All-steel transverse-cord tyre with reinforced layer at tyre bead

A technology of reinforcement layer and radial line, applied in the direction of tire bead, tire parts, transportation and packaging, etc., can solve the problems of reducing the safety performance of tires, shortening the service life of tires, bulging and sub-port bursting, etc. Service life, the effect of preventing the cracking of the inner end point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

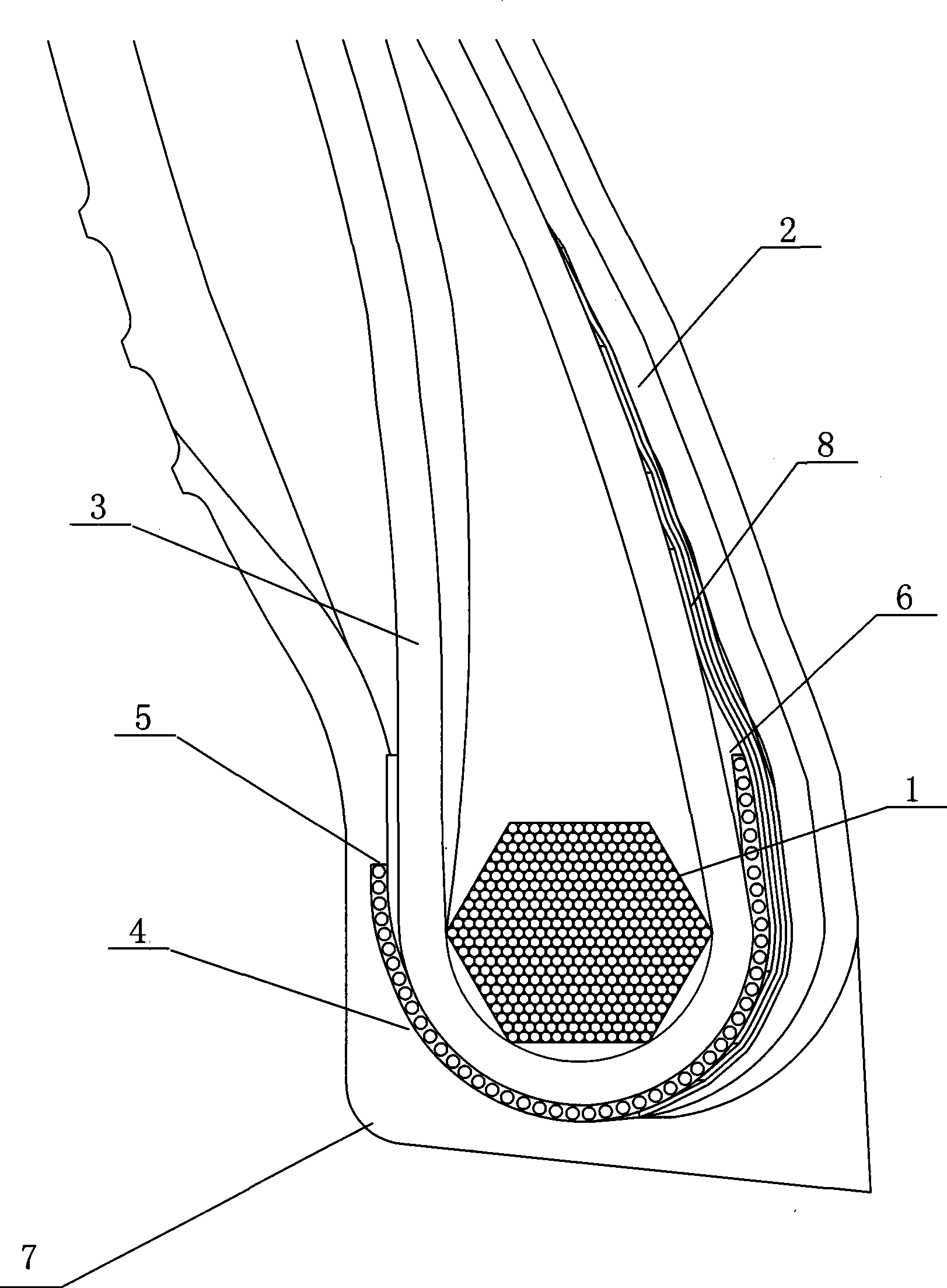

[0017] The bead is an all-steel radial giant tire with a reinforced layer, including the crown, sidewall and bead, and the bead 7 is as figure 1 As shown, it includes a bead ring 1, a carcass ply 2 and a carcass ply turnup 3 surrounding the bead ring 1; a layer of steel cord reinforcement is wrapped outside the carcass ply 2 and the carcass ply turnup 3 4. The steel cord reinforcement layer 4 is U-shaped, and the outer end point 5 of the steel cord reinforcement layer 4 is lower than the rim rim. In this embodiment, the outer end point 5 of the steel cord reinforcement layer 4 is 30mm lower than the rim rim. The inner end point 6 of the steel cord reinforcement layer 4 is 50mm higher than the rim rim; the angle between the steel cord and the carcass cord in the steel cord reinforcement layer 4 is 42°; A fiber cord reinforcement layer 8 is provided; in this embodiment, the fiber cord reinforcement layer 8 is a nylon cord reinforcement layer, the tear strength of the nylon cords...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com