Laminated plate lifting appliance and steel beam

A technology of laminated slabs and spreaders, which is applied in the field of spreaders and steel beams, can solve problems such as few stress points at the top, poor stability of laminated slabs, and swaying, etc., to expand the range, promote stability, even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

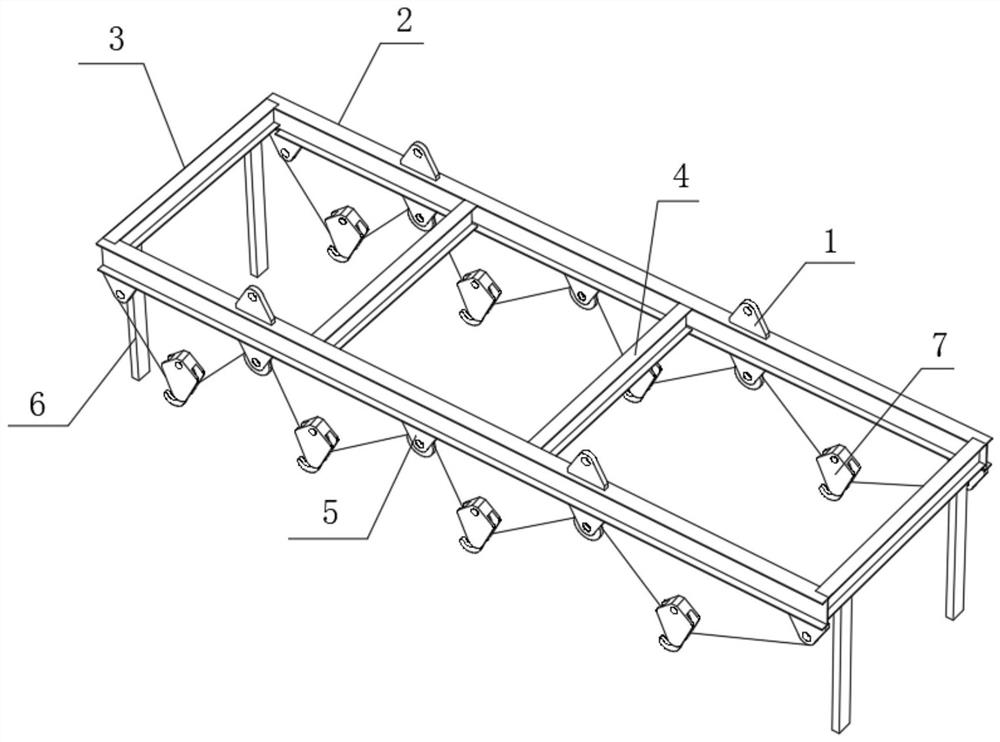

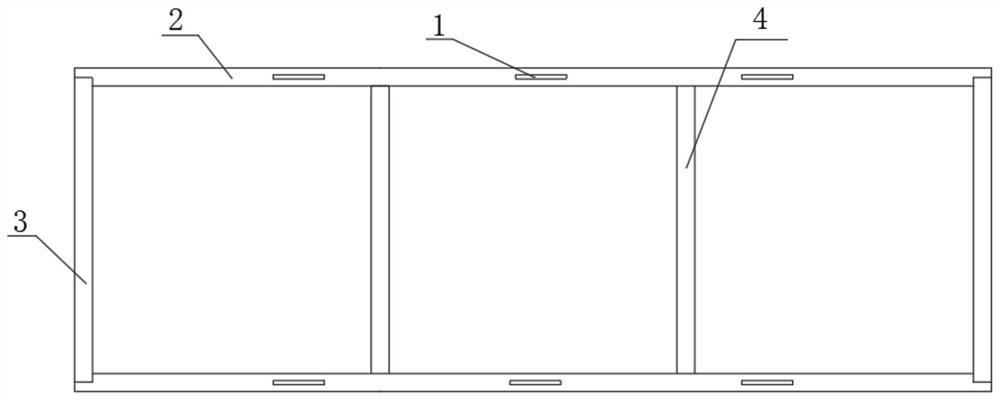

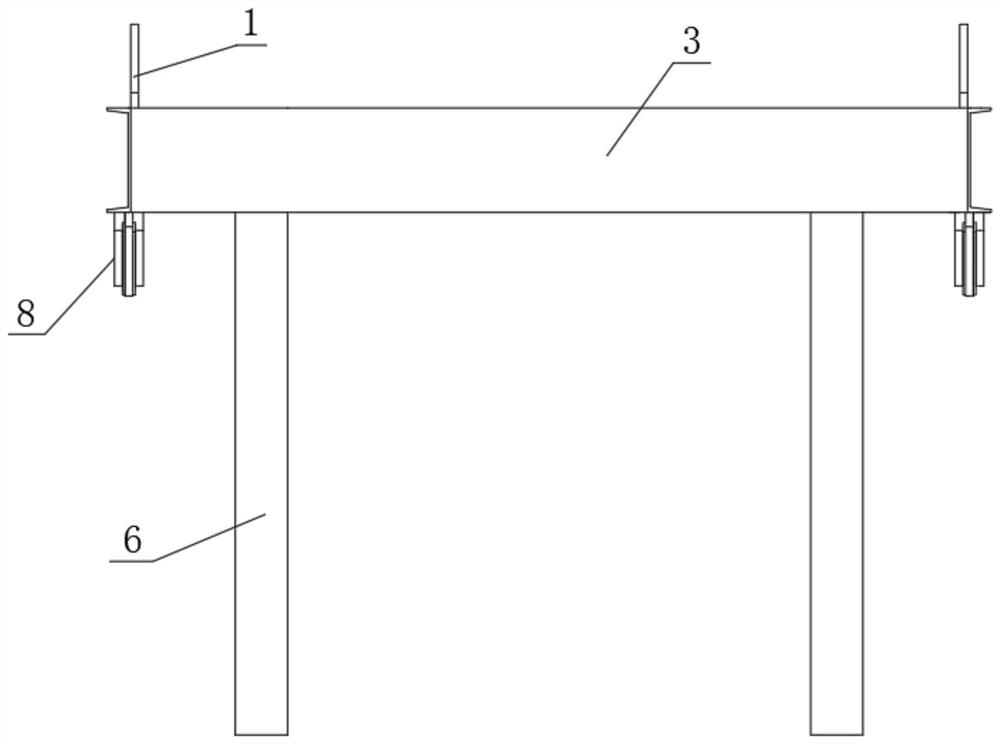

[0033] Laminated slab spreaders and beams, such as Figure 1-6 As shown, two first I-beams 2 and two second I-beams 3 are included, welding grooves 12 are opened at both ends of the two first I-beams 2, and two second I-beams The two ends of 3 are respectively welded to the welding grooves 12 of the two first I-beams 2, the two first I-beams 2 and the two second I-beams 3 form a rectangular frame structure, and the two first I-beams Two welding holes are respectively opened on the top outer wall of the beam 2, and a hanging plate 1 is welded on the inner wall of each welding hole, and a hanging hole is opened on one side outer wall of each hanging plate 1, and the two first I-beams The outer walls of the bottom at both ends of 2 are fixed with triangular support plates by bolts, and the outer walls of one side of each triangular support plate are inserted with fixed shafts, and the outer bottom walls of the two first I-beams 2 are welded with fixed The pulley assembly 5 has a...

Embodiment 2

[0040] Laminated slab spreaders and beams, such as Figure 8 As shown, in order to facilitate the lifting of wallboards of different lengths; this embodiment makes the following improvements on the basis of embodiment 1: preferably, two second I-beams 3 with channel steel 6 are replaced with no The two second I-beams 3 of the channel steel 6 effectively expand the scope of the overall structure for hoisting objects, especially for hoisting wallboards of different lengths.

[0041] When this embodiment is in use, the lifting requirements for stacked plates of different lengths are effectively met by the two second I-beams 3 without the channel steel 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com