Tool for drilling central holes of steering knuckle arm

A technology of steering knuckle arms and tooling, which is applied to positioning devices, manufacturing tools, metal processing equipment, etc., can solve problems such as product scrapping, low efficiency, and inaccurate center hole positions, and achieve elimination of product scrapping, high processing efficiency, and guaranteed The effect of concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

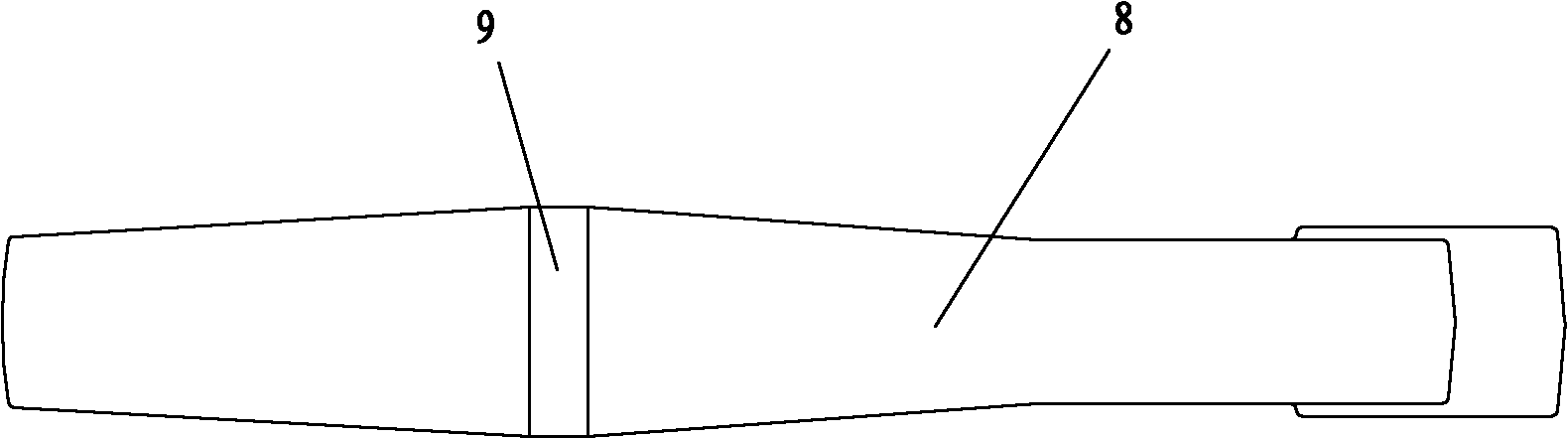

[0017] see figure 1 , the steering knuckle arm punching tooling includes a base 1 and a support 2, the base 1 is provided with a fixing hole 7, the support 2 is installed vertically with the base 1, and the support 2 is provided with an upper V-shaped block 3 located on the upper V-shaped block 3 The lower V-shaped block 4 directly below is provided with a positioning device on the base 1, and the positioning device is a groove 5 arranged on the base; the upper V-shaped block 3 and the lower V-shaped block 4 have the same size, and the V The openings are consistent.

[0018] see figure 2 , as shown in the figure, the steering knuckle arm punching tooling includes a base 1 and a support 2, the base 1 is provided with a fixing hole 7, the support 2 is installed vertically with the base 1, and the support 2 is provided with an upper V-shaped block 3 on the The lower V-shaped block 4 just below the upper V-shaped block 3 is provided with a positioning device on the base 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com