Paper-plastic composite packaging material with high air permeability and preparation method thereof

A paper-plastic composite and packaging material technology, applied in the field of packaging materials, can solve the problems of poor air permeability and achieve the effects of improved air permeability, stable film blowing process, and good low-temperature adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

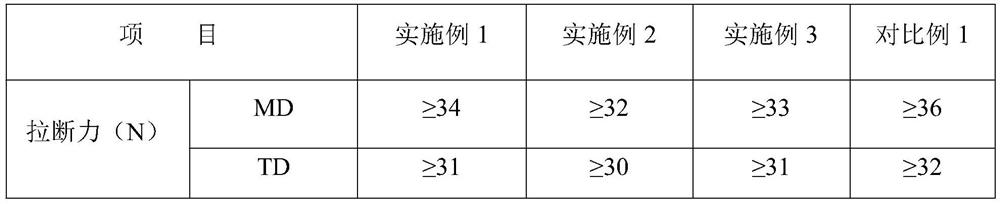

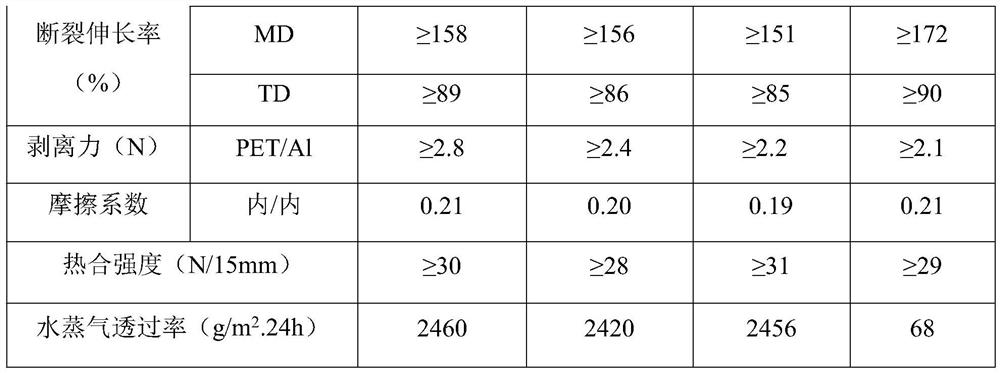

Examples

Embodiment 1

[0030] S1. Weigh the raw materials of each corresponding weight component according to the formula composition of the film bonding layer, the middle layer and the heat-sealing layer, wherein the bonding layer is composed of 100 parts by mass of modified EVA resin, and the middle layer is composed of 75 parts by mass The high-density polyethylene resin and the low-density polyethylene resin of 25 mass parts are composed; The heat-sealing layer is composed of 75 mass parts of low-density polyethylene resin, 25 mass parts of metallocene polyethylene resin, 1.5 mass parts of smooth Masterbatch, 1 part by mass of open masterbatch and 0.2 part by mass of processing aids are added to the three barrels of W&H film blowing equipment;

[0031] The raw materials in the above three barrels are mixed and melted to form a tube blank, and the tube blank is stretched and then punched out from the center of the extruder die and compressed air, so that the tube blank is blown into a film bubble,...

Embodiment 2

[0035] S1. Weigh the raw materials of each corresponding weight component according to the formula composition of the film bonding layer, the middle layer and the heat sealing layer, wherein the bonding layer is composed of 95 parts by mass of modified EVA resin, and the middle layer is composed of 75 parts by mass The high-density polyethylene resin and the low-density polyethylene resin of 25 mass parts are composed; The heat-sealing layer is composed of 80 mass parts of low-density polyethylene resin, 25 mass parts of metallocene polyethylene resin, 1.5 mass parts of smooth Masterbatch, 1 part by mass of open masterbatch and 0.2 part by mass of processing aids are added to the three barrels of W&H film blowing equipment;

[0036] The raw materials in the above three barrels are mixed and melted to form a tube blank, and the tube blank is stretched and then punched out from the center of the extruder die and compressed air, so that the tube blank is blown into a film bubble, ...

Embodiment 3

[0040] S1. Weigh the raw materials of each corresponding weight component according to the formula composition of the film bonding layer, the middle layer and the heat sealing layer, wherein the bonding layer is composed of 90 parts by mass of modified EVA resin, and the middle layer is composed of 75 parts by mass The high-density polyethylene resin and the low-density polyethylene resin of 25 mass parts are composed; The heat-sealing layer is composed of 85 mass parts of low-density polyethylene resin, 25 mass parts of metallocene polyethylene resin, 1.5 mass parts of smooth Masterbatch, 1 part by mass of open masterbatch and 0.2 part by mass of processing aids are added to the three barrels of W&H film blowing equipment;

[0041] The raw materials in the above three barrels are mixed and melted to form a tube blank, and the tube blank is stretched and then punched out from the center of the extruder die and compressed air, so that the tube blank is blown into a film bubble, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com