Method for manufacturing outer shuttle of rotating shuttle by injection molding

A technology of injection molding and manufacturing method, which is applied in the field of sewing machine accessories, can solve the problems of low utilization rate of metal materials, cumbersome manufacturing and processing procedures, and inability to produce on a large scale, so as to achieve good sintering shrinkage consistency, high utilization rate of metal materials, and eliminate The effect of compositional segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

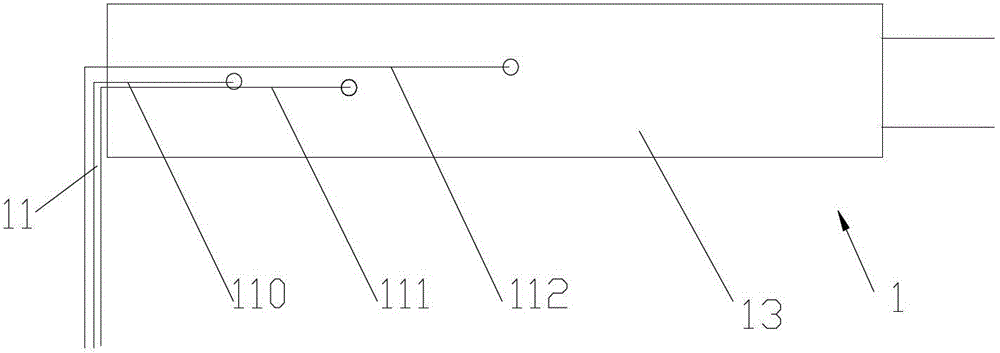

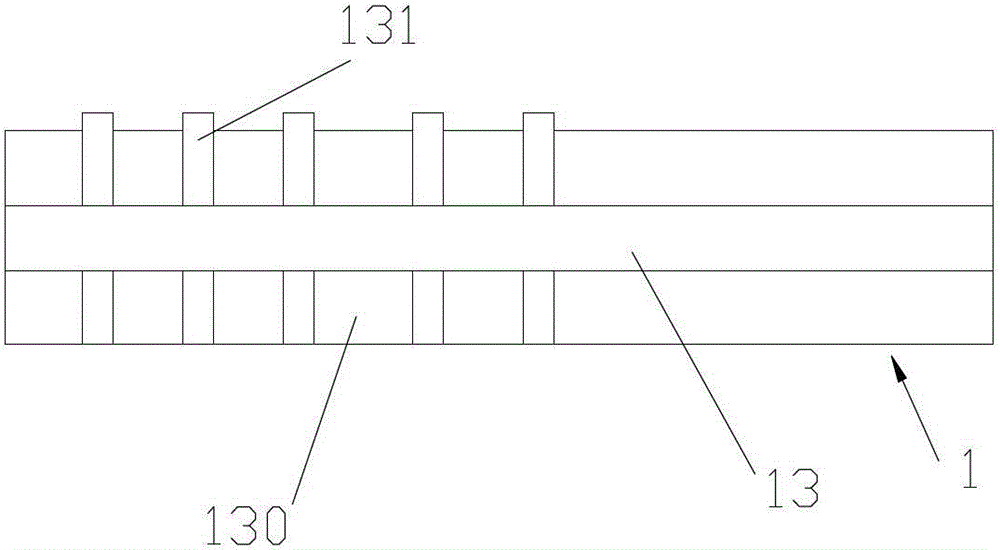

Image

Examples

Embodiment 1

[0038] The alloy material is Fe2NiMo, and its raw material composition is: 2% carbonyl nickel powder, 0.25% Mo powder, the remaining powder is carbonyl iron powder, and the particle size of the raw material is 0.5-80 microns. First, the alloy powder is mixed without segregation, and then the alloy powder is placed in a furnace for alloying treatment under a protective atmosphere. The treatment temperature is 200~800℃, and the alloying time is 0.2~6 hours. The alloying treatment adopts a vacuum furnace, a continuous furnace or a batch furnace with a protective gas (inert gas, reducing gas). After alloying, the powder is milled and sieved. The particle size of the raw material alloy powder obtained after grinding and sieving is 0.5-80 microns. Then the raw material alloy powder is prepared for feeding, and then the feeding is injection molded; after molding, the outer shuttle of the rotary hook is sintered.

[0039] The comparative example of embodiment 1 is injected with the ...

Embodiment 2

[0041] The alloy material is FeCrMo, and its raw material composition is: 1% Cr powder, 0.25% Mo powder, and the rest is carbonyl iron powder, and the raw material particle size is 0.5-80 microns. Firstly, segregation-free mixing is carried out, and then the raw material alloy powder is placed in a furnace for alloying treatment under a protective atmosphere. The treatment temperature is 200~800℃, and the alloying time is 0.2~6 hours. After alloying, the powder is milled and sieved. The particle size of the raw material alloy powder obtained after grinding and sieving is 0.5-80 microns. Then the raw material alloy powder is prepared for feeding, and then the feeding is injection molded; after molding, the outer shuttle of the rotary hook is sintered.

[0042] The comparative example of embodiment 2, the atomized 20Cr material of equal particle size is injected; Under the same condition, after sintering, Fe2Ni material material size one-time pass rate is 92%, 20Cr material, o...

Embodiment 3

[0044] The alloy material is FeCr, and its raw material composition is: 1% Cr powder, the rest is carbonyl iron powder, and the particle size of the raw material is 0.5-80 microns. Firstly, segregation-free mixing is carried out, and then the raw material alloy powder is placed in a furnace for alloying treatment under a protective atmosphere. The alloying treatment temperature is 200~800℃, and the alloying time is 0.2~6 hours. After alloying, the powder is milled and sieved. The particle size of the raw material alloy powder obtained after grinding and sieving is 0.5-80 microns. Then the raw material alloy powder is prepared for feeding, and then the feeding is injection molded; after molding, the outer shuttle of the rotary hook is sintered.

[0045] In the comparative example of embodiment 3, the atomized 20Cr material of the same particle size is injected; under the same conditions, after sintering, the first pass rate of FeCr material size is 90.2%, and the first pass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com