Tundish coating

A tundish and coating technology, used in casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problem of low service life of the tundish, and achieve increased fluidity and thermal insulation performance, long service life, and chemical properties. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

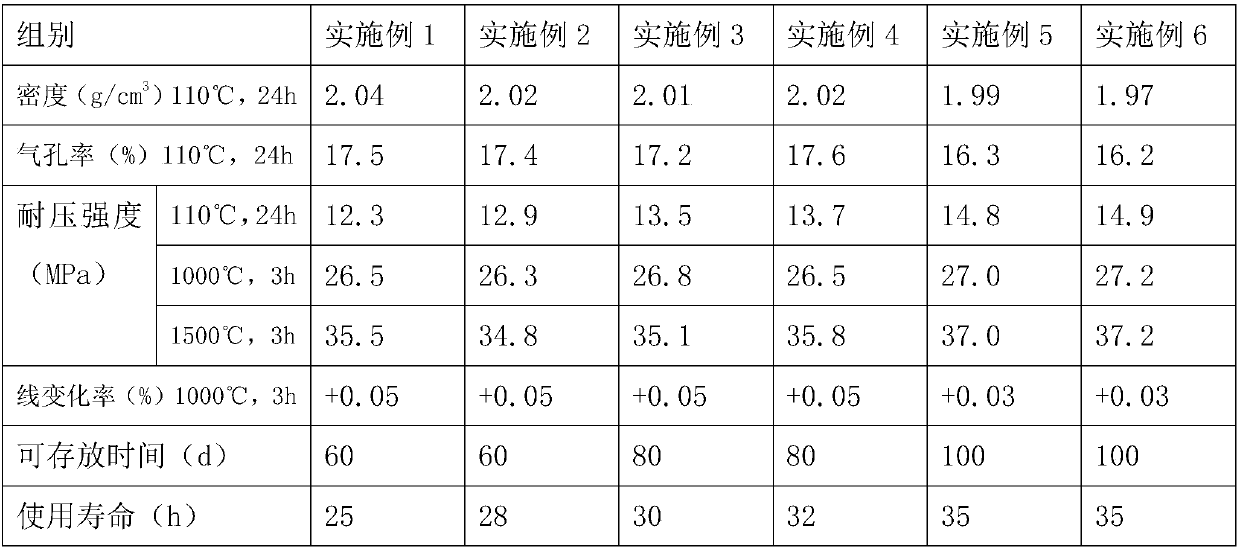

Examples

Embodiment 1

[0020] Composition of raw materials (parts by weight): 80 parts of medium-grade sintered magnesia, 7 parts of slaked lime, 15 parts of glass fiber, 10 parts of metal aluminum powder, 5 parts of melamine, 3 parts of rosin, 10 parts of magnesium sulfate, 20 parts of hollow ceramic microspheres and chlorine Aluminum 14 parts.

[0021] The MgO content of the mid-range sintered magnesia is above 95%.

[0022] The particle size of the mid-grade sintered magnesia is between 0.3-2mm.

Embodiment 2

[0024] Composition of raw materials (parts by weight): 100 parts of mid-range sintered magnesia, 12 parts of slaked lime, 25 parts of glass fiber, 20 parts of metal aluminum powder, 12 parts of melamine, 10 parts of rosin, 15 parts of magnesium sulfate, 30 parts of hollow ceramic microspheres and chlorine Aluminum 18 parts.

[0025] The MgO content of the mid-range sintered magnesia is above 95%.

[0026] The particle size of the mid-grade sintered magnesia is between 0.3-2mm.

Embodiment 3

[0028] Composition of raw materials (parts by weight): 85 parts of medium-grade sintered magnesia, 8 parts of slaked lime, 16 parts of glass fiber, 12 parts of metal aluminum powder, 6 parts of melamine, 4 parts of rosin, 11 parts of magnesium sulfate, 22 parts of hollow ceramic microspheres and chlorine Aluminum 15 parts.

[0029] The MgO content of the mid-range sintered magnesia is above 95%.

[0030] The particle size of the mid-grade sintered magnesia is between 0.3-2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com