Main bearing disassembling method and main bearing maintenance method of main drive of shield machine

A main drive and shield machine technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problem of difficult disassembly and maintenance of the main bearing, and achieve the effect of improving work efficiency, improving work efficiency, and avoiding the increase in use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

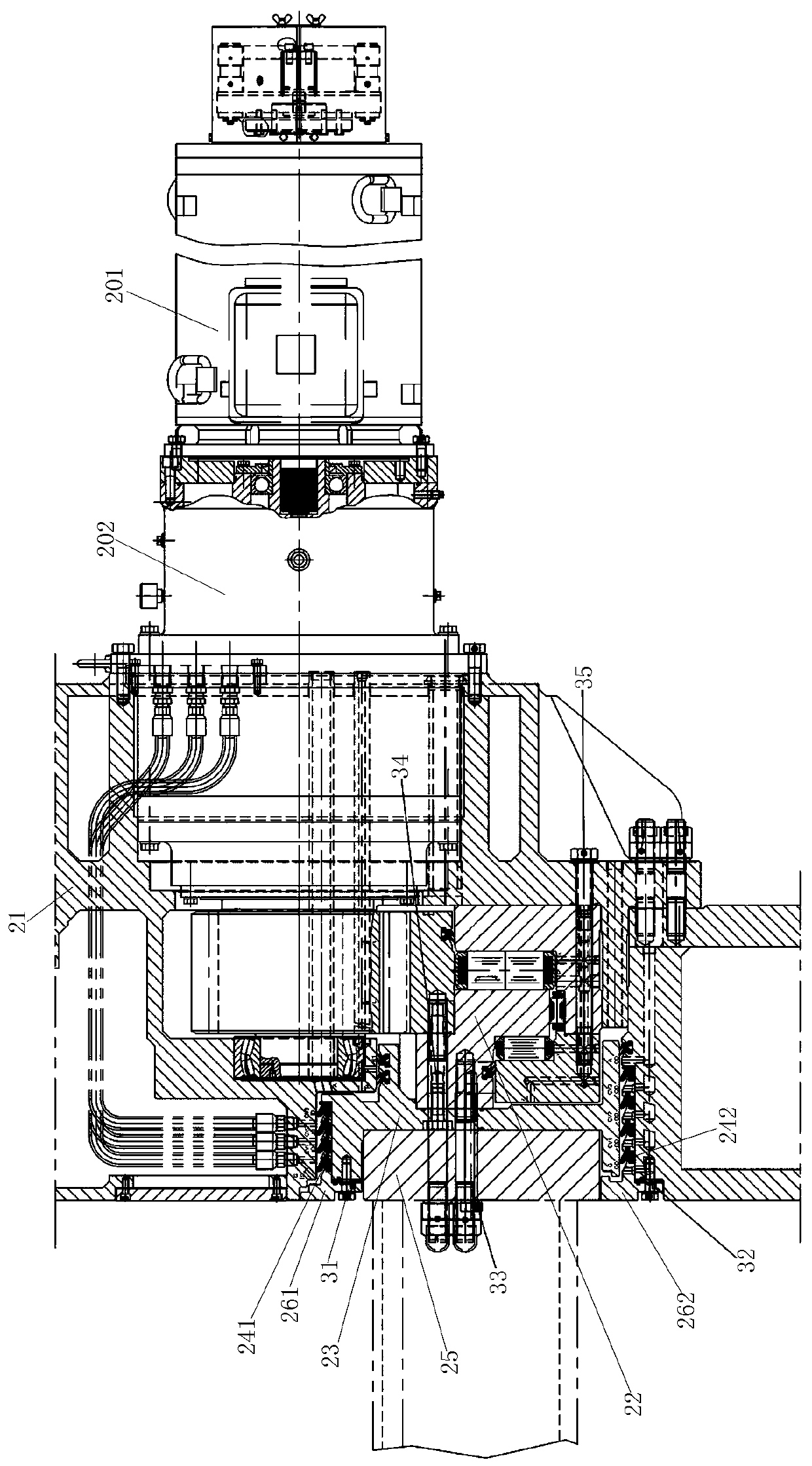

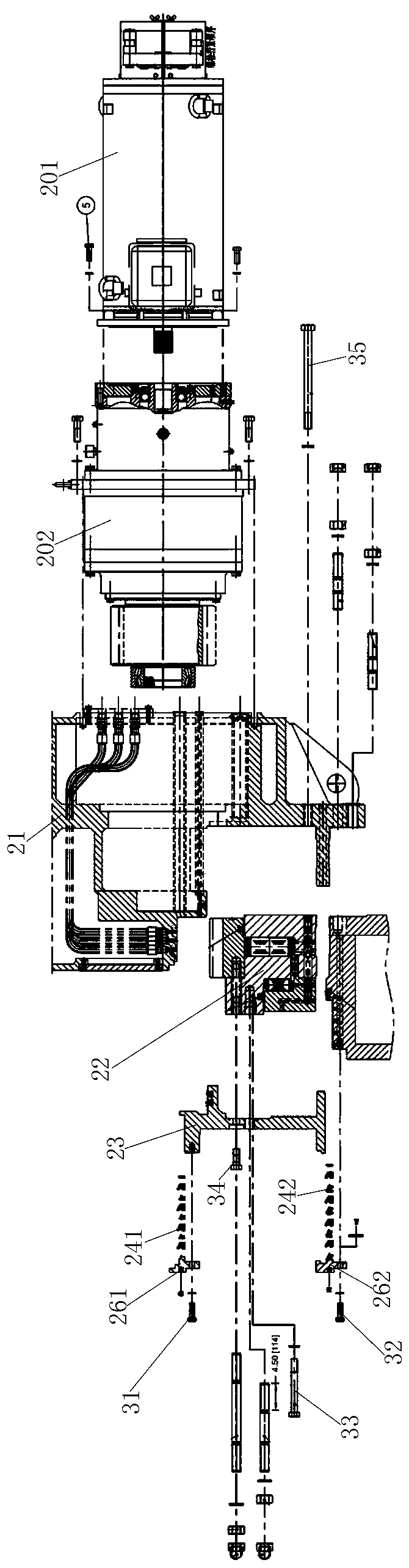

[0051] A dismantling method of the main bearing of the main drive of the shield machine, please refer to Figure 2 to Figure 8 .

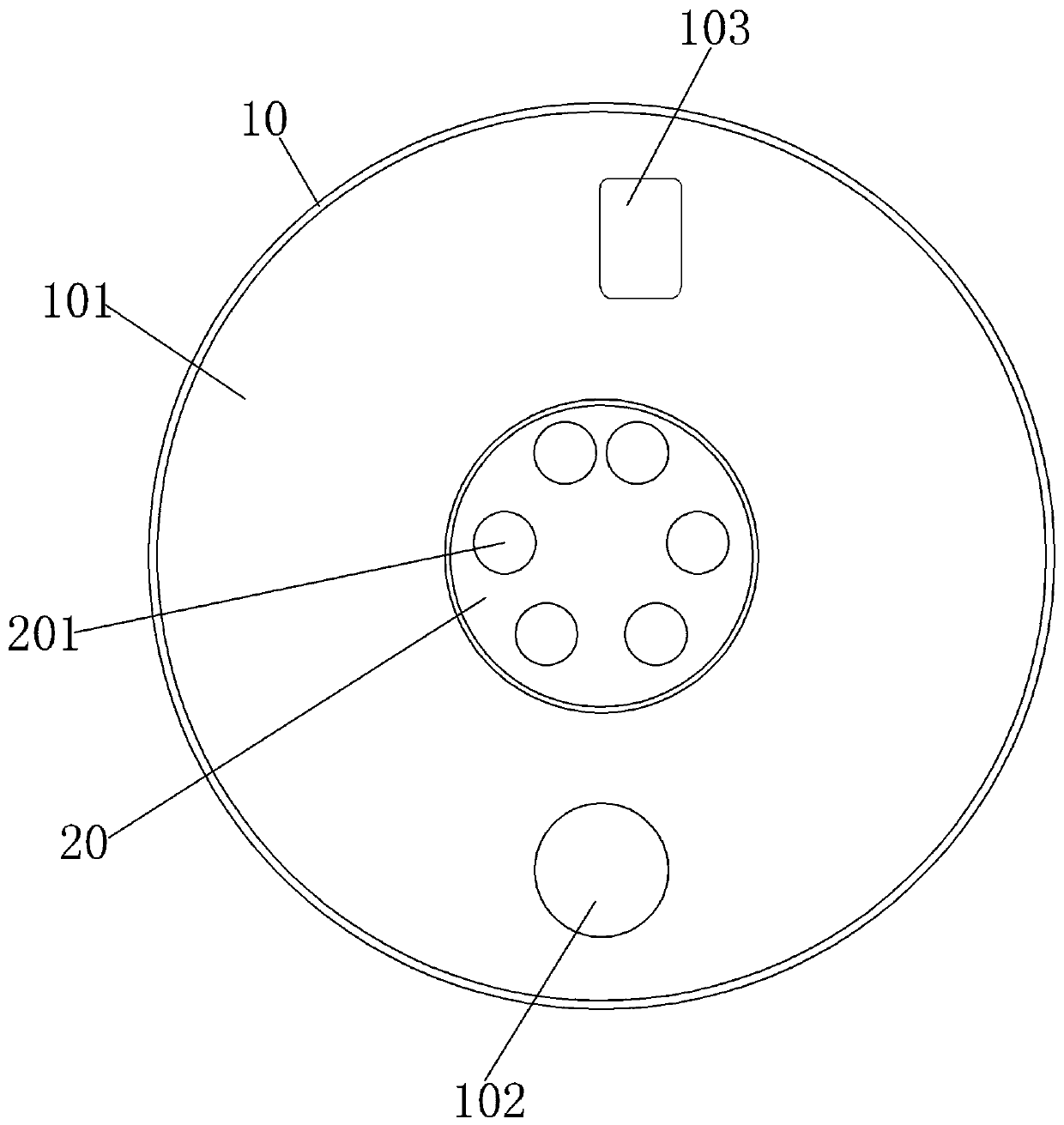

[0052] like figure 2 and image 3 As shown, the main drive of the shield machine disassembled in the embodiment of the present invention includes a main drive box 21, and a main bearing 22 and a sealing slip ring 23 are installed in the front part of the main drive box 21. The gap between the sealing slip ring 23 and the main drive box 21 There are four large lip seals 241 and five small lip seals 242 between them. The front side of the main drive box 21 is equipped with a cutter head drive flange 25 and a lip seal pressure ring. The lip seal pressure ring includes a large lip seal. Sealing pressure ring 261 and small lip-shaped sealing pressure ring 262 .

[0053] The large lip seal pressure ring 261 is used to compress the large lip seal 241 to prevent the large lip seal 241 from breaking away from the gap between the seal slip ring 23 and th...

Embodiment 2

[0067] A maintenance method for the main bearing of a shield machine, please refer to Figure 9 .

[0068] like Figure 9 As shown, the main bearing repaired by the shield machine main bearing maintenance method in the embodiment of the present invention includes an outer ring and an inner ring. The left end cover 223 and the right end cover 224 are connected by bolts screwed into the bolt holes 62, an outer lip seal ring 225 is provided between the spacer ring 222 and the left end cover 223, and an inner lip seal ring 225 is provided between the ring gear 221 and the right end cover 224. The lip seal ring 226 is provided with a main thrust roller 227, a reverse thrust roller 228 and a radial thrust roller 229 between the outer ring and the inner ring.

[0069] The ring gear 221 of the main bearing is driven to rotate by the reducer, so that the outer ring of the main bearing rotates relative to the inner ring. Therefore, the contact surface between the outer lip seal ring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com