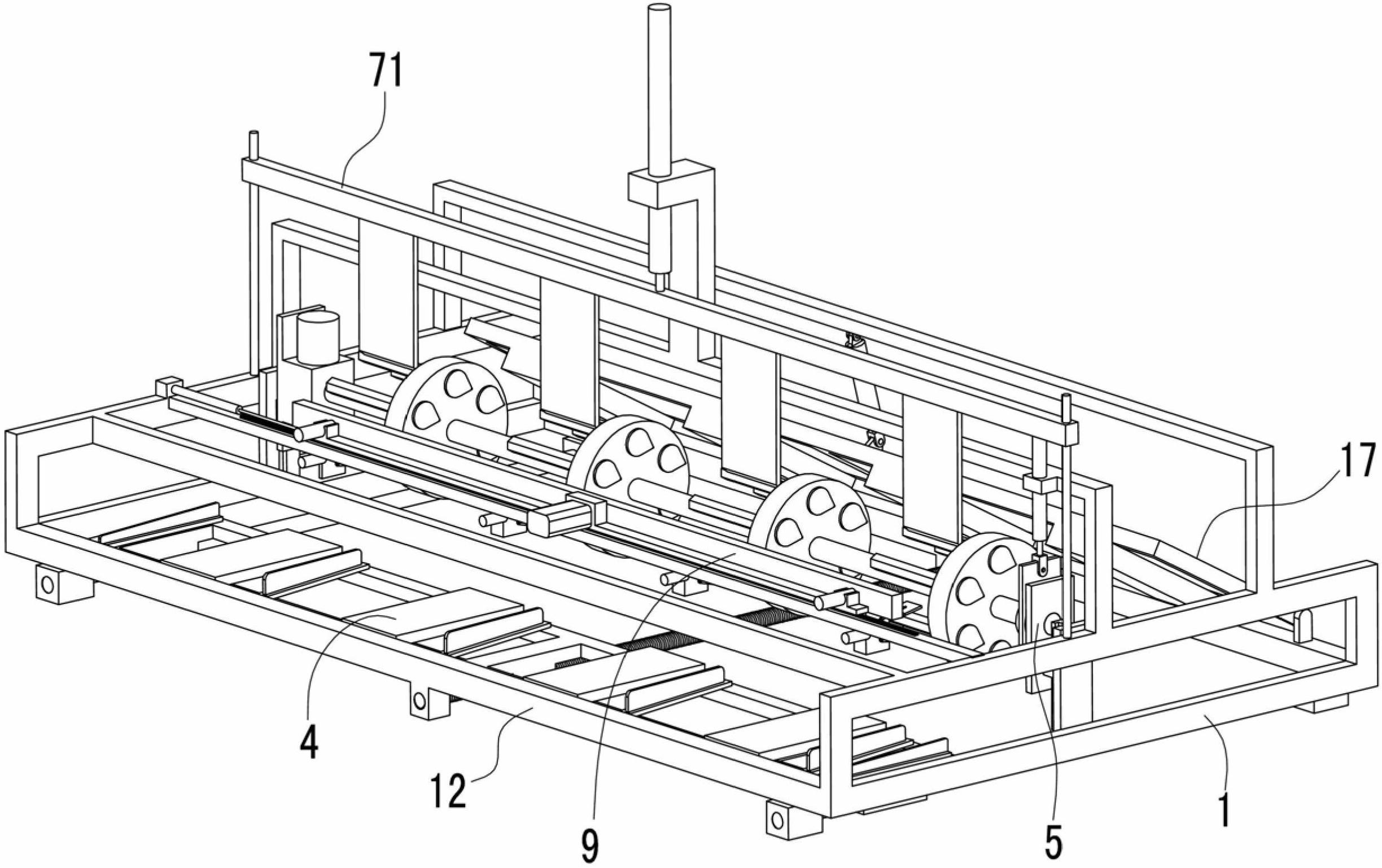

[0047] Such as Figure 1 to Figure 20 As shown, a manual-like automatic egg roll machine includes a frame 1, a controller (not shown in the figure) and several egg roll processing units arranged on the frame, wherein each egg roll processing unit includes Unloading device, heating device, coiling device and manipulator unloading device 9,

[0048] Such as Figure 5 to Figure 10 As shown, the unloading device is installed at the tail end of the frame, including a hopper 21, the hopper 21 has a first discharge port 211, and also includes a three-way valve 22, and the three-way valve 22 has a feed port 221, a pump The feed port 222 and the second discharge port 223, the first discharge port 211 of the hopper is connected to the feed port 221 of the three-way valve, and the pump feed port 222 is provided with a pumping pump 23;

[0049...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com