Water-based polyacrylic emulsion laminating adhesive and preparation method thereof

A technology of water-based acrylic and laminating adhesive, which is applied in the direction of adhesive types, ester copolymer adhesives, etc., can solve the problems of insufficient bonding strength, poor initial tack, embossed wrinkling, etc., and achieve improved initial tack and bonding strength, improving low-temperature bonding performance, and improving the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

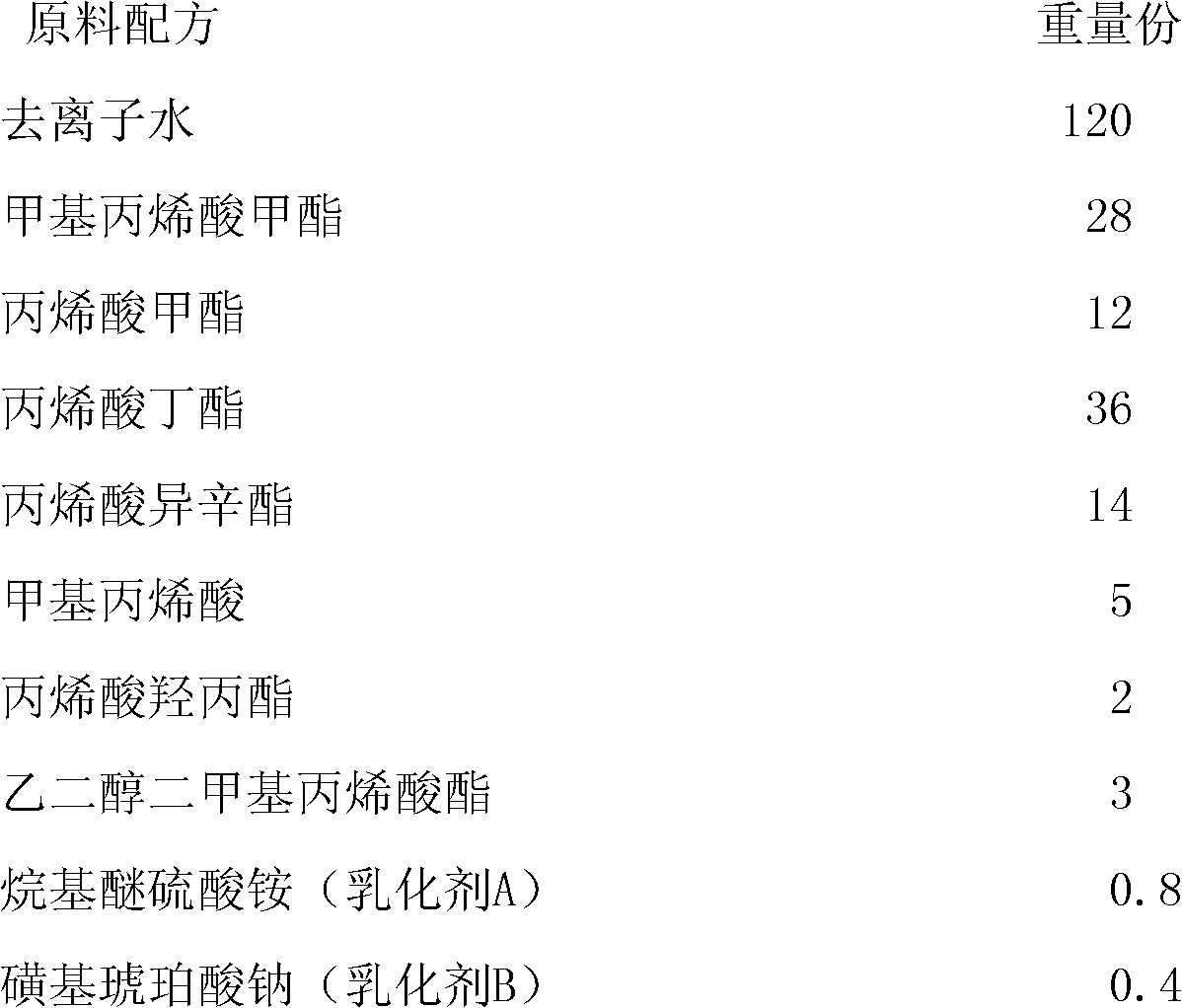

[0018] This embodiment provides a water-based acrylic emulsion laminating adhesive, which is made of monomers, emulsifiers, initiators, buffers, pH regulators, water-based additives and deionized water as raw materials, pre-emulsified, The laminating glue with a solid content of 40-50% is prepared by the steps of seed reaction, polymerization reaction and compounding;

[0019] Wherein, said monomer comprises hard monomer, soft monomer and the functional monomer containing -COOH, -OH group; Described hard monomer is made of methyl methacrylate (MMA) and methyl acrylate (MA) Composition; The soft monomer is composed of butyl acrylate (BA) and isooctyl acrylate (EHA); the functional monomer containing -COOH, -OH groups in the monomer is composed of methacrylic acid (MAA ) or acrylic acid (AA), any of hydroxyethyl acrylate (HEA) or hydroxypropyl acrylate (HPA), and ethylene glycol dimethacrylate (EGDMA).

[0020] According to the total weight of each raw material in the monomer a...

Embodiment 2

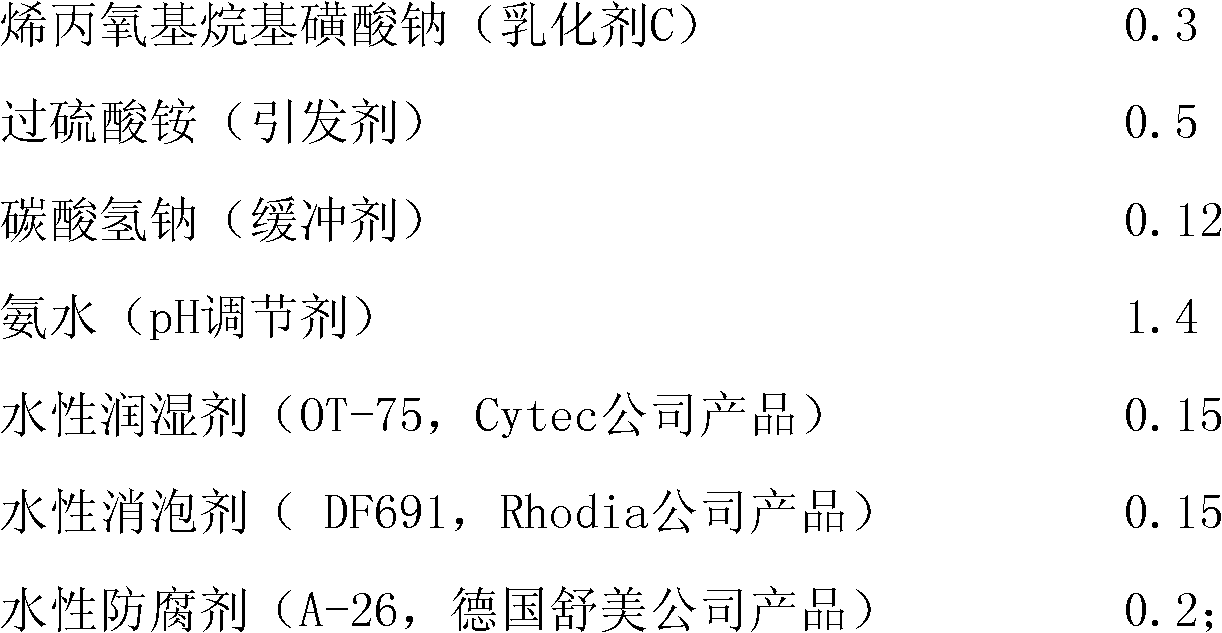

[0034] This embodiment provides a water-based acrylic emulsion laminating adhesive, which can be used in paper / plastic interface compounding. The laminating adhesive includes:

[0035]

[0036]

[0037] The preparation method of above-mentioned water-based acrylic acid emulsion laminating adhesive is carried out according to the following steps:

[0038] (1) Pre-emulsification: in the emulsification tank, drop into deionized water accounting for 40% of the total weight of deionized water, emulsifying agent A accounting for 50% of the total weight of emulsifying agent A, accounting for emulsifying agent B of 50% of the total weight of emulsifying agent B and All emulsifier C and all monomers were stirred and emulsified for more than 30 minutes to prepare a pre-emulsion;

[0039](2) Seed reaction: Add deionized water accounting for 40% of the total weight of deionized water, the remaining emulsifier A, the remaining emulsifier B, and buffer into the polymerization reactor,...

Embodiment 3

[0043] This embodiment provides a water-based acrylic emulsion laminating adhesive, which can be used in paper / plastic interface compounding. The laminating adhesive includes:

[0044]

[0045]

[0046] The preparation method of above-mentioned water-based acrylic acid emulsion laminating adhesive is carried out according to the following steps:

[0047] (1) Pre-emulsification: put into the emulsification kettle the deionized water accounting for 45% of the total weight of deionized water, the emulsifier A accounting for 50-60% of the total weight of emulsifier A, and the emulsifier A accounting for 50-60% of the total weight of emulsifier B Emulsifier B, all emulsifier C, and all monomers, start stirring and emulsifying for more than 30 minutes to prepare a pre-emulsion;

[0048] (2) Seed reaction: Add deionized water accounting for 45% of the total weight of deionized water, the remaining emulsifier A, the remaining emulsifier B, and buffer into the polymerization reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com