Blast furnace loading material sequence control method and system

A control method and blast furnace technology, applied in the field of blast furnace smelting, can solve problems such as unstable gas distribution in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

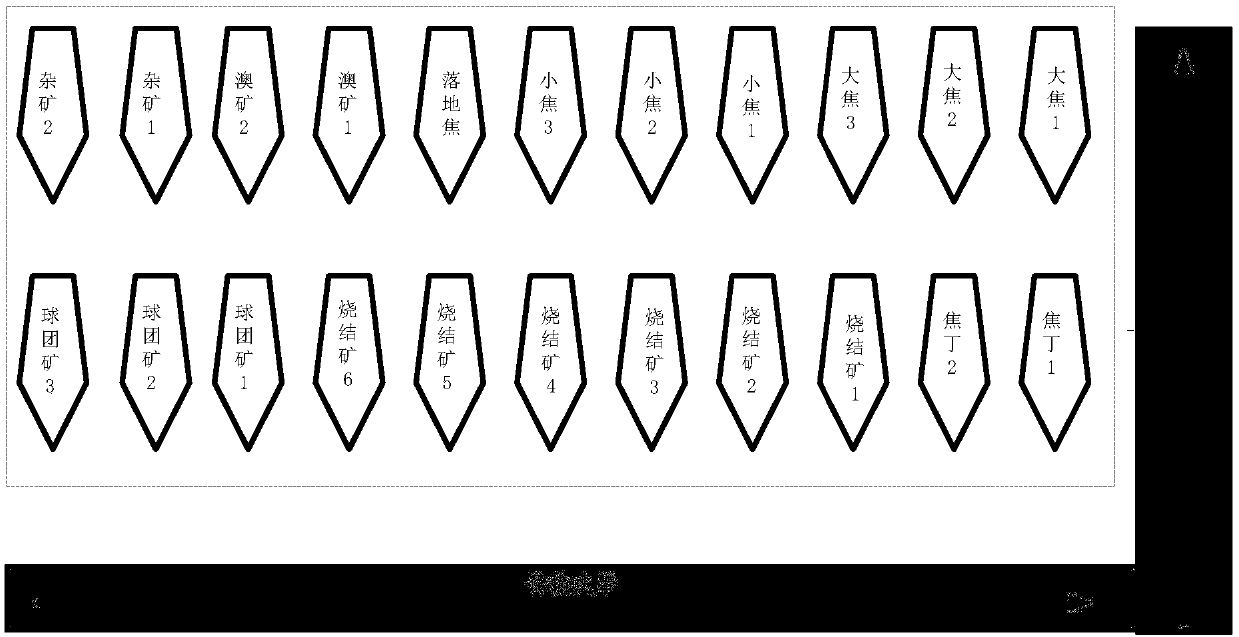

Image

Examples

Embodiment 1

[0108] If the N kinds of materials needed for the current smelting include ground coke, small dry coke and large dry coke that are classified and placed in different silos, then in the process of the current smelting, start from the moment when the current smelting starts Delay timing, the feeding sequence of ground coke, small dry coke and large dry coke is as follows: when the delay timing reaches 10s and 80s, respectively open a gate for placing large dry coke until it is put into the blast furnace When the total discharge time of the large dry coke is 131s, close the gates of the two bins for the large dry coke that have been opened at the same time; Gate, until the total time of discharging small dry coke into the blast furnace is 84s, close the gates of the two bunkers for placing small dry coke that have been opened at the same time; The gate of the coke silo is closed until the total discharge time of ground coke is 18s.

[0109] In this embodiment, the opening of the...

Embodiment 2

[0117] If the N kinds of materials required for the current smelting include ground coke and mixed dry coke that are classified and placed in different silos, the time delay is performed starting from the moment when the current secondary blast furnace smelting starts. During the current smelting process, The feeding sequence of ground coke and mixed dry coke is as follows:

[0118] When the delay timing reaches 10s, 28s, 52s, and 80s, respectively open the gates of a bunker for placing mixed dry coke until the total time for putting mixed dry coke into the blast furnace is 124s, then close the already opened storage bin for placing mixed dry coke. The gates of the four hoppers for dry coke; when the delay time reaches 28s, open the gate of a silo where the ground coke is placed, and close it when the total discharge time of the ground coke is 18s.

[0119] In the second embodiment, the opening of the gate for storing mixed dry coke is 25 cm; the gate opening for storing small...

Embodiment 3

[0126] If the N kinds of materials required for the current smelting include sintered ore, pellet ore, coke, Australian ore and limestone classified in different silos, start the time delay from the start time of the current secondary blast furnace smelting. During the current smelting process, the feeding sequence of sinter, pellets, coke, Australian ore and limestone is as follows:

[0127] When the delay timing reaches 1s and 45s, respectively open the gate of a bunker for placing pellets until the total time of discharging pellets into the blast furnace is 135s, close the two gates for placing pellets that have been opened. The gate of each silo; when the delay timer reaches 10s, 50s, and 90s, open a sintered ore storage bin respectively, and close the opened sintered ore storage bin until the total discharge time of sintered ore into the blast furnace reaches 165s. The gates of the three bunkers; when the delay timer reaches 35s, open the gate of a bunker for placing coke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com