Environmental-friendly modified starch / feather protein grafted copolymer composite size, preparation method and application thereof

A graft copolymer and feather protein technology is applied in the field of environment-friendly modified starch/feather protein graft copolymer composite slurry and preparation, and can solve the problems of difficult decomposition, difficulty in desizing and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

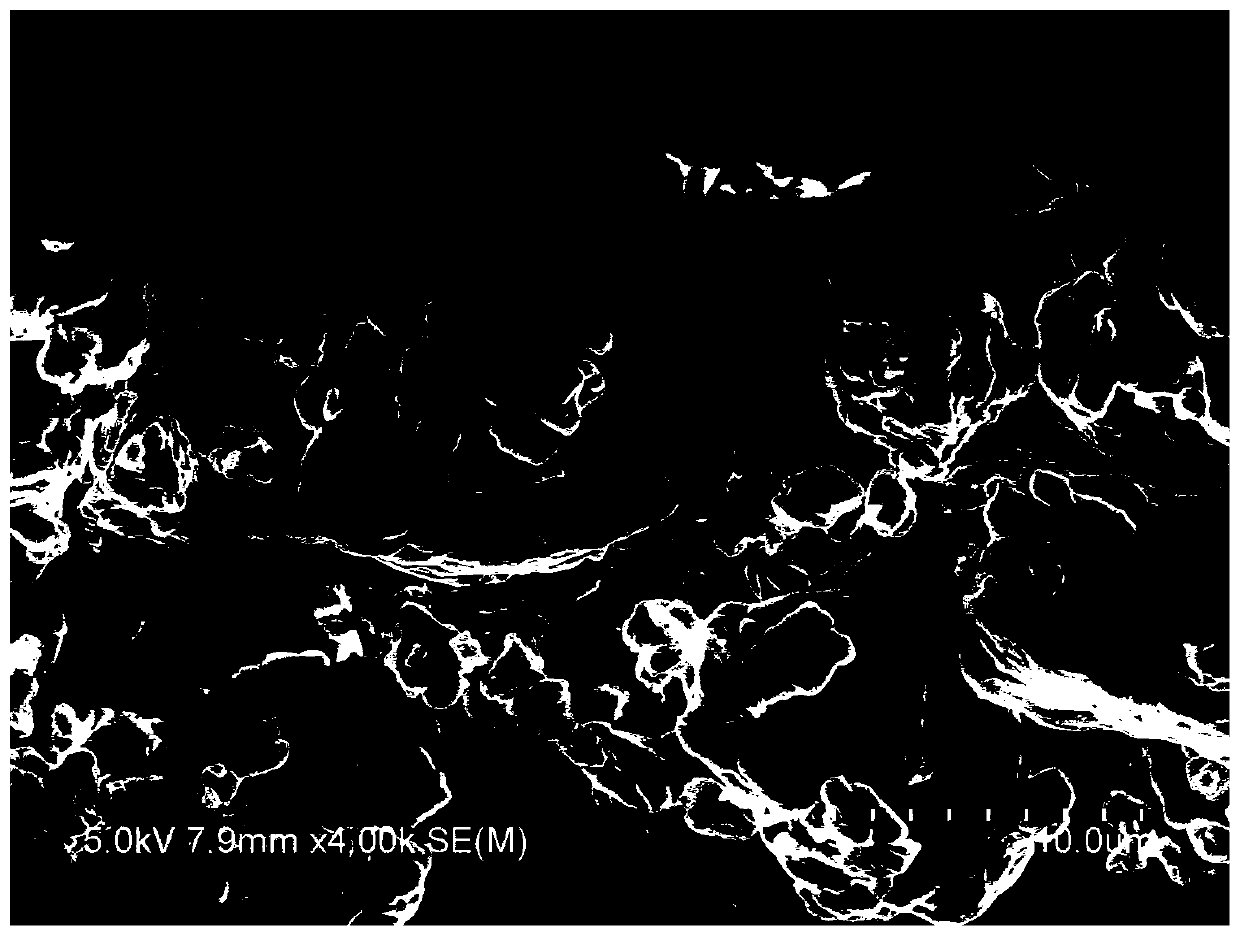

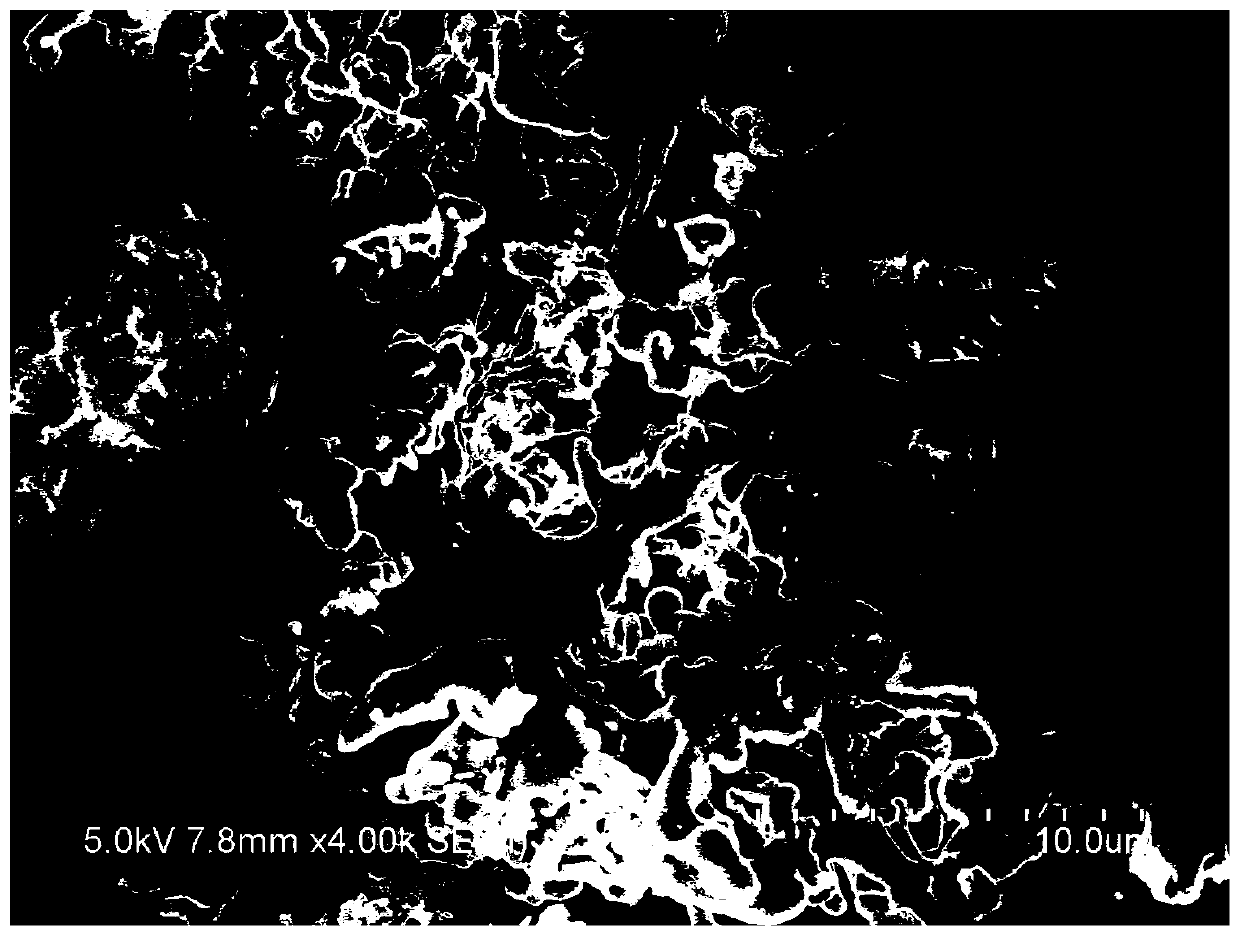

Image

Examples

Embodiment 1

[0032] Composite slurry preparation includes the following steps:

[0033] (1) Extraction of feather protein: 1) Dry the washed feathers in an oven at 45°C to half-dry, cut them into pieces, then continue to dry them, and smash them with a powder machine to obtain feather powder; 6 times the volume of feather meal), hydrochloric acid (30% of feather meal mass), distilled water (1400mL) are added in the 3L beaker that 100g feather meal is housed, plastic wrap covers the mouth of beaker, adjust water bath temperature to be 70 ℃, continue under stirring After 4 hours, suction filter, wash several times with distilled water, dry, and weigh; 3) put the feather meal processed in step 2 into a beaker, and add sodium bisulfite (30% of the quality of the feather meal processed in step 2) Add it to the feather meal, add 1400mL of distilled water, adjust the water bath temperature to 70°C, and continue for 3 hours under stirring, then filter it with suction; 4) put the pretreated feather...

Embodiment 2

[0038] Composite slurry preparation steps (1), (2) are the same as in Example 1; (3) use sulfo-etherified-hexanoate starch as the main slurry, and first stir the water dispersion of the main slurry at 95°C After gelatinization for 1 hour to form a slurry, cool down to 60°C, add the aqueous solution of feather protein graft copolymer that has been fully stirred at 60°C for 60 minutes in the main slurry (the content of the feather protein graft copolymer is 50% of the main slurry quality). 5%) to form a composite liquid with a mass fraction of the main slurry of 1%, and fully stir at 60° C. for 60 minutes to fully compound, to obtain the composite slurry (named as composite slurry 2).

Embodiment 3

[0040] Composite slurry preparation steps (1), (2) are the same as in Example 1; (3) use sulfo-etherified-hexanoate starch as the main slurry, and first stir the water dispersion of the main slurry at 95°C After gelatinization for 1 hour to form a slurry, cool down to 60°C, add the aqueous solution of feather protein graft copolymer that has been fully stirred at 60°C for 60 minutes in the main slurry (the content of the feather protein graft copolymer is 50% of the main slurry quality). 7.5%) to form a composite solution with a mass fraction of 1% of the main slurry, and fully stir at 60° C. for 60 minutes to fully compound to obtain the composite slurry (named as composite slurry 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com