Silk sock

A technology of silk and silk stockings, which is applied in socks, pantyhose, clothing, etc., can solve the problems that the wearing comfort is not as good as that of natural fibers, cannot be used as stockings, and the life of socks is limited, etc. It achieves low cost, simple method, and reduced raw materials the effect of dependence on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

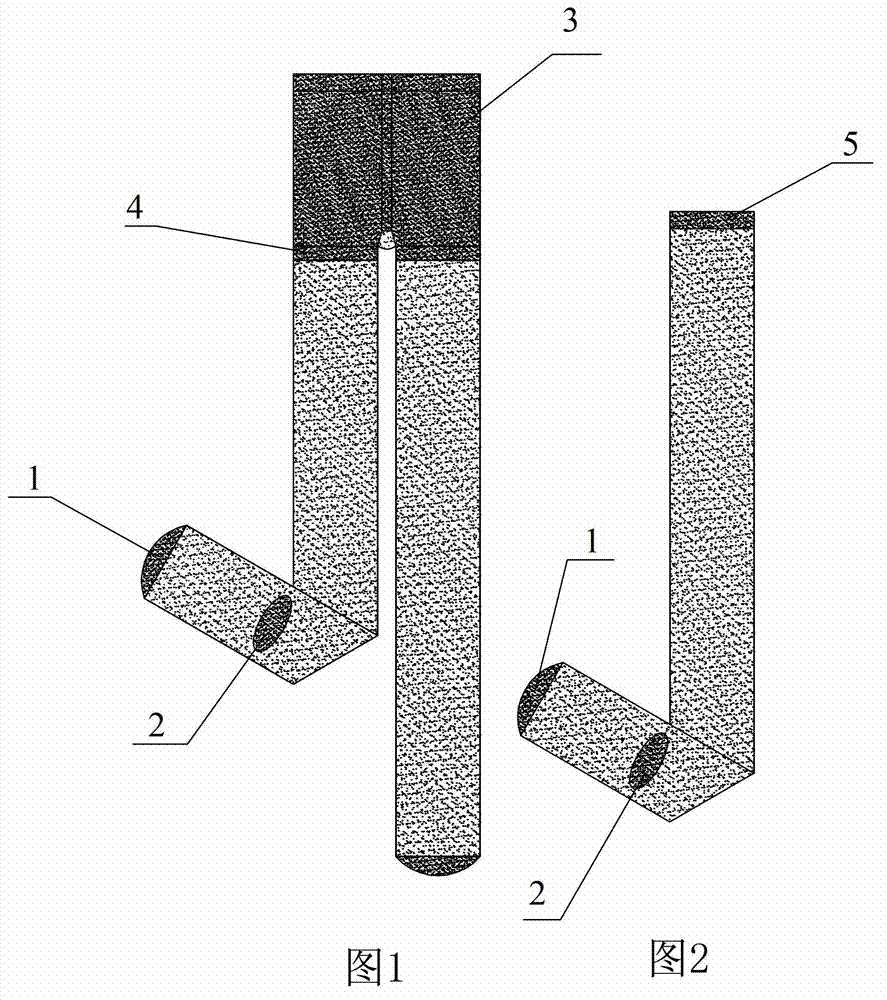

[0010] Embodiment 1, with reference to attached figure 1 , 3 .

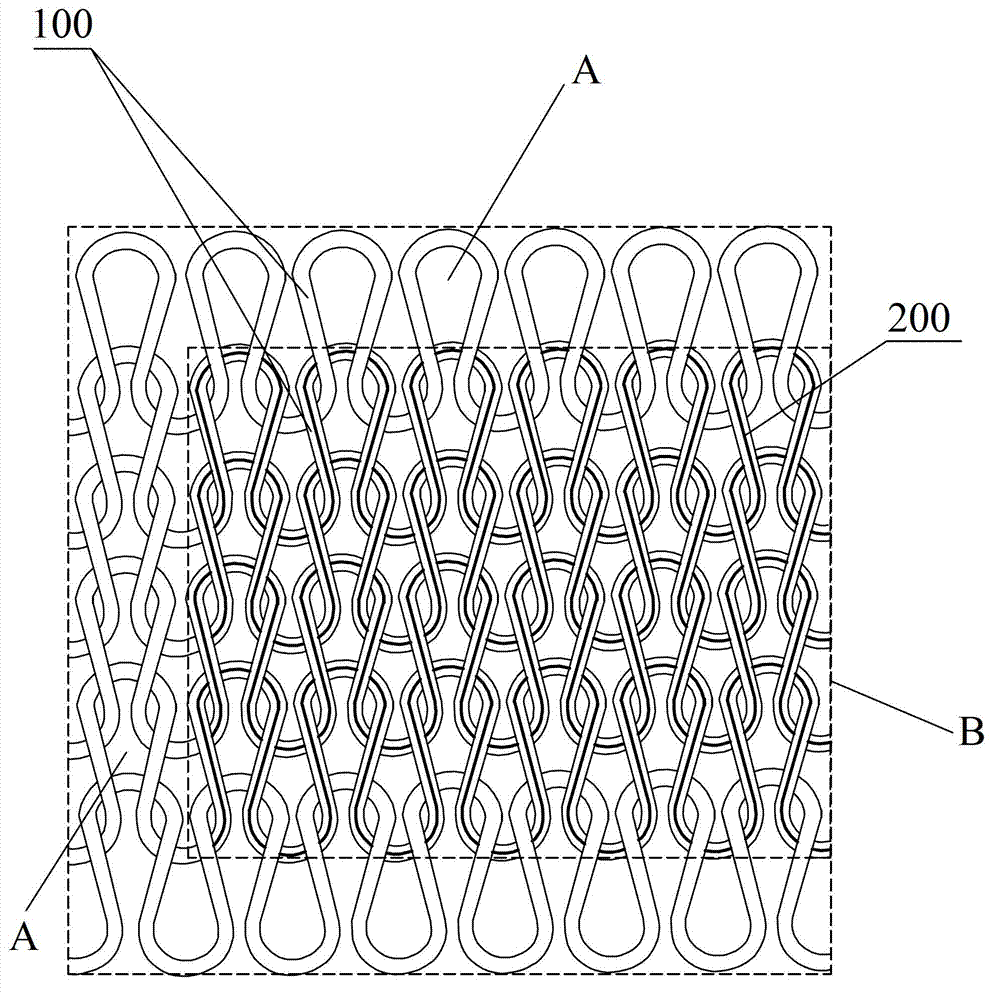

[0011] The stockings provided by the present invention have a toe part 1 corresponding to the toe area and a heel part 2 corresponding to the heel area. 100 and nylon yarn 200 are weft-knitted in parallel to form the toe part 1 and the heel part 2, and the nylon yarn 200 is on the outside of the parallel yarn of real silk and nylon yarn, and the real silk 100 is on the outside of the parallel yarn of real silk and nylon yarn. The inside (that is, the side that is close to the human body).

[0012] In this embodiment, the silk stockings are pantyhose, and the whole of the pantyhose is weft-knitted from silk, and the area 3 above the crotch and the thigh slightly below the crotch of the pantyhose are The upper region 4 is also composed of the parallel weft knitting of the real silk 100 and the nylon yarn 200, and the nylon yarn 200 is outside the parallel yarn of the real silk and the nylon yarn, and the real si...

Embodiment 2

[0014] Embodiment 2, with reference to attached figure 2 , 3 .

[0015] The stockings provided by the present invention have a toe part 1 corresponding to the toe area and a heel part 2 corresponding to the heel area. 100 and nylon yarn 200 are weft-knitted in parallel to form the toe part 1 and the heel part 2, and the nylon yarn 200 is on the outside of the parallel yarn of real silk and nylon yarn, and the real silk 100 is on the outside of the parallel yarn of real silk and nylon yarn. The inner side (that is, the side that is close to the human body).

[0016] The silk stockings are tube socks, and the whole tube socks are weft-knitted from real silk. At the sock opening 5, the silk 100 and nylon yarn 200 are weft-knitted in parallel to form the sock opening 5, and the The above-mentioned nylon yarn 200 is on the outside of the parallel yarns of real silk and nylon yarn, and the real silk 100 is on the inside of the parallel yarn of real silk and nylon yarn (that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com