Oil-seepage-resistant, low-temperature-resistant and high-stripping-force hot-melt pressure-sensitive adhesive and preparation method of thereof

A technology of hot-melt pressure-sensitive adhesives and low temperature resistance, which is applied in the direction of adhesives, polymer adhesive additives, adhesive types, etc., and can solve the problems of unstable adhesive performance, downstream products, unstable adhesive performance, etc. Achieve good performance balance, reduce system viscosity, and achieve high peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also discloses a preparation method of the above-mentioned hot-melt pressure-sensitive adhesive with oil seepage resistance, low temperature resistance and high peeling force, which specifically includes the following steps:

[0034] Step A, add plasticizer in the formula amount, low molecular weight synthetic liquid polybutadiene rubber, antioxidant, 25%-40% tackifying resin into the reaction kettle, heat up while stirring, and set the speed at 30- 50rpm, the material temperature is controlled at 140-150°C, the reactor is sealed, vacuumed for 0.5h-1.0h, and the reaction pressure is controlled to be ≤-0.09MPa;

[0035] Step B, close the vacuum, open the reaction kettle, after the tackifying resin 1 is completely melted and mixed evenly with the plasticizer and antioxidant, add thermoplastic elastomer 1, thermoplastic elastomer 2 and thermoplastic elastomer 3, and heat up to 150 ℃-155℃ and heat preservation and vacuum stirring until thermoplastic el...

Embodiment 1

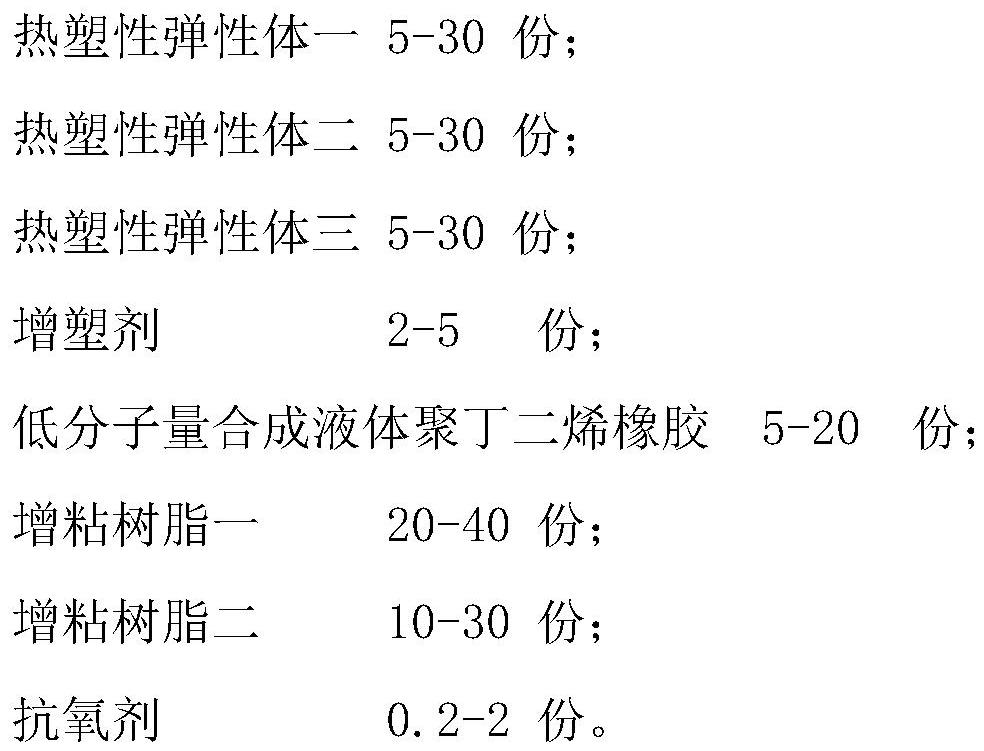

[0039] In the present embodiment, get the raw material of following weight portion:

[0040]

[0041]

[0042] Wherein, in the preparation steps of this embodiment, preferably, the thermoplastic elastomer is selected from styrene-isoprene-styrene copolymer; the styrene content is 13.0%-17.0% (preferably 17% ), the styrene-isoprene diblock content is 40.0%-55.0% (preferably 55%).

[0043] The thermoplastic elastomer is selected from styrene-isoprene-styrene copolymer; wherein the styrene content is 17.0%-21.0% (preferably 21%) by weight percentage, and the styrene block content is 28.0%-32.0% % (preferably 32%).

[0044]The thermoplastic elastomer three is selected from styrene-butadiene-styrene copolymer; wherein the styrene content is 33.0%-37.0% (preferably 37%) by weight percentage, and the styrene block content is 67.0%-73.0% (preferably 73%).

[0045] The plasticizer is preferably a synthetic base oil.

[0046] Tackifying resin - preferably hydrogenated dicyclop...

Embodiment 2

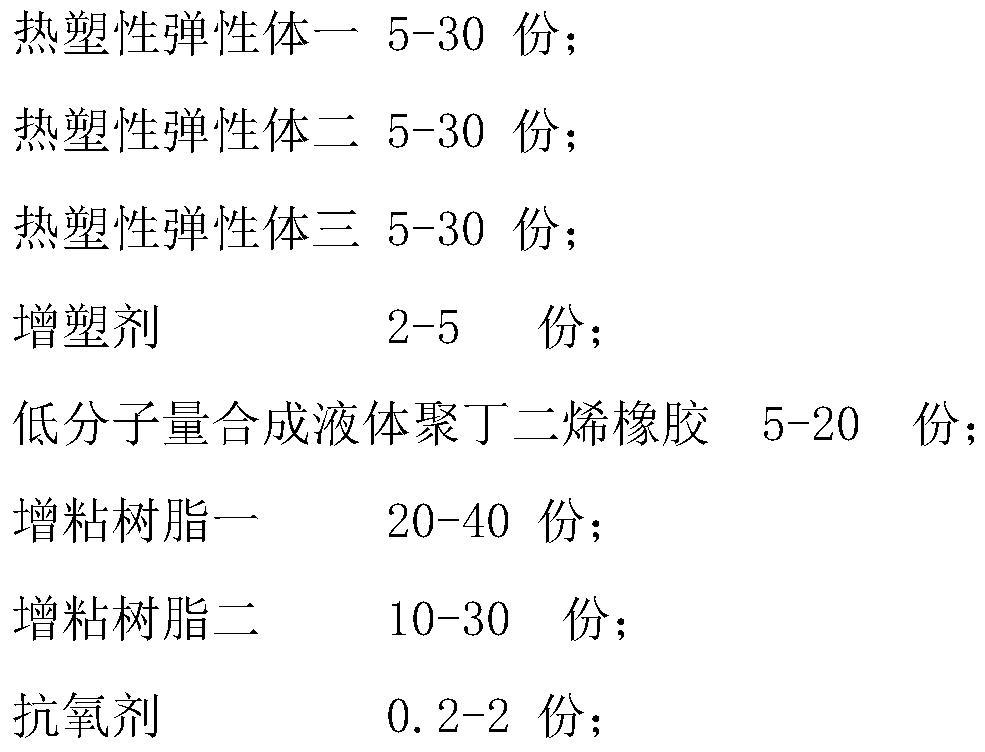

[0056] In the present embodiment, get the raw material of following weight portion:

[0057]

[0058] Wherein, preferably, thermoplastic elastomer one is selected from styrene-isoprene-styrene copolymer; Styrene content is 13.0%-17.0% (preferably 15%) by weight percentage, styrene-isoprene The olefinic diblock content ranges from 40.0% to 55.0% (preferably 53%).

[0059] The thermoplastic elastomer is selected from styrene-isoprene-styrene copolymer; wherein the styrene content is 17.0%-21.0% (preferably 19%) by weight, and the styrene block content is 28.0%-32.0 % (preferably 30%).

[0060] The thermoplastic elastomer three is selected from styrene-butadiene-styrene copolymer; wherein the styrene content is 33.0%-37.0% (preferably 35%) by weight percentage, and the styrene block content is 67.0%-73.0% (preferably 70%).

[0061] The plasticizer is preferably a hydronaphthenic oil.

[0062] Tackifying resin - preferably hydrogenated C9 petroleum resin.

[0063] Tackifyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com