Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Ensure wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

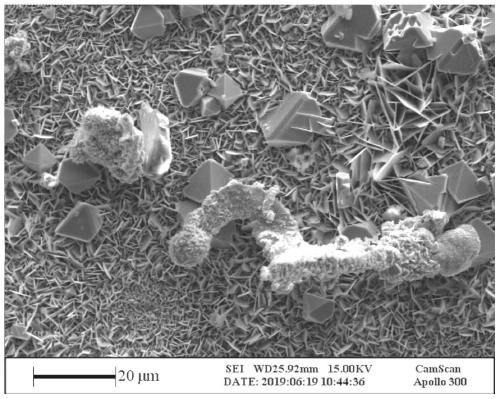

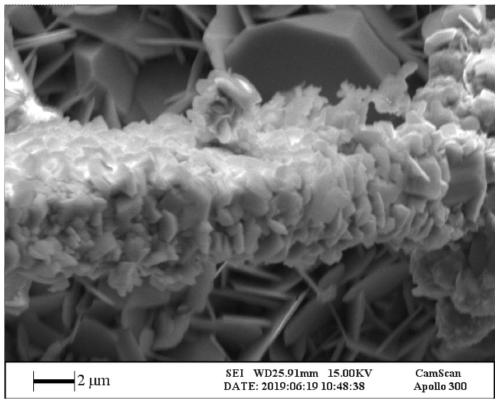

High-performance copper-diamond electrical contact material and preparation process thereof

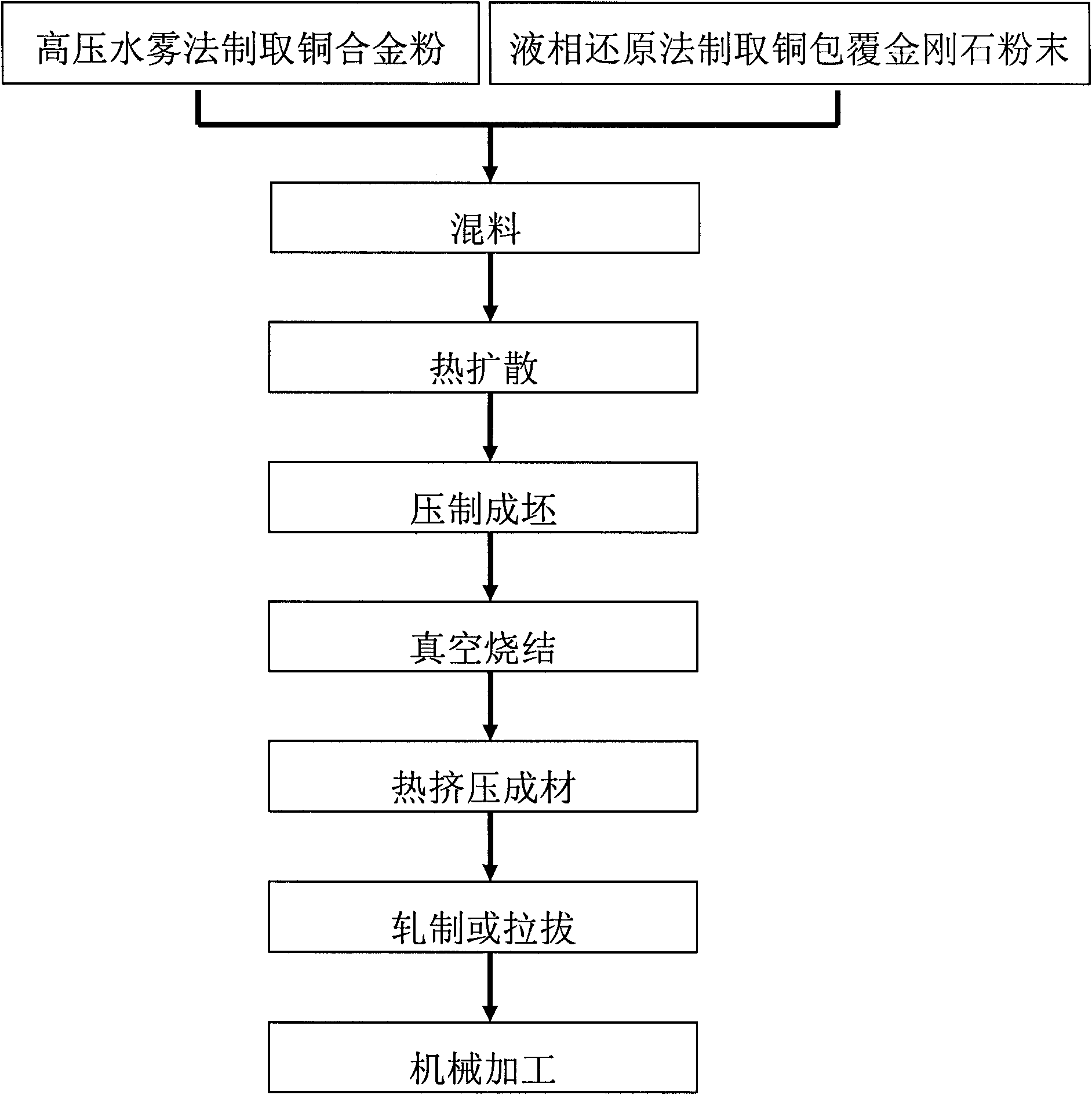

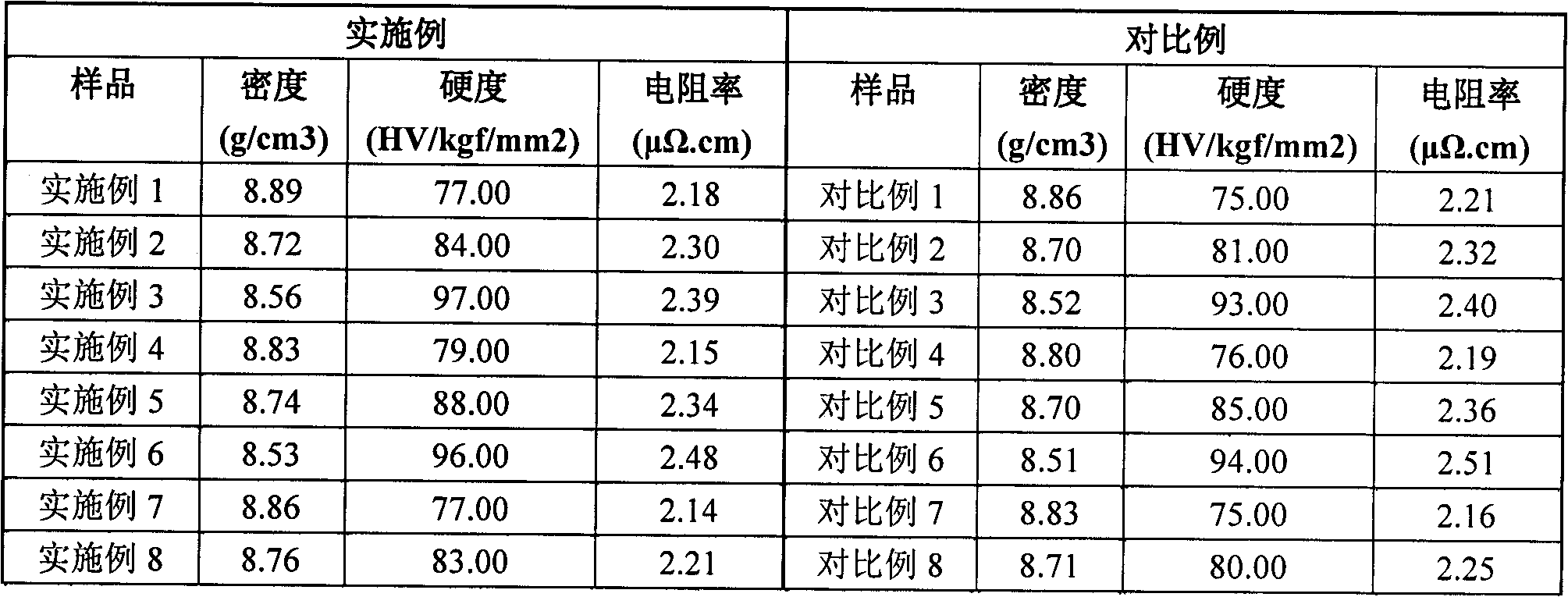

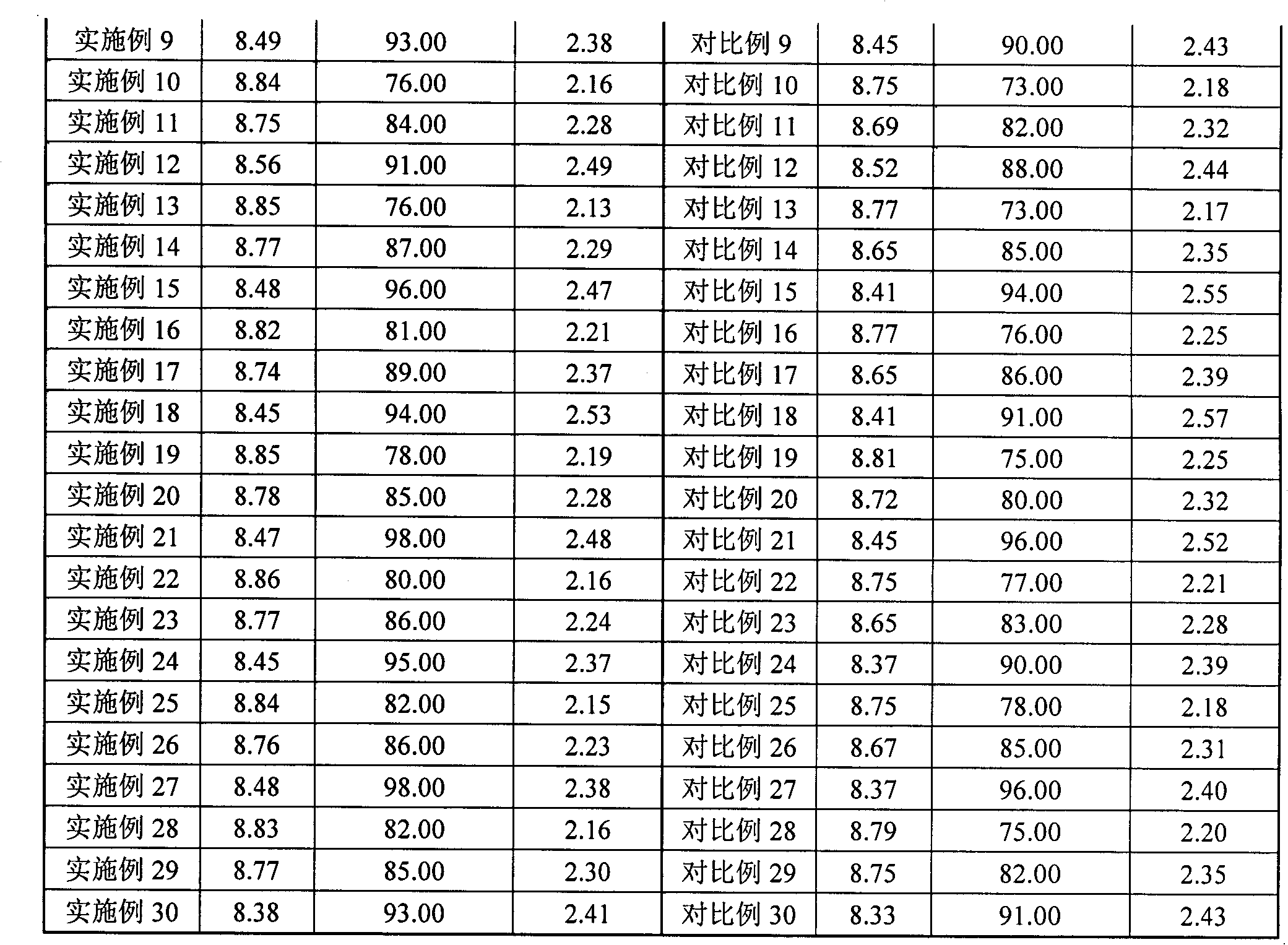

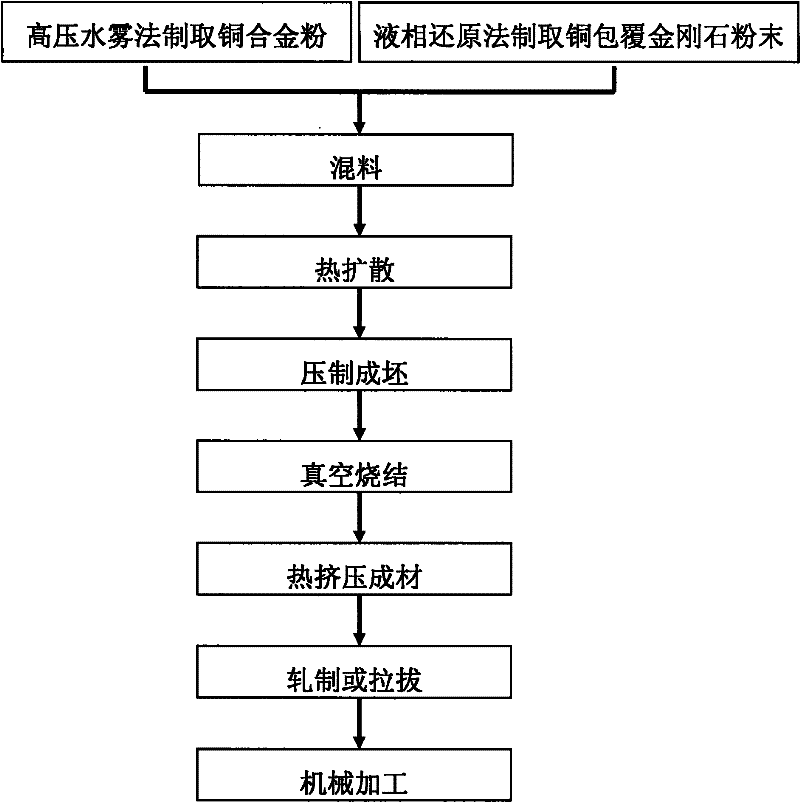

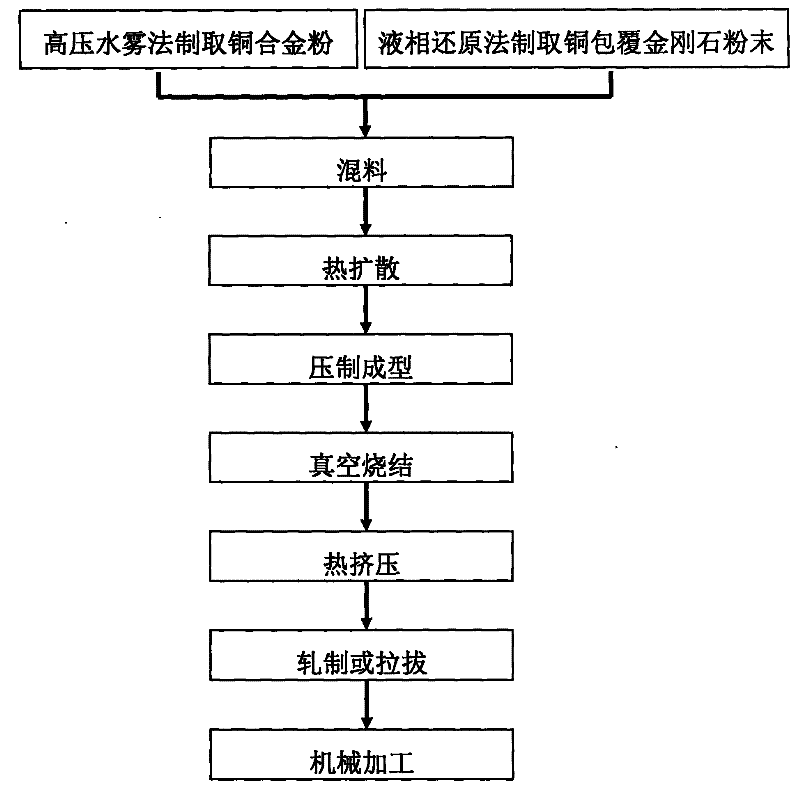

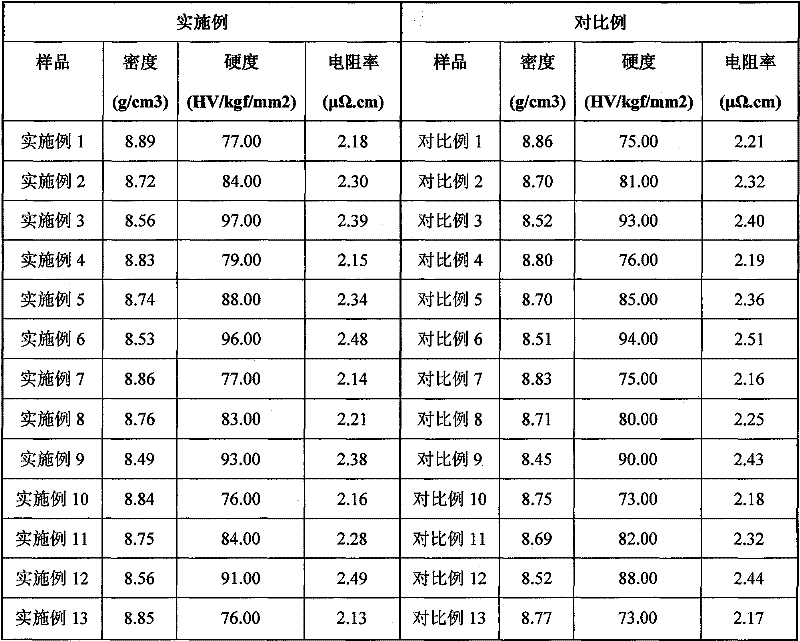

The invention relates to a preparation process of powder metallurgy material, in particular to high-performance copper-diamond electrical contact material and a preparation process thereof. The high-performance copper-diamond electrical contact material comprises the following raw materials by weight percentage: 0.001%-5.0% of diamond powder and 95%-99.999% of copper alloy powder, wherein the grain size of the diamond powder is 0.1-15 mum, and the surface of the diamond powder is coated with copper. The preparation process of the high-performance copper-diamond electrical contact material comprises the following steps: (1) preparing the raw materials: preparing the copper alloy powder by using a high-pressure spray method, preparing the copper-coated diamond powder by using a liquid-phase reduction method and mixing the copper alloy powder and the copper-coated diamond powder; (2) preparing the electrical contact material: firstly, carrying out thermal diffusion treatment to the mixture of the copper alloy powder and the copper-coated diamond powder, sintering the compressed and moulded mixture in vacuum, and thermally extruding and moulding the mixture; and (3) preparing electrical contact sectional material: rolling or drawing and machining the copper-diamond electric contact into the required-size sectional material.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

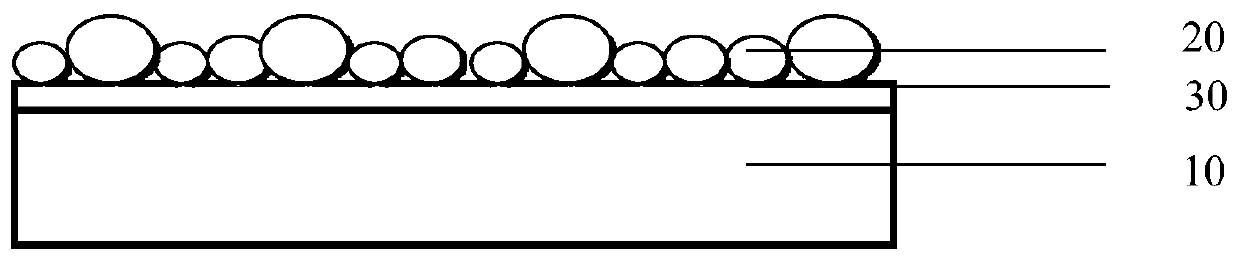

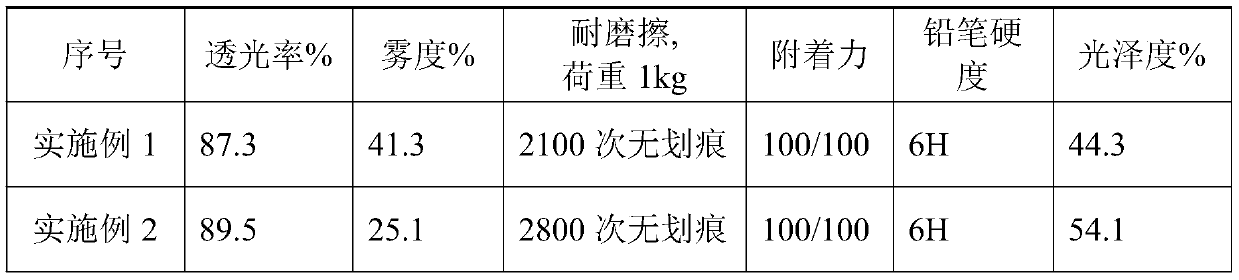

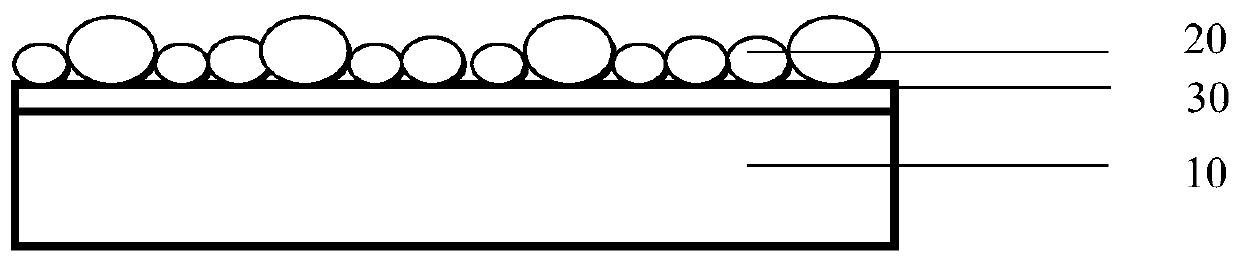

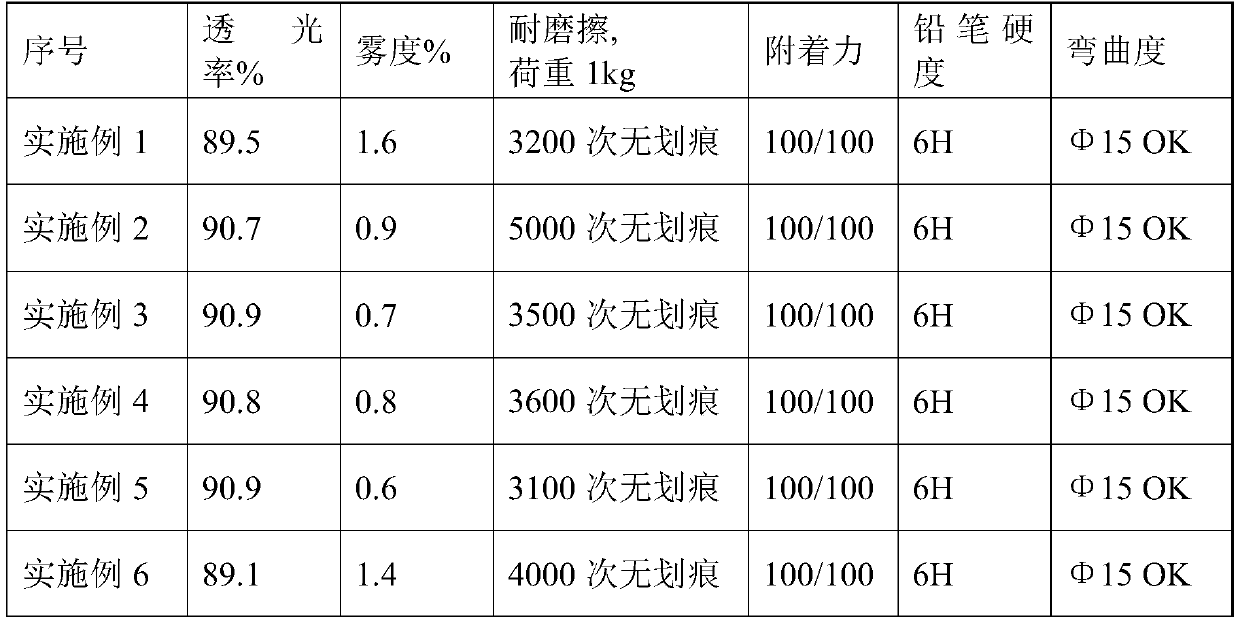

High-hardness and anti-dazzle hardening layer coating liquid and hardening film

The invention relates to the technical field of a hardening film, in particular to high-hardness and anti-dazzle hardening layer coating liquid and a hardening film. In order to solve the problems that the existing hardening film cannot realize high hardness or anti-dazzle performance at the same time, the invention provides the high-hardness and anti-dazzle hardening layer coating liquid and thehardening film. The hardening layer coating liquid contains 40 to 80 percent of acrylic ester prepolymers, 10 to 30 percent of acrylic ester monomers, 7 to 30 percent of silicon dioxide, 2 to 6 percent of photoinitiators and 0.1 to 0.5 percent of auxiliary agents in percentage by weight. The hardening layer coating liquid provided by the invention forms a hardening layer after the curing; high hardness and anti-dazzle performance are realized. The hardening film provided by the invention has high hardness and anti-dazzle protection effects.

Owner:NINGBO EXCITON TECH

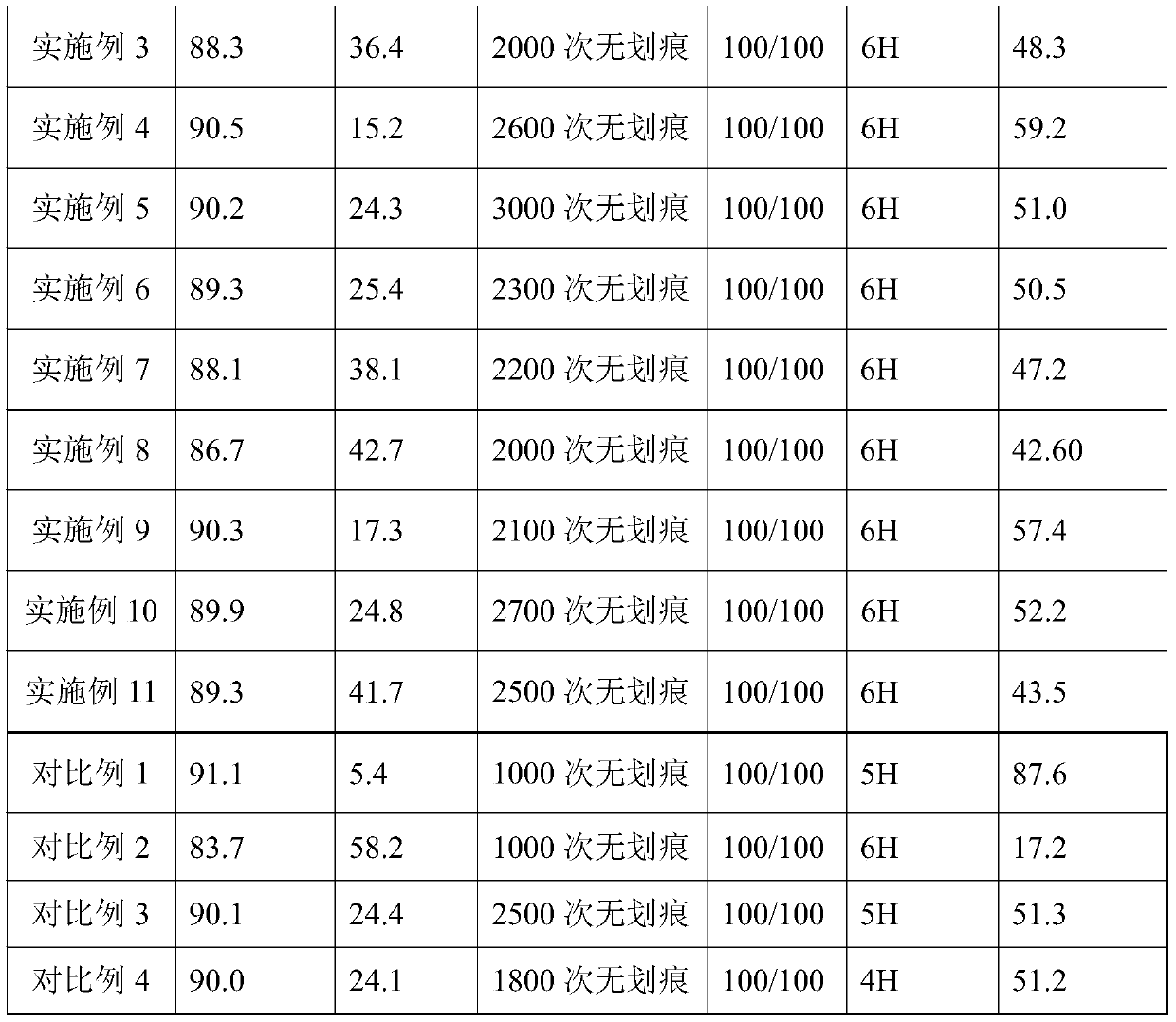

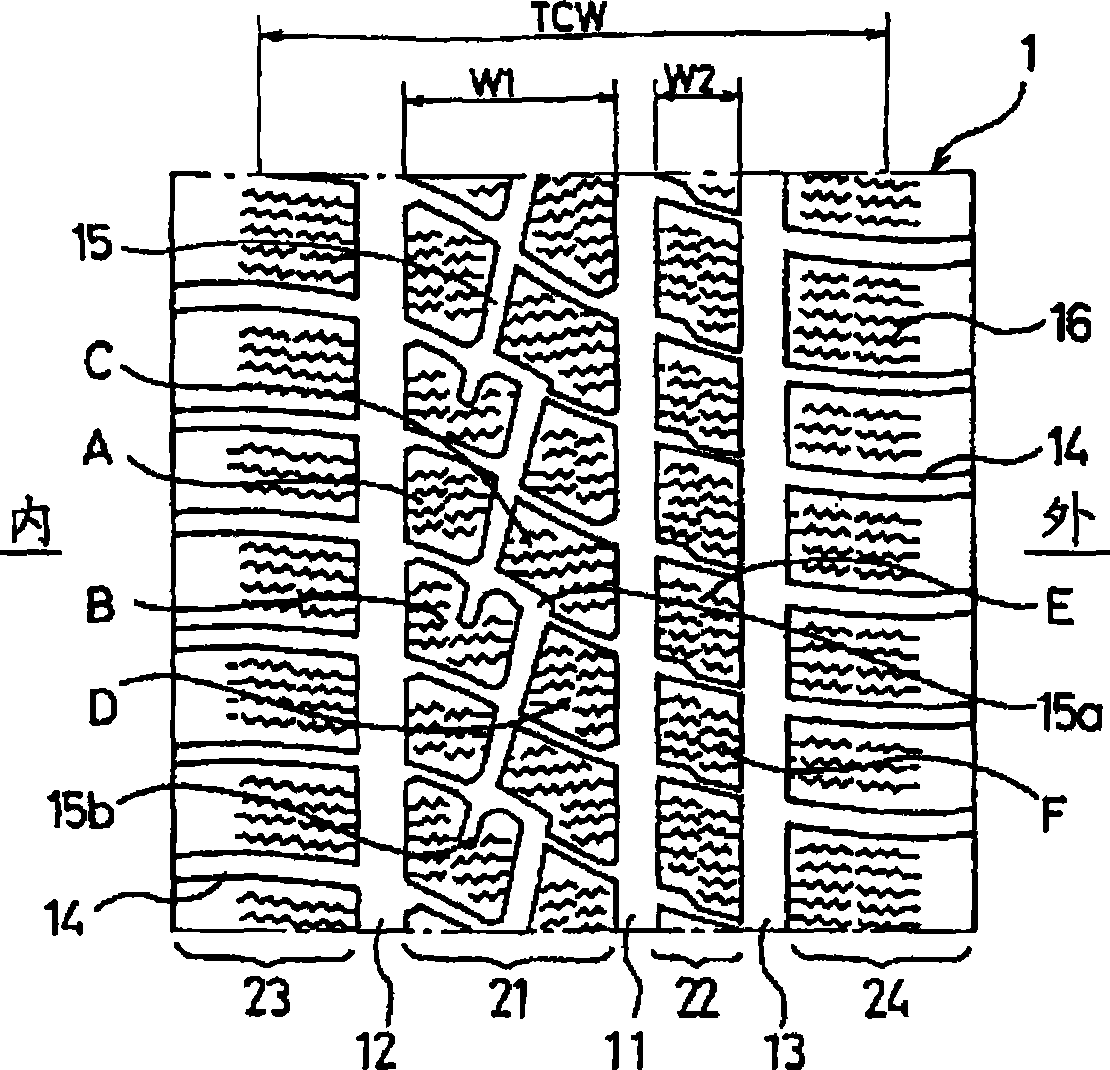

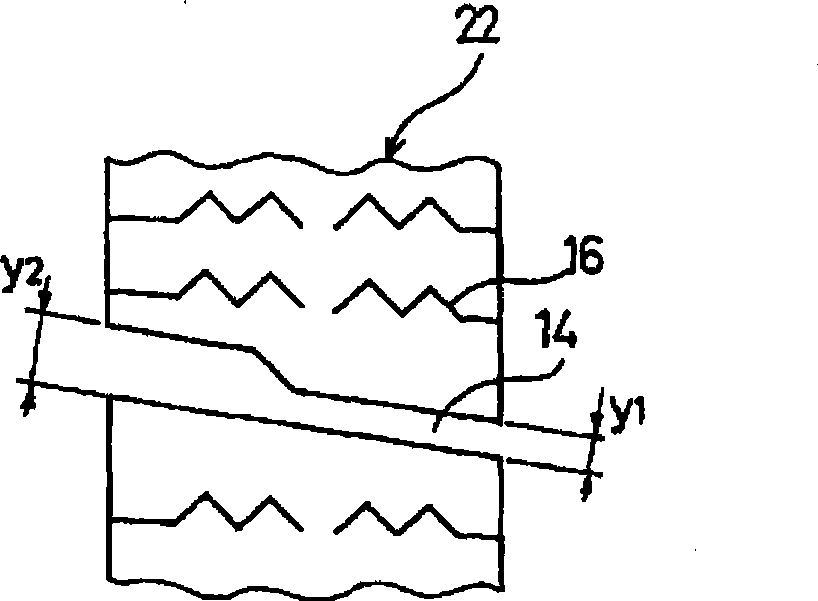

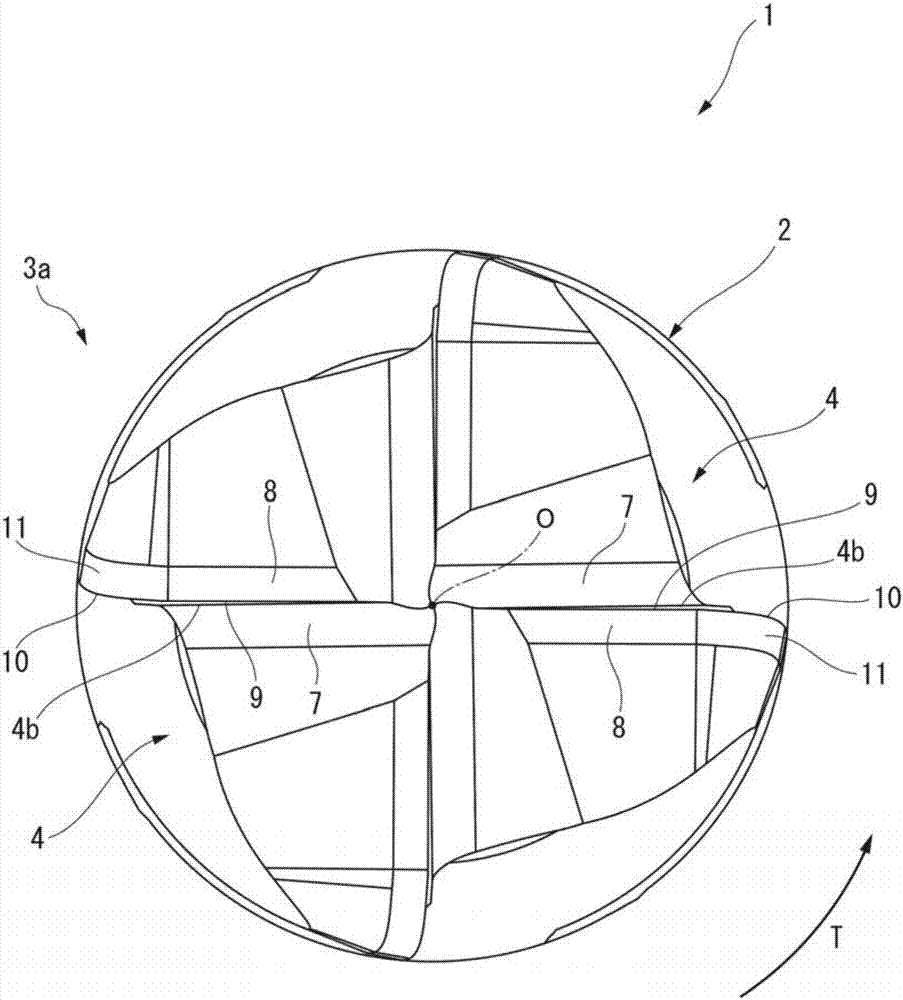

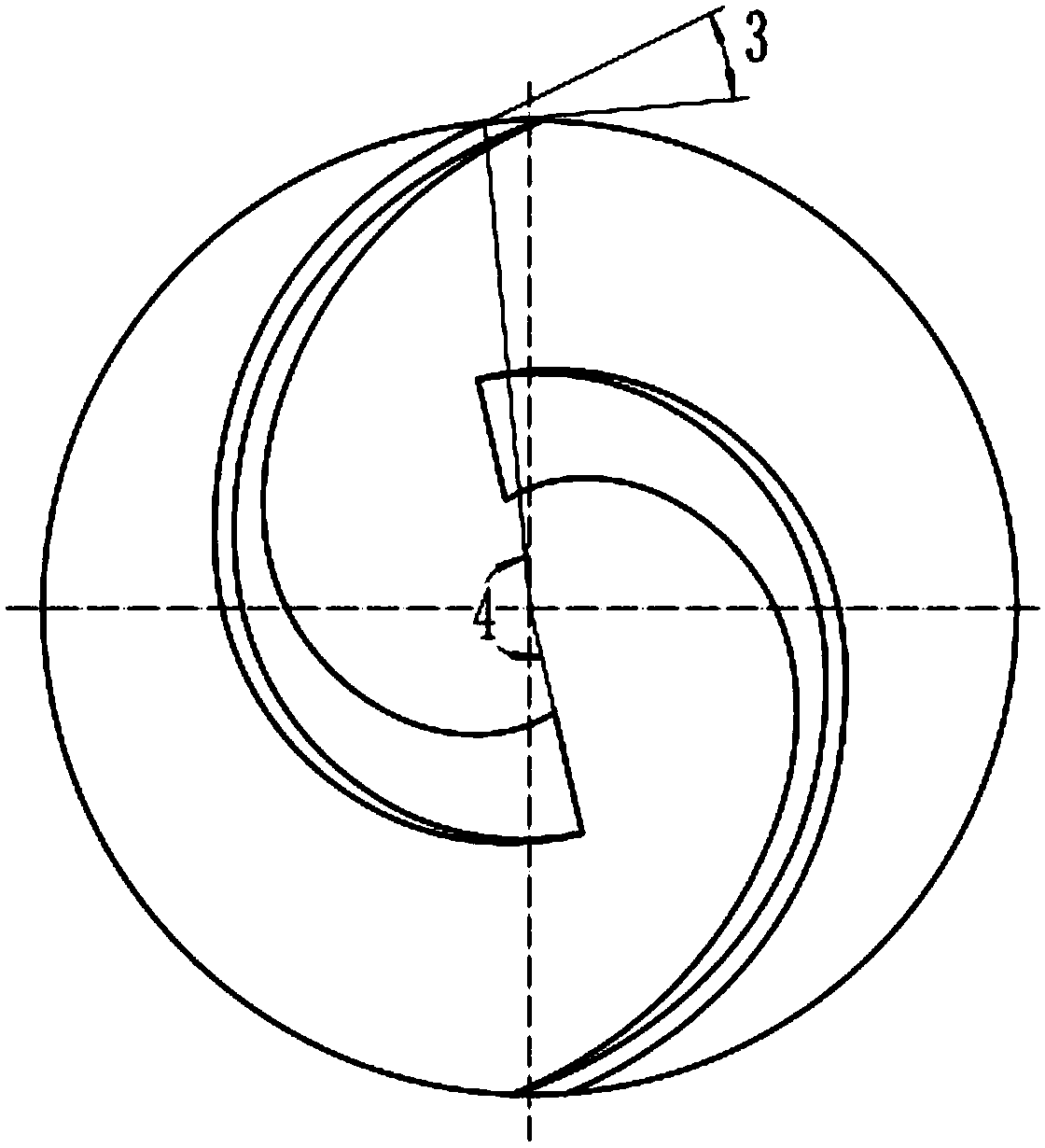

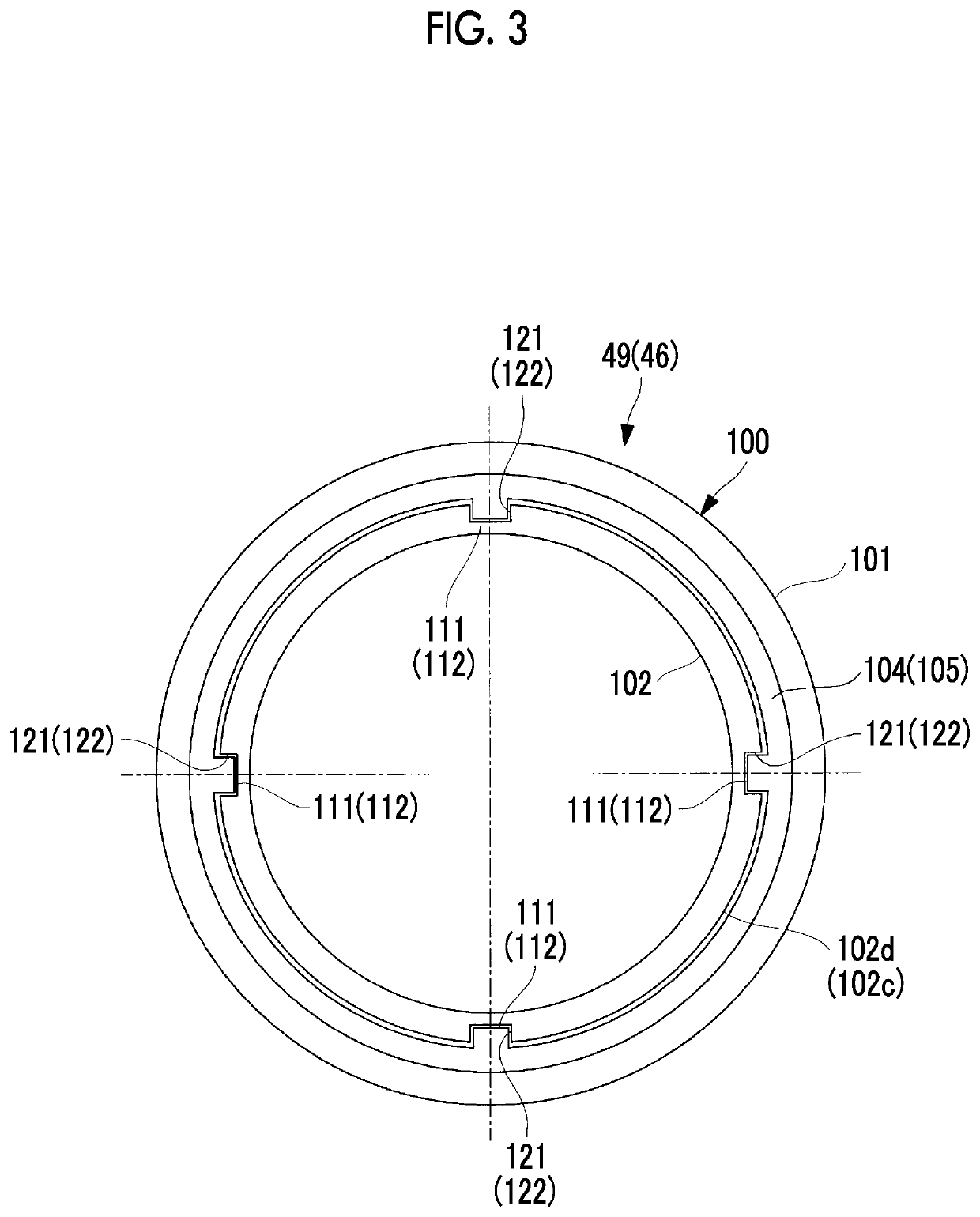

Pneumatic tyre

ActiveCN101505976AEnsure wear resistanceImprove handling stabilityTyre tread bands/patternsShoulder regionMechanical engineering

A pneumatic tire whose front and rear sides need to be oriented to specific directions when it is mounted on a vehicle. The tire has, on a tread section, a first groove extending in the circumferential direction of the tire, a second main groove extending in the circumferential direction of the tire, in a shoulder region that is closer to the inner side of a vehicle than the first groove, a third main groove extending in the circumferential direction of the tire, in a shoulder region that is closer to the outer side of the vehicle than the first main groove, and lug grooves extending from one shoulder side to the other shoulder side. The width of a first land section segmented between the first main groove and the second main groove is set greater than the width of a second land section segmented between the first main groove and the third main groove. Inclined grooves are formed in the first land section, and the grooves communicate with at least three lug grooves while inclining relative to the circumferential direction of the tire. One end of each inclined groove is opened in the lug grooves and the other end is ended in a block.

Owner:THE YOKOHAMA RUBBER CO LTD

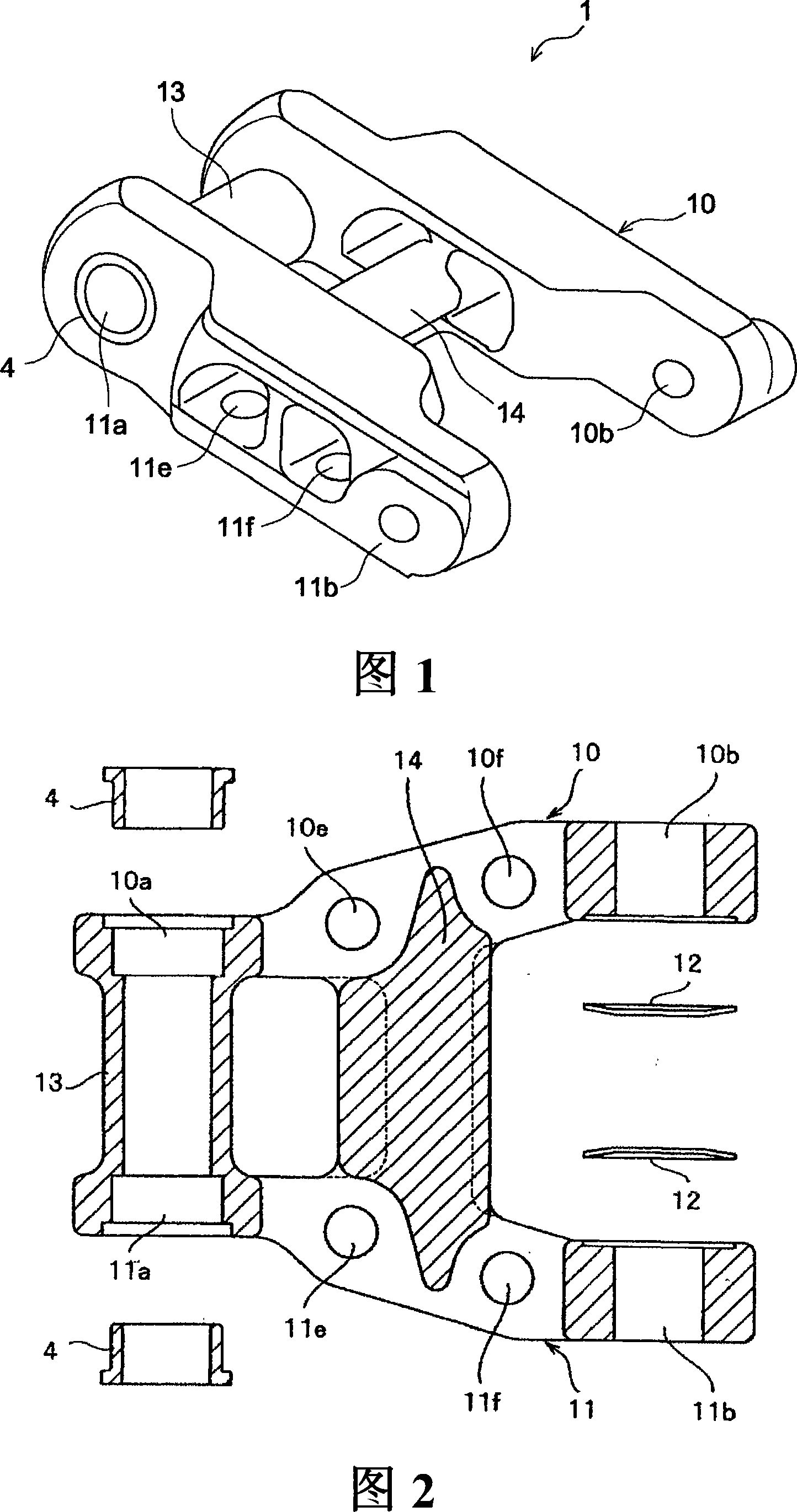

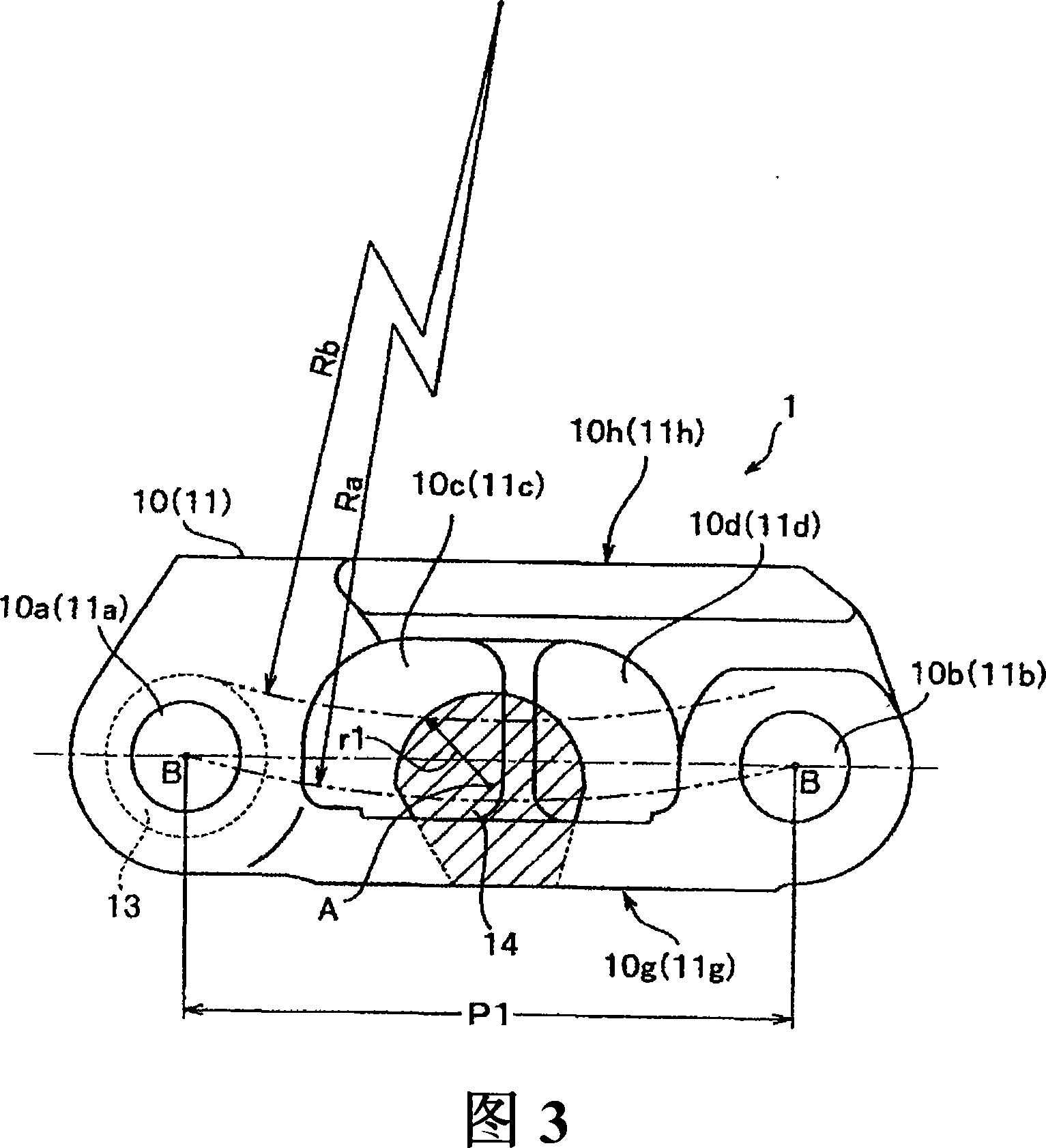

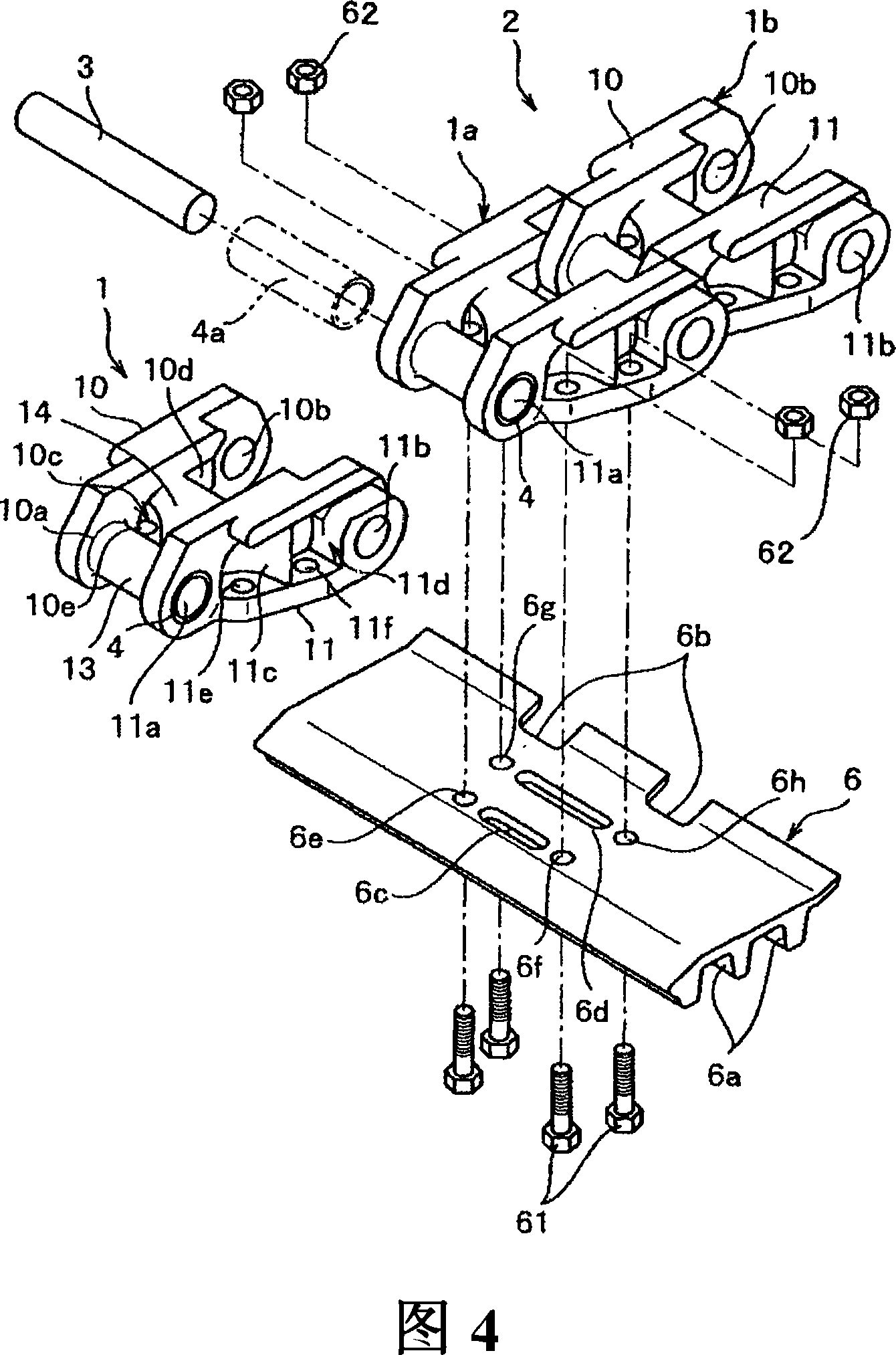

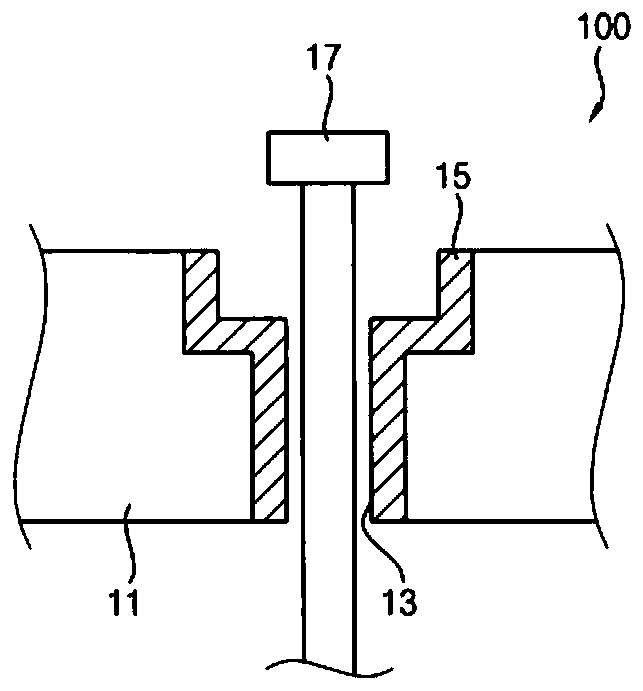

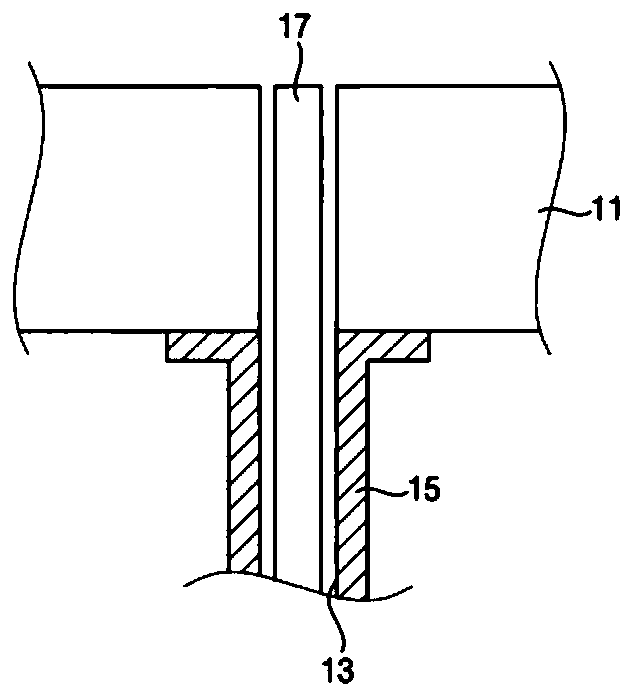

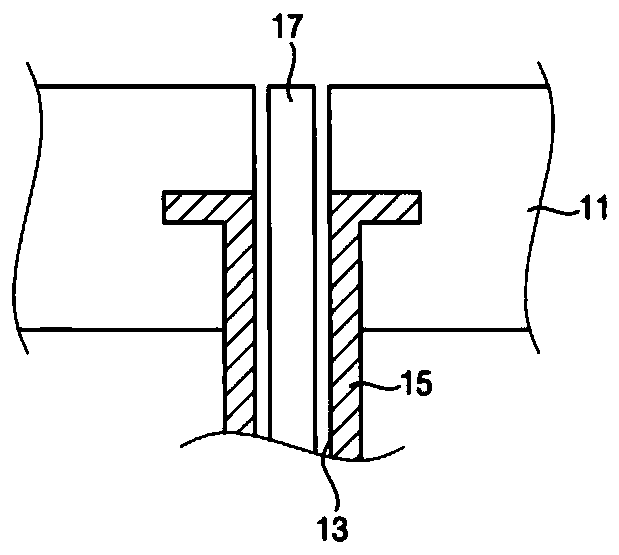

Link structure bodies for track belt and link chain formed by connecting the link structure bodies

InactiveCN101072706AEasy to assembleReduce the cross-sectional areaEndless track vehiclesSprocketEngineering

Link structure bodies for a track belt, which link structure bodies each can be easily assembled, reduced in cost, and is highly durable, and a link chain using the link structure bodies. Each link structure body is constructed by integrally forming the following: a left and right pair of link sections (10, 11) having, at their front and rear sections, first and second through-holes (10a, 11a, 10b, 11b); a tubular first connection section (13) for communicating the first through-holes (10a, 11a) of the pair of link sections (10, 11) with each other and connecting them; and a solid second connection section (14) for connecting to each other the center sections in the longitudinal direction of the pair of link sections (10, 11). A cross-sectional shape of the second connection section (14) is designed so that only the second connection section (14) carries all the sprocket load with the hollow first connection section (13) carrying no sprocket load.

Owner:KOMATSU LTD

Anti-aging and wear-resistant rubber material for tire

The invention discloses an anti-aging and wear-resistant rubber material for a tire. The anti-aging and wear-resistant rubber material for the tire is prepared from, by weight, 15-35 parts of natural rubber, 25-35 parts of 320 type chloroprene rubber, 25-35 parts of neoprene, 20-50 parts of modified kaolinite, 0.5-1.5 parts of 616 antiager, 0.2-0.8 part of phosphite, 0.5-1.2 parts of tetramethyl thiuram disulfide, 0.5-1.5 parts of zinc oxide, 1-3 parts of magnesium oxide, 5-15 parts of pumice, 10-18 parts of zinc borate, 1-2 parts of aluminum borate whiskers, 12-18 parts of sodium antimonite, 5-15 parts of aluminum phosphate, 10-20 parts of carbon black, 0.2-0.8 part of polyepoxy soybean oil, 0.1-0.9 part of hydroxyl silicone oil, 1-2 parts of white oil, 1-3 parts of pine tar, 0.2-0.8 part of fatty acid, 0.5-1.5 part of stearic acid and 1-2 parts of 3-aminopropyltrimethoxysilane. The anti-aging and wear-resistant rubber material for the tire is good in wear-resistant and anti-tear performance and excellent in anti-aging performance.

Owner:DELUN RUBBER

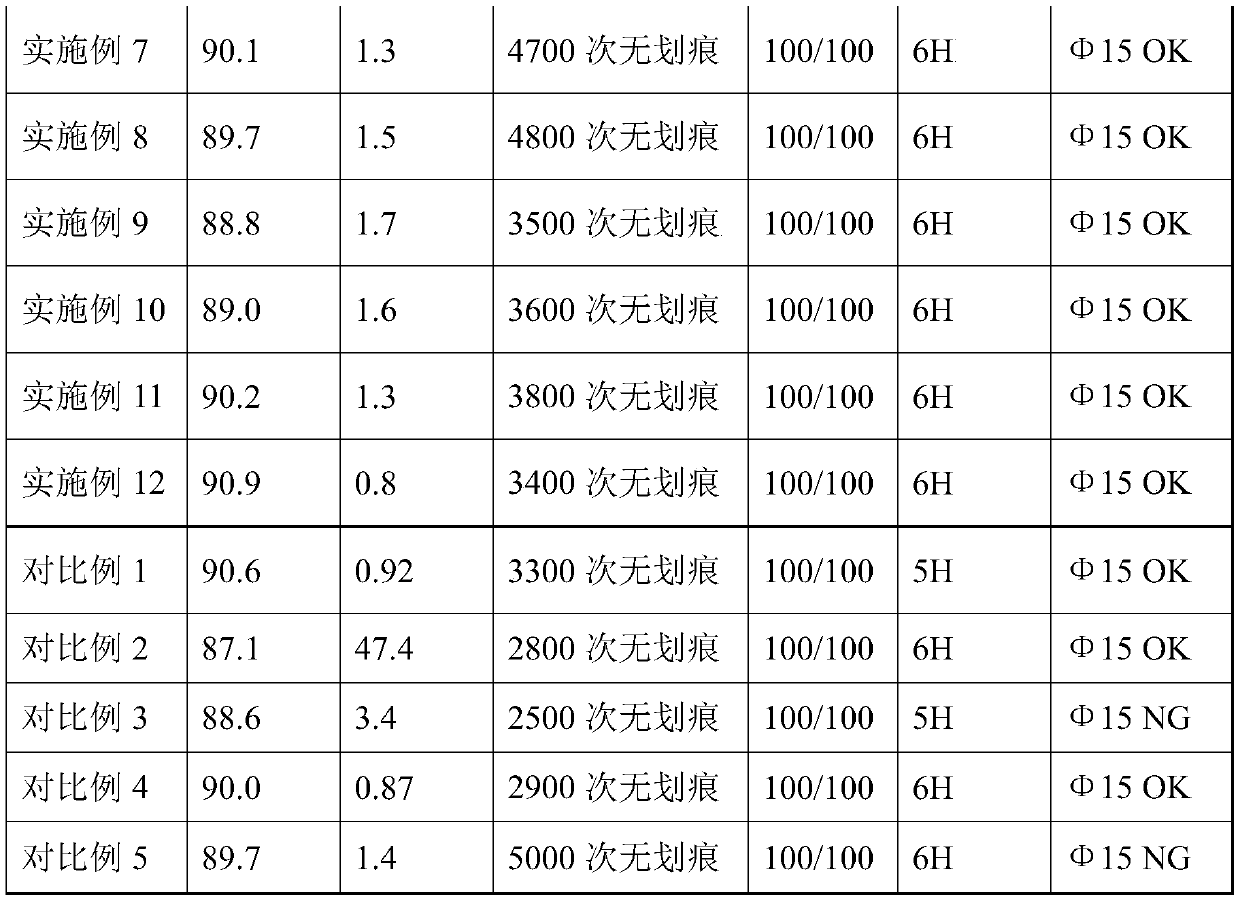

High-wear-resistance high-toughness hardened layer coating liquid and hardened film

InactiveCN109880507AImprove wear resistanceImprove toughnessPolyurea/polyurethane coatingsPliabilityTransmittance

The invention relates to the technical field of hardened films, in particular to a high-wear-resistance high-toughness hardened layer coating liquid and a hardened film. In order to solve the problemof poor wear resistance of the surface of an existing transparent film, the invention provides the high-wear-resistance high-toughness hardened layer coating liquid and the hardened film. The hardenedlayer coating liquid comprises the following components in percentage by weight: 30%-80% of an acrylate prepolymer, 5%-30% of an acrylate monomer, 10%-40% of silicon dioxide nanoparticles, 1%-6% of aphotoinitiator and 0.1%-0.5% of an auxiliary agent, wherein the particle size of the silicon dioxide nanoparticles is 10-100 nm. The hardened layer coating liquid provided by the invention has high wear resistance and good flexibility after being cured to form a hardened layer. The hardened film provided by the invention has the characteristics of high hardness, high wear resistance, high light transmittance and low haze, meets the proper toughness requirement, and is suitable for the external protection function of a display screen.

Owner:NINGBO EXCITON TECH

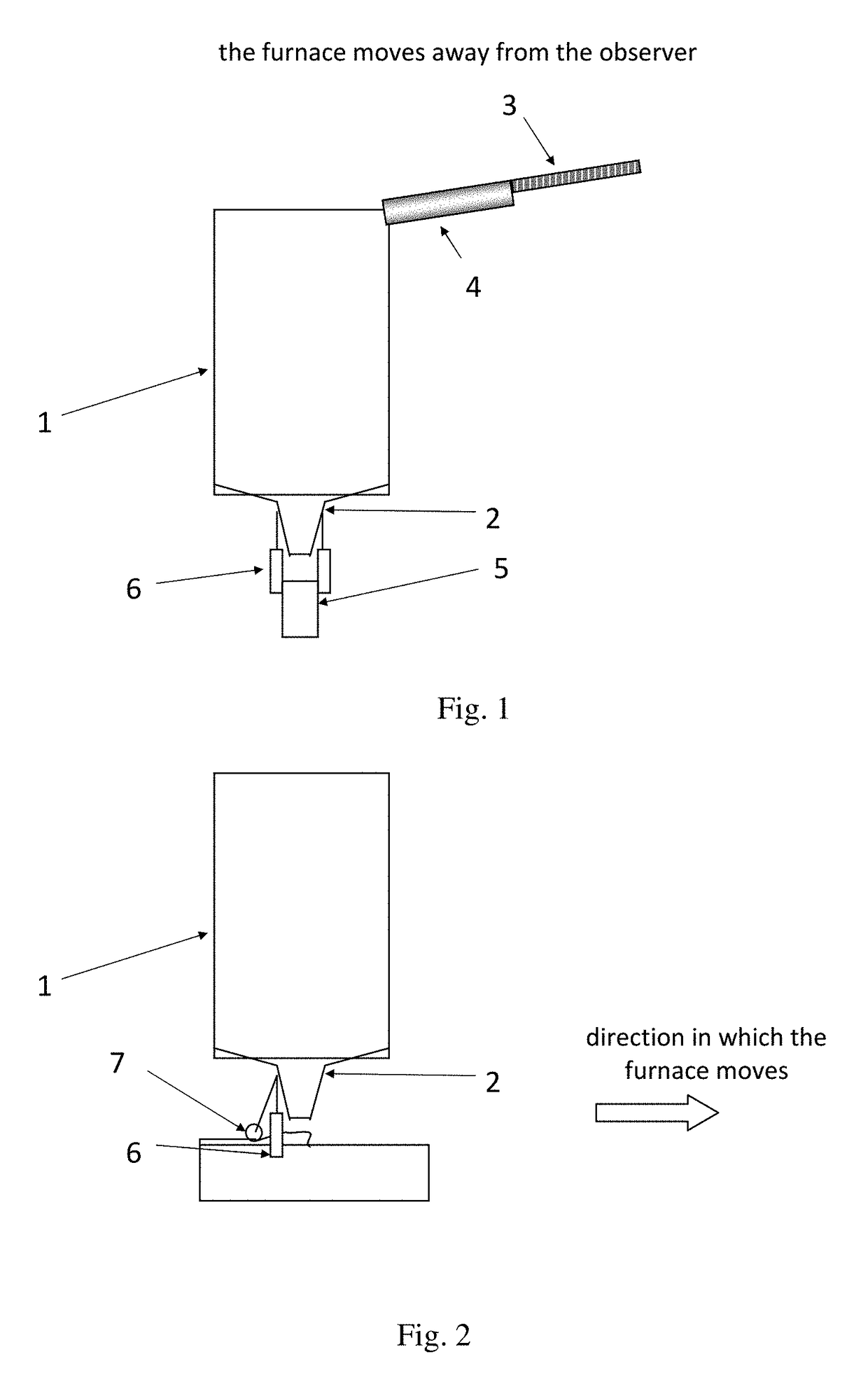

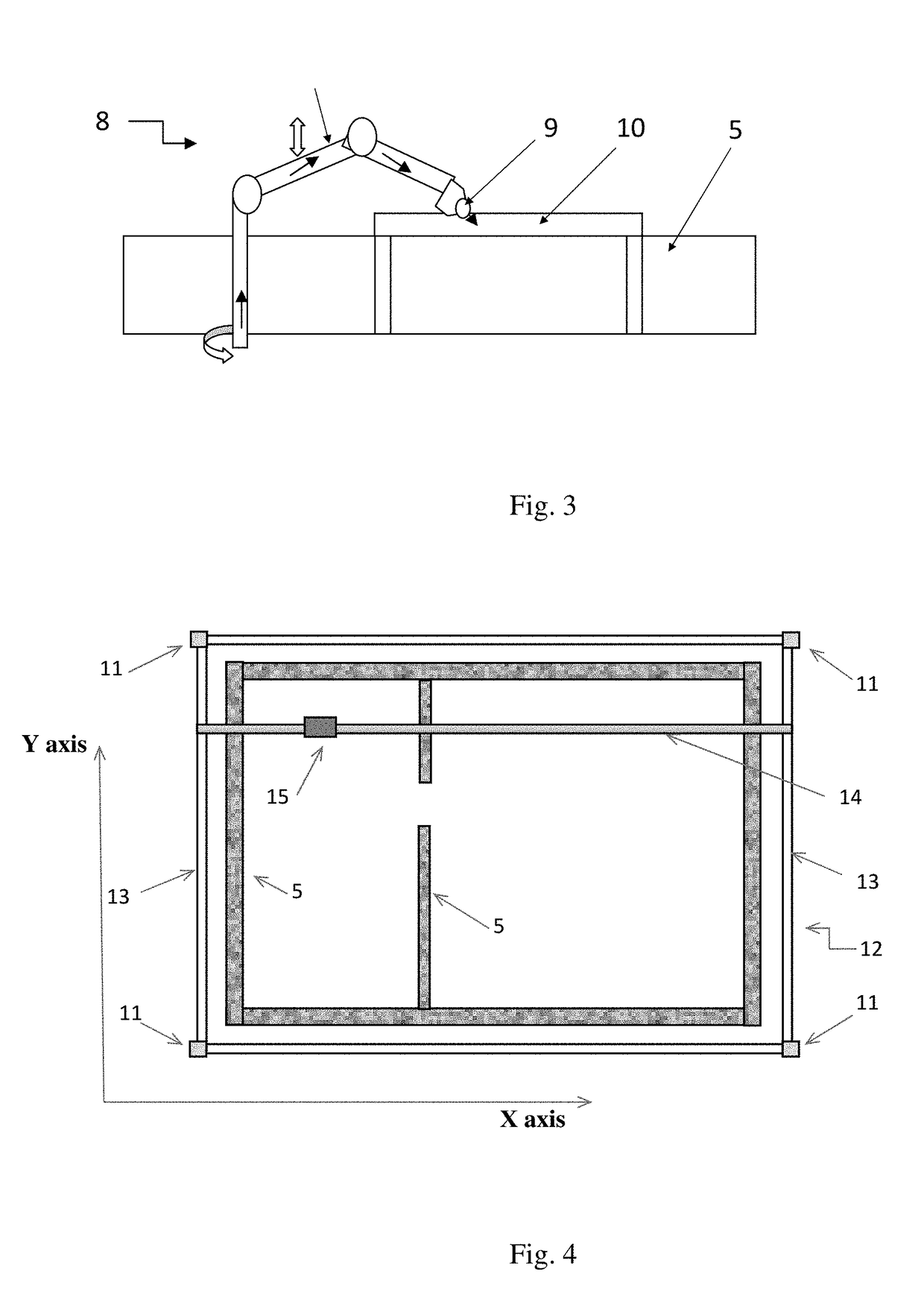

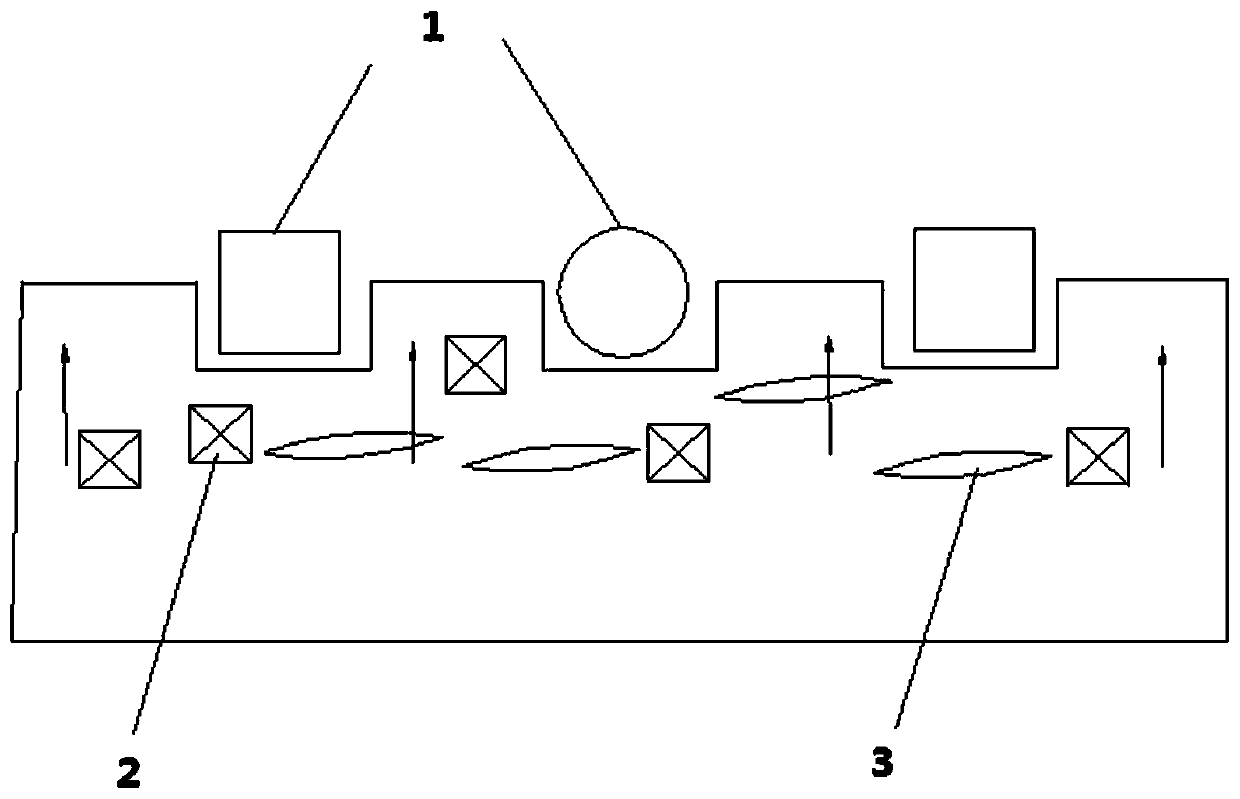

Method for 3D printing of buildings and a device for implementation thereof

InactiveUS20170283297A1Strong characteristicHeavy loadAdditive manufacturing apparatusGlass forming apparatus3d coordinates3D printing

Owner:KULMAGAMBETOV ANUAR RAYKHANOVICH

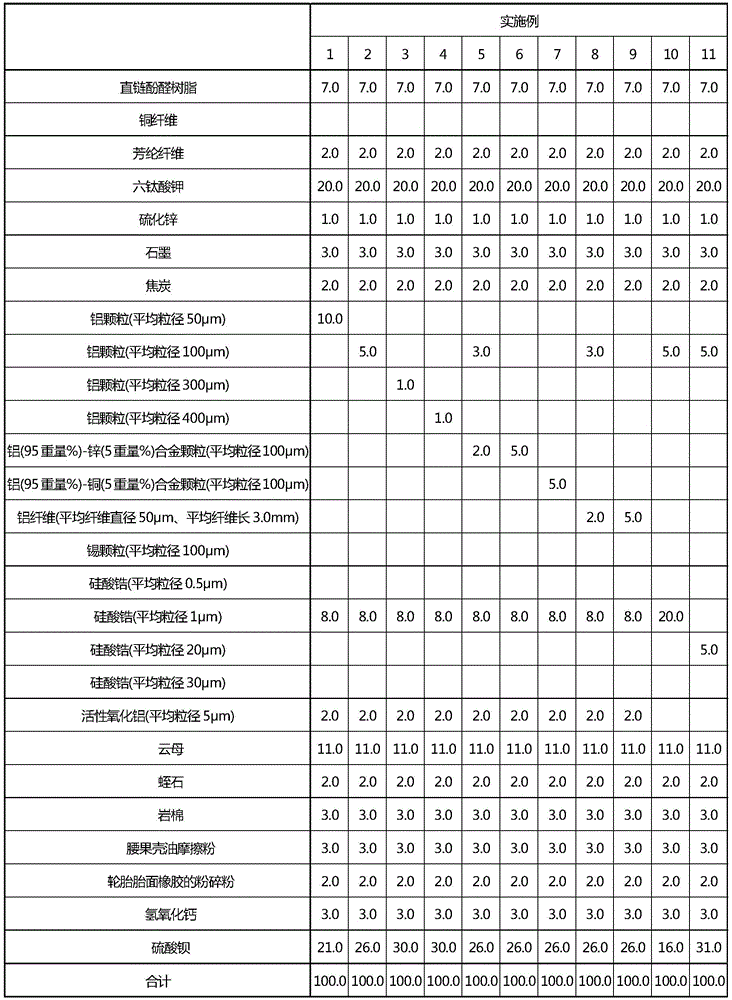

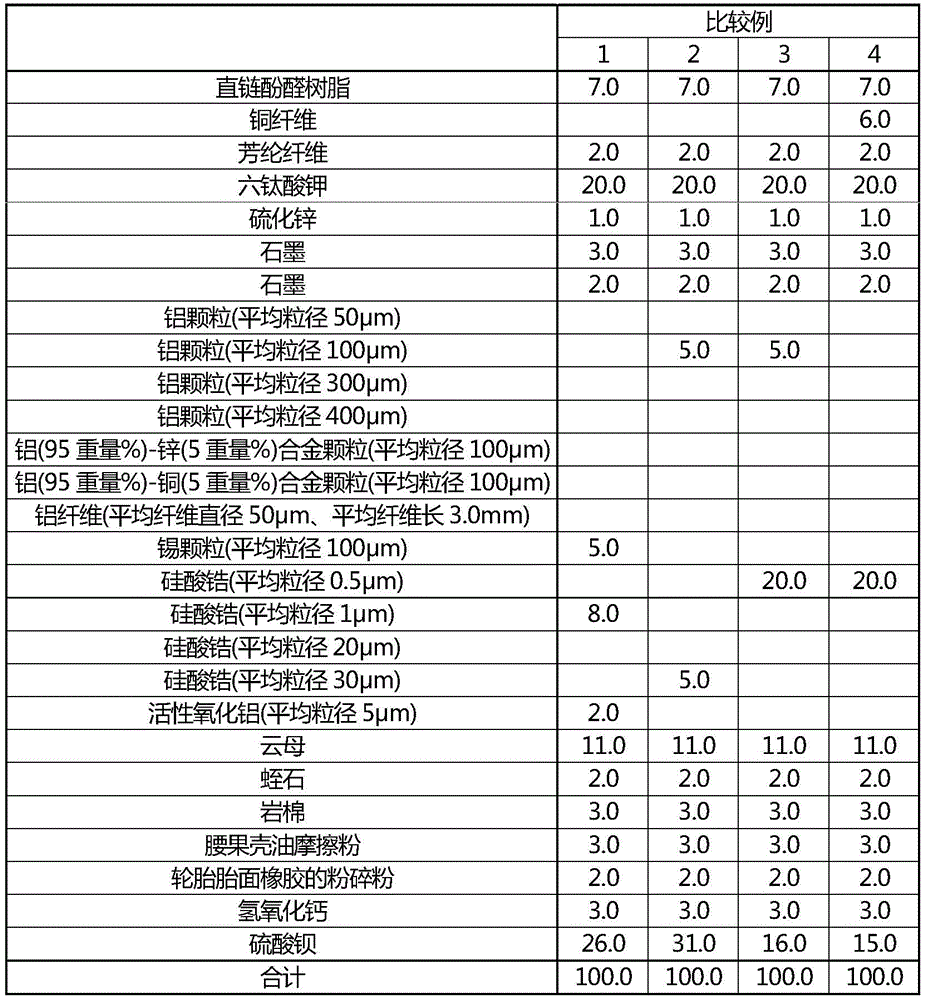

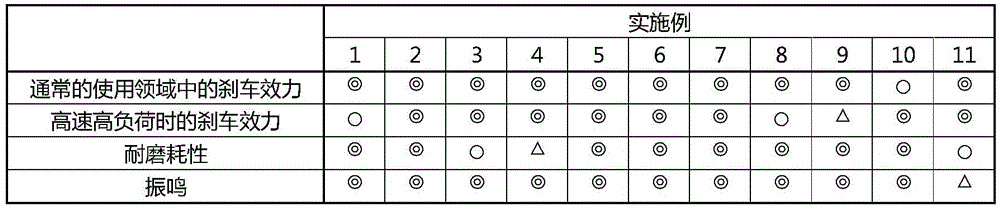

Friction material

ActiveCN105531496AEnsuring braking efficiencyEnsure wear resistanceOther chemical processesFriction liningFiberMohs scale of mineral hardness

The present invention addresses the problem of providing a friction material for a disc brake pad, the material being able to maintain braking effect and abrasion resistance at high speeds and high loads while satisfying laws and regulations relating to copper content. The solution to this problem is a non-asbestos organic (NAO) friction material used in a disc brake pad and formed by molding a friction material composition comprising a fiber substrate, a binding material, and a friction adjustment material, wherein used is a friction material composition comprising, as an inorganic friction adjustment material, and with respect to the total weight of the friction composition, 1-10% by weight of one or more selected from the group consisting of aluminum particles, aluminum fibers, alloy particles with aluminum as a primary constituent, and alloy fibers with aluminum as a primary constituent and 5-20% by weight of hard inorganic particles with a mean particle diameter of 1-20 mum and a Mohs hardness of at least 4.5, and the friction material composition also including a total copper content of less than 0.5% by weight.

Owner:NISSHINBO BRAKE INC

Waterborne bicomponent epoxy iron red shop primer and preparation method thereof

InactiveCN107974166APoisonousFlame retardant and explosion-proofEpoxy resin coatingsPriming paintsEpoxyNano al2o3

The invention discloses waterborne bicomponent epoxy iron red shop primer and a preparation method thereof, and relates to a coating composition. The waterborne bicomponent epoxy iron red shop primerprovided by the invention comprises a component A and a component B, wherein the component A is prepared from waterborne epoxy resin, an iron red pigment, nano alumina, a dispersant, a filling material, a waterborne antifoaming agent, a waterborne preservative, negative ion distilled water and a waterborne amine curing agent; the component B is prepared from a waterborne epoxy resin emulsion, a waterborne antifoaming agent, a waterborne wetting and flatting agent, a waterborne preservative, a water-soluble active thinner and water. The component A and the component B adopted by the waterbornebicomponent epoxy iron red shop primer provided by the invention are both waterborne products, and are easily mixed; a sufficient curing purpose can be achieved. The waterborne bicomponent epoxy ironred shop primer has higher impact resistance, cannot generate foaming and stripping phenomena, meanwhile, has advantages of nontoxicity, flame retarding effect, explosion-proof effect, long application period, high hardness of film and high toughness, has uniform color and cluster, and can be used for meeting requirements of safety and environmental protection.

Owner:YIXING JUREN PAINT

Method for manufacturing wear-resistant metal piece

InactiveCN101941142AImprove impact resistanceEnsure wear resistanceWelding apparatusWear resistantThermal treatment

The invention provides a method for manufacturing a wear-resistant metal piece. A body of the wear-resistant piece is manufactured according to the conventional process, and, in a work area of the body of the wear-resistant piece, the following process steps are performed: manufacturing blind holes which are alternated one another on the surface of the body of the wear-resistant piece; and overlaying and filling a wear-resistant welding material in the blind holes. After the blind holes are overlaid and filled, the wear-resistant welding material is continuously overlaid on the surface to form a wear-resistant protective layer. The wear-resistant welding materials in different specifications can be adopted on the same body. The wear-resistant metal piece subjected to the overlaying process is subjected to thermal treatment to eliminate internal stress generated in welding. The method can meet the requirements on abrasion resistance, impact resistance, thick layer abrasion resistance and the like of the wear-resistant metal piece. The method is simple and reasonable, is easy to operate, and has low cost. The wear-resistant metal piece has good wear resistance, and the service life is remarkably prolonged. The method is suitable for companies manufacturing wear-resistant metal pieces.

Owner:HUNAN DEUSINO WEAR RESISTANT IND CO LTD

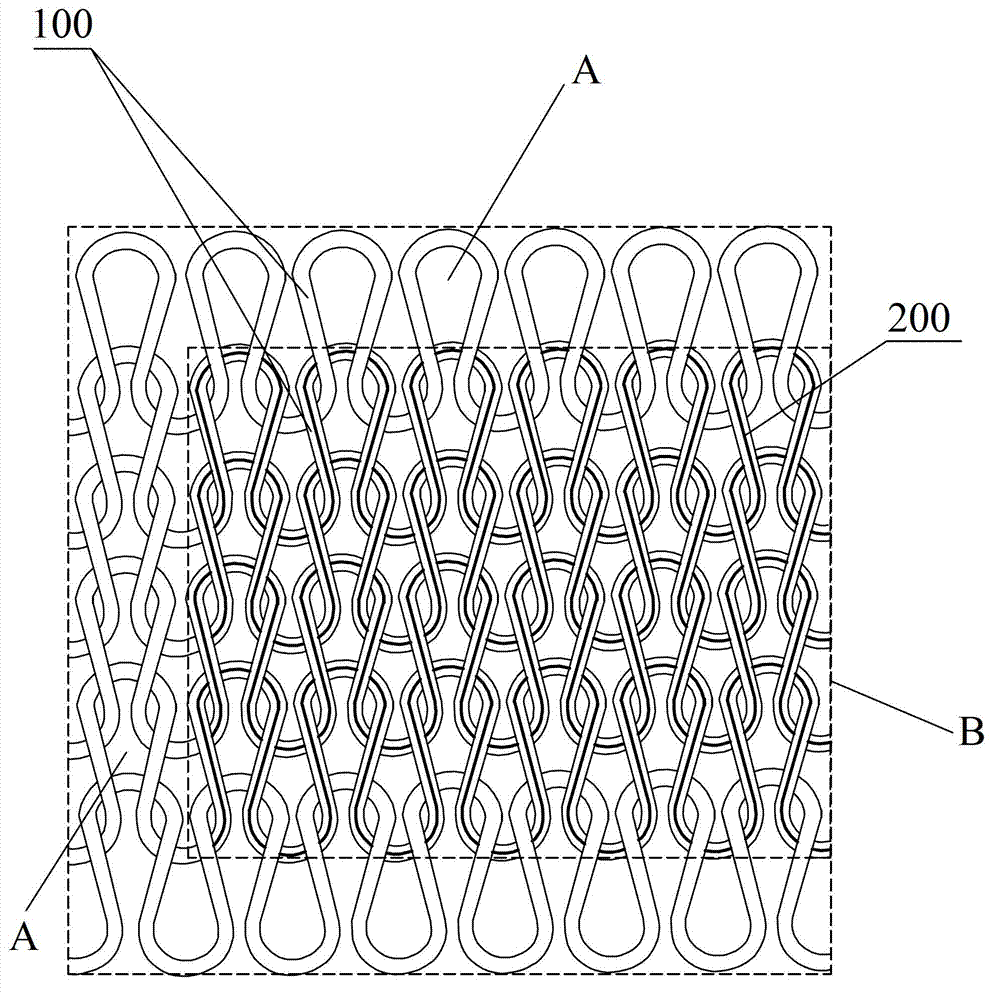

Method for producing high-count recoon dog fur woolen knitting yarns

The invention discloses a method for producing high-count recoon dog fur woolen knitting yarns. The method adopts recoon dog fur as raw materials and comprises the steps of dyeing, wool blending, wool carding, spinning, spooling, doubling and double twisting, in the wool blending step, the oil-water ratio is 1:3-4, through being metered by weight, wool blending oil accounts for 4 percent to 6 percent of the weight of the recoon dog fur, reinforcing agents account for 0.3 percent to 0.5 percent of the weight of the recoon dog fur, the life preserving time is controlled to be 10 to 14 hours, and the resurgence before the blending is controlled to be 25 percent to 28 percent; and in the wool carding step, the average temperature of a carding machine is 26 DEG C, the humidity is 78 percent, a three-roller peeling mode is adopted, the drafting between a net entering shaft and a tail doffer is 1.05, the drafting between a rubbing plate and a cutting leather lacing is regulated to be 1.07, and the fixed length is controlled to be smaller than 200m during wool cake coiling. Compared with the prior art, the method has the advantages that the process parameters are reasonably selected, so the recoon dog fur has higher spinnability through woolen spinning equipment, the yarn forming rate is high, the batch production of the recoon dog fur in the wool spinning field is also realized, and the metric counts of the woolen recoon dog fur fiber product can reach 26 to 32 counts.

Owner:CONSINEE GRP CO LTD

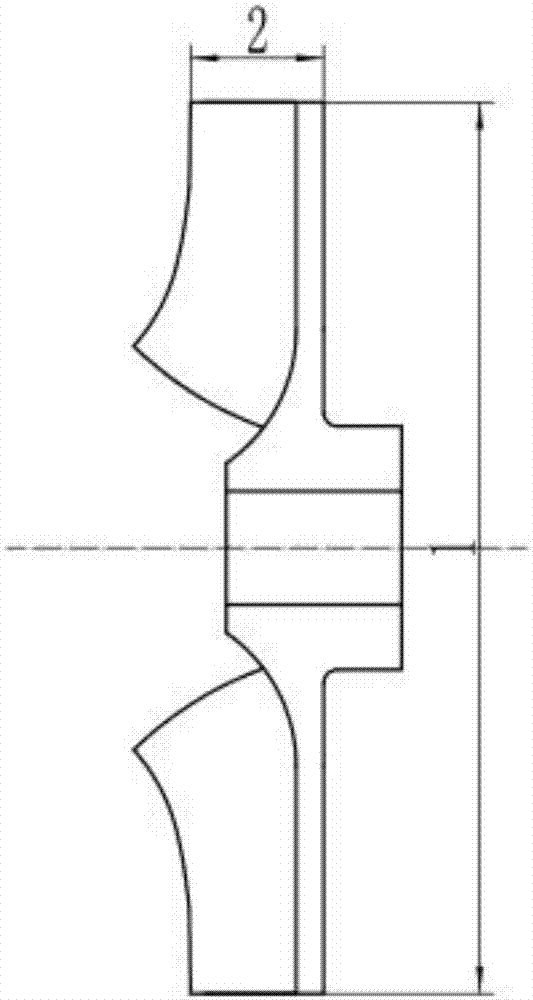

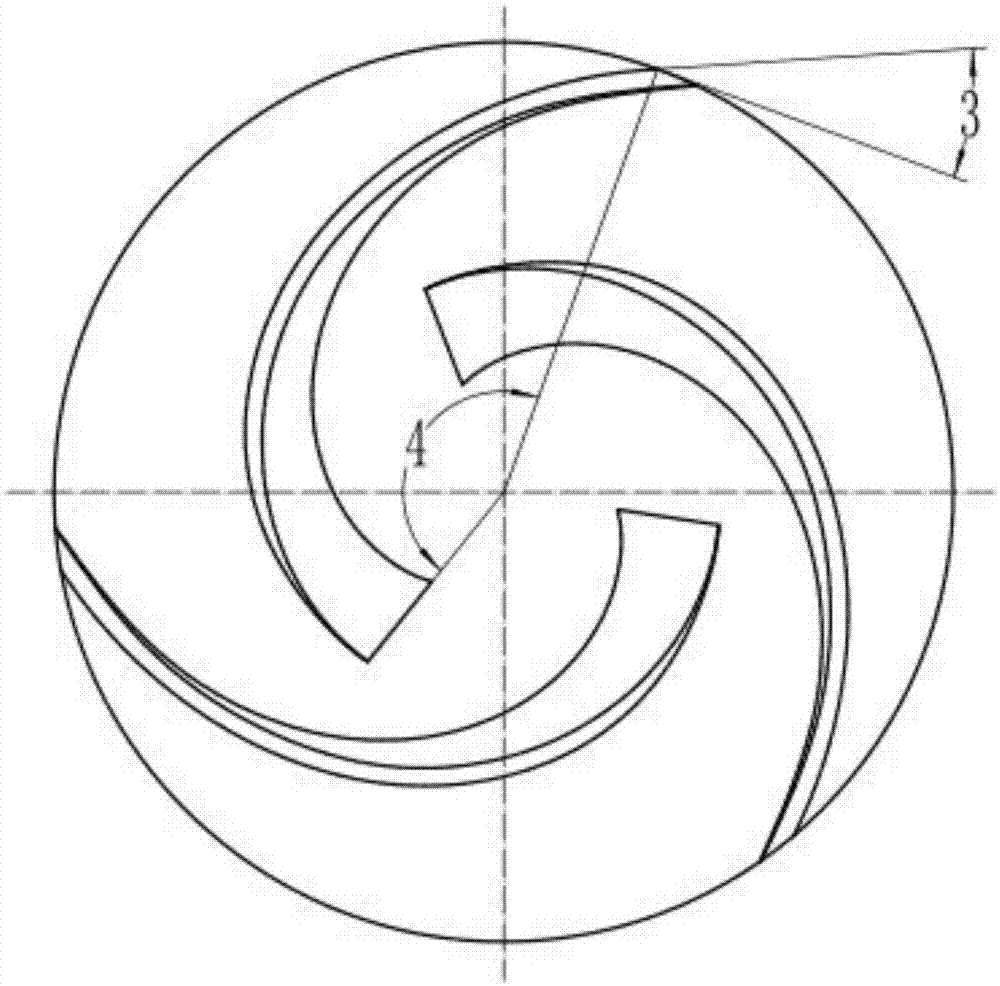

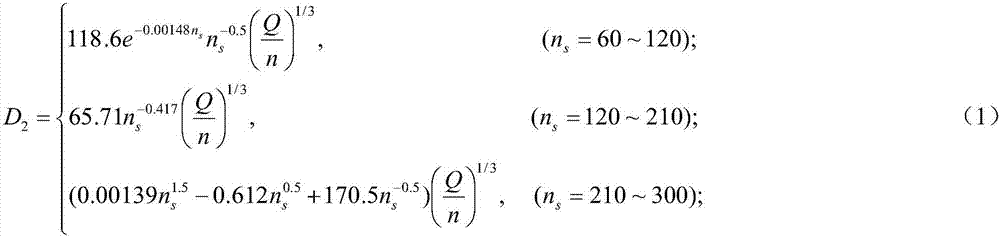

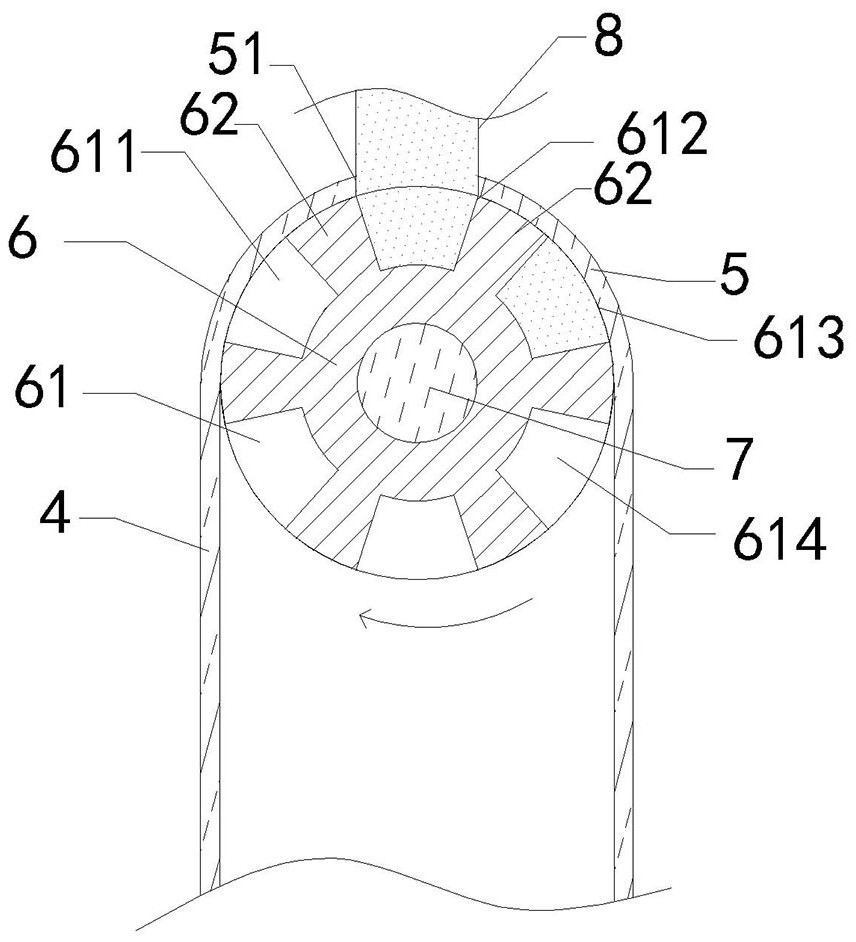

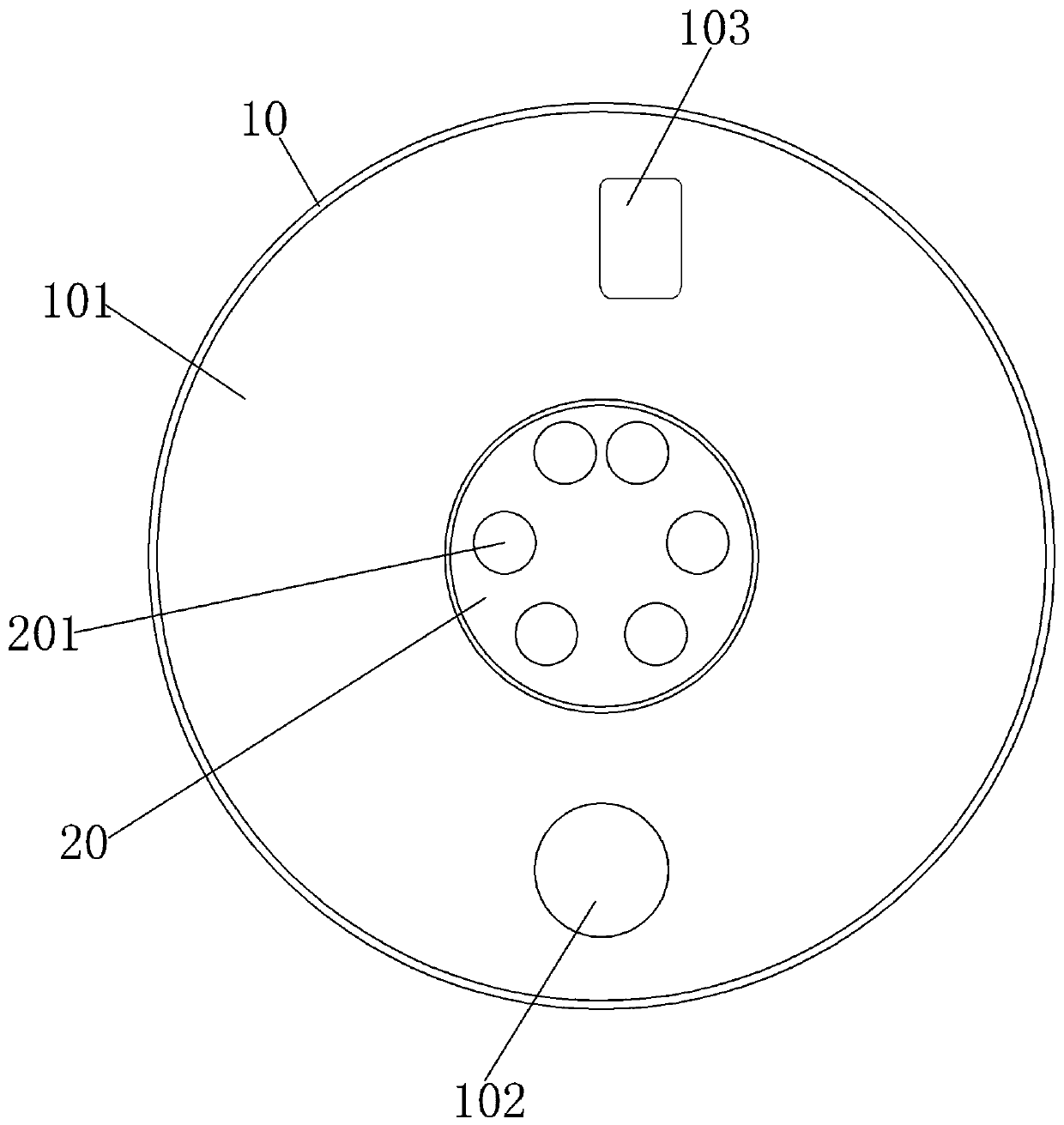

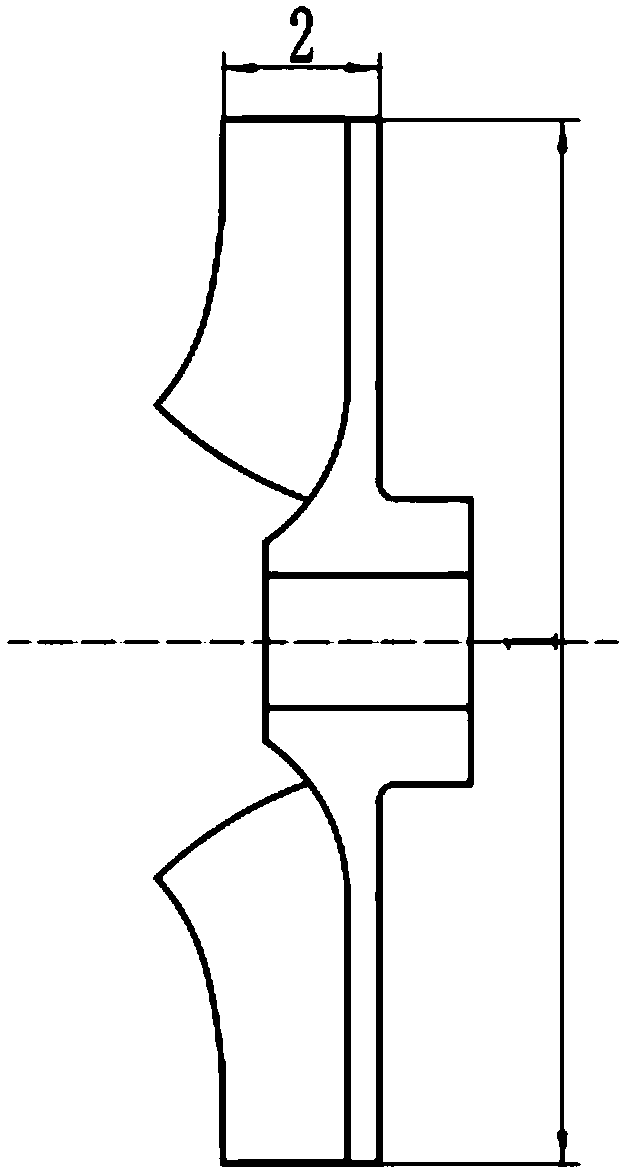

Hydraulic design method of semi-open type three-blade blockage-free impeller

InactiveCN107514385AStrong abrasion resistanceImprove reliabilityGeometric CADPump componentsImpellerSemi open

The invention provides a hydraulic design method of a semi-open type three-blade blockage-free impeller. The hydraulic design method of the semi-open type three-blade blockage-free impeller is characterized in that the impeller is of the three-blade semi-open type, the surface of the impeller is coated with nanometer WC-8Co super-hard composite coating through a high-velocity oxygen-fuel spraying technology, the design method of the main geometric parameters of the impeller is provided, and the main geometric parameters of the impeller comprise the outer diameter D2 of the impeller, the outlet width b2 of the impeller, the outlet installation angle beta 2 of the impeller and the wrap angle phi of each blade. On one hand, an existing design scheme is improved; on the other hand, the work environments of domestic and chemical sewage pumps are taken into fuller consideration, and for the work specificity of the domestic and chemical sewage pumps and the problems prone to generation in practice, targeted optimization of the design formula is conducted; the wear resistance and efficient and stable work of the semi-open type impeller can be ensured, and the adaptability of the semi-open type impeller to adverse work environments is improved.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

Silk sock

The invention provides a silk sock. The silk sock is provided with a toe part corresponding to a tiptoe area and a heel part corresponding to a heel area. The silk sock is characterized in that the overall silk stocking is made of silk by weft knitting. The silk and polyamide yarns are weft-knitted in parallel at the toe position and the heel position to form the toe part and the heel part. The polyamide yarns are located outside parallel yarns of the silk and the polyamide yarns, while the silk is located inside the parallel yarns of the silk and the polyamide yarns. The silk stock is as light, thin and firm as polyamide socks and is comfortable and breathable to wear.

Owner:浙江宝娜斯袜业有限公司

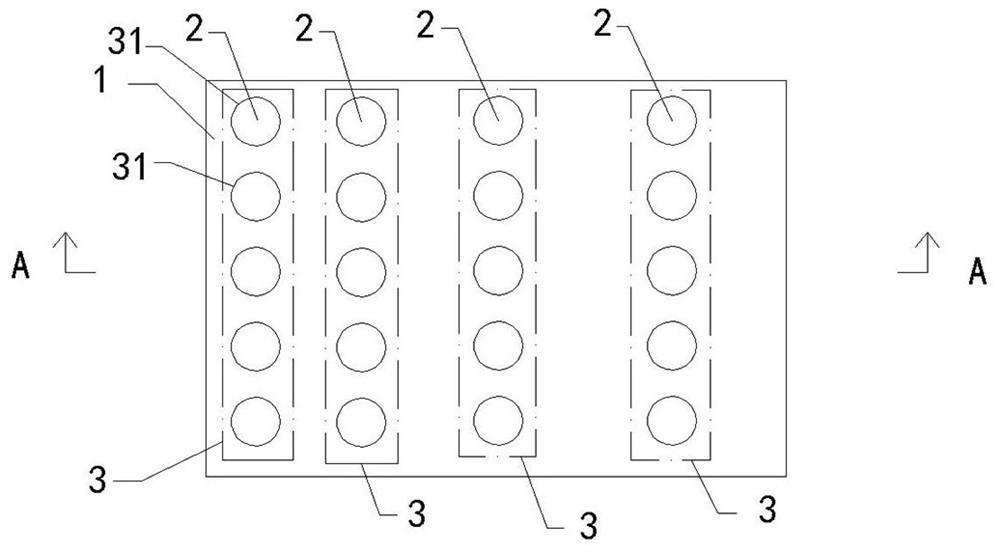

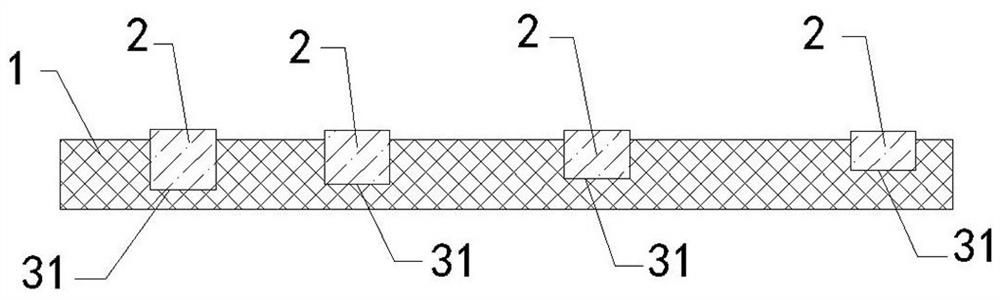

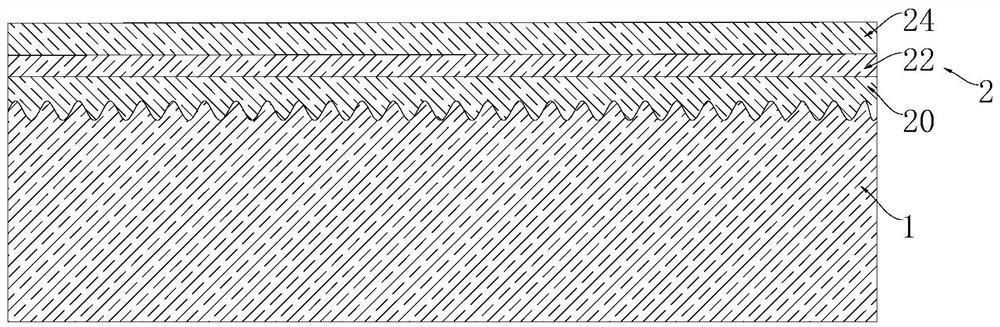

Protective plate for coal falling opening of circulating fluidized bed boiler and preparation device and method of protective plate

ActiveCN113324243ASevere wear and tearHigh hardnessFluidized bed combustionApparatus for fluidised bed combustionFluidized bedEngineering

The invention discloses a protective plate for a coal falling opening of a circulating fluidized bed boiler and a preparation device and method of the protective plate. The protective plate comprises a heat-resistant steel base plate and reinforcing filler, a plurality of linear groove arrays are sequentially formed in the upper surface of the heat-resistant steel base plate from left to right, and each linear groove array comprises a plurality of grooves which are sequentially arranged along a straight line. Each groove is cylindrical, the reinforcing filler is arranged in the grooves through laser cladding, the radius r of each groove is 3-6 mm, the depth of each groove is 3-4 mm, the reinforcing filler is 1-2 mm higher than an opening of each groove, and the depth of each groove is gradually reduced from left to right. The height difference between the top of the reinforcing filler and the opening of each groove is only 1-2 mm, so that although the reinforcing filler slightly higher than the opening of each groove hinders the coal, the coal is decelerated in the process of colliding with the coal, abrasion of the coal to the upper surface of the heat-resistant steel base plate is reduced, and the coal cannot be prevented from sliding on the upper surface of the heat-resistant steel base plate.

Owner:浙江物产环能浦江热电有限公司

Method for manufacturing bushing, substrate supporting assembly and substrate processing apparatus

PendingCN110394938AHigh surface roughness and uniformityEnsuring heat resistance and wear resistanceSemiconductor/solid-state device manufacturingInjection molding processBiomedical engineering

The invention provides a method for manufacturing a bushing, a substrate supporting assembly and a substrate processing apparatus. The substrate support assembly may include a plate, a top rod, and abushing. The plate may be used to configure a substrate. The top rod can penetrate the plate to move upward and downward in order to support the bottom surface of the substrate. The bushing may have an internal hole through which the ejector pin passes for guiding movement of the ejector pin when the plate moves. The bushing may be obtained by an injection molding process using a molding member including a molding space for forming an outer shape of the bushing and an inner pin for forming the inner hole in order to simultaneously form the outer shape of the bushing and the inner hole.

Owner:SEMES CO LTD

Coating and cooking utensil

PendingCN112137423AAvoid scratchesAvoid wear and tearCooking-vessel materialsCoatingsPolymer sciencePolymer chemistry

The invention provides a coating and a cooking utensil, the coating comprises a non-stick coating, and the coating also comprises an inorganic porous material and a heat conduction material; wherein the mass ratio of the inorganic porous material in the coating is 1%-20%; and the heat conduction coefficient of the heat conduction material is not less than 30W / mK. The thermal conductivity of the non-stick layer can be improved, and the thermal conductivity of the non-stick layer can be improved.

Owner:WUHAN SUPOR COOKWARE

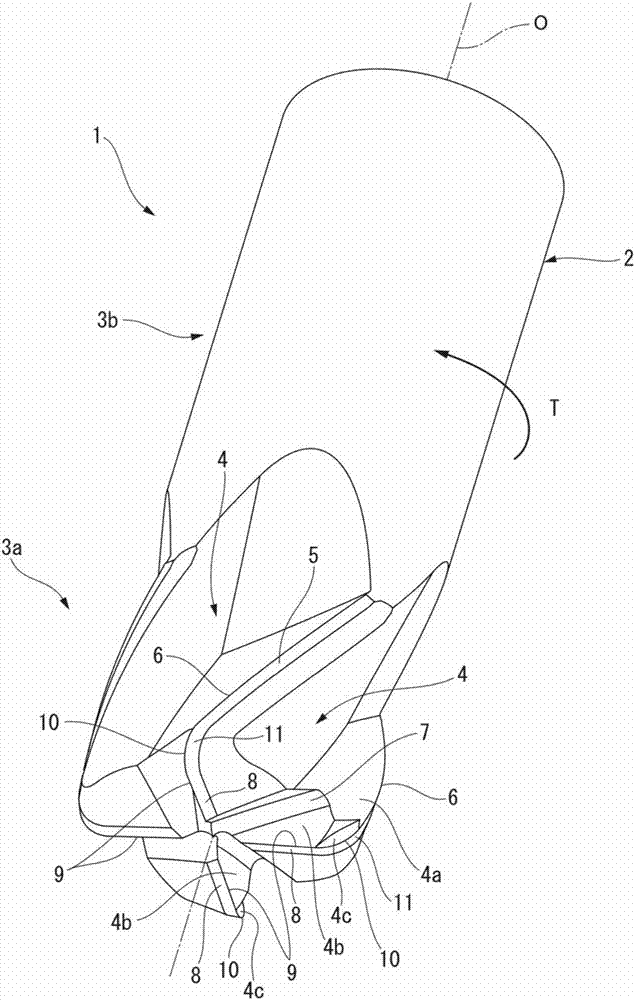

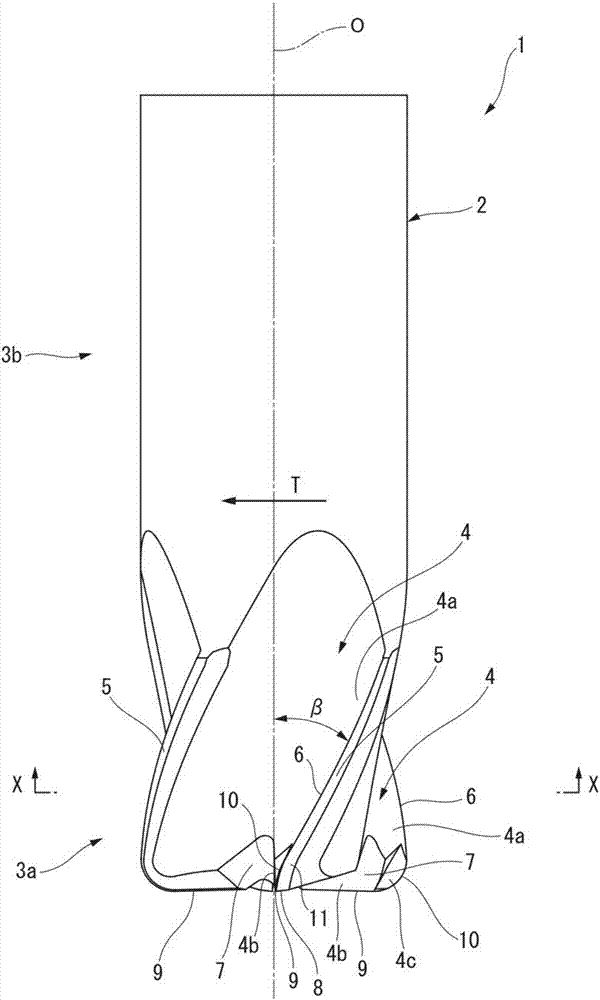

Radius end mill, ball end mill, and end mill

InactiveCN107000080AAchieve processing efficiencyHigh strengthMilling cuttersWorkpiecesMilling cutterEngineering

The present invention is provided with: a ceramic end mill main body (2); chip discharge grooves (4) formed in an outer periphery of the end mill main body (2); outer peripheral cutting edges (6) formed at intersecting ridge lines between wall surfaces which face in a tool rotation direction (T), in the chip discharge grooves (4), and an outer peripheral surface of the end mill main body (2); base cutting edges formed at intersecting ridge lines between the wall surfaces in the chip discharge grooves (4) and a tip end surface of the end mill main body (2); and corner cutting edges which are located in tip end outer peripheral portions of the end mill main body (2), connect the outer ends of the base cutting edges with the tip ends of the outer peripheral cutting edges (6), and are formed in the shape of convex curved lines which have a convexity facing toward the tip end outer peripheral side of the end mill main body (2). From among the outer peripheral cutting edges (6), the base cutting edges and the corner cutting edges, a radial rake angle (angle alpha) of at least the outer peripheral cutting edges (6) is set to a negative angle. The radial rake angle (angle alpha) of the outer peripheral cutting edges (6) is between -20 deg and -10 deg.

Owner:MITSUBISHI MATERIALS CORP

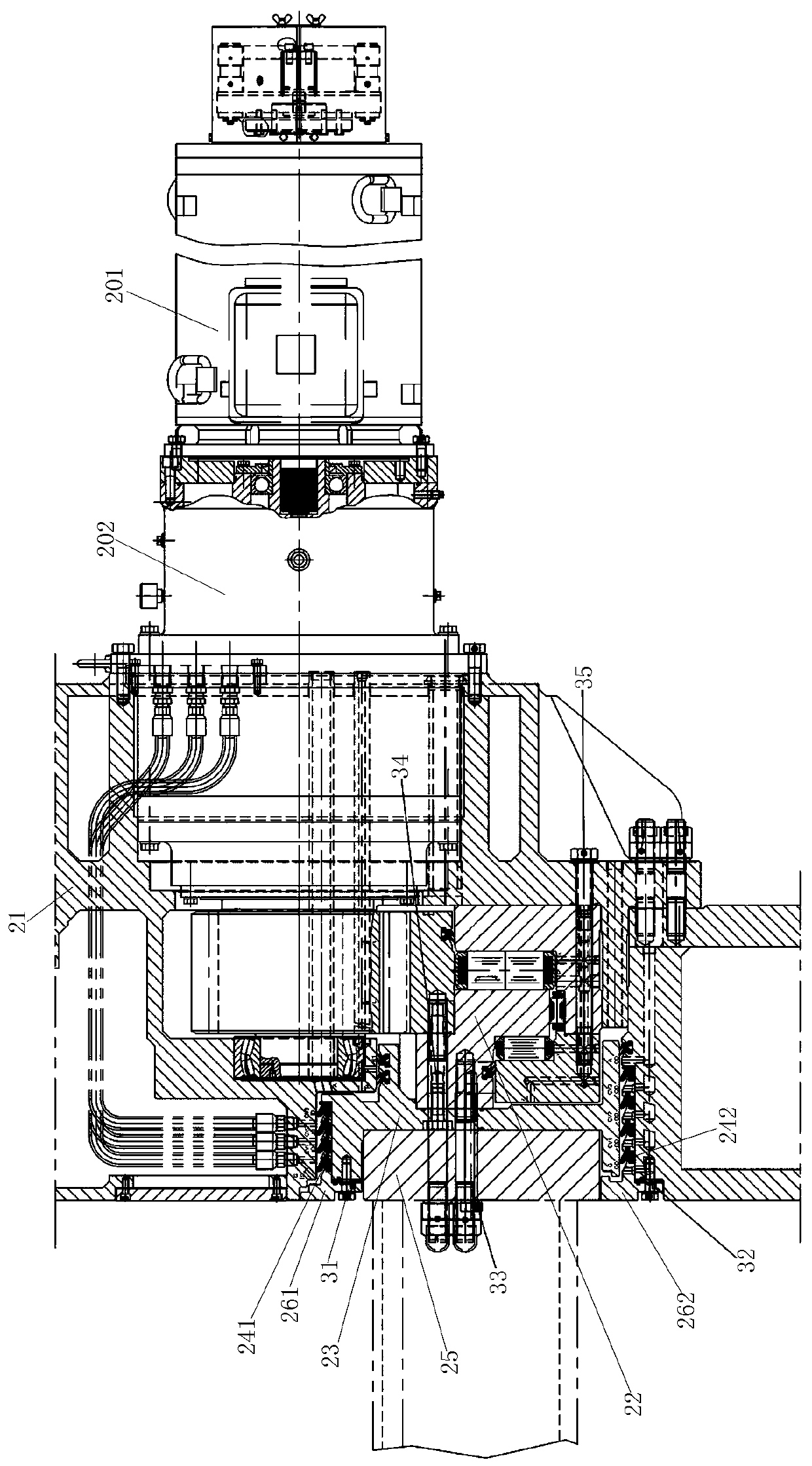

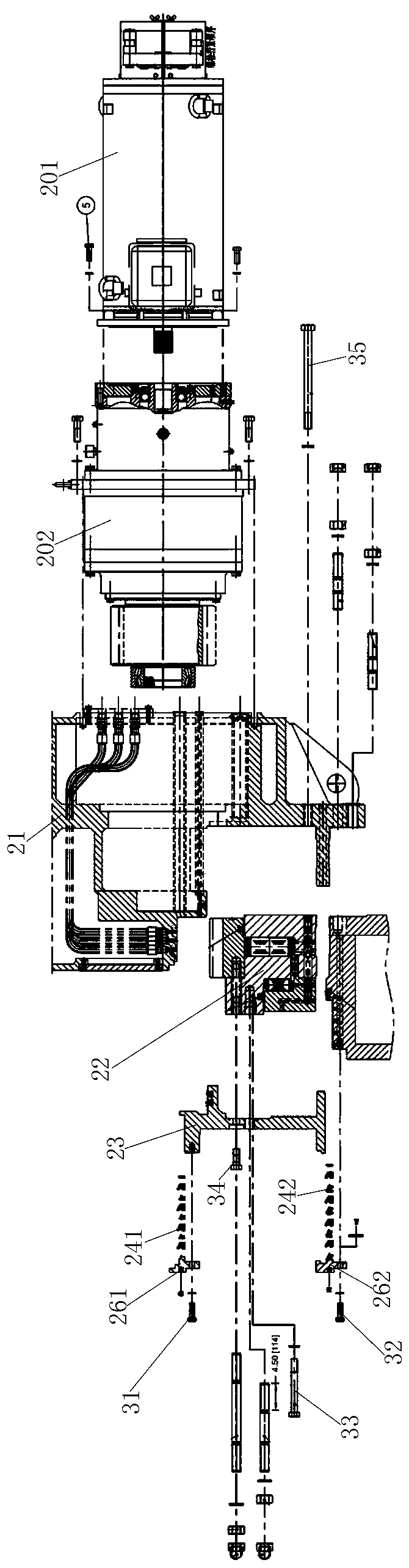

Main bearing disassembling method and main bearing maintenance method of main drive of shield machine

The invention discloses a main bearing disassembling method and a main bearing maintenance method of a main drive of a shield machine. The main bearing disassembling method for the main drive of the shield machine is characterized in that the front side of the main drive of the shield machine is downwards transported to a supporting platform, parts at the forefront end of the main drive of the shield machine are dismounted, then the rest part of the main driving part of the shield machine is transported away from the supporting platform, the disassembled parts are left on the previous supporting platform, the main drive of the shield machine is continuously adjusted to different supporting platforms, and the difficulty caused by large volume weight of parts driven by the shield machine is effectively overcome. According to the main bearing maintenance method of the shield machine, a main bearing of the shield machine is maintained, the working efficiency of the main bearing is improved, grooves needing to be repaired on the slideway surface and the raceway surface are subjected to surfacing, grinding and electroplating treatment, and the smoothness and wear resistance of the trimmed slideway surface and the raceway surface can be ensured.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

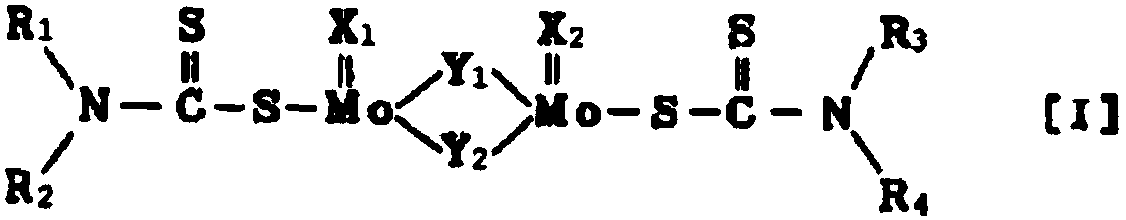

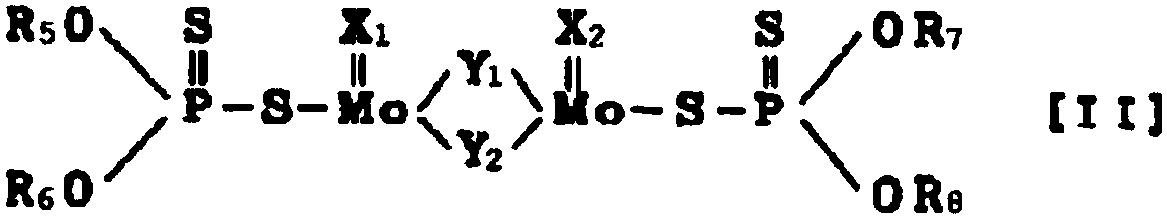

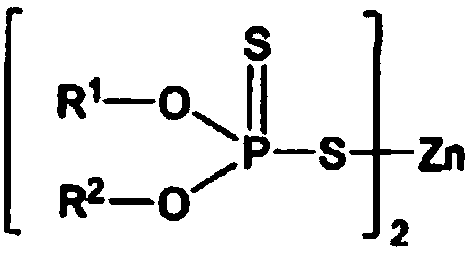

Lubricant composition

The invention provides a lubricant composition with which it is possible to reduce friction while ensuring anti-wear properties even at reduced viscosity. A lubricant composition containing a lubricant base oil, (A) a magnesium-based detergent, and (B) a molybdenum-based friction adjuster, wherein the lubricant composition is characterized in that the amount of component (A) is within the range of200-1200 ppm by mass expressed as the concentration [Mg], which is derived from the mass (ppm) of magnesium in the lubricant composition, and the amount of component (B) is within the range of 500-1500 ppm by mass expressed as the concentration [Mo], which is derived from the mass (ppm) of molybdenum in the lubricant composition.

Owner:EXXON RES & ENG CO +1

Method and acceleration method for coating micron-sized material with chromium oxide coating by using segregation and adhesion precipitated by chromium oxide

ActiveCN111172527AEnsure resistance to high temperature steam oxidationEnsure wear resistanceSolid state diffusion coatingHeat inorganic powder coatingMicro nanoMicron scale

The invention discloses a method and acceleration method for coating a micron-sized material with a chromium oxide coating by using segregation and adhesion precipitated by chromium oxide, and relatesto the field of micron-sized material coating methods. The method aims to solve the technical problems that the existing electroplating or plasma spraying is not suitable for micro-nano-scale test pieces and the spraying cost is high. The coating method comprises the following steps of placing the micron-sized material on the surface of the high-Cr stainless steel substrate, and then placing a component in an aging oven for high-temperature aging treatment. The accelerating method comprises the following steps that micron-sized grooves are machined in the surface of the high-Cr stainless steel substrate; and the micron-sized material is placed on the surface of the high-Cr stainless steel substrate, and then the component is placed in the aging oven to be subjected to high-temperature aging treatment. According to the method, the stable and compact Cr<2>O<3> steam oxidation resistant coating is coated on the surface of the micron-sized material by using the segregation and adhesion ofCr<2>O<3> precipitated by the high-Cr stainless steel in high-temperature aging. The method is used for coating the micron-sized material with a chromium oxide coating.

Owner:HARBIN BOILER

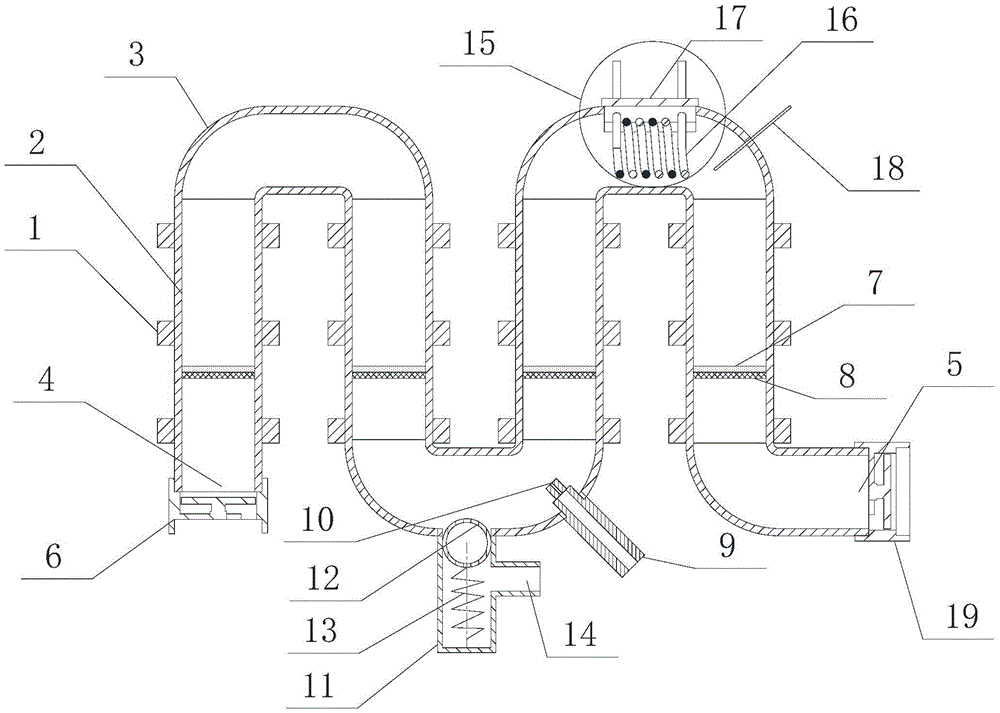

A Large Gas Turbine Air Intake System

The invention discloses a large-scale gas turbine air intake system. An air filter is arranged at the air intake of the large-scale gas turbine. The air filter is composed of a filter tube and a permanent magnet sheathed on the outer circle of the filter tube. The filter tube consists of at least four pieces arranged side by side. It is composed of a vertical ventilation pipe and an elbow. Two adjacent ventilation pipes are connected through an elbow. One end of the filter is provided with an air inlet, and the other end is provided with an air outlet. There is a first axial flow fan at the air inlet. , the air intake system of this large gas turbine has a simple structure, and the ventilation pipe is magnetized by a permanent magnet, so that the inner wall of the ventilation pipe has a magnetic adsorption of metal powder, dust and mine dust in the air, which is easy to operate, low in cost, long in service life, and the shaft The flow fan can ensure the air intake and ensure the normal operation of large gas turbines.

Owner:江苏华强新能源科技有限公司

Double-blade semi-open type sewage pump impeller hydraulic design method

InactiveCN107620736AStrong abrasion resistanceImprove reliabilityPump componentsPumpsImpellerSemi open

The invention provides a double-blade semi-open type sewage pump impeller hydraulic design method. The double-blade semi-open type sewage pump impeller hydraulic design method is characterized in thatan impeller is of a double-blade semi-open type, and the surface of the impeller adopts high velocity oxy-fuel technology and is coated with a nanometer WC-8Co super-hard composite coating. A designmethod for main geometrical parameters of the impeller is provided, which comprises an impeller outer diameter D2, an impeller exit width b2, a blade exit placing angle beta 2, and a blade wrap angle.The double-blade semi-open type sewage pump impeller hydraulic design method not only improves the existing design scheme, but also more fully considers life and chemical sewage pump working environment and specifically optimizes a design formula for the problems in special work and practice. The double-blade semi-open type sewage pump impeller hydraulic design method can ensure abrasion resistance, and high-efficiency and stable work of a semi-open type impeller, and enhances adaptive capacity on bad working environment.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

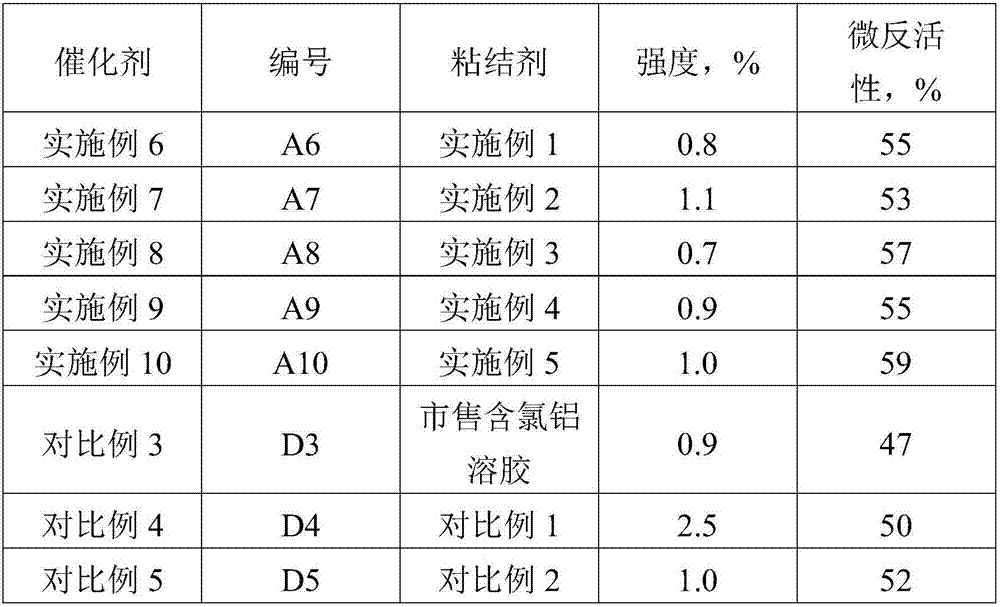

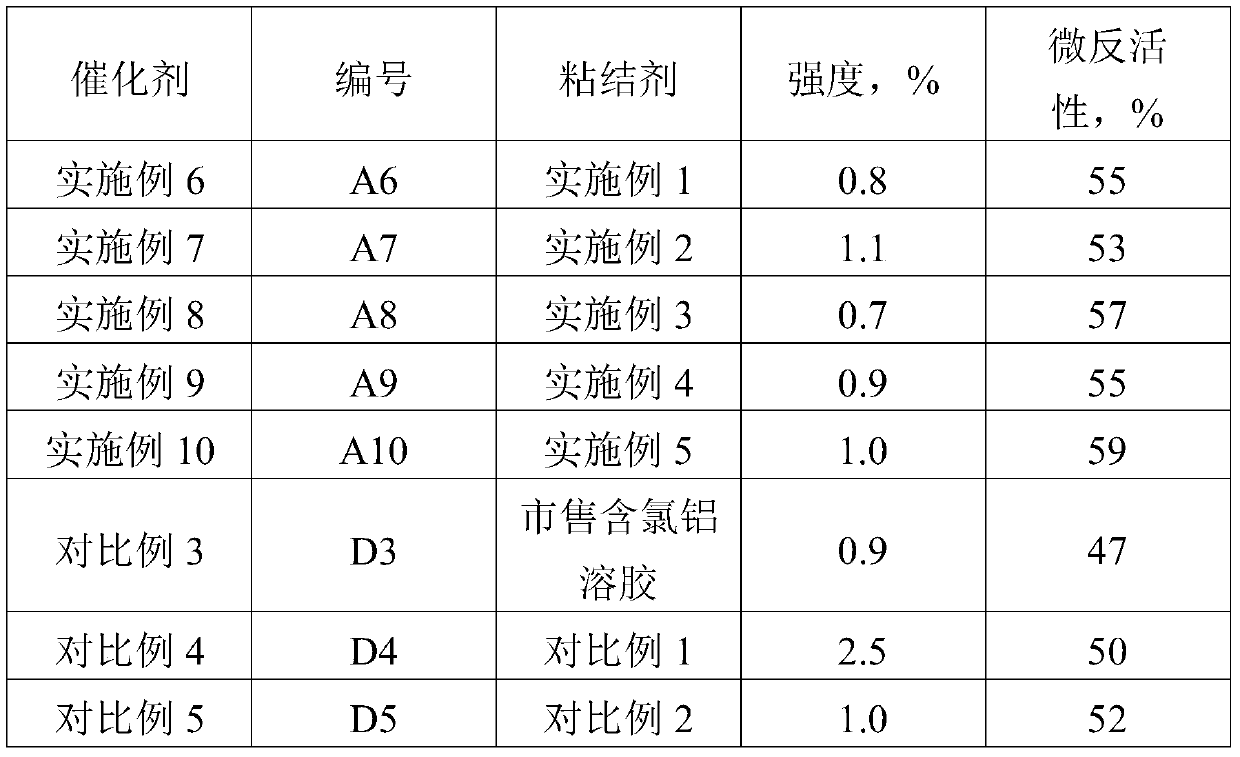

Aluminum phosphate sol and preparation method thereof

ActiveCN107304044AImprove stabilityReduce the impactCatalytic crackingPhosphorus compoundsPhosphoric acidBoehmite

The invention relates to aluminum phosphate sol and a preparation method thereof. The aluminum phosphate sol contains the following components in percentage by mass: 10%-50% of Al2O3, 0.5%-10% of soluble salt with an anion of C6H7O7<-> or CH2COO<-> or HCOO<-> and 1.5%-15% of P. The preparation method comprises the following steps: (1) stirring pseudo-boehmite, the soluble salt with the anion of C6H7O7<-> or CH2COO<-> or HCOO<-> and deionized water, and standing; and (2) uniformly stirring the slurry obtained in the step (1), and adding phosphoric acid or a mixture of phosphoric acid and phosphate. The aluminum phosphate sol is used for preparing a catalyst, so that the environmental pollution caused by chloride ions and nitrate ion is avoided; the aluminum phosphate sol can be directly used as a bonder of a catalytic cracking catalyst; and the heating is not required during the preparation, a preparation process is simple, high in phosphorus-aluminum ratio, the range is adjustable, and the industrial production is easily realized.

Owner:PETROCHINA CO LTD

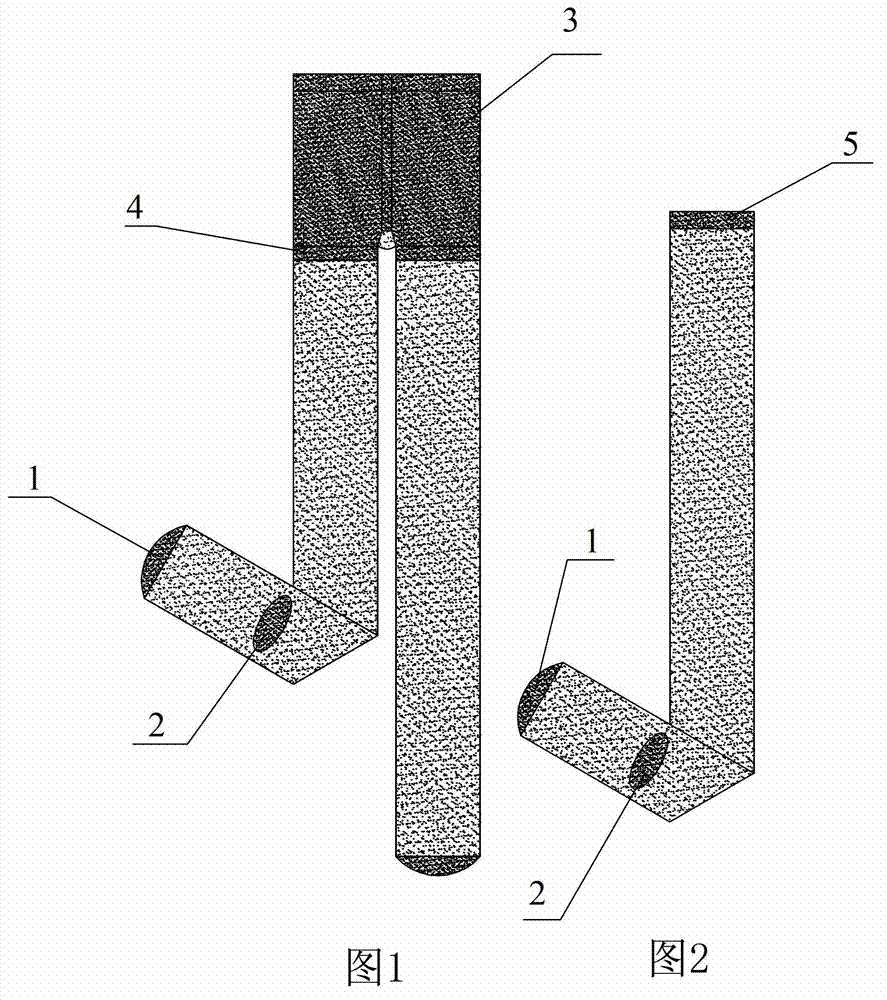

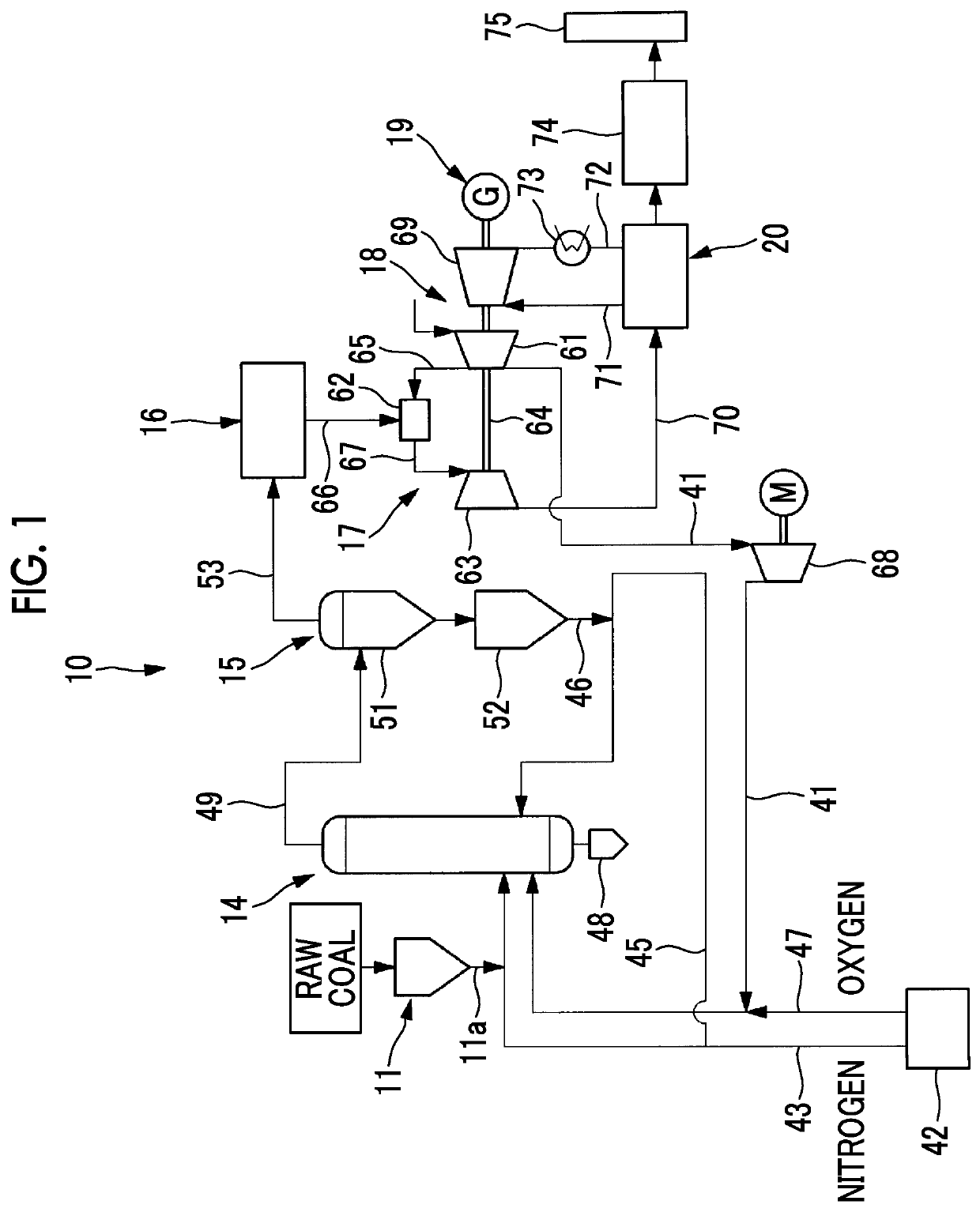

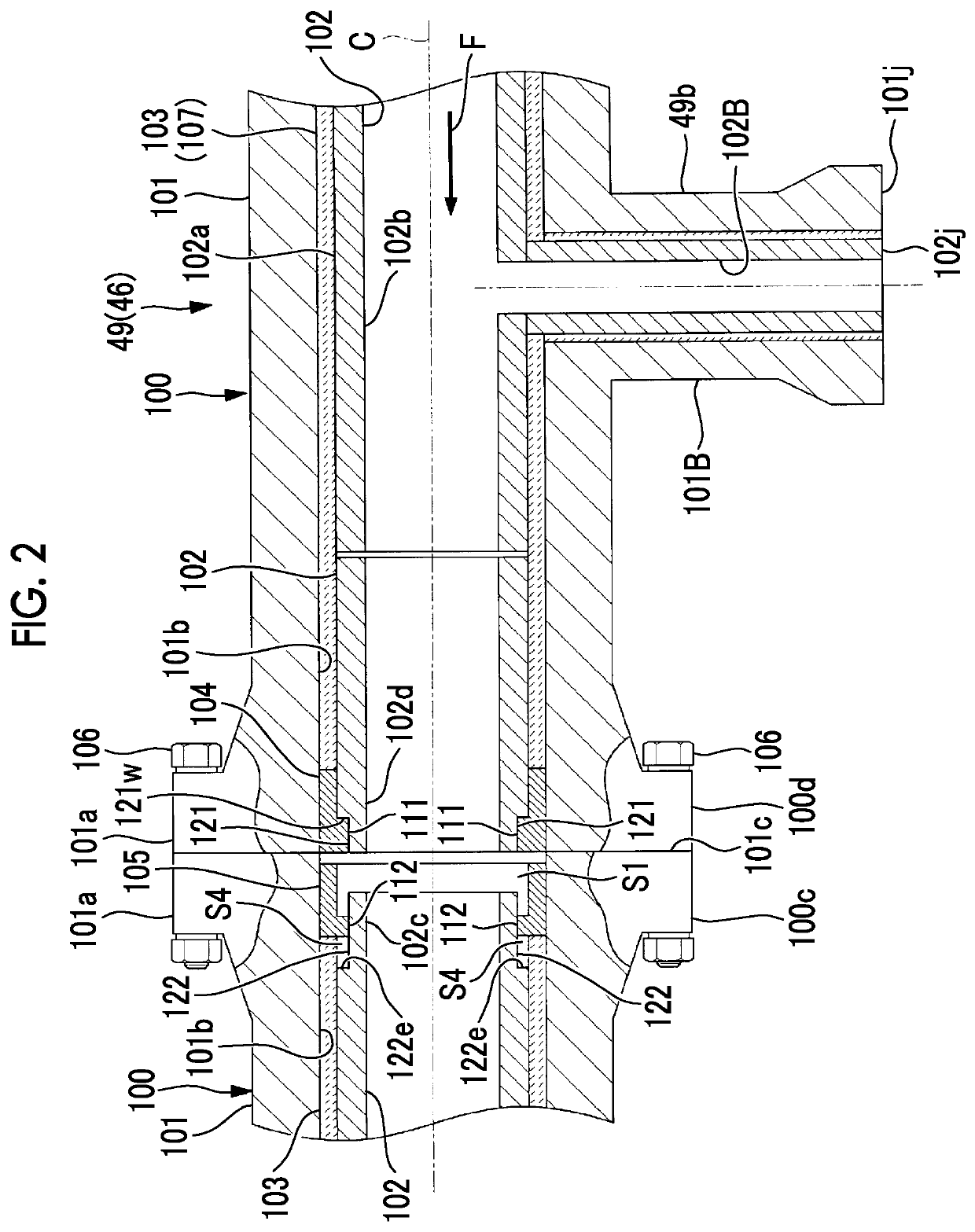

Pipe member, gasification combined power generation device, and pipe member assembly method

PendingUS20210087482A1Ensure of resistance corrosionEnsure wear resistanceFuel feeding arrangementsPipeline expansion-compensationPhysicsPipe

In order to allow for thermal elongation of a liner, a pipe member, in the interior of which flows a fluid containing solids, is provided with: a tubular outer pipe; a single tubular liner provided inside the outer pipe with a gap therebetween in the radial direction, or a plurality thereof arranged serially in the direction of the pipe axis C; a refractory material filled in between the outer pipe and the liner; a first liner holding member that is provided on an end portion side of the outer pipe, and that holds the liner arranged on the end portion side in a restrained state in the pipe axis C direction and the circumferential direction around the pipe axis C; and a second liner holding member that is provided on an end portion side of the outer pipe, and that holds the liner arranged on the end portion side.

Owner:MITSUBISHI HEAVY IND LTD

High-performance copper-diamond electrical contact material and preparation process thereof

The invention relates to a preparation process of powder metallurgy material, in particular to a preparation process of a high-performance copper-diamond electrical contact material. The preparation process of the high-performance copper-diamond electrical contact material comprises the following steps: (1) preparing the raw materials: preparing the copper alloy powder by using a high-pressure spray method, preparing the copper-coated diamond powder by using a liquid-phase reduction method and mixing the copper alloy powder and the copper-coated diamond powder; (2) preparing the electrical contact material: firstly, carrying out thermal diffusion treatment to the mixture of the copper alloy powder and the copper-coated diamond powder, sintering the compressed and moulded mixture in vacuum, and thermally extruding and moulding the mixture; and (3) preparing electrical contact sectional material: rolling or drawing and machining the copper-diamond electric contact into the required-size sectional material.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

High-toughness wear-resistant composite material and preparation method thereof

InactiveCN114835498AHigh hardnessHigh hardness characteristics, TiN material has high strengthEtchingTitanium nitride

The invention relates to the technical field of wear-resistant material processing, and discloses a high-toughness wear-resistant composite material and a preparation method thereof.The high-toughness wear-resistant composite material comprises 5-10% of MXene powder, 65-80% of SiC particles (312 microns), 10-15% of SiC particles (200 microns), 5-9% of SiC particles (50 microns), 1-3% of silicon powder, 1-3% of carbon black, 1-3% of graphite, 0.5-1.0% of a sintering aid and 3-5% of dextrin powder.The preparation method is characterized by comprising the steps that S1, MXene is prepared, specifically, 2 g of villiaumite is weighed and dissolved in 30 mL of 12 mol / L concentrated hydrochloric acid (HCl); according to the high-toughness wear-resistant composite material and the preparation method thereof, by introducing nitrogen, on one hand, MXene is prevented from being oxidized, on the other hand, TiN is generated, the hardness characteristic of the wear-resistant material is improved, the TiN material has the advantages of being high in strength, high in hardness, resistant to acid and alkali etching, resistant to wear and the like, the hardness of the TiN material is close to that of diamond, and the wear resistance of the TiN material is improved. The titanium nitride material film coated on the surface of the high-speed steel cutting tool can reduce the wear of the tool, improve the cutting speed and prolong the service life of the tool.

Owner:江苏尊释智能科技有限公司

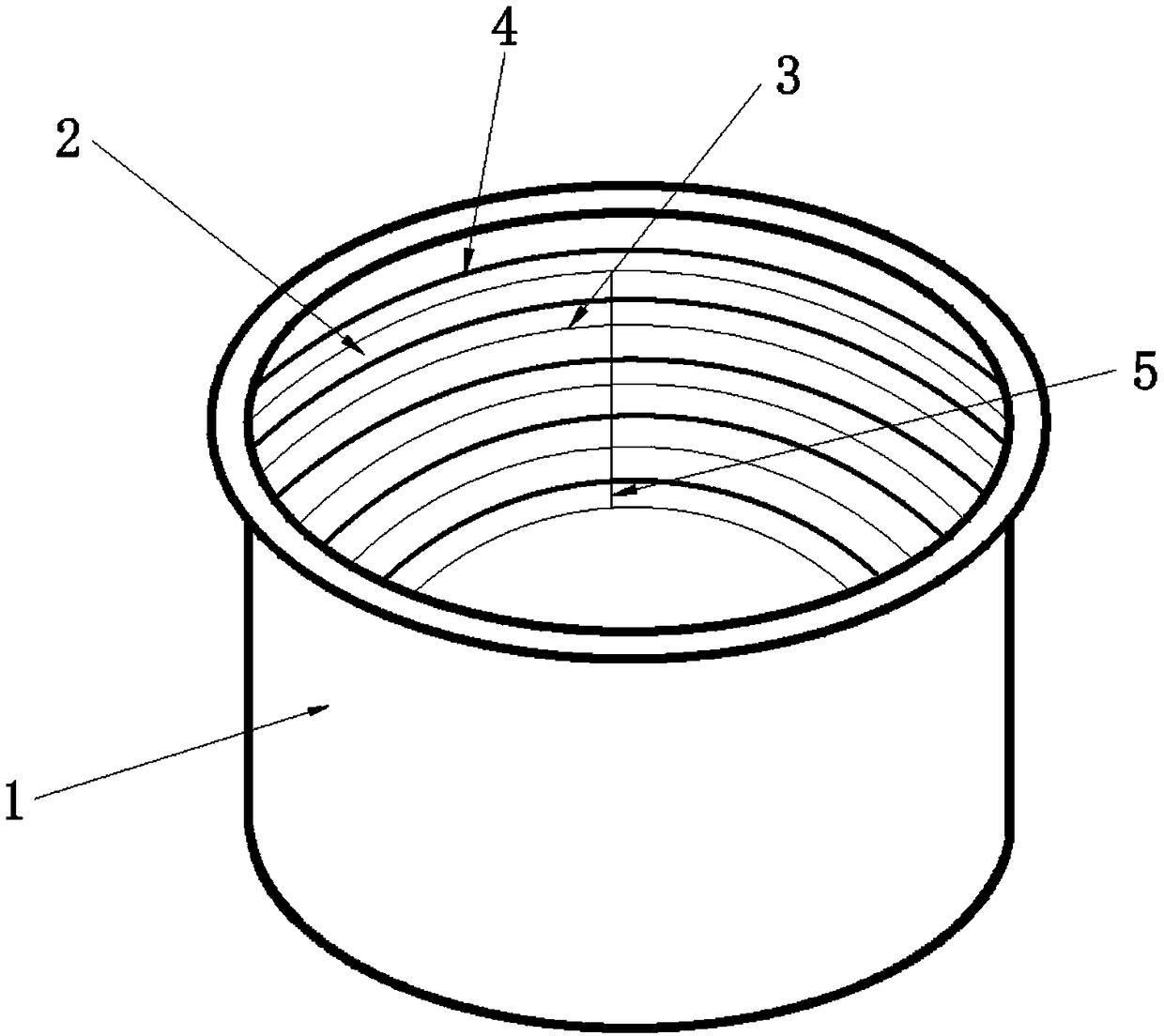

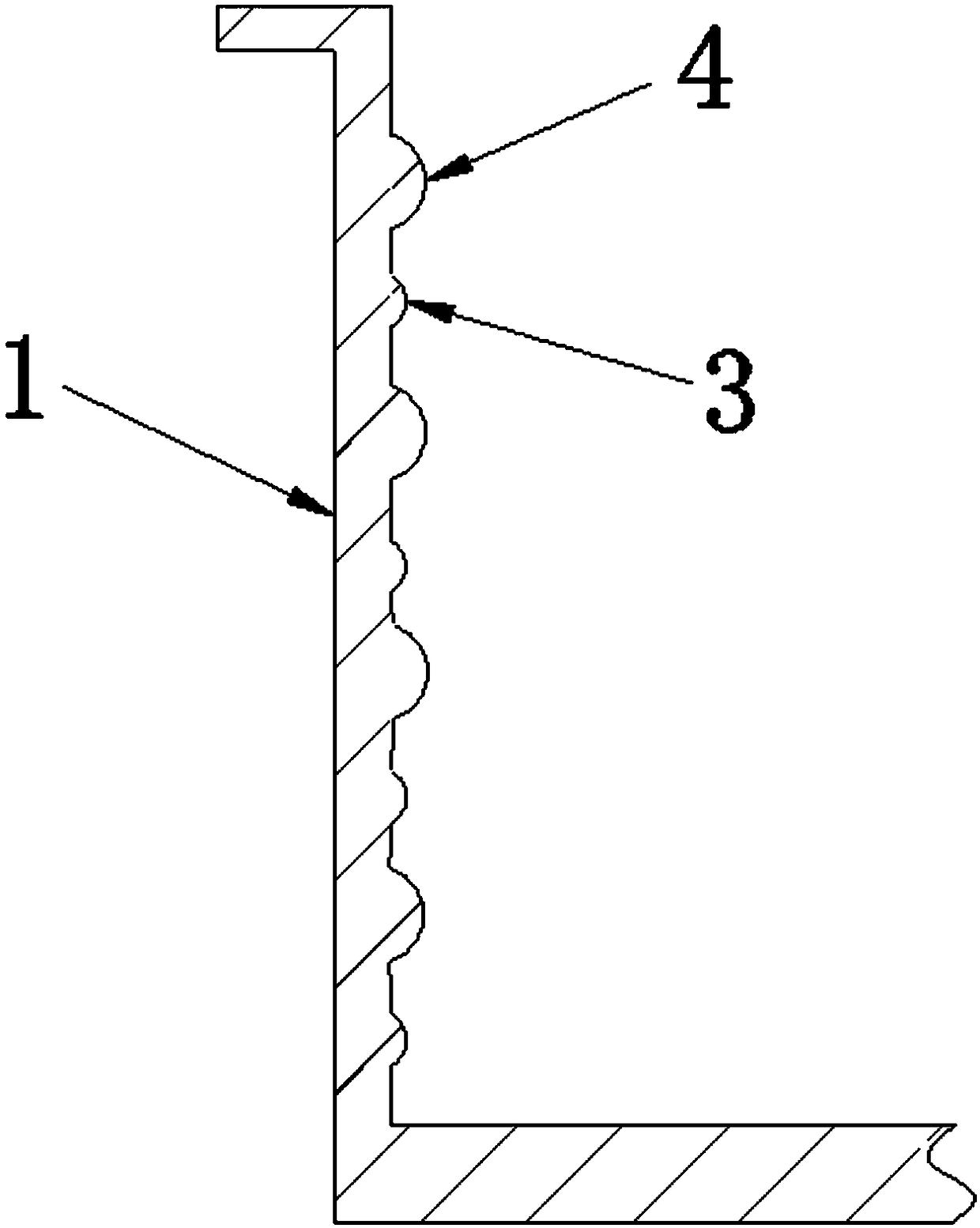

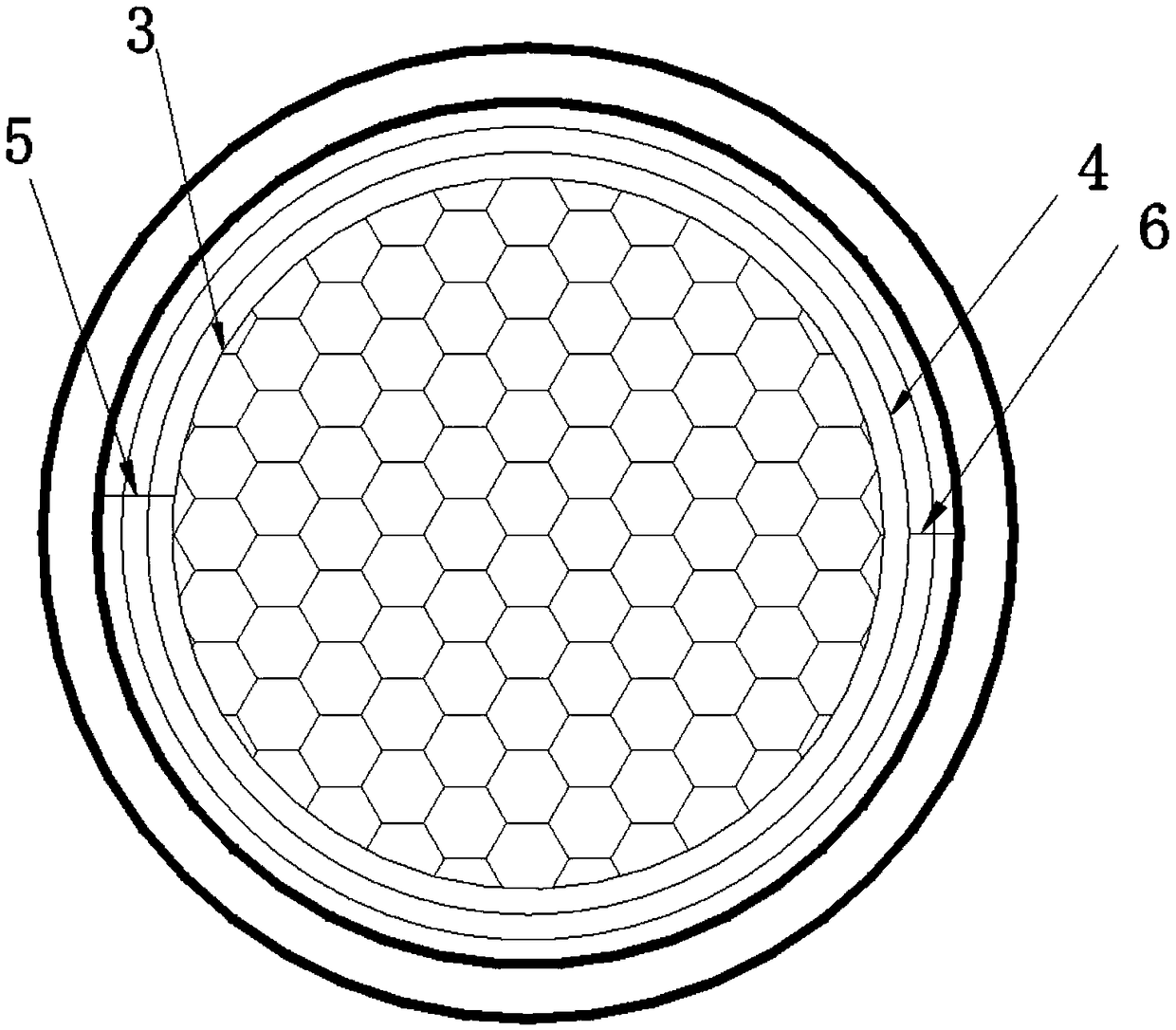

Novel electric cooker inner container

PendingCN108903611AClearly know the ratioSimple structureCooking vessel constructionsEngineeringCooker

The invention provides a novel electric cooker inner container mainly comprising an electric cooker and an inner container body used for the electric cooker. The inner wall of the inner container bodyis provided with annular scale lines and the scale lines and the inner container body are formed integrally; the scale lines protrude out of the inner wall of the inner container, wherein the protruding surfaces of the scale lines are in the structure of a circular arm; the scale lines include a rice quantity line and a water quantity line. The novel electric cooker inner container is simple in structure and safe and convenient to use; the scale lines and the inner container body are formed integrally and the scale lines protrude out of the inner wall of the inner container body, so that thewear resistance during daily use can be effectively guaranteed; the scale lines are annular, so that users can clearly know the required ratio; the protruding surfaces of the scales lines are in the structure of a circular arm, so that it is guaranteed that residues are prevented from remaining between the protruding surfaces and the inner wall and the inner container body and daily cleaning is easy.

Owner:深圳市奕胜时科技有限公司

Brake pad

The invention discloses a brake pad. The brake pad is prepared from, by volume, 40-50 parts of a fiber base material, 4-10 parts of an adhesive, 5-8 parts of steel fibers, 1-5 parts of calcium pyrophosphate and 20-30 parts of ferric oxide by pressing. The brake pad is low in cost, long in service life, slow in abrasion and high in hardness, complies with laws and regulations related to copper content and guarantees braking effectiveness and abrasion resistance in high-speed high-load braking.

Owner:长沙丰畅车辆工程技术有限公司

A kind of aluminum phosphate sol and preparation method thereof

ActiveCN107304044BEliminate pollutionEnsure wear resistanceCatalytic crackingPhosphorus compoundsPhosphatePhosphoric acid

The invention relates to aluminum phosphate sol and a preparation method thereof. The aluminum phosphate sol contains the following components in percentage by mass: 10%-50% of Al2O3, 0.5%-10% of soluble salt with an anion of C6H7O7<-> or CH2COO<-> or HCOO<-> and 1.5%-15% of P. The preparation method comprises the following steps: (1) stirring pseudo-boehmite, the soluble salt with the anion of C6H7O7<-> or CH2COO<-> or HCOO<-> and deionized water, and standing; and (2) uniformly stirring the slurry obtained in the step (1), and adding phosphoric acid or a mixture of phosphoric acid and phosphate. The aluminum phosphate sol is used for preparing a catalyst, so that the environmental pollution caused by chloride ions and nitrate ion is avoided; the aluminum phosphate sol can be directly used as a bonder of a catalytic cracking catalyst; and the heating is not required during the preparation, a preparation process is simple, high in phosphorus-aluminum ratio, the range is adjustable, and the industrial production is easily realized.

Owner:PETROCHINA CO LTD

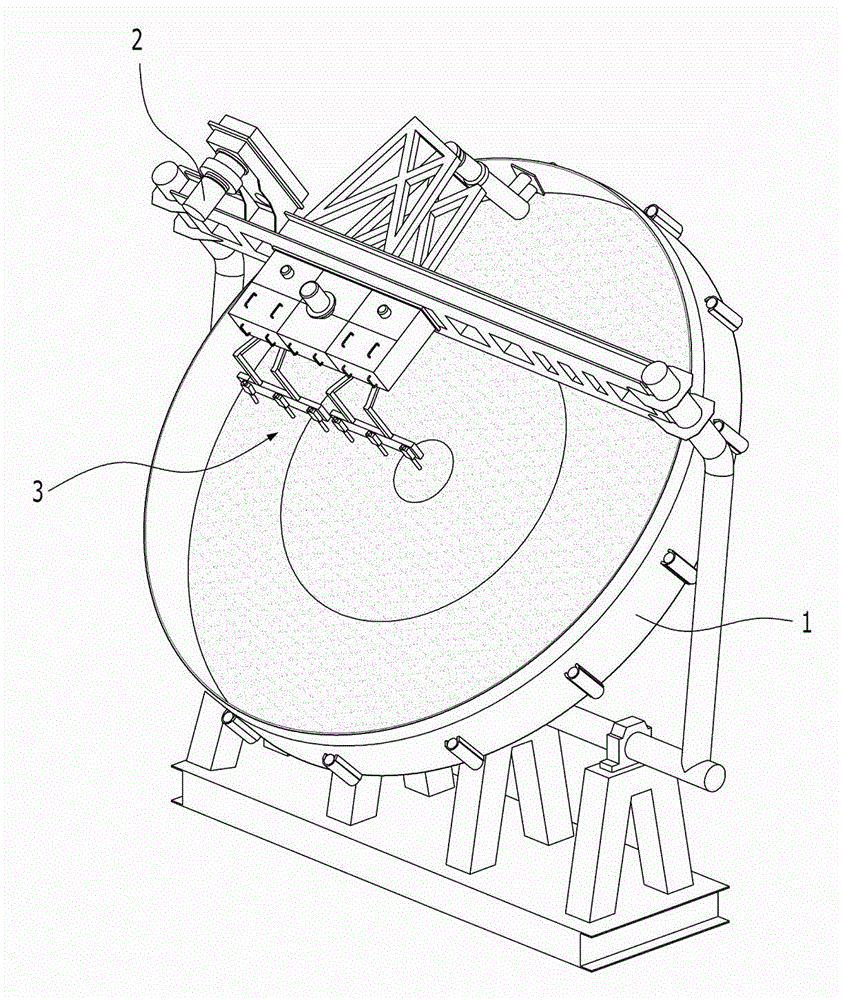

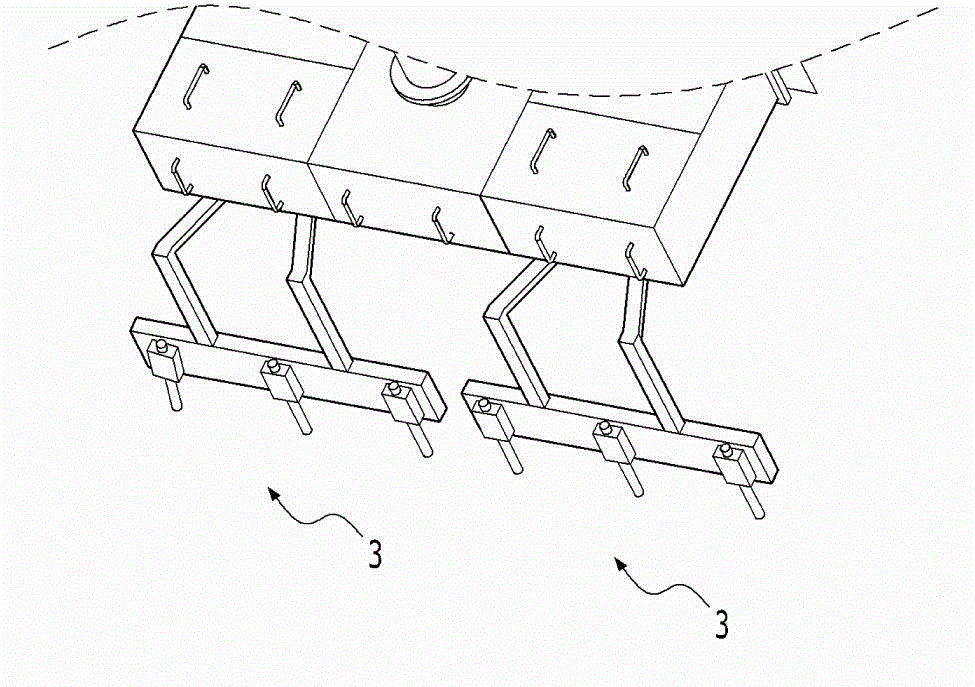

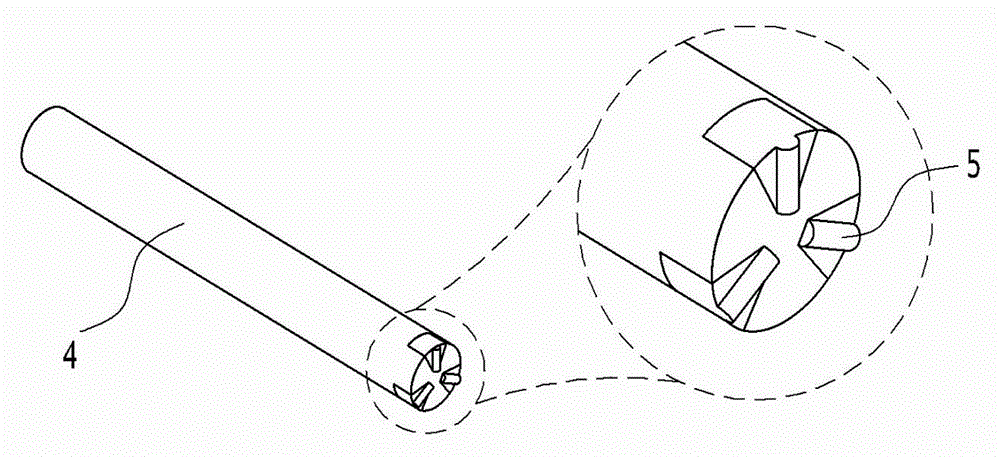

Composite type scraper having spraying function and granulating machine by use of composite type scraper

InactiveCN104549039ASimple structureLow investment costGranulation in rotating dishes/pansProduction rateComposite function

The invention relates to a scraper of a granulating machine and in particular relates to a composite type scraper having a spraying function and a granulating machine by use of the composite type scraper. Besides having an original function of scraping residues, the composite type scraper has a composite function of spraying moisture and air, therefore, the integral structure can be simplified, the investment expense of the equipment is saved, and the production rate of small granules is improved. According to the scraper, the scraper is used for the granulating machine which is used for processing powdery raw materials into small granules. The scraper comprises a scraper body and a scraper nozzle, wherein more than one flow path is formed inside the scraper body, and the scraper nozzle is formed at one end of the scraper body; and a flow path communicated with the flow path of the scraper body is formed on the scraper nozzle.

Owner:YULIM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com