Lubricant composition

A kind of lubricating oil composition, lubricating oil technology, applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve problems such as easy occurrence of wear, and achieve the effect of reducing friction and ensuring anti-wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

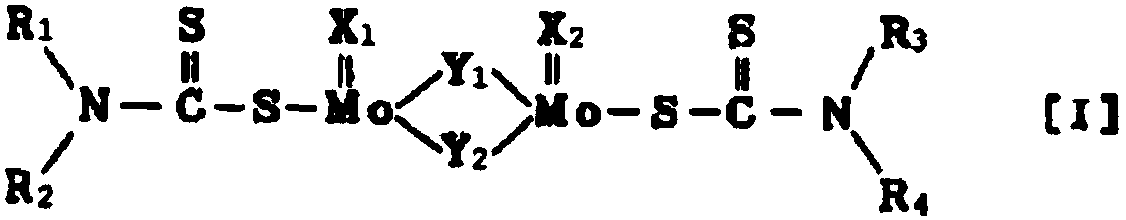

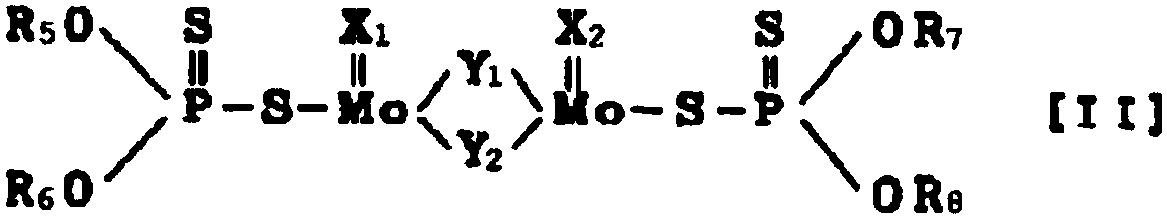

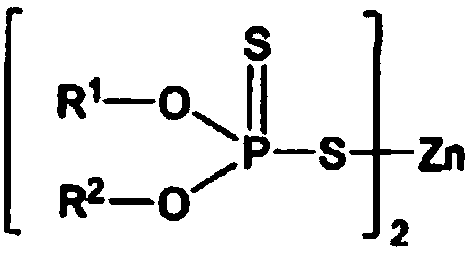

Method used

Image

Examples

Embodiment 1~8 and comparative example 1~6

[0133] The components in the amounts shown in Table 1 were mixed to prepare lubricating oil compositions. The amounts of magnesium-based detergents, calcium-based detergents, and molybdenum-based friction modifiers are expressed in ppm by mass relative to the total amount of the lubricating oil composition converted to the contents of magnesium, calcium, and molybdenum, and the amounts of anti-wear agents and other additives The amount is expressed in parts by mass relative to the total amount (100 parts by mass) of the lubricating oil composition. In addition, the amounts of the magnesium-based detergent and the calcium-based detergent were made such that the total molar amounts of magnesium and calcium contained in these detergents were made as equal as possible in all Examples and Comparative Examples. The following tests were performed on the obtained composition. The results are shown in Table 1.

[0134] (1) High temperature high shear viscosity at 150°C (HTHS150)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com