Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about How to "Eliminate scrapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

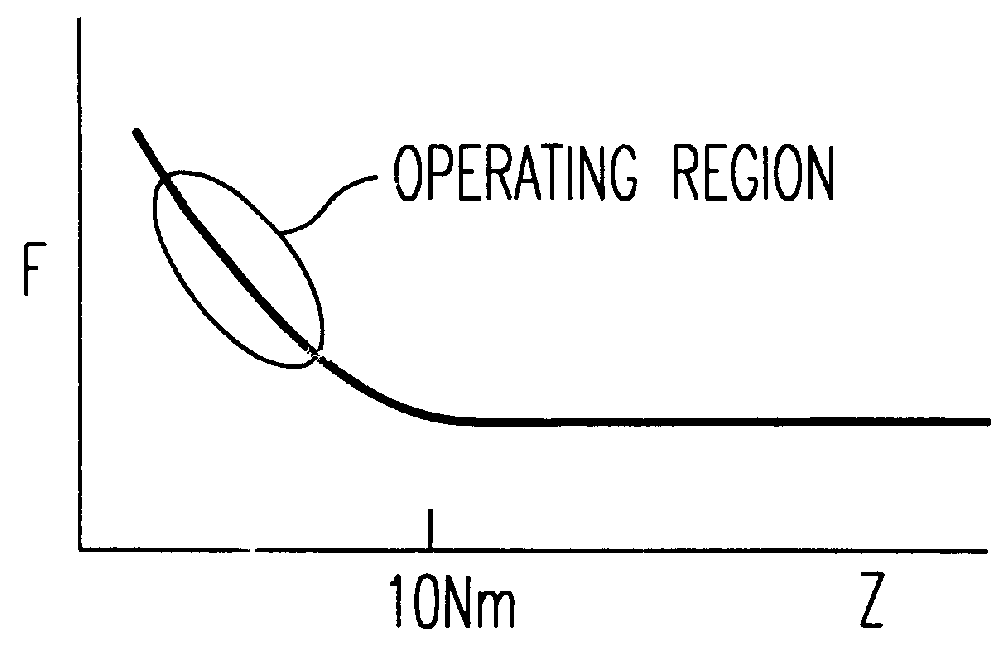

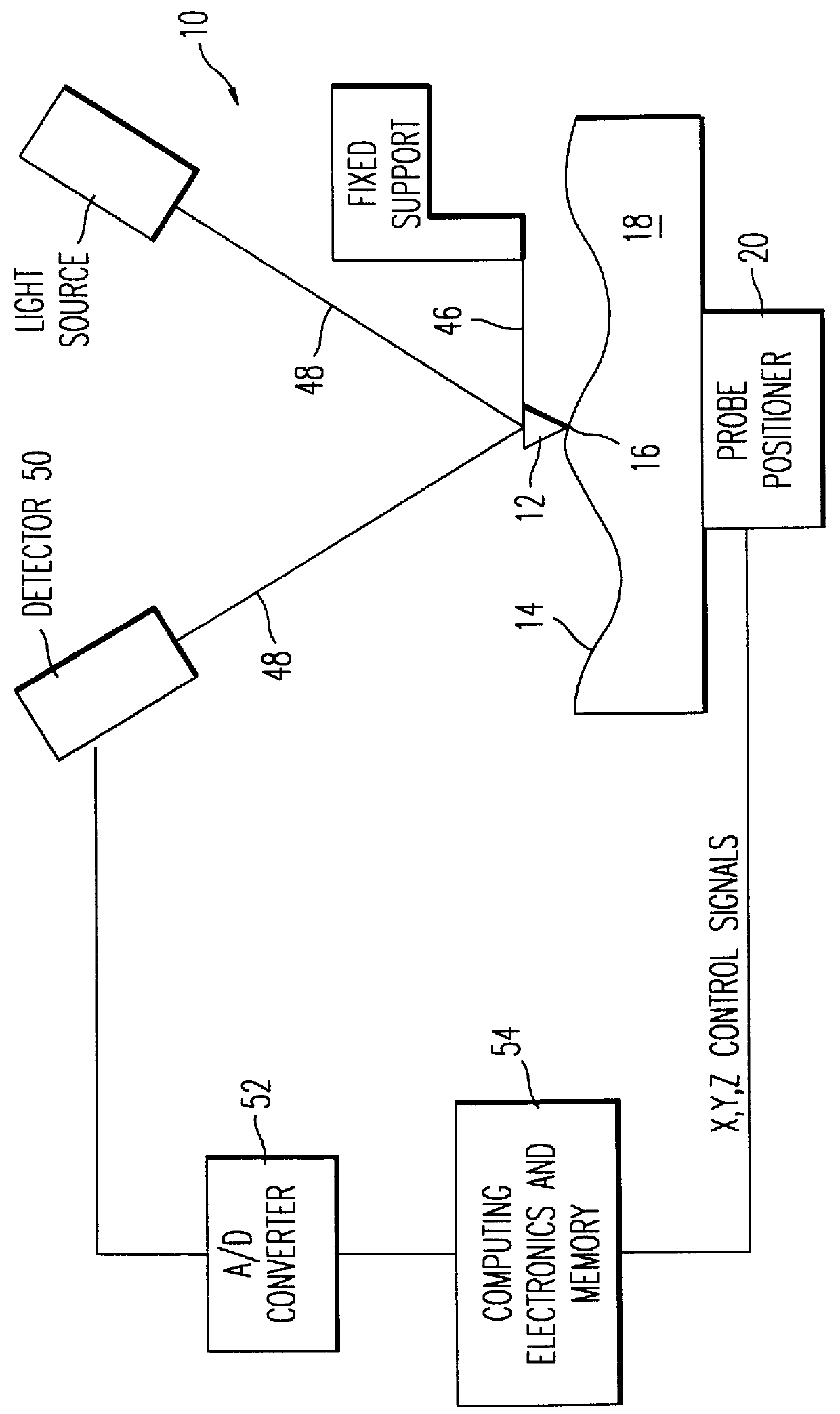

Tapping atomic force microscope with phase or frequency detection

InactiveUSRE36488E1High resolutionHigh sensitivityMaterial analysis using wave/particle radiationBeam/ray focussing/reflecting arrangementsPhysicsMicroscope

An atomic force microscope in which a probe tip is oscillated at a resonant frequency and at amplitude setpoint and scanned across the surface of a sample, which may include an adsorbed water layer on its surface, at constant amplitude in intermittent contact with the sample and changes in phase or in resonant frequency of the oscillating are measured to determine adhesion between the probe tip and the sample. The setpoint amplitude of oscillation of the probe is greater than 10 nm to assure that the energy in the lever arm is much higher than that lost in each cycle by striking the sample surface, thereby to avoid sticking of the probe tip to the sample surface. In one embodiment the probe tip is coated with an antibody or an antigen to locate corresponding antigens or antibodies on the sample as a function of detected variation in phase or frequency. In another embodiment, the frequency of oscillation of the probe tip is modulated and relative changes in phase of the oscillating probe tip observed in order to measure the damping of the oscillation due to the intermittent or constant tapping of the surface by the tip. In a further embodiment, the slope of the phase versus frequency curve is determined and outputted during translating of the oscillating probe. Force dependent sample characteristics are determined by obtaining data at different tapping amplitude setpoints and comparing the data obtained at the different tapping amplitude setpoints.

Owner:BRUKER NANO INC

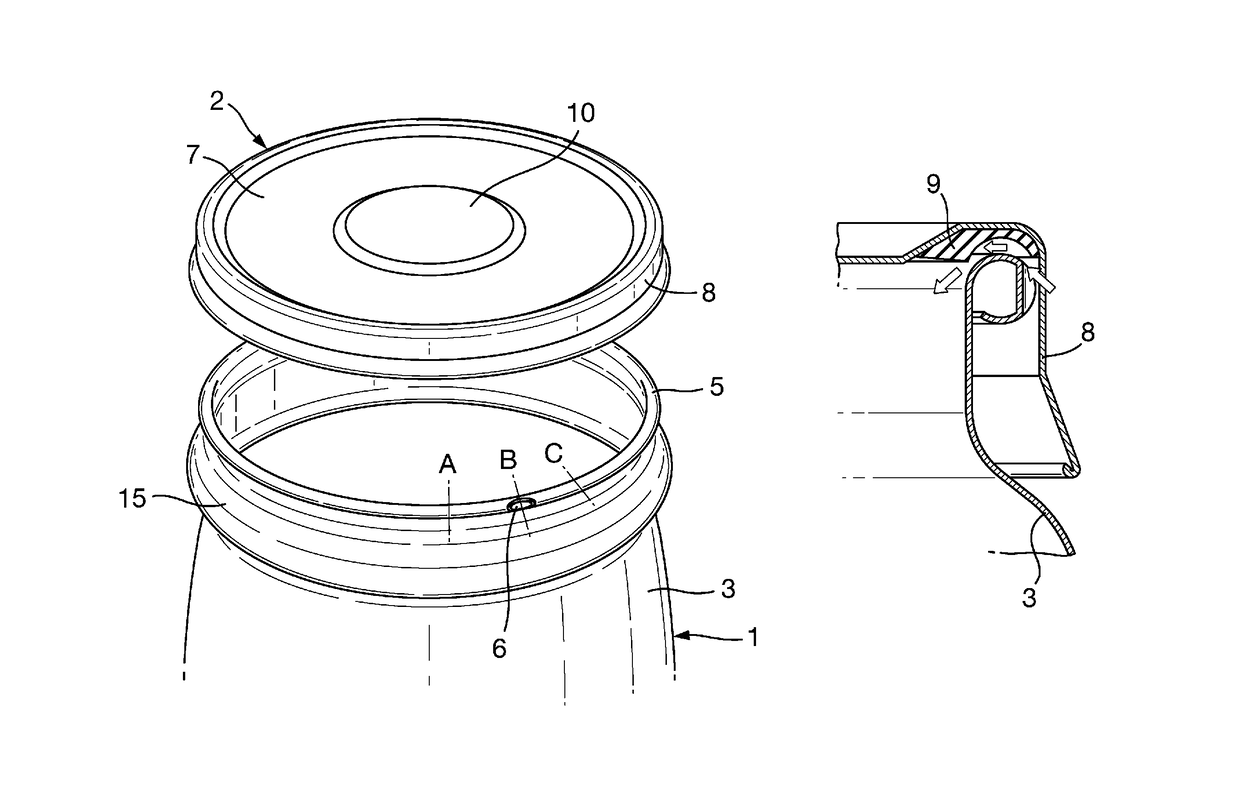

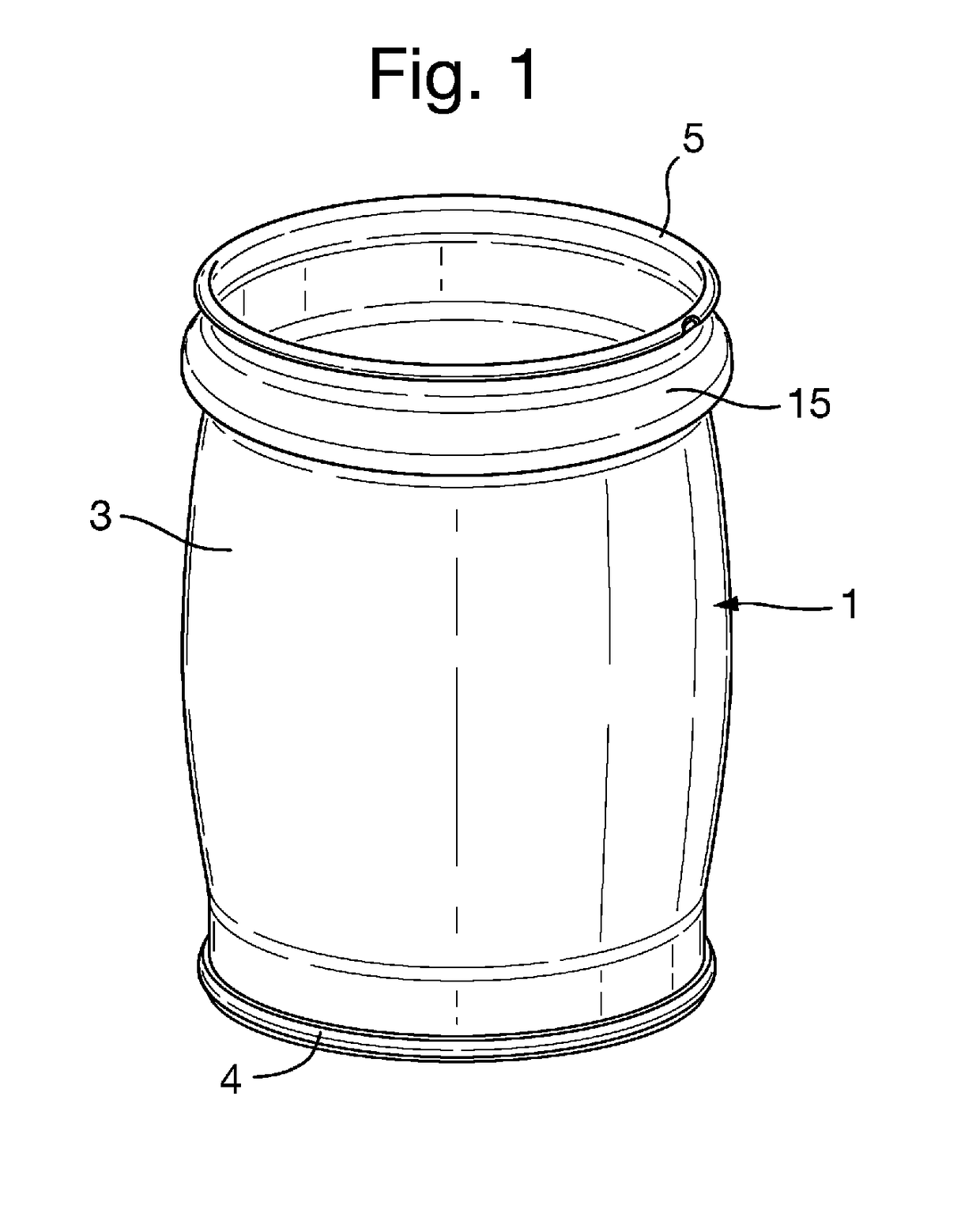

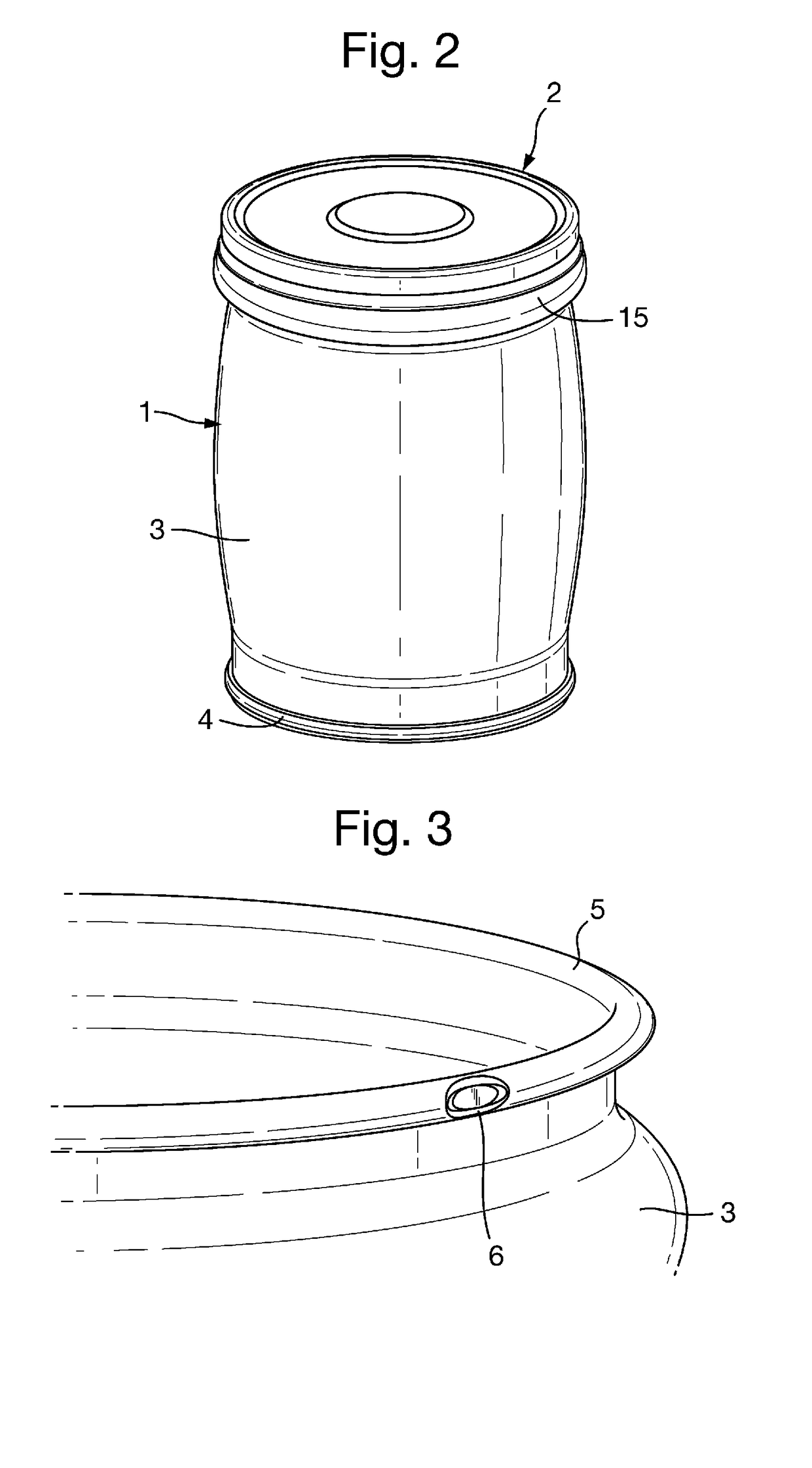

Metal container

A metal container body 1 comprises a base and a generally cylindrical side wall 3. The top edge of the cylindrical side wall is rolled over to form a hollow annular bead 5 surrounding the upper open end of the container body and a notch 6 is formed at a circumferential point in the annular bead. The container body is for use with a releasable closure 2 formed with an end wall 7 and a depending skirt 8 and having an annular layer of sealing material 9 provided on the inside of the end wall adjacent the skirt. When the closure is pressed onto the container body, the annular bead engages the annular layer of sealing material and some of that material extends into the notch 6. The closure is held on the container only by the partial vacuum formed therein during processing of a food product in the container. After processing, the user opens the container by rotating the closure. Sealing material in the notch forces the closure to lift off from the container to break the seal and release the closure.

Owner:CROWN PACKAGING TECH

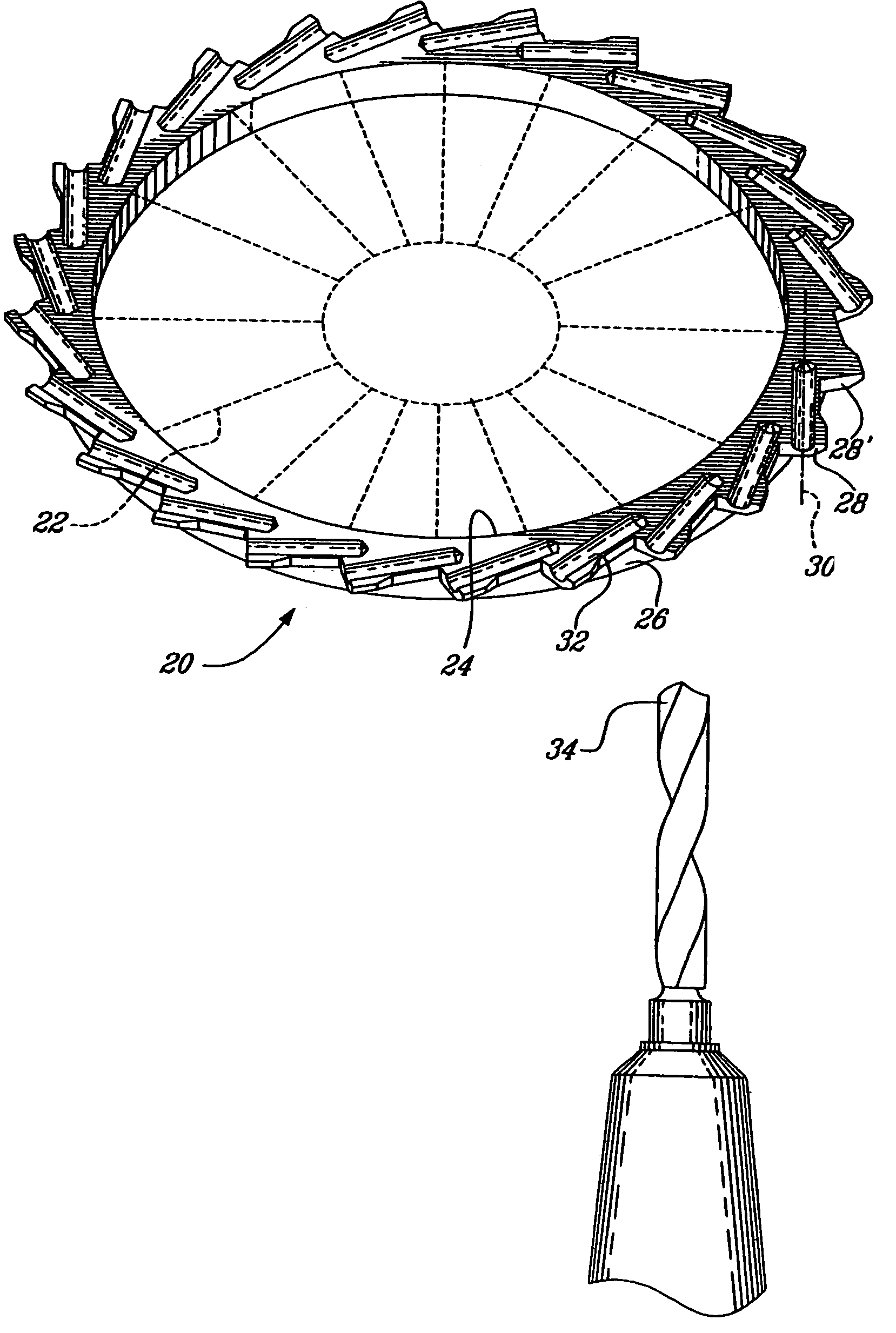

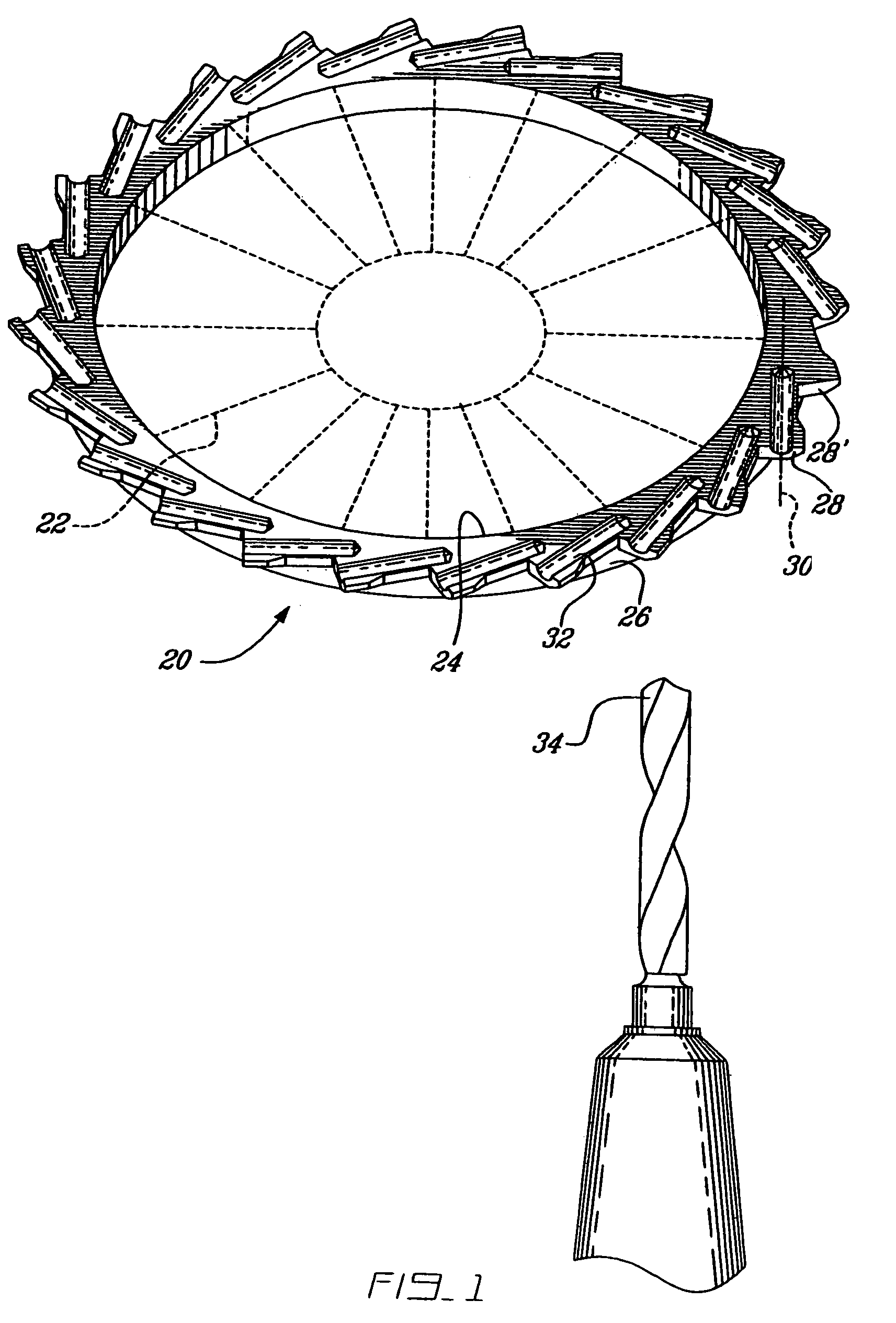

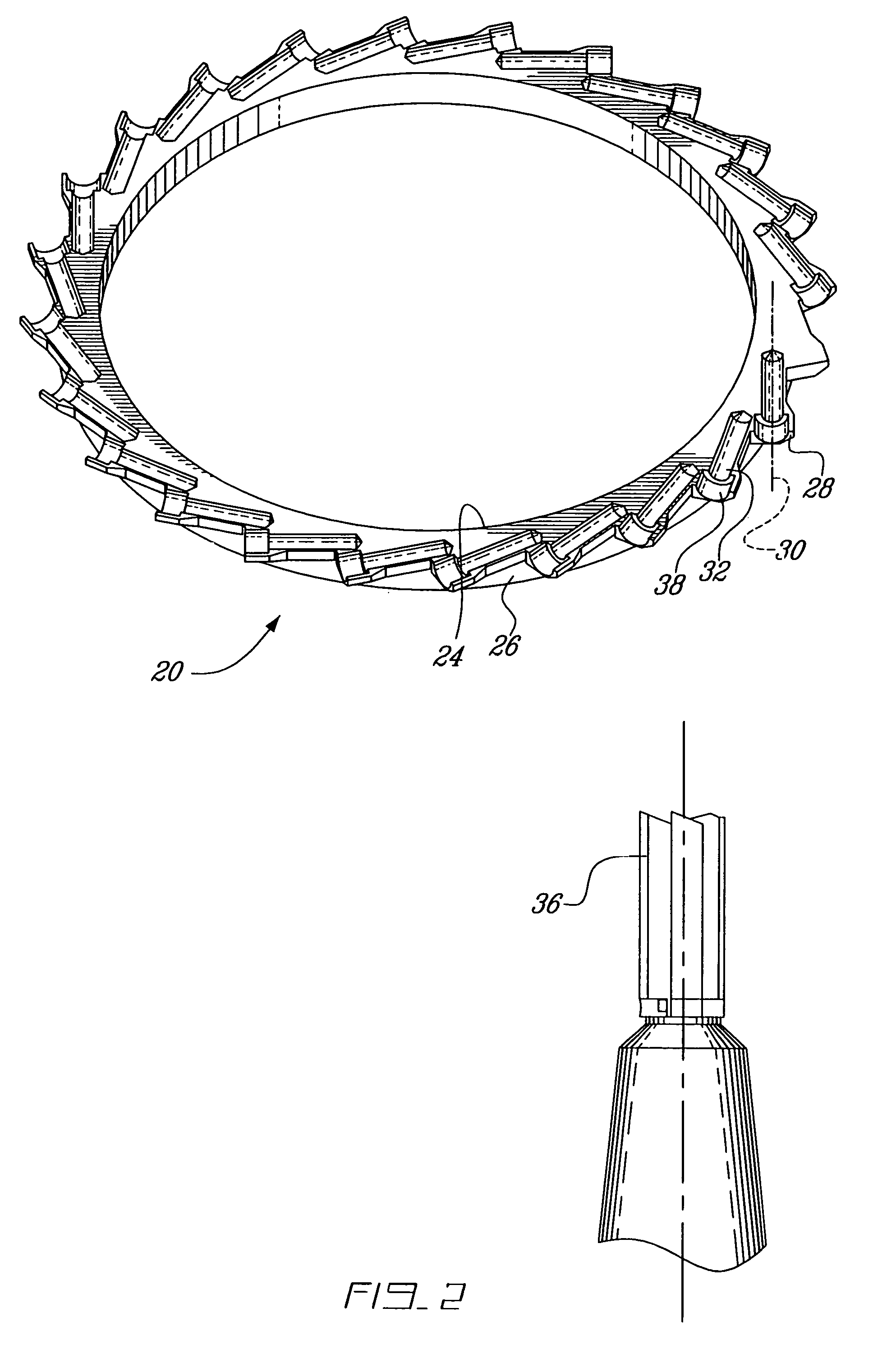

Method of making a gas turbine engine diffuser

InactiveUS7114255B2Minimizes tool deflectionMinimize deflectionEngine manufacturePump componentsTurbineGas turbines

Owner:PRATT & WHITNEY CANADA CORP

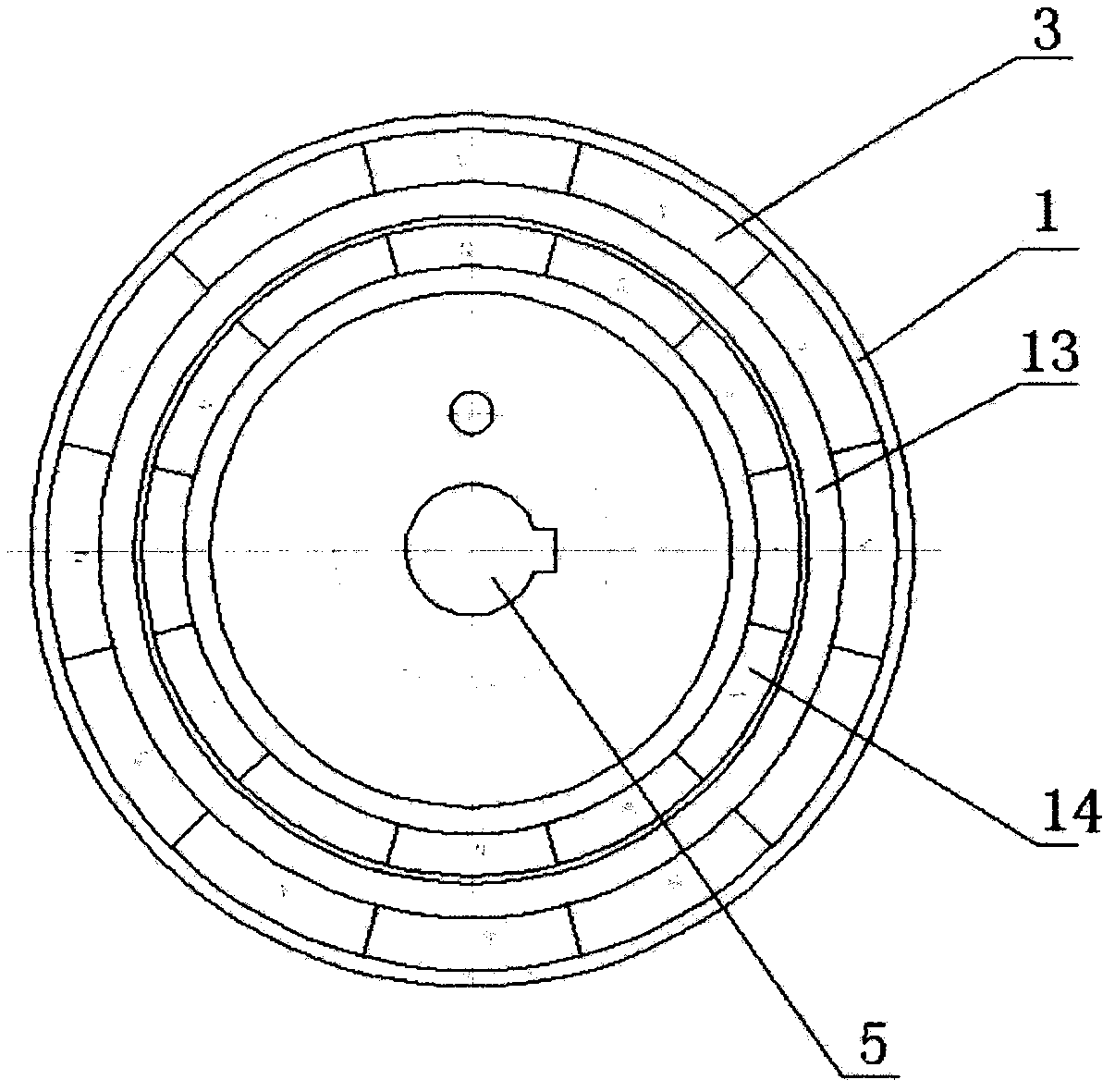

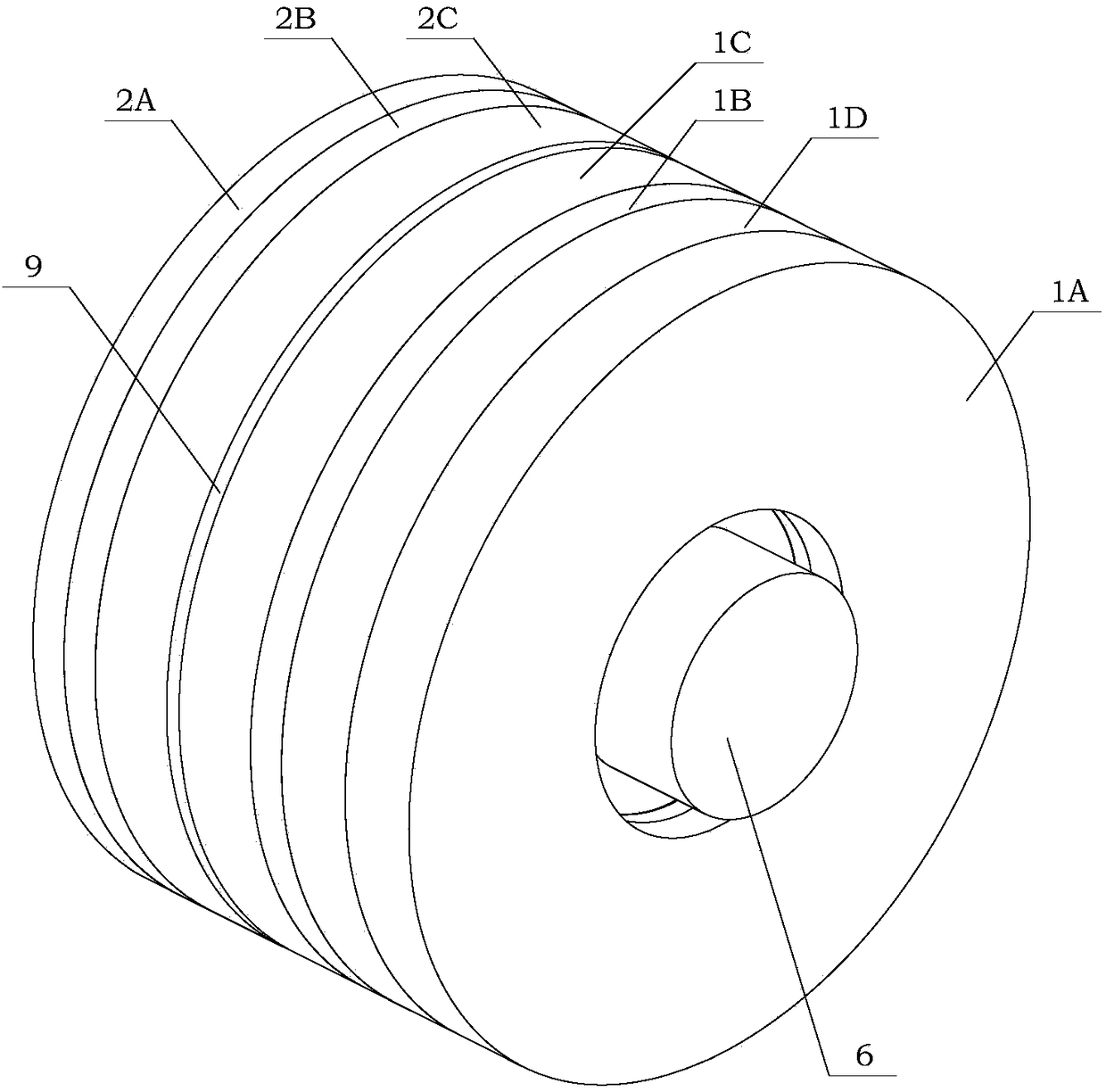

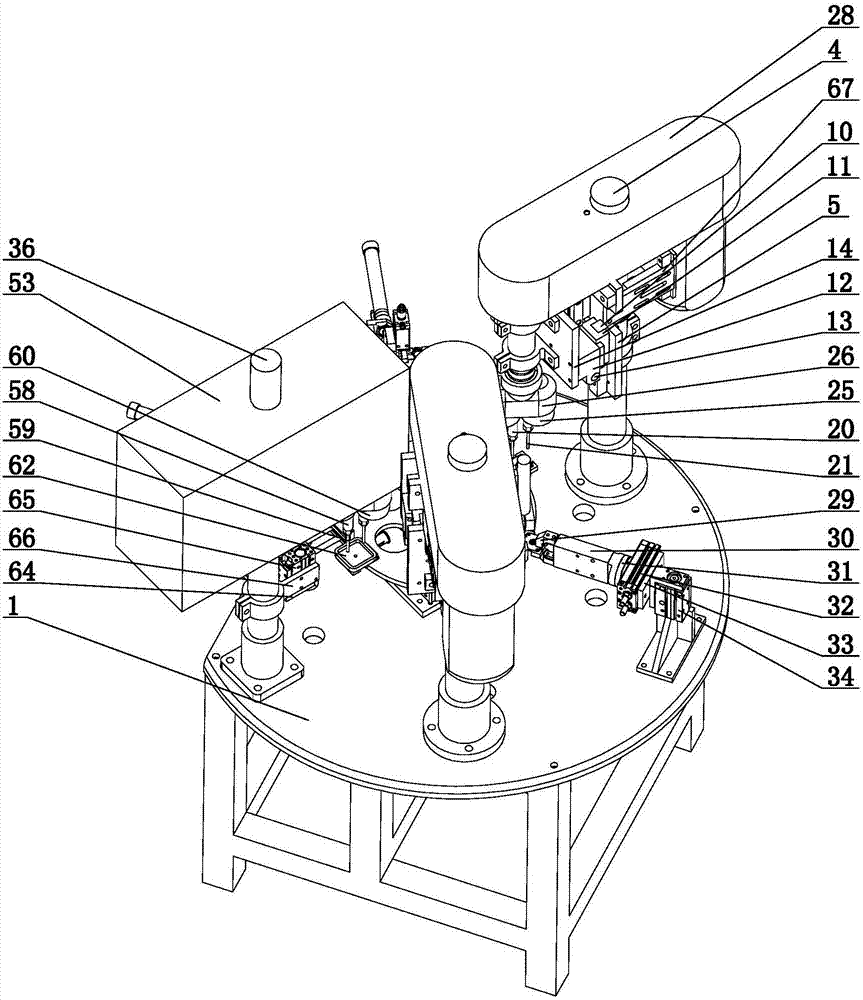

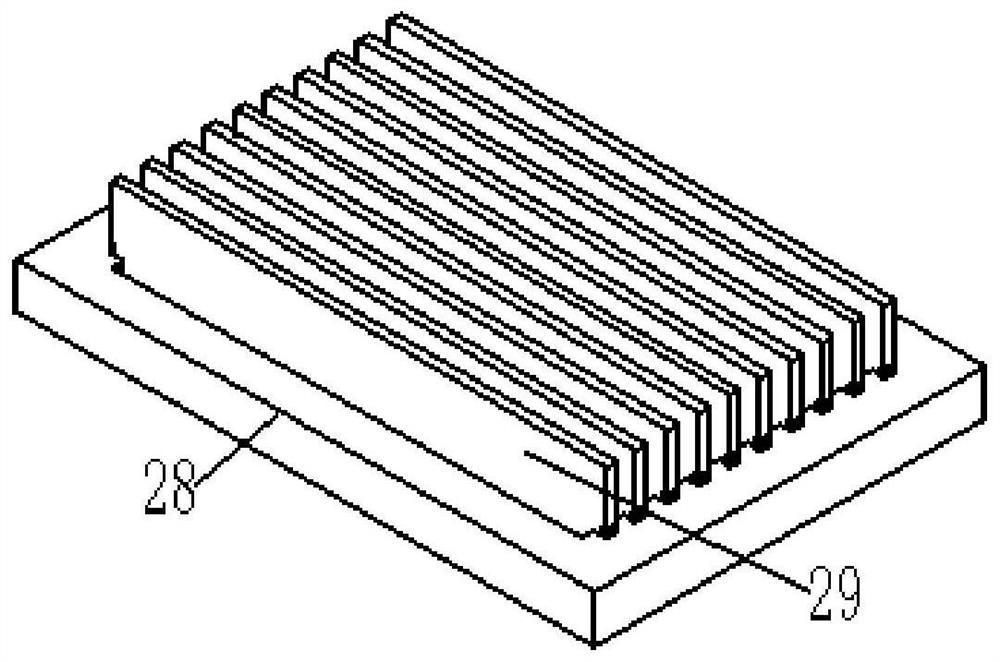

Manufacturing process of magnet rotor in magnetic pump

ActiveCN104242572ANo splashGuarantee welding qualityManufacturing stator/rotor bodiesEngineeringSpot welding

The invention discloses a manufacturing process of a magnet rotor in a magnetic pump. The manufacturing process comprises the following steps that a, a welding tool for the magnet rotor in the magnetic pump is made; b, a magnetic flow coil, multiple magnetic patches and a cushion block are mounted on a rotor base, and a sheath baffle, a sheath and the rotor base are connected in a spot welding mode to form a workblank of the magnet rotor in the magnetic pump; c, the workblank of the magnet rotor in the magnetic pump is taken up and placed on the welding tool for the magnet rotor in the magnetic pump; d, the sheath baffle is welded to the rotor base, the left end and the right end of the sheath are welded to the rotor base and the sheath baffle respectively, and then a semi-finished piece of the magnet rotor in the magnetic pump is made; e, the semi-finished piece of the magnet rotor in the magnetic pump is machined, and a finished piece of the magnet rotor in the magnetic pump is obtained if the machined piece passes inspection. In this way, the manufacturing process of the magnet rotor in the magnetic pump has the advantages that no splashing occurs in the welding process, welding quality can be guaranteed, product scrapping caused by internal stress is also eliminated, the product percent of pass is increased, and manufacturing cost is lowered.

Owner:安徽星球盛唐泵业有限公司

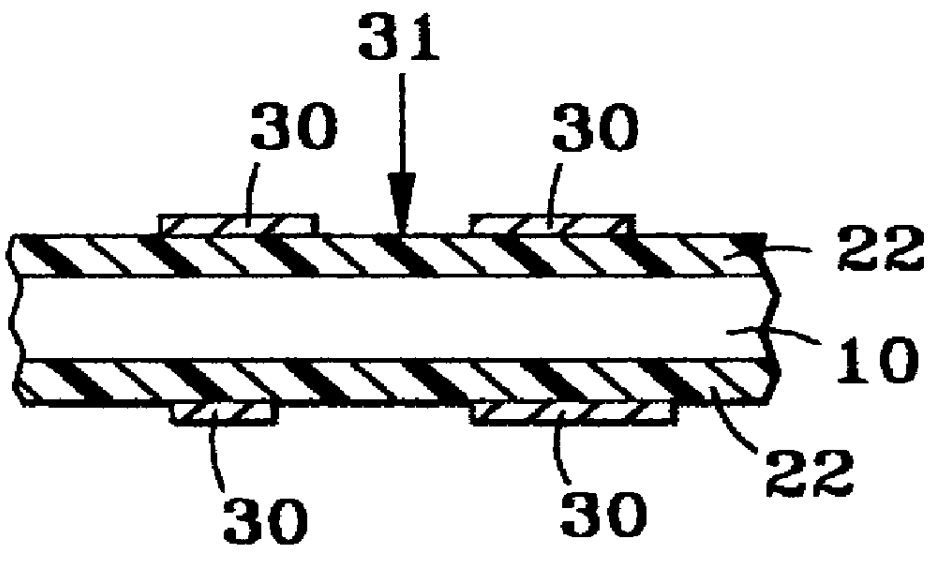

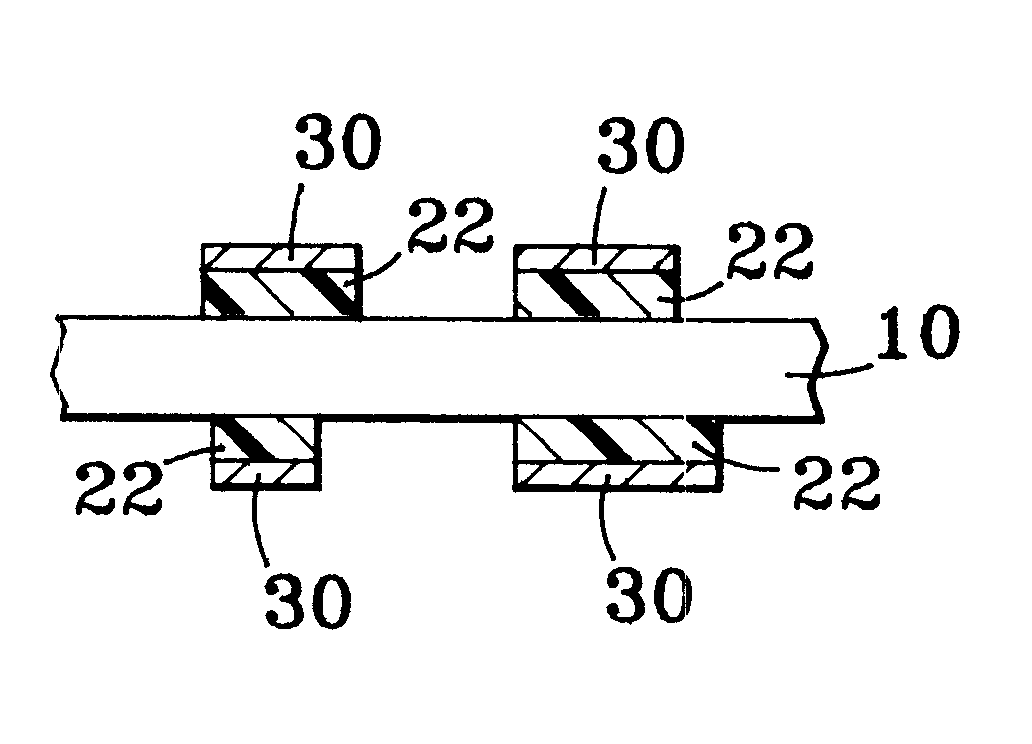

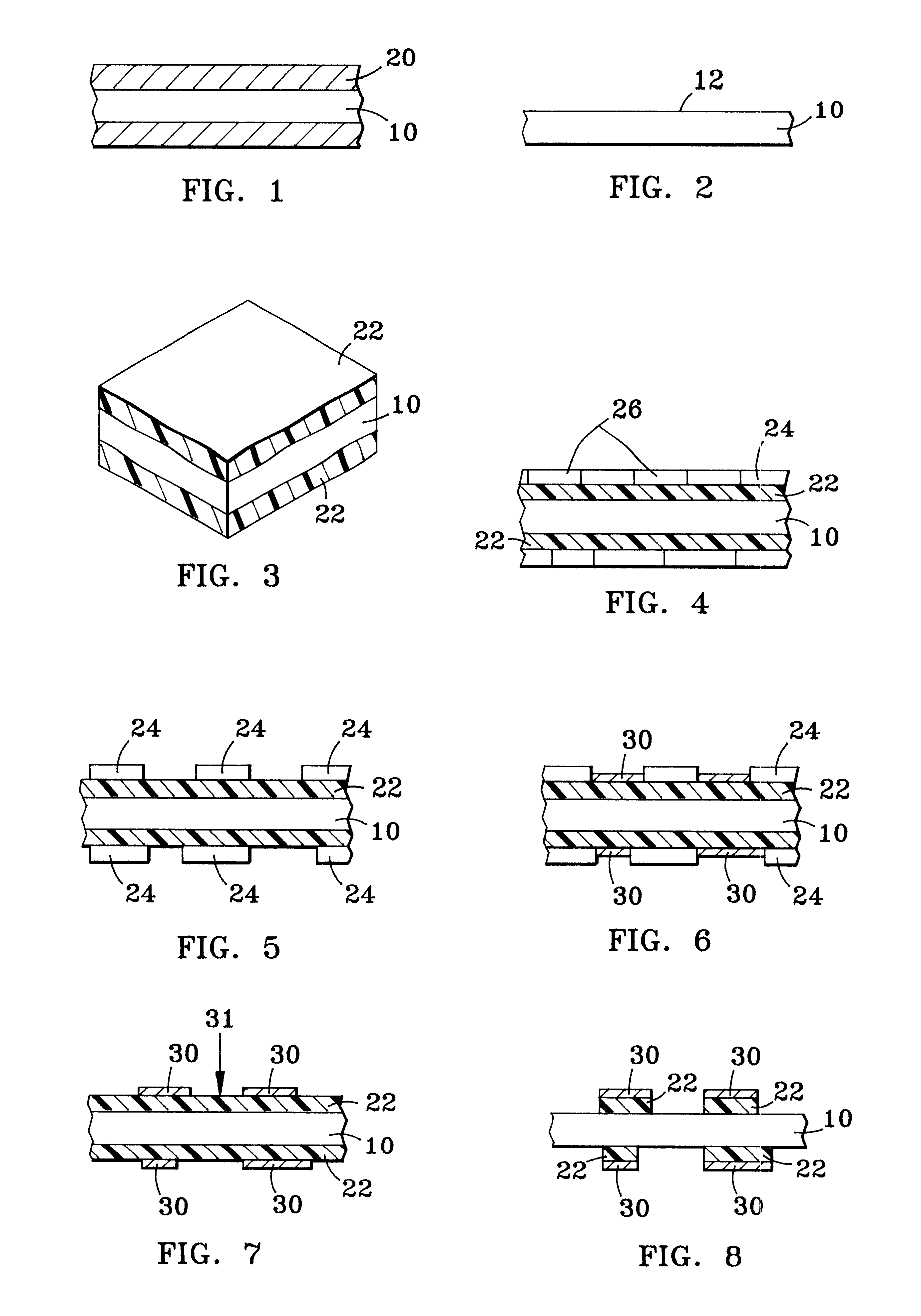

Process for removal of undersirable conductive material on a circuitized substrate and resultant circuitized substrate

InactiveUS6063481AEliminate electrical shortingEliminate scrappingPrinted circuit aspectsDomestic articlesCyanide compoundPERMANGANATE ION

A process for removal of undesirable conductive material (e.g., catalyst material and seeped circuit material) on a circuitized substrate and the resultant circuitized substrates disclosed. Such process and resultant circuit effectively address the electrical shorting problems caused by nonremoval of the residual catalyst material and circuit material which has seeped under the residual catalyst material. The process includes the steps of: a) providing a catalyst layer (e.g., palladium and tin) having circuit pattern (e.g., copper) thereon; b) pretreating the catalyst layer and the circuit pattern (e.g., with a cyanide dip) for removal of undesirable portions of each which cause electrical leakage between circuit lines of the circuit pattern; c) oxidizing the catalyst layer and the circuit pattern (e.g., with chlorite, permanganate, hydrogen peroxide, or air at a temperature elevated above ambient conditions); and d) removing the undesirable portions of the catalyst layer and the undesirable portions of the circuit pattern (e.g., with a cyanide submersion). The resultant circuitized substrate includes a circuit pattern on a catalyst layer wherein undesirable portions of the catalyst layer and circuit pattern are completely removed between the circuit features of the circuit pattern so that electrical leakage between the circuit features does not occur.

Owner:META PLATFORMS INC

Expendable casting process method for heat-resistant steel perforated grate plate

An expendable casting process method for a heat-resistant steel perforated grate plate comprise employing a copolymerization material for foaming for preparing an expendable-casting-process heat-resistant steel perforated grate plate foam model, singly preparing a pouring gate, binding the heat-resistant steel perforated grate plate model with the pouring gate for combination, so as to form a combined model; putting the combined model in a special coating pool for three-time sagging of a coating and three-time baking, and controlling the accumulated thickness of the coating subjected to three-time baking to be 0.8 mm-1.5 mm; again combining the baked combined model in a negative-pressure sandbox by taking 10 models as a pouring body, and forming two pouring bodies; adding sand into the sandbox and compacting through shaking; vacuumizing the sandbox and performing oxygen-enriched combustion on the model to form a hollow shell; and finally performing casting. The casting method is simple in steps, convenient to operate, high in casting efficiency and good in effect, is capable of effectively improving the surface quality of the casting and preventing disadvantages that the casting generates burnt-on sand, sand inclusions, pores and carburets, and helps to reduce labor intensity and save production cost.

Owner:渠县金城合金铸业有限公司

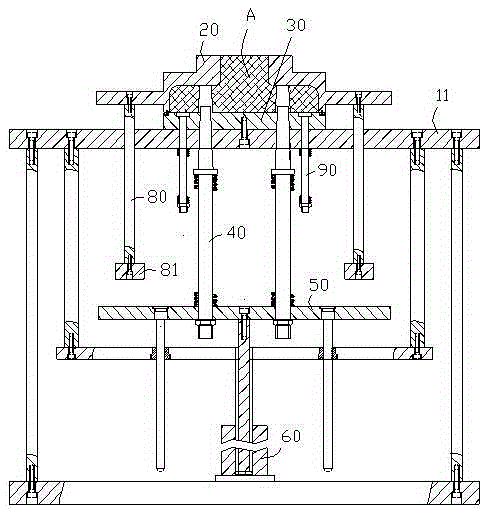

Casting mould structure capable of pulling core firstly and then ejecting

ActiveCN105290331AReduce manufacturing costExtend your lifeFoundry mouldsFoundry coresHydraulic cylinderMolten metal

The invention provides a casting mould structure capable of pulling a core firstly and then ejecting. The casting mould structure comprises a rack as well as a movable mould, a fixed mould, a movable core rod, an ejector board and a hydraulic cylinder which are arranged on the rack, wherein the movable mould and the fixed mould are arranged up and down; the movable mould and the fixed mould are in mutual contact and form a mould cavity; when the mould works, molten metal is firstly poured into the mould cavity from a sprue of the movable mould, and then, the ejector board is pulled down by virtue of the hydraulic cylinder to drive the movable core rod to move downwards and separate from a through hole of a product, so that shrinkage stress is released; after a product is molded, the movable mould and the product are ejected sequentially through a top mould rod and an ejector rod; and the casting mould structure is suitable for mould opening of the product with the through hole, so that the product with the through hole is prevented from a cracking phenomenon during mould opening.

Owner:安徽熠辉新材料有限公司

Method for manufacturing rotating shuttle inner shuttle through injection molding method

The invention discloses a method for manufacturing a rotating shuttle inner shuttle through an injection molding method. The rotating shuttle inner shuttle adopts the following alloy material: Fe2NiMo, FeCrMo or FeCr; and the manufacturing method of the rotating shuttle inner shuttle comprises the following steps: firstly, performing segregation-free mixing on raw material alloy powder, secondly, performing alloying treatment on the raw material alloy powder, thirdly, grinding and screening the raw material alloy powder, fourthly, performing feed preparation on the raw material alloy powder, fifthly, performing injection molding on feed, sixthly, sintering a molded rotating shuttle inner shuttle, seventhly, performing surface shaping treatment, so as to achieve the required size, and eighthly, performing sandblasting or polishing treatment on the surface of the rotating shuttle inner shuttle. The method has the advantages that Fe2NiMo, FeCrMo or FeCr is adopted as raw material, so that composition segregation and unnecessary internal impurities are eliminated, and the sintering and shrinkage uniformity of the product is good.

Owner:ZHEJIANG YIHUO TECH

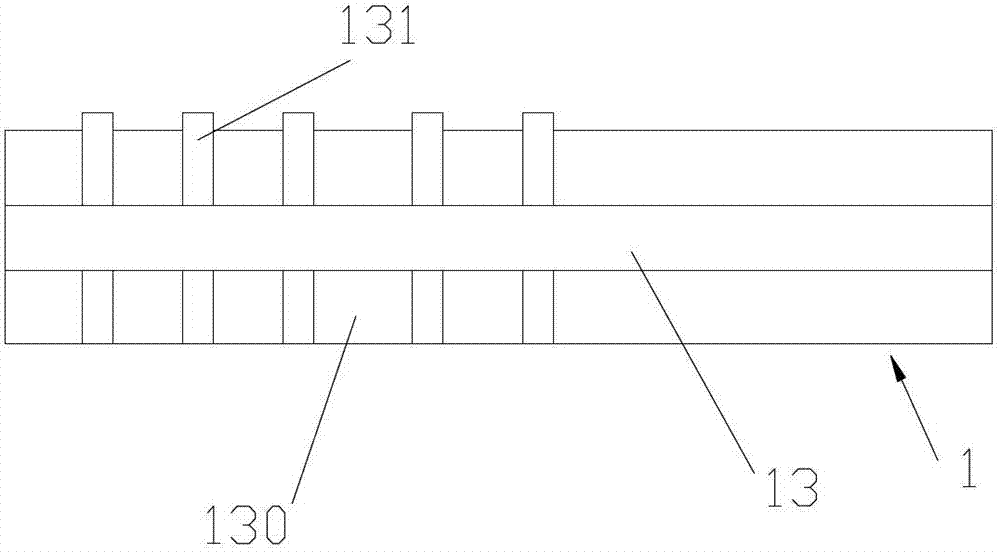

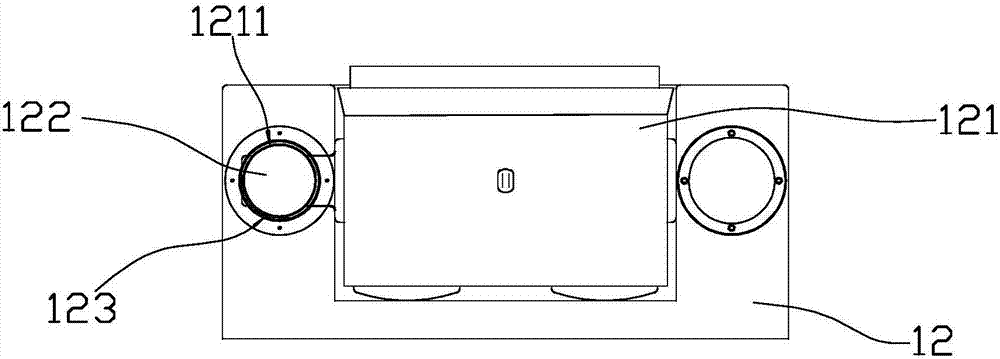

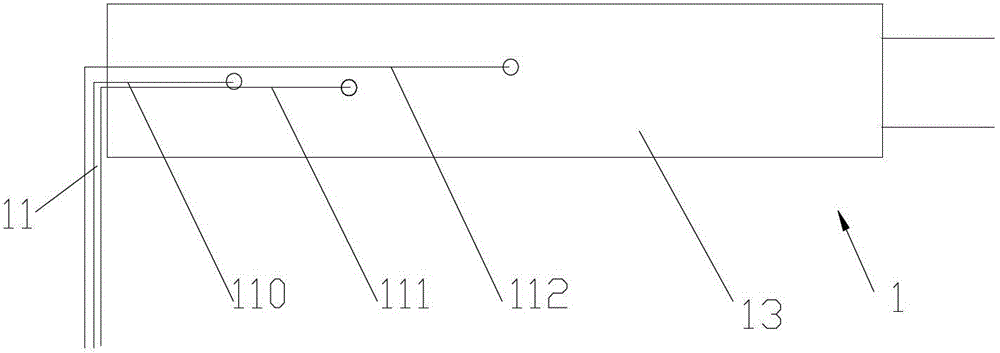

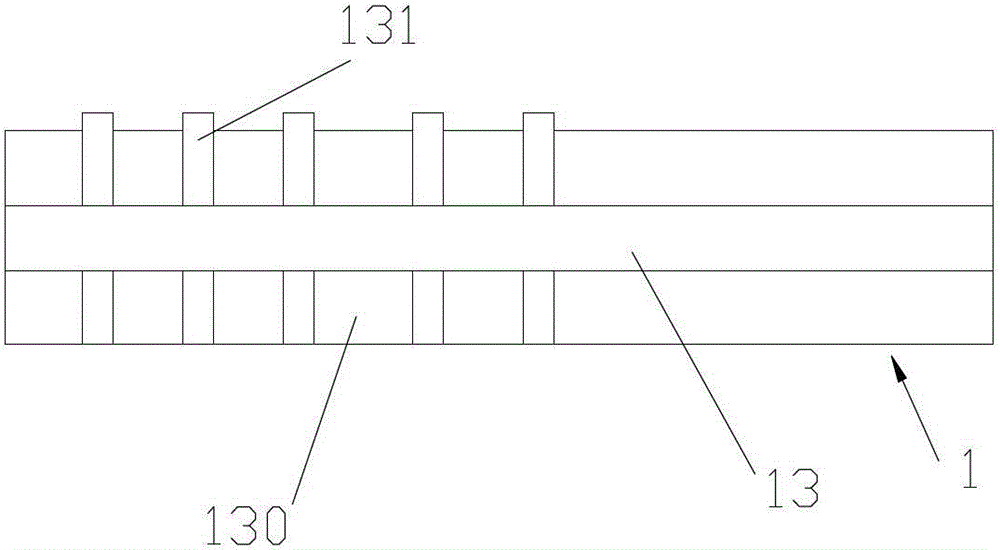

Storage rack for electric energy meters

ActiveCN107032026AEliminate scrappingEasy to keepStorage devicesConveyor partsEngineeringManipulator

The invention relates to a storage rack for electric energy meters. The storage rack comprises a storage frame, a navigation frame, a walking frame, a lifting driving assembly and a mechanical arm part; the storage frame comprises a plurality of columnar vertical plates which are distributed at intervals, and a plurality of layers of conveyance and pickup units are arranged between every two adjacent columnar vertical plates; the conveyance and pickup units comprise conveying belts and pickup guide plates arranged right below the conveying belts, U-shaped sliding chutes are formed in the pickup guide plates, and bearing slides are arranged inside the U-shaped sliding chutes in a matched mode and can slide in the U-shaped sliding chutes; the navigation frame is fixed to the inner end side of the storage frame; the walking frame is arranged on the navigation frame and moves between every two adjacent columnar vertical plates in a reciprocating mode; the mechanical arm part is installed on a base (lifting base) of the lifting driving assembly; the base of the lifting driving assembly can move up and down; and a mechanical arm of the mechanical arm part can be matched with the lifting base through a rod part extending and contracting in the linear direction from inside to outside. According to the storage rack, conditions can be created for implementing the first-in-first-out warehouse-out principle for the electric energy meters, and the problem that the existing electric energy meters are scrapped due to too long storage time can be solved.

Owner:BEIJIG YUPONT ELECTRIC POWER TECH

Manufacturing process of magnetic rotor in magnetic pump

ActiveCN104242572BNo splashGuarantee welding qualityManufacturing stator/rotor bodiesRotor magnetsEngineering

Owner:安徽星球盛唐泵业有限公司

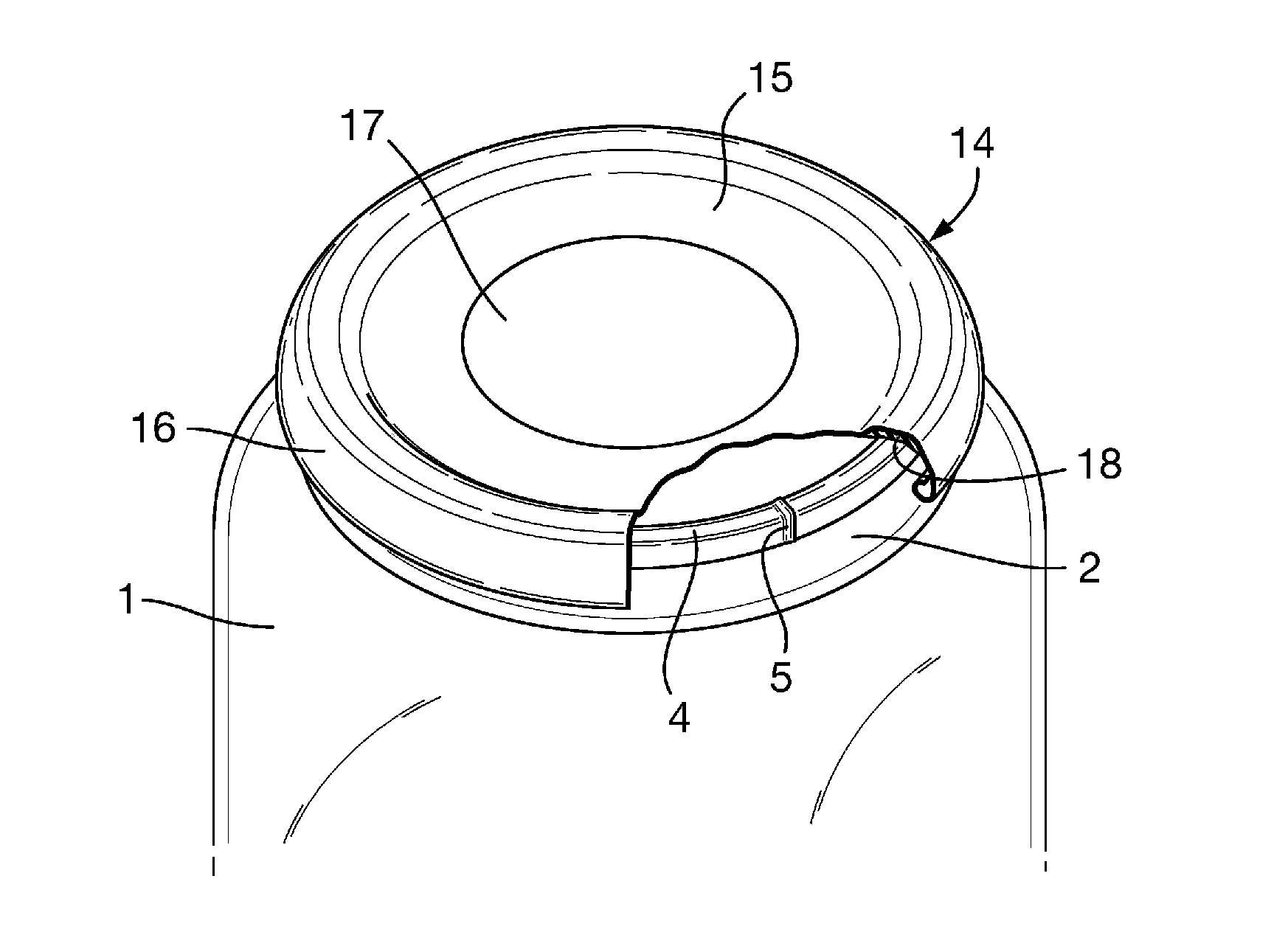

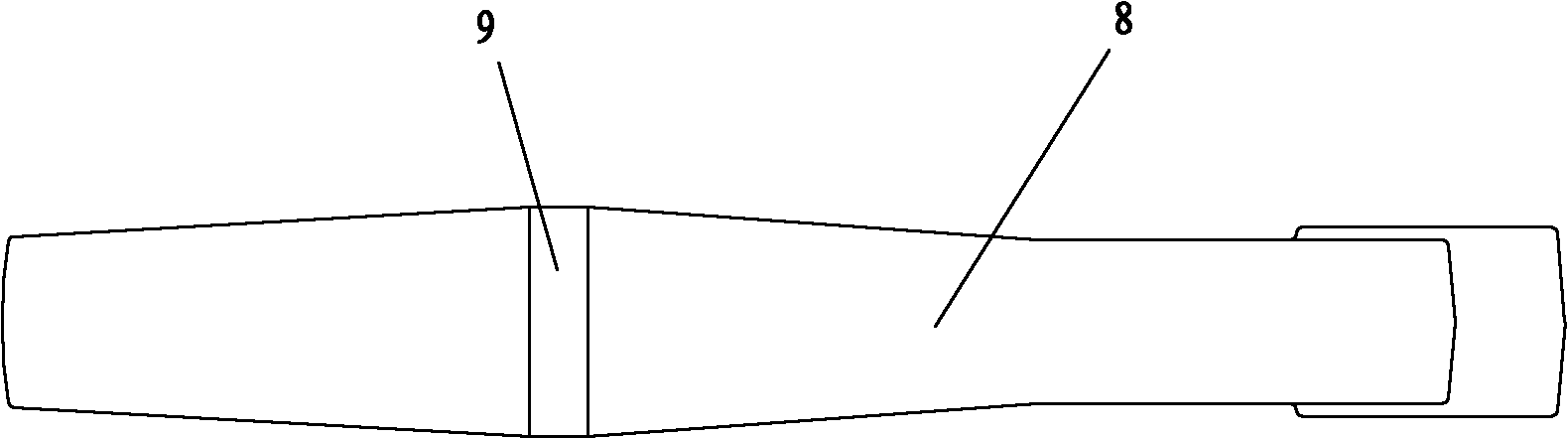

Container with twist-off closure

ActiveUS20150108132A1Reduction in opening torqueOpening torqueCapsClosure capsEngineeringLocalised protrusion

A container comprises a releasable metal closure 14 formed with an end wall 15 and a depending skirt 16 and having an annular layer 18 of sealing compound provided on the inside of the end wall adjacent the skirt and a container body 1 comprising a neck 2 with an annular sealing surface 4 surrounding a circular opening and adapted to seal against the annular layer of sealing compound over an annular sealing interface in the closed position of the closure on the container body. The container body 1 and the closure 14 are formed with no mechanical means for coupling them together to form or maintain a seal therebetween and the seal is provided by a partial vacuum formed in the container during processing. The annular sealing surface 4 of the container body 1 is formed with a localised protrusion 5 or recess 10 which provides a discontinuity in the annular sealing interface, whereby relative rotation of the closure 14 and container body 1 from the closed position creates a venting path from the interior of the container body to the exterior so that the seal is broken and the closure is released.

Owner:CROWN PACKAGING TECH

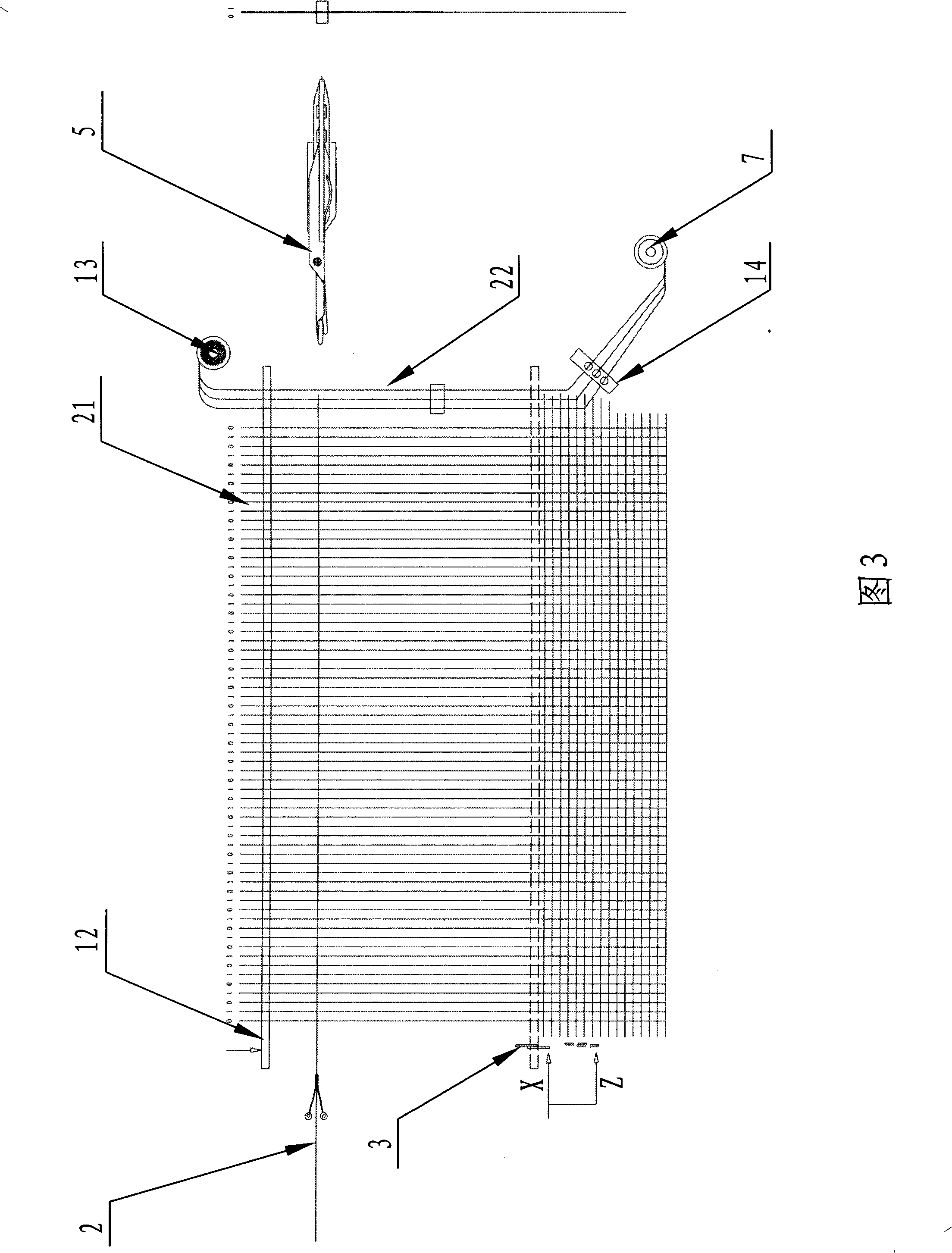

Method for economizing material of gripper loom and apparatus thereof

The invention relates to a method for saving materials for a gripper loom and a device thereof. A movable scissors device is arranged on the position on one side of the gripper loom, which is fixed with scissors previously; a warp edge thread feed wheel, a warp edge thread separating mechanism and a warp edge thread winding device are arranged on the other side of the gripper loom; on one side of the movable scissors device, when a woof feed mechanism of the gripper loom pushes forward, the movable scissors device withdraws to avoid impacting with the woof feed mechanism, while the woof feed mechanism returns, the movable scissors device returns back, and cut off a woof yearn; and on the other side of the movable scissors device, a warp edge thread used for nipping the woof yarn to move from the warp edge thread feed wheel towards the warp edge thread winding device, and passes through the warp edge thread separating mechanism in the middle, and under the action of the warp edge thread separating mechanism, the warp edge thread is separated from the woof yarn which is knitted in a knitting area. Through the method and the device, the invention has the advantage of effectively saving materials.

Owner:陈仲纪

Process for removal of undesirable conductive material on a circuitized substrate and resultant circuitized substrate

InactiveUS6544584B1Eliminate electrical shortingEliminate scrappingPhotomechanical apparatusSemiconductor/solid-state device manufacturingCyanide compoundConductive materials

A process for removal of undesirable conductive material (e.g., catalyst material and seeped circuit material) on a circuitized substrate and the resultant circuitized substrates disclosed. Such process and resultant circuit effectively address the electrical shorting problems caused by nonremoval of the residual catalyst material and circuit material which has seeped under the residual catalyst material. The process includes the steps of: a) providing a catalyst layer (e.g., palladium and tin) having circuit pattern (e.g., copper) thereon; b) pretreating the catalyst layer and the circuit pattern (e.g., with a cyanide dip) for removal of undesirable portions of each which cause electrical leakage between circuit lines of the circuit pattern; c) oxidizing the catalyst layer and the circuit pattern (e.g., with chlorite, permanganate, hydrogen peroxide, or air at a temperature elevated above ambient conditions); and d) removing the undesirable portions of the catalyst layer and the undesirable portions of the circuit pattern (e.g., with a cyanide submersion). The resultant circuitized substrate includes a circuit pattern on a catalyst layer wherein undesirable portions of the catalyst layer and circuit pattern are completely removed between the circuit features of the circuit pattern so that electrical leakage between the circuit features does not occur.

Owner:INT BUSINESS MASCH CORP

Strategically placed large grains in superalloy casting to improve weldability

ActiveUS20100025382A1Cracking is reduced and eliminatedReduce crackingTurbinesPolycrystalline material growthRegioselectivitySuperalloy

Process for reducing cracking in superalloy metal components by selectively growing large single grains during the casting operation at a region where fusion welding will be required.

Owner:GENERAL ELECTRIC CO

Tool for drilling central holes of steering knuckle arm

InactiveCN102009207APrecise positioningGuaranteed coaxialityPositioning apparatusBoring/drilling componentsEngineeringKnuckle

The invention discloses a tool for drilling central holes of a steering knuckle arm, comprising a pedestal and a support, the pedestal is provided with a fixing hole, the support is vertically installed with the pedestal, the support is provided with an upper V-shaped block and a lower V-shaped block directly below the upper V-shaped block, and the pedestal is provided with a location device. The upper V-shaped block and the lower V-shaped block are same in size and have accordant V-shaped openings. The location device is a flute located on the pedestal. The location device is a conic tip fixed on the pedestal. The tool provided by the invention is accurate in location, centers of the central holes of two ends are in same straight line, so that axiality is ensured, and products discarding caused by axiality error is eliminated; the tool is simple and practical, convenient in operation and high in processing efficiency.

Owner:WUHU XINDA FORGING

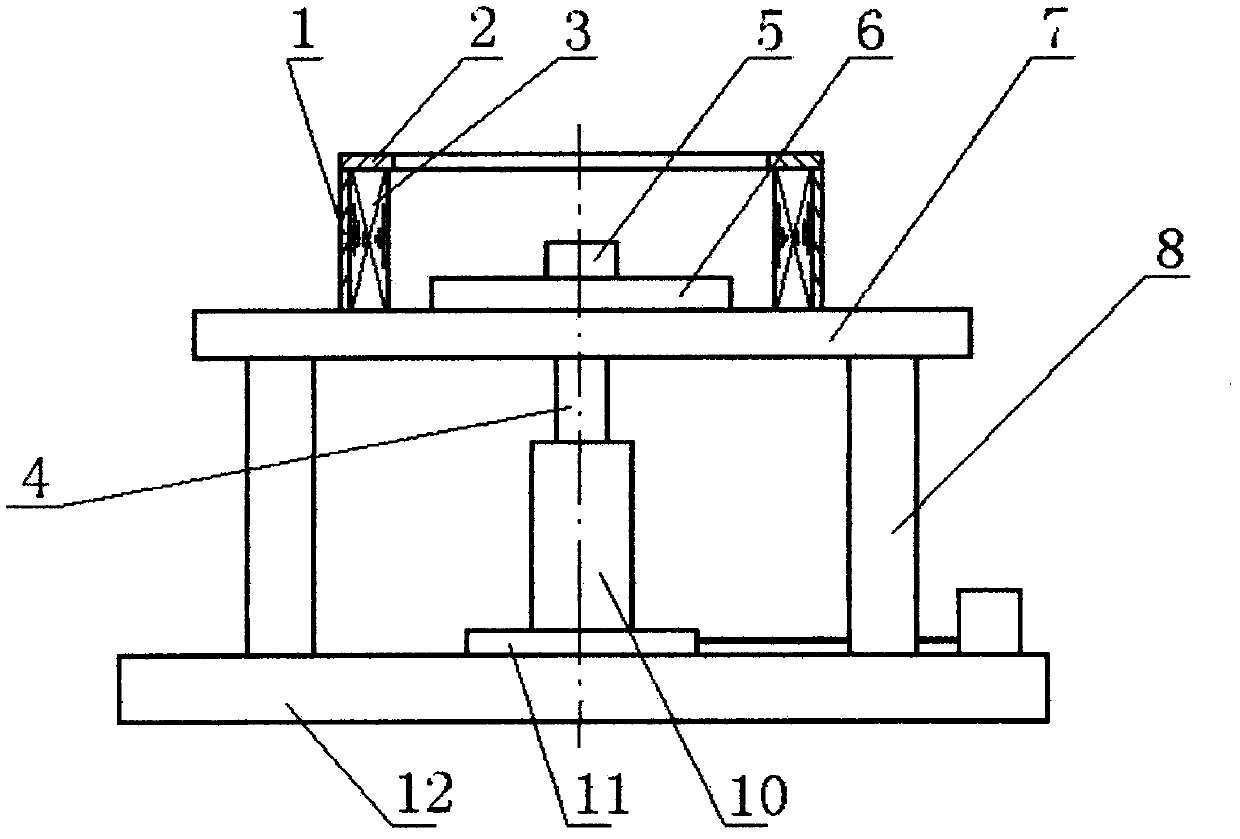

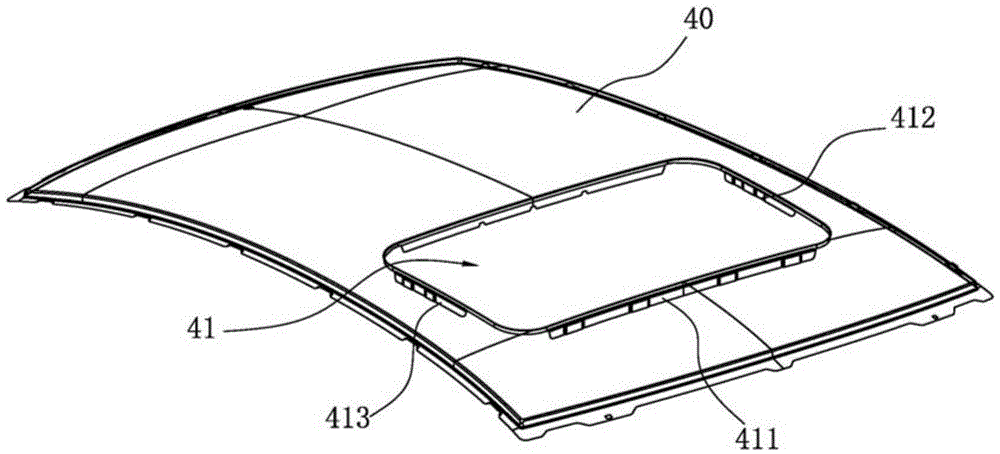

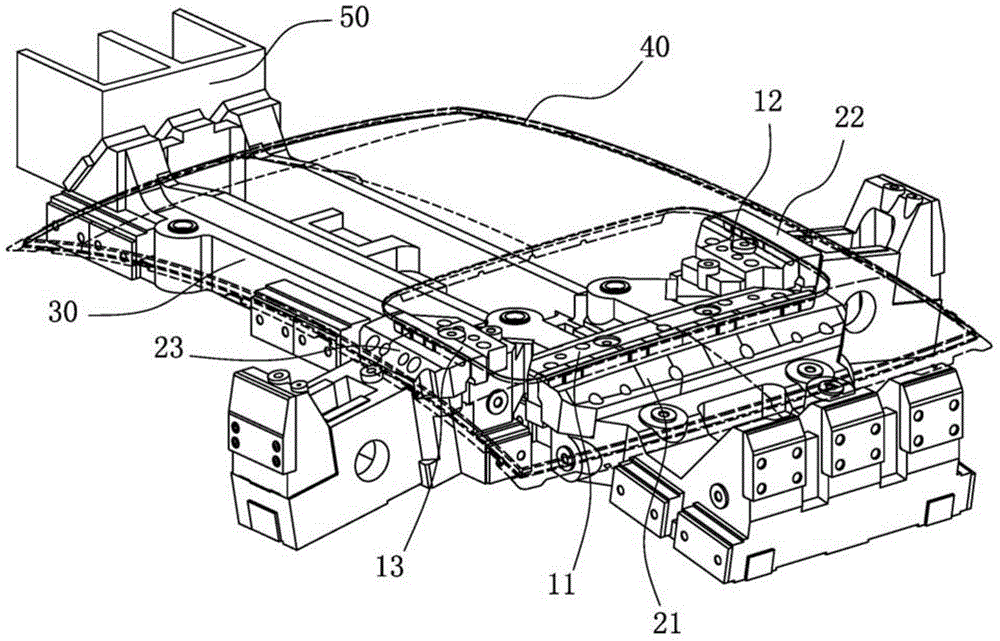

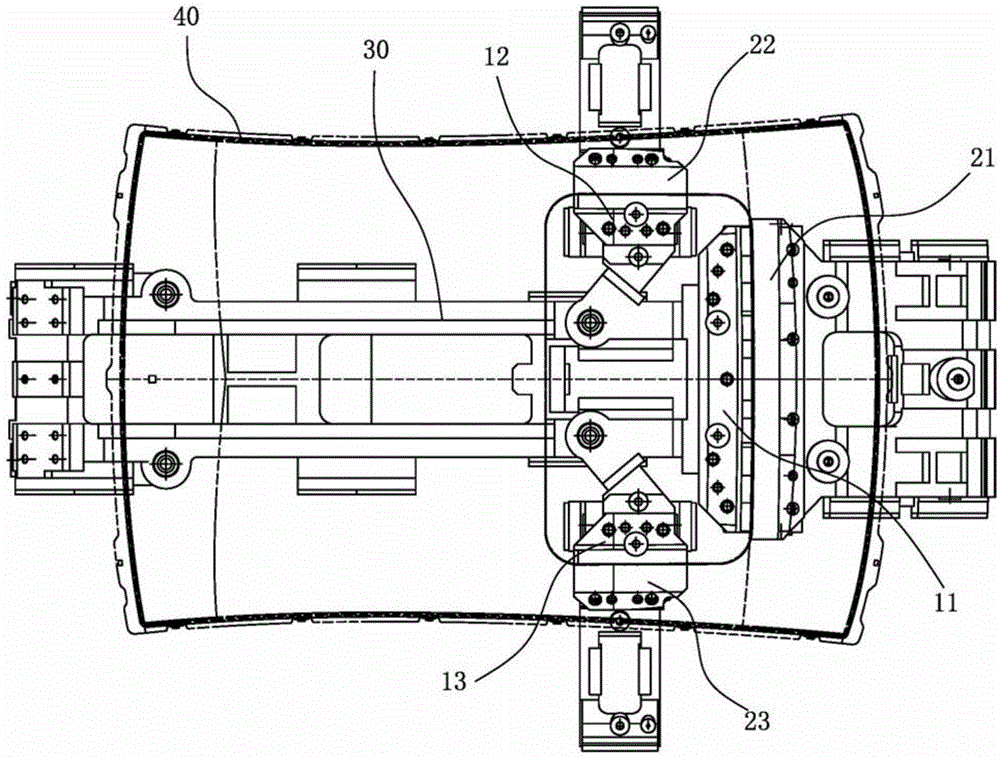

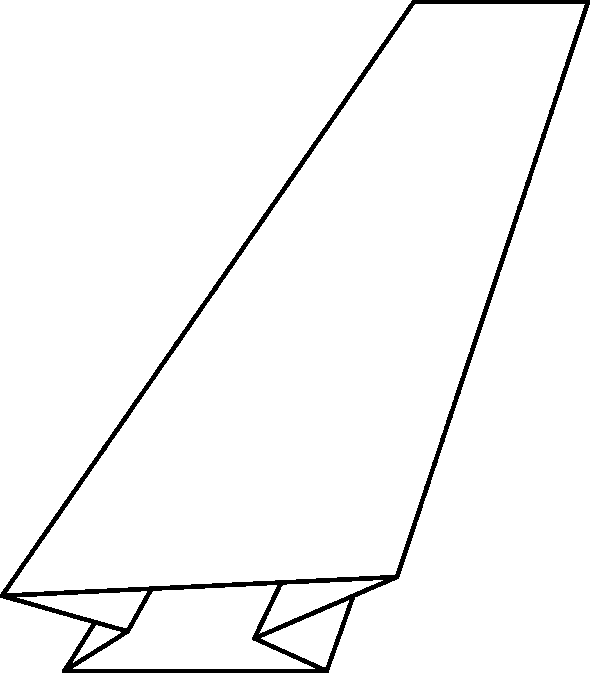

Skylight lateral shaping die

The invention belongs to the field of automobile body sheet metal manufacturing, and particularly relates to a skylight lateral shaping die, which comprises a male die opposite to the inner side of the flange of a skylight, and a female die opposite to the outer side of the flange of the skylight, wherein the male die and the female die are respectively arranged on a lower die base slidably; an open-close type structure is formed between the male die and the female die; the male die and the female die are respectively driven by an inclined wedge driver block on an upper die base; the lower die base is also provided with a push rod for transmitting driving force of the inclined wedge driver block to the male die; the push rod extends to the outer side of the edge of a top cover through the lower part of the top cover from the skylight position; the push rod and the inclined wedge driver block form transmission fit on the outer side of the edge of the top cover. According to the skylight lateral shaping die, when the top cover without the skylight is produced, the skylight lateral shaping die can avoid the top cover, so that the skylight lateral shaping die has no need to be disassembled, the production efficiency is improved, and the risks of workpiece scrappage and die damage caused by misoperation are eliminated.

Owner:CHERY AUTOMOBILE CO LTD

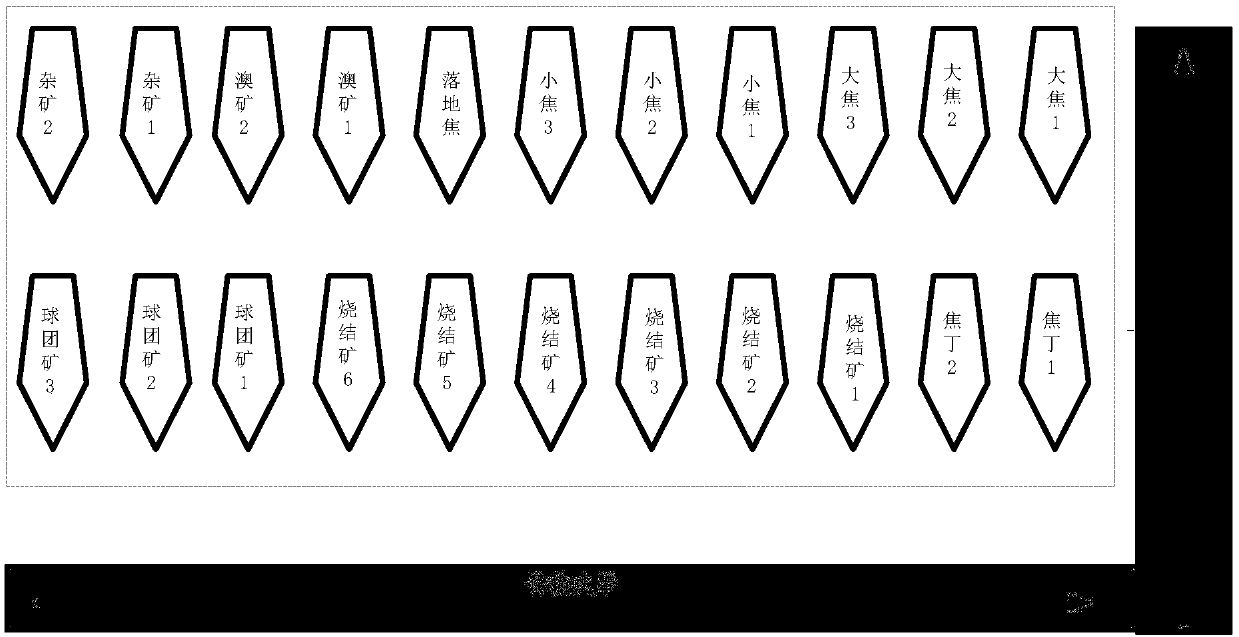

Blast furnace loading material sequence control method and system

ActiveCN107641671AEliminate scrappingReasonable distributionBlast furnace detailsSequence controlSmelting process

The invention discloses a blast furnace loading material sequence control method and system. The method comprises the following steps: before a blast furnace begins the current smelting, determining Pcabins in which N materials are disposed from M cabins according to the N materials required at the current smelting; separately setting a gate opening delay, discharging duration and gate openness of the P cabins according to addition amounts of the N materials required at the current smelting; controlling a loading sequence of the N materials in the current smelting process as follows: performing delay timing by adopting a start moment of the current smelting as start, at the moment when the delay timing reaches the gate opening delay timing of the i cabin of the P cabins, opening a gate of the i cabin to the gate openness set for the i cabin so as to dispense a material in the i cabin to a transport belt; when the actual discharging duration of the i cabin is equalto the discharging duration set for the i cabin, closing the gate of the i cabin. By adopting the blast furnace loading material sequence control method and system, the problem that the distribution of coal gas in the furnace is unstable due to the existing loading system can be solved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Method for manufacturing outer shuttle of rotating shuttle by injection molding

The invention discloses a method for manufacturing an outer shuttle of a rotating shuttle by injection molding. The outer shuttle of the rotating shuttle is made of alloy materials including Fe2Ni, Mo, FeCrMo or FeCr. The method for manufacturing the outer shuttle of the rotating shuttle includes the steps: (1) mixing raw alloy powder in a segregation-free manner; (2) alloying the raw alloy powder; (3) screening the raw alloy powder; (4) preparing feed with the raw alloy powder; (5) performing injection molding of the feed; (6) sintering the molded outer shuttle of the rotating shuttle; (7) shaping the surface of the outer shuttle to reach needed size; and (8) performing sand blasting or polishing for the surface of the outer shuttle. The Fe2Ni, the Mo, the FeCrMo or the FeCr is used as raw materials, composition segregation and unnecessary internal impurities are eliminated, the outer shuttle is fine in sintering shrinkage uniformity, the granularity of the raw material powder is proportionally adjusted within the range of nanometers to 80 micrometer as needed, the cost of raw materials is greatly reduced, and the density and the performance of the outer shuttle meet requirements.

Owner:ZHEJIANG YIHUO TECH

Chamfering and tapping machine for cover plate

ActiveCN107378496AEliminate repairsEliminate scrappingOther manufacturing equipments/toolsMachineWorkstation

The invention relates to the field of processing of gas components, in particular to a chamfering and tapping machine for a cover plate. The chamfering and tapping machine for the cover plate comprises a bottom table, wherein a rotating plate mechanism is arranged in the middle of the surface of the bottom table and comprises a rotating plate and a divider; the rotating plate is rotatably arranged on the divider; six square cover plate fixing seats are uniformly distributed on the surface of the edge of the rotating plate; the surfaces of the cover plate fixing seats are inwards recessed to form a cover plate accommodating groove; and a first workstation, a second workstation, a third workstation, a fourth workstation, a fifth workstation and a sixth workstation are successively arranged on the periphery of the rotating plate clockwise. The chamfering and tapping machine for the cover plate has the beneficial effects that the structure is novel, the design is skillful, chamfering processing and tapping processing are finished in a process, chamfering, tapping, turning and the like do not need to be carried out independently artificially, the labor cost is low, and the processing efficiency is high.

Owner:CIXI TIANXING ELECTRIC

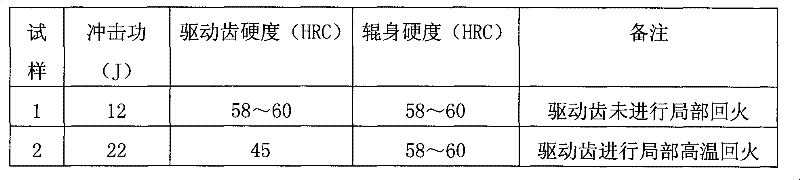

Heat treating method for driving roll and driving gear of rolling mill

InactiveCN102312057ADoes not affect strengthDoes not affect wear resistanceFurnace typesHeat treatment furnacesRoom temperatureOil cooling

The invention relates to a heat treating method for a driving roll and a driving gear of a rolling mill. The heat treating method comprises the following steps: I insulating the driving roll in a salt bath furnace at the temperature of 980 DEG C-1080 DEG C for 40-50 minutes, then suspending into quenching oil with the temperature of 20 DEG C-80 DEG C for cooling, cooling the roll to the temperature below 120 DEG C, II putting the driving roll into a nitrate furnace with the temperature of 510 DEG C-600 DEG C for tempering three times, wherein each time lasts 3.5-5 hours, air cooling after the first two times tempering, performing the third tempering after cooling the temperature of roll lower than 60 DEG C; cooling to the room temperature after performing the third tempering; III carrying out a partial high-temperature tempering to the driving gear of the tempered roll, immersing the whole driving gear into the nitrate furnace with the temperature of 560 DEG C-680 DEG C for 1-4 hours and then oil cooling, cooling the roll to the temperature below 40 DEG C. According to the invention, the driving gear processed by the heat treatment method has high impact resistance.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

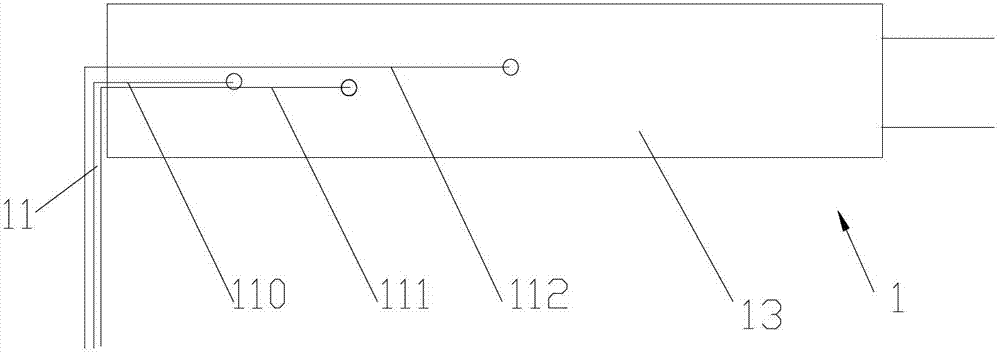

Orthogonal magnetic circuit radial-axial-integrated magnetic bearing based on symmetrical self-lubricating flexible backup bearing structure

ActiveCN108361279AAvoid hyperthermiaAvoid scrapping the whole machineShaftsMagnetic bearingsStatorEngineering

The invention discloses an orthogonal magnetic circuit radial-axial-integrated magnetic bearing based on a symmetrical self-lubricating flexible backup bearing structure. A radial magnetic bearing coil of the orthogonal magnetic circuit radial-axial-integrated magnetic bearing is mounted on a stator tooth set of a stator iron core; two radial rigid magnetic-conductive rings are mounted at an outerdisc of the stator iron core so as to prevent the short circuit problem of permanent magnetic circuits, wherein a certain gap exists between the two radial rigid magnetic-conductive rings; an axial magnetic bearing coil is located at a thrust disc of a rotor shaft and mounted in a cavity formed by the two magnetic-conductive rings; graphite rings and backup bearing skeletons which achieve the axial self-lubricating effect are arranged on the two sides of the thrust disc correspondingly; and a radial backup bearing skeleton and a graphite internal convex ring are arranged in an inner ring cavity of a radial flexible magnetic conductive ring for achieving the radial self-lubricating effect. By adopting the technical means that axial and radial electromagnetic circuits are combined into a whole, and a radial magnetic bearing and a backup bearing are combined into a whole, the technical problem that traditional magnetic bearings are low in coaxiality is solved.

Owner:BEIHANG UNIV

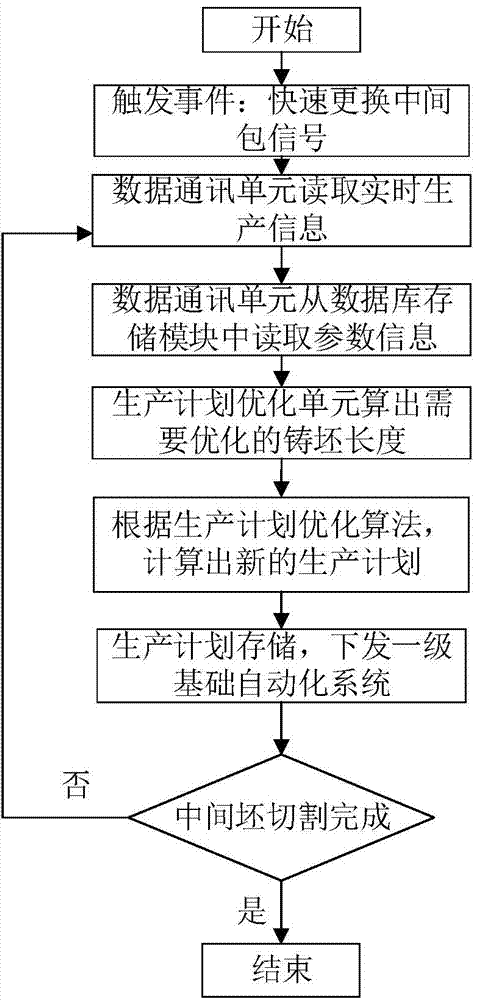

Optimization device and method for casting blank production plan during period of rapidly exchanging tundish

An optimization device and method for a casting blank production plan during a period of rapidly exchanging a tundish belongs to the field of automatic control of continuous casting. The length of an intermediate blank is adjusted into the sum of the length of a fixed size blank length, a blank head setting length and a blank tail setting length through optimizing the casting blank production plan before a joint point is optimized; when the optimization device is used for linearly cutting, only the blank head setting length and the blank tail setting length are cut off, and a residual casting blank is still a casting blank product without quality problems. The device is composed of industrial equipment and a software processing unit; the industrial equipment comprises a server and an industrial computer; the software processing unit comprises a data communication unit, a data storage unit, a production plan optimization calculation unit and a client. The optimization device and method have the advantages that waste blanks are reduced with regard to cutting optimization treatment of the tundish produced during the period of rapidly exchanging the tundish, the yield of liquid steel is improved and the production cost is reduced.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

Chamfering and tapping machine

ActiveCN107344290AEliminate scrappingAvoid reworkFeeding apparatusOther manufacturing equipments/toolsEngineeringMachine

The invention relates to the field of gas part machining and particularly relates to a chamfering and tapping machine. The chamfering and tapping machine comprises a bottom platform; a turntable structure is arranged on the middle position of the surface of the bottom platform; the turntable structure comprises a turntable and a splitter; the turntable is rotatably arranged on the splitter; the surface of the edge of the turntable is uniformly distributed with six square cover plate fixing seats; the surfaces of the cover plate fixing seats are inwards sunken to form cover plate accommodating slots; and the periphery of the turntable is sequentially and clockwise provided with a first working position, a second working position, a third working position, a fourth working position, a fifth working position and a sixth working position. The chamfering and tapping machine has the beneficial effects of novel structure, artful design, capability of finishing chamfering and tapping in the one process, no need of manual independent chamfering, tapping and turnover, low labor cost and high machining efficiency.

Owner:CIXI TIANXING ELECTRIC

FR-4 ceramic PCB support plate manufacturing method

InactiveCN107484342AEliminate scrappingReduce scrap rateCircuit board tools positioningCeramic substrateComposite material

The invention discloses an FR-4 ceramic PCB support plate manufacturing method. Inactive PCB boundary materials are used, a grinded through groove plus a controlled deep groove is adopted, a ceramic board can be fixed in the groove, an effective area in the board can be leaked, horizontal line liquid medicine is ensured to be thoroughly reacted with the board surface, scrap caused by board falling or board clamping on the horizontal line are eliminated, the scrap rate is greatly reduced, and a PCB enterprise does not need to arrange the horizontal line independently for the ceramic substrate.

Owner:长沙牧泰莱电路技术有限公司

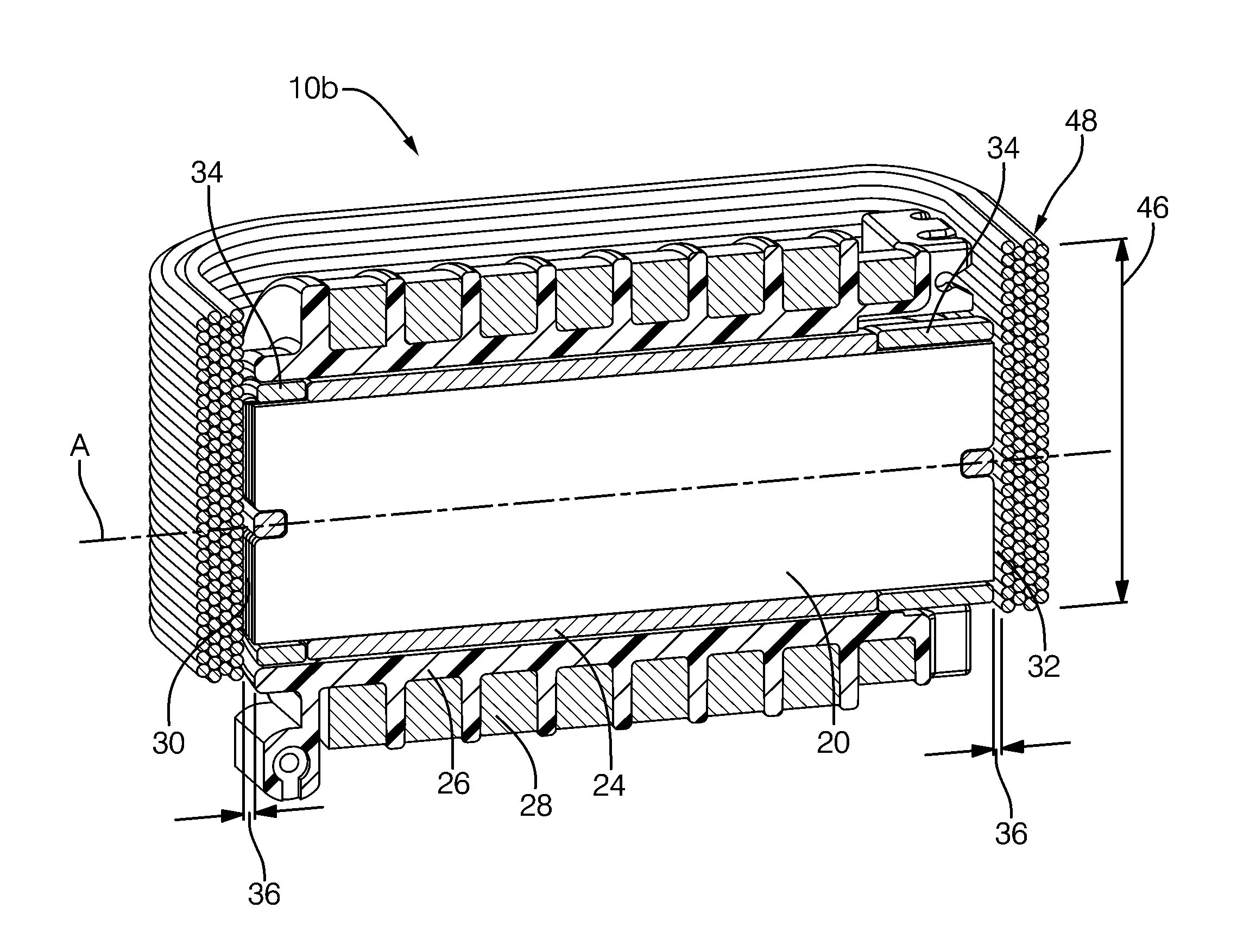

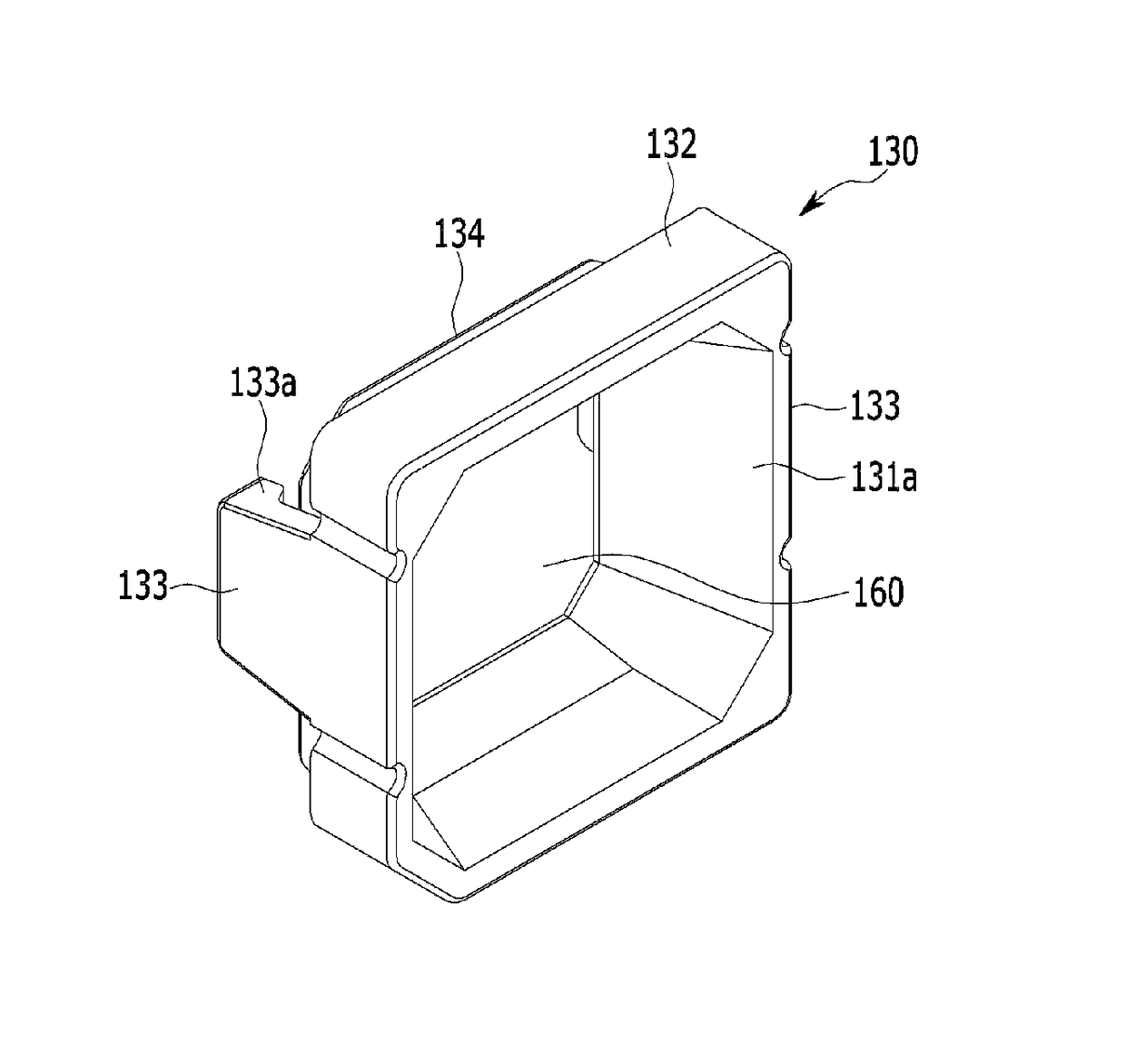

Ignition coil

ActiveUS8360039B2Reduce the amount requiredReduce amountTransformersTransformers/inductances casingsIgnition coilEngineering

Owner:DELPHI TECH IP LTD

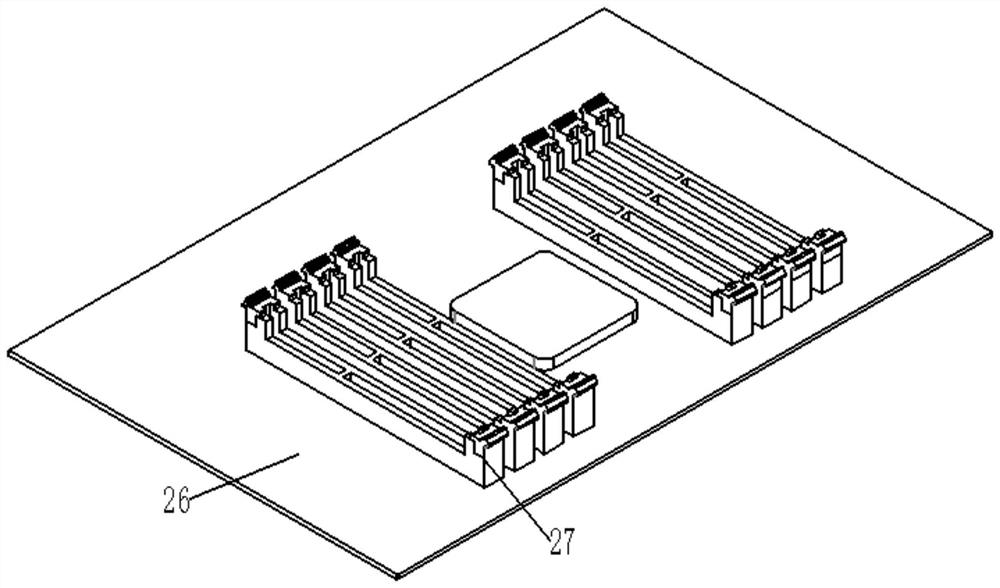

Device suitable for placing memory banks in memory slot of mainboard in batches

ActiveCN113608585ASimple structureEasy to assembleDigital processing power distributionEnergy efficient computingMemory bankEngineering

The invention discloses a device suitable for placing memory banks in a mainboard memory slot in batches, which comprises a base and clamping arms, the resettable clamping arms are mounted on the base, resettable buckles are arranged on one sides of the clamping arms, and a release block for moving the buckle is arranged on one side of the base; a positioning wedge matched with the clamping arms is arranged between the clamping arms, a positioning beam used for moving the positioning wedge is arranged on the upper side of the base, and a pressing handle used for moving the positioning beam is arranged on one side of the base. According to the invention, the spacing of the memory banks is adjusted through the cooperation of the positioning beam and the positioning wedge, so that the device is suitable for trays with different spacing of the memory banks or mainboards with different spacing of memory slots, and is flexible and changeable to use; and by installing different numbers of clamping arms, different numbers of memory banks can be clamped at a time, and the practicability is high. The device is suitable for a server or a PC complete machine needing to be provided with a plurality of memory banks, the memory banks can be held and placed in batches, and the operation that the memory banks are held and placed independently at present is replaced.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

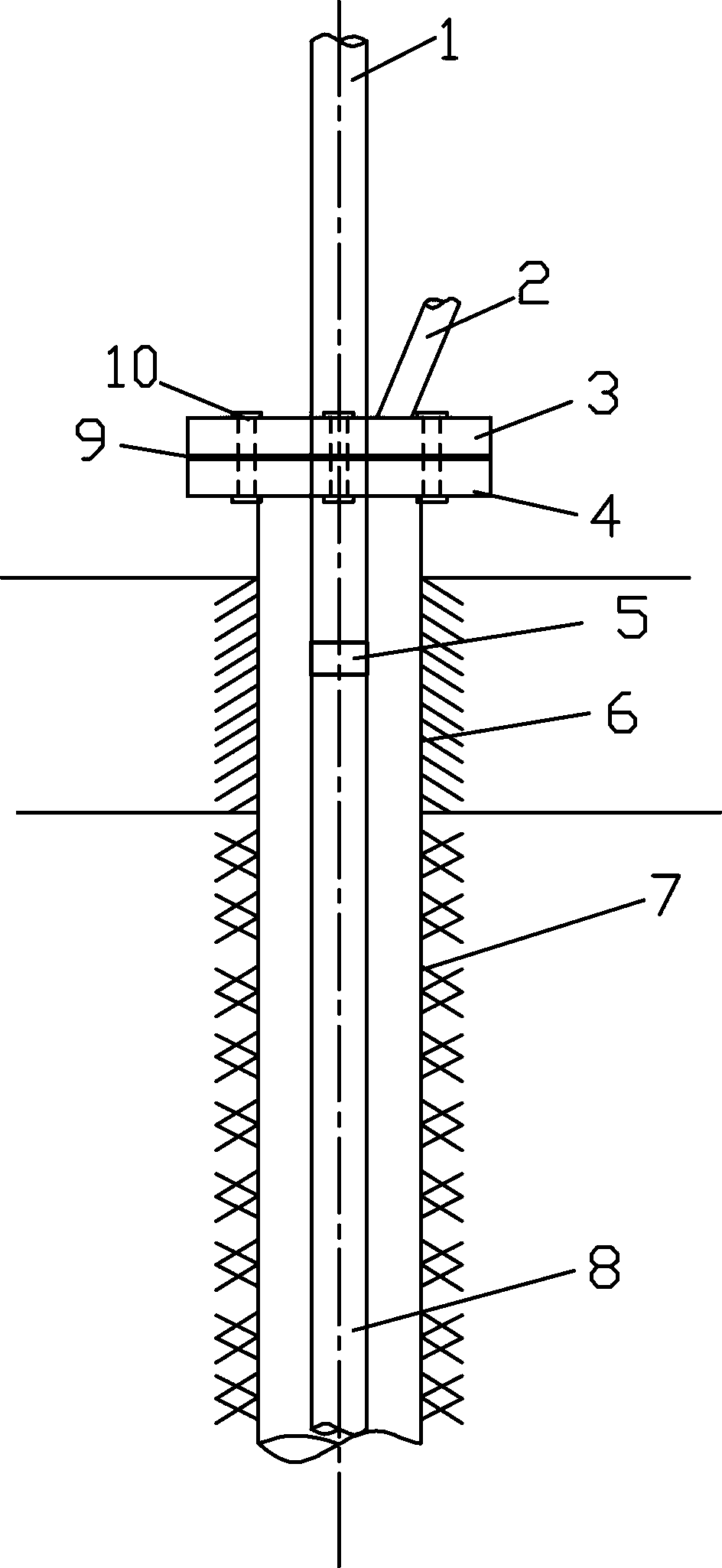

Quick grouting device and grouting method thereof

ActiveCN104110037AEliminate scrappingNot easy to adhere to the pipe wallFoundation engineeringThin walledFrost

The invention provides a quick grouting device. A flange plate is fixedly mounted on an embedded orifice pipe; a grout return pipe is fixedly mounted on a gland plate; a polyethylene thin-wall grout injection pipe is communicated with a grout inlet pipe by use of a grout injection pipe connection snap ring; the polyethylene thin-wall grout injection pipe is a strip-like pipe of which the two sides are symmetrically folded inwards; the grout outlet of the polyethylene thin-wall grout injection pipe is double-V-shaped. A grouting method by use of the quick grouting device comprises the steps of 1) welding the flange plate, 2) forming a grouting hole, 3) drooping the polyethylene thin-wall grout injection pipe, 4) fastening the gland plate and the flange plate, 5) mounting a high-pressure pipe, 6) beginning frost boiling operation at the bottom of the grouting hole, 7) flushing the grout inlet and outlet pipelines, and 8) taking out and recovering the polyethylene thin-wall grout injection pipe. The quick grouting device and the grouting method thereof have the advantages that the disadvantages of the orifice-closed grouting method in the existing drilling grouting construction process can be overcome and the construction problem that drilling pipe casting accidents are easy to happen in the grouting hole.

Owner:GEZHOUBA GROUP FOUND ENG

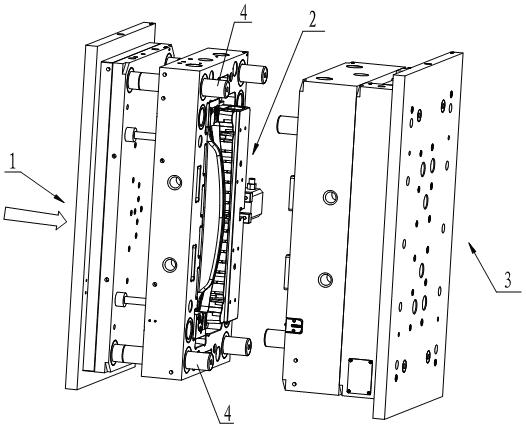

In-mold injection mold for integrally molding refrigerator decorative bar

ActiveCN102490319AReduce manufacturing costMeet production requirementsCoatingsEngineeringRefrigerated temperature

Owner:QINGDAO HAIER MOLDS

Method for manufacturing metallic reflector for LED package

ActiveUS10014435B2Simple manufacturing processReduce manufacturing costSolid-state devicesSemiconductor devices for light sourcesEngineeringNotching

A metallic reflector manufacturing method for an LED package. The method includes preparing a metal plate, and processing a stamping reflector that includes a lower body and an upper body that is extended from an upper side of the lower body and is integrally formed with the lower body. A reflection surface that is slanted by a predetermined angle is formed at a central portion of the upper body and the lower body to reflect the light of the LED chip to the outside. A fixation portion is formed to fix the lower body on a substrate that the LED chip is mounted on. The method further includes sequentially plating Ni and Ag on the reflection surface or the stamping reflector surface. The stamping processing includes a piercing step, a drawing step, a first noting step, a half etching step that forms the fixation portion, and a second notching step.

Owner:FIRSTENG CO LTD

Manufacturing method of V-type-channel microchannel plate

ActiveCN106158554AEliminate factors that reduce gainEliminate scrappingCold cathode manufactureWhiteboardNitrogen

The invention discloses a manufacturing method of a V-type-channel microchannel plate. The manufacturing method is mainly used for manufacturing the high-gain V-type-channel microchannel plate. The manufacturing method is characterized in that a thermal adhesion bonding process for manufacturing the high-gain V-type-channel microchannel plate comprises the operation steps of: a, cleaning clamps; b, checking and cleaning whiteboards; c, installing the first piece of whiteboard; d, installing the second piece of whiteboard; e, placing a graphite flake; f, placing a load; g, carrying out vacuum heating; h, filling nitrogen and taking the clamps out; i, and performing inspection. The application proves that the manufactured V-type-channel microchannel plate can be directly applied to the product, the phenomena that the gain is low and the product is liable to scrap when original microchannel plates are stacked for use are overcame fundamentally, and the performance quality of the microchannel plate in use is effectively improved and guaranteed, and the technical requirements of the products are satisfied.

Owner:NORTH NIGHT VISION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com