Aluminium pot with compound bottom and manufacturing method thereof

A manufacturing method and composite bottom technology, applied in applications, kitchen utensils, special materials for cooking utensils, etc., can solve problems such as different thermal expansion coefficients, scratches on electromagnetic cooktops, upturning around convex posts, etc., to achieve ideal thermal conductivity and prevent scratches Effect of flower, close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

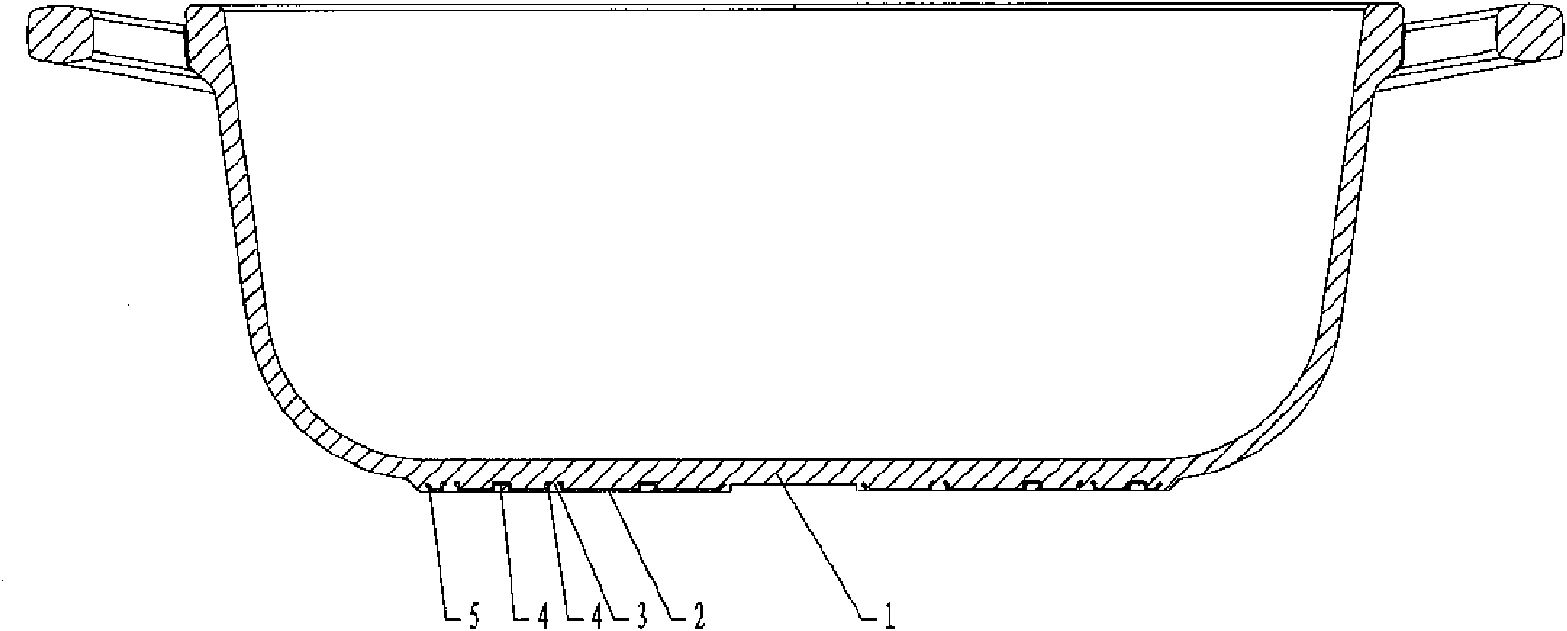

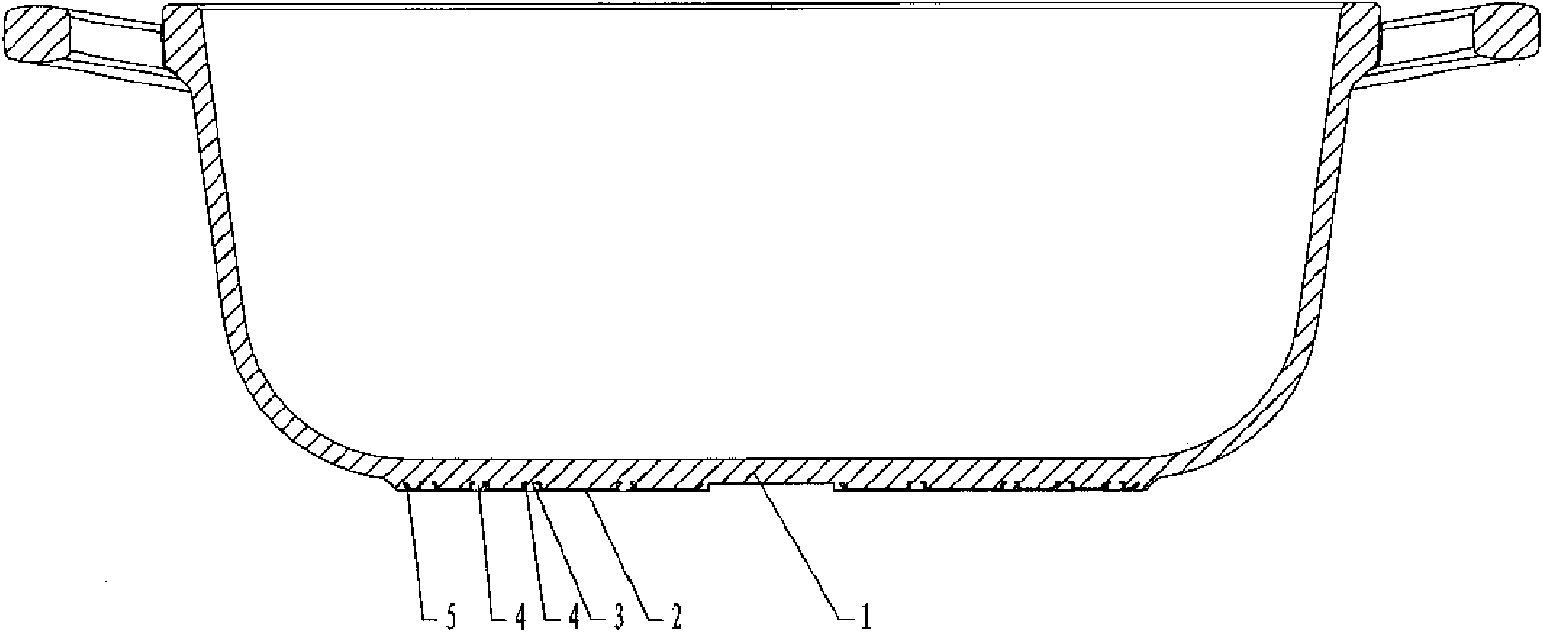

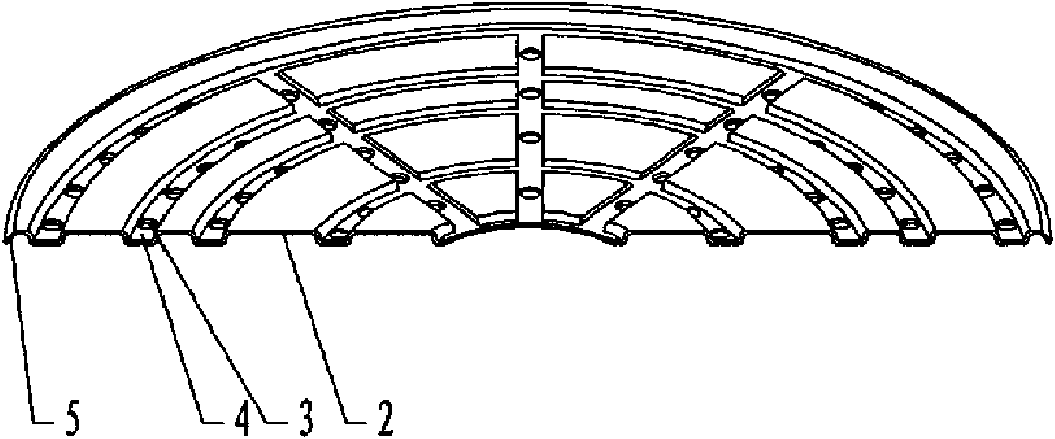

[0033] combine figure 1 , figure 2 , image 3 , Figure 4 As shown: the aluminum pot with a composite bottom in this embodiment includes: the bottom 1 of the pot is fixed with a metal magnetic conductive sheet 2 . The metal magnetic sheet is provided with several openings 3 and grooves 4, the openings 3 are located at the bottom of the groove 4, the groove 4 communicates at least two openings 3, and the bottom of the pot is connected to the metal magnetic sheet. Die-casting is integrated by a die-casting machine, and aluminum alloy is filled in the groove 4, and the aluminum alloy in the groove is connected with the aluminum alloy at the bottom of the pot through the opening.

[0034] The edge of the metal magnetic sheet 2 is folded and pressed to form a raised flange 5, and the outer surface of the flange 5 is covered by aluminum alloy. The bottom of the pot is provided with a pattern consisting of the outer surface of the metal magnetic conductive sheet 2, the groove 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com