Method for economizing material of gripper loom and apparatus thereof

A rapier loom and material-saving technology, which is applied in looms, textiles, textiles, and papermaking, etc., can solve the problems of size and length waste, waste, and long distance, and achieve the effect of eliminating weft waste and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

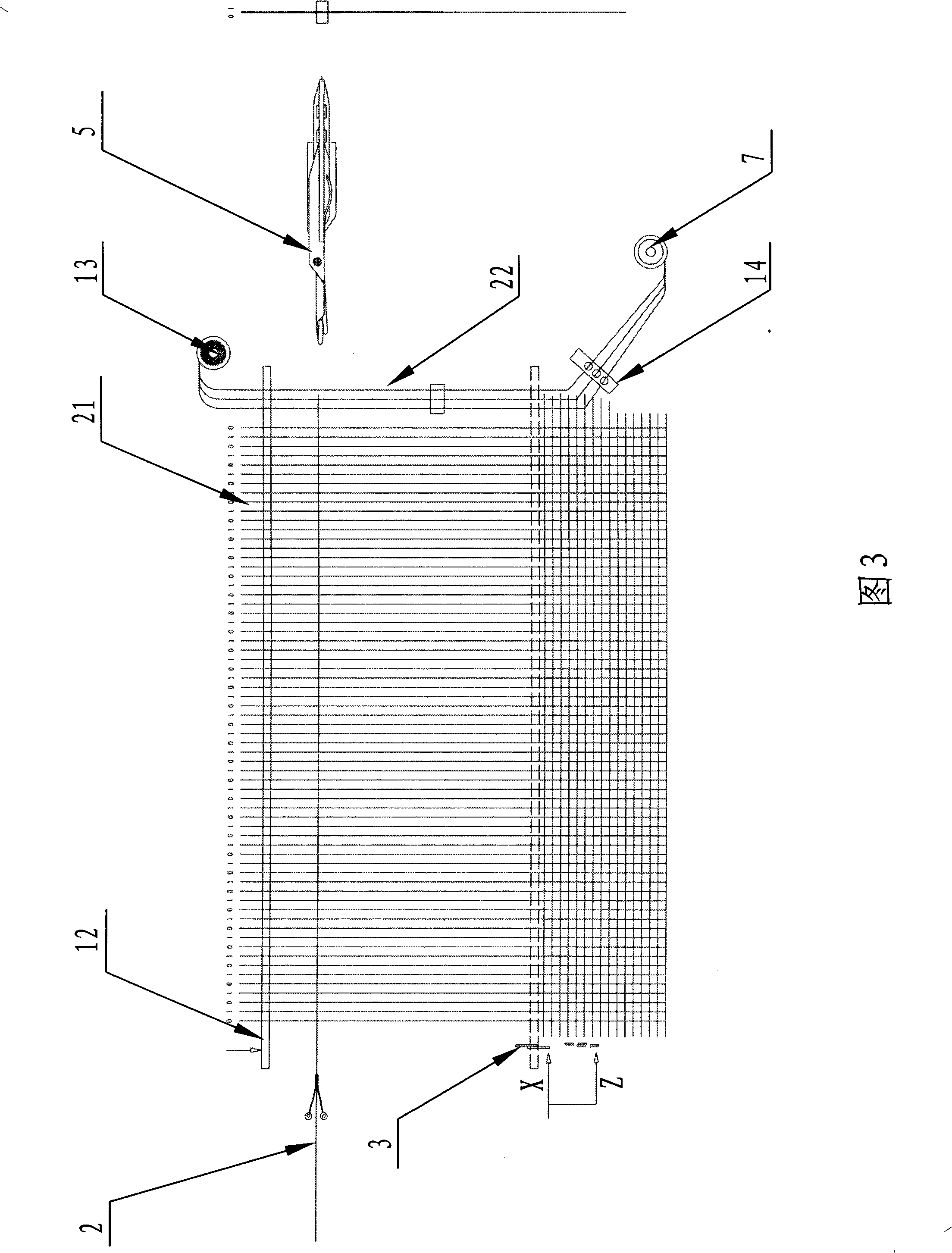

[0041] Embodiment 1: as shown in Figure 2, Figure 4, Figure 5 As shown, the working principle of the rapier loom 1 is that the weft thread 2 and the warp thread 21 are woven together by the wire feeding device 51 and the wiring device 5 . The method of the present invention is specifically as follows: install a movable scissors device 3 at the position where the fixed scissors 11 were originally installed on one side of the rapier loom 1, and install the warp edge delivery wheel 13 and the warp edge thread on the other side of the rapier loom 1. Separation mechanism 14 and warp edge coil winding device 7; When working, on the movable scissors device 3 side, when the weft thread advancing mechanism 12 of rapier loom 1 advances, the movable scissors device 3 moves from X to Y, avoids contact with When the weft thread propulsion mechanism 12 collides, when the weft thread propulsion mechanism 12 returns, the movable scissors device 3 returns to X from Y, and cuts the weft thread ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com