Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83 results about "Three roll mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A three roll mill or triple roll mill is a machine that uses shear force created by three horizontally positioned rolls rotating in opposite directions and different speeds relative to each other, in order to mix, refine, disperse, or homogenize viscous materials fed into it.

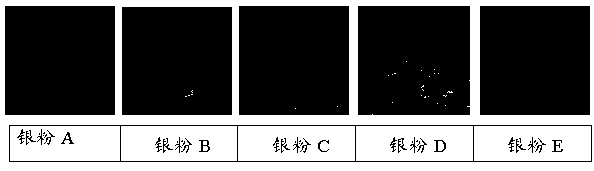

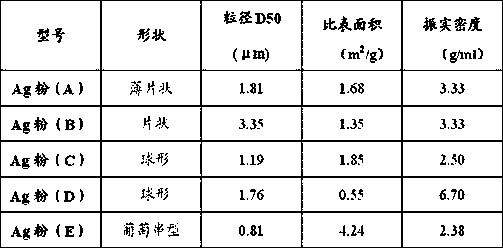

Silver paste for solar cells and preparation method thereof

ActiveCN102324263AImprove photoelectric conversion efficiencyStrong adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureEnvironmental resistanceSolar cell

The invention discloses a silver paste for solar cells. The silver paste consists of silver powder, lead-free glass powder and an organic carrier, the organic carrier consists of organic solvent and organic additive, the silver powder is spherical and / or flaky, and the grain sizes of the silver powder are coarse and fine; the lead-free glass powder adopts a lanthanum-boron-zinc glass system, and the components of the lead-free glass powder are La2O3, B2O3, Al2O3, ZnO, Na2O, LiO2, V2O5 and P2O5. A preparation method for the silver paste includes the following steps: after being uniformly mixed, the materials of the lead-free glass powder are put into a high-temperature muffle furnace to heat, the temperature is preserved, and the melted glass powder particles are quenched and then ball-milled; the organic solvent and the organic additive are uniformly mixed and stirred according to proportion; the silver powder, the lead-free glass powder and the organic carrier are weighed, uniformly stirred in a container, put into a three-roll mill and ball-milled, and thereby the uniform silver paste for the solar cells is prepared. Under the premise of meeting the electrical properties of the solar cells, the silver paste also can meet the requirement on lead-free environment-friendliness.

Owner:JIANGSU RUIDE NEW ENERGY TECH

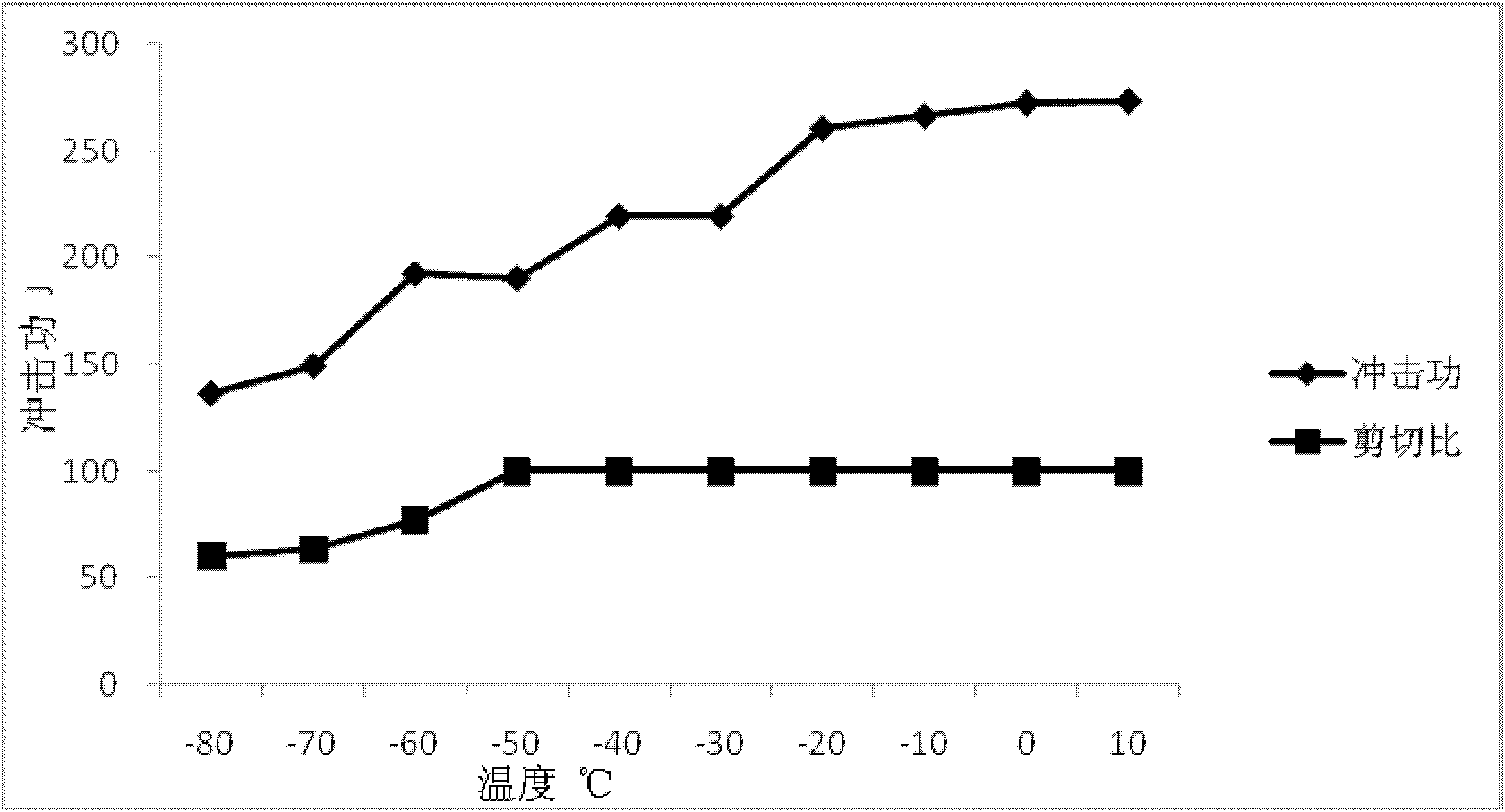

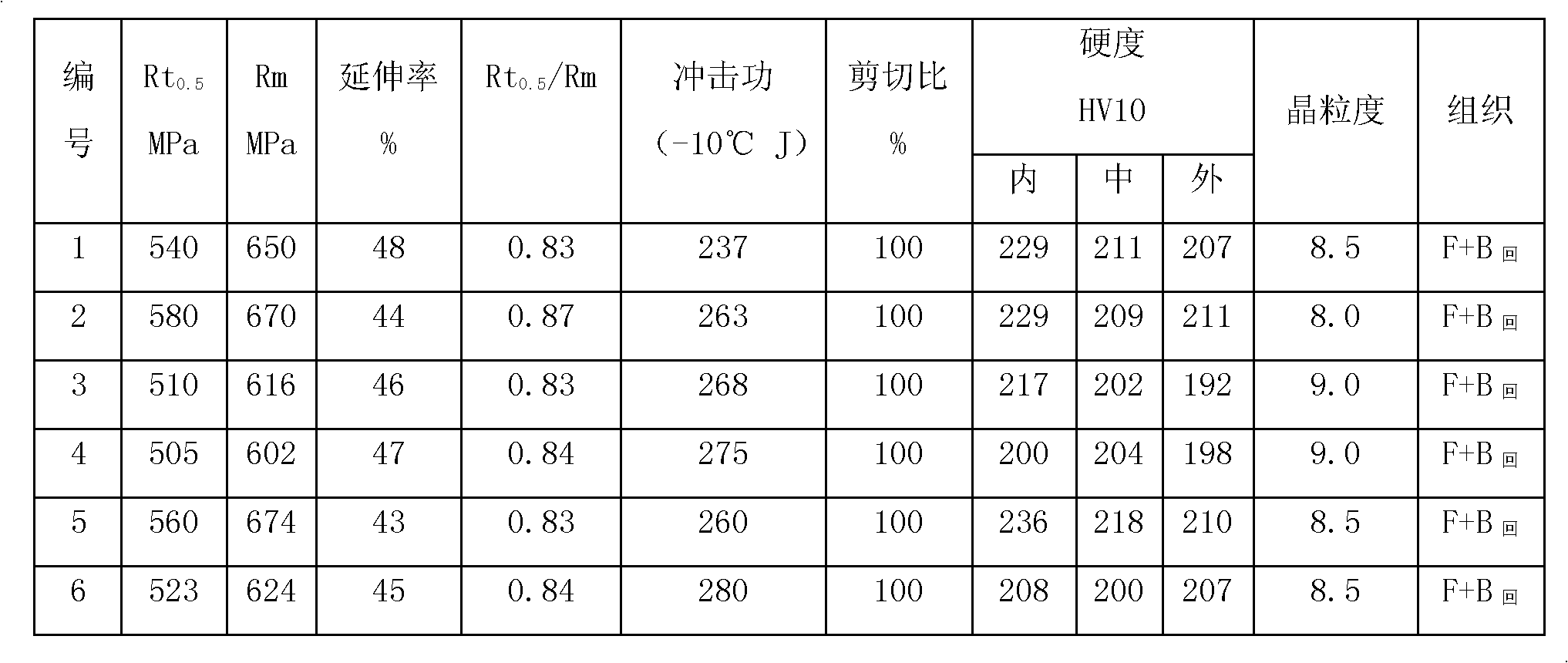

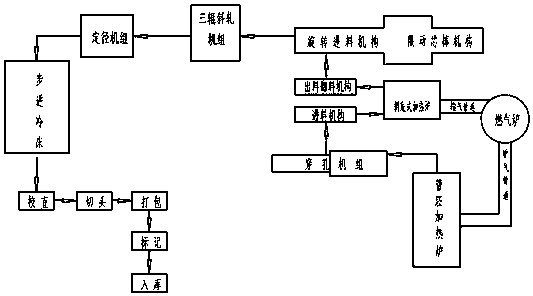

Manufacturing method of X70QS seamless line pipe for acid environment

InactiveCN101892432ASmall fluctuation rangeGuaranteed geometryFurnace typesHeat treatment furnacesSteelmakingHigh pressure

The invention provides a manufacturing method of an X70QS seamless line pipe for an acid environment, comprising the following steps: 1. steelmaking, i.e. electrosmelting, external refining, carrying out VD or RH vacuum treatment, carrying out silicon-calcium wire treatment, and adopting a continuous-casting short-flow process combined with a clean steel smelting technology for controlling the content of P, S and inclusions; 2. tube rolling, i.e. adopting a hot-rolling seamless pipe process at the continuous rolling temperature of more than 950 DEG C, jointly controlling the dimensional precision of the tube by a PQF three-roll mill and a tension-reducing mill or a sizing mill; and 3. heat treatment, i.e. under the quenching temperature of 910-980 DEG C and the tempering temperature of 550-730 DEG C, carrying out high-temperature sizing and straightening control at the temperature of 480-630 DEG C to guarantee performance and size of the pipe. The manufacturing method has the advantages of accurate composition design, high dimensional control accuracy, low manufacturing cost and easy production; and the pipe obtained by the method has good mechanical property and good corrosion resistance, thus being applicable to a high-pressure gas delivery pipeline under an acid condition.

Owner:TIANJIN PIPE GROUP CORP

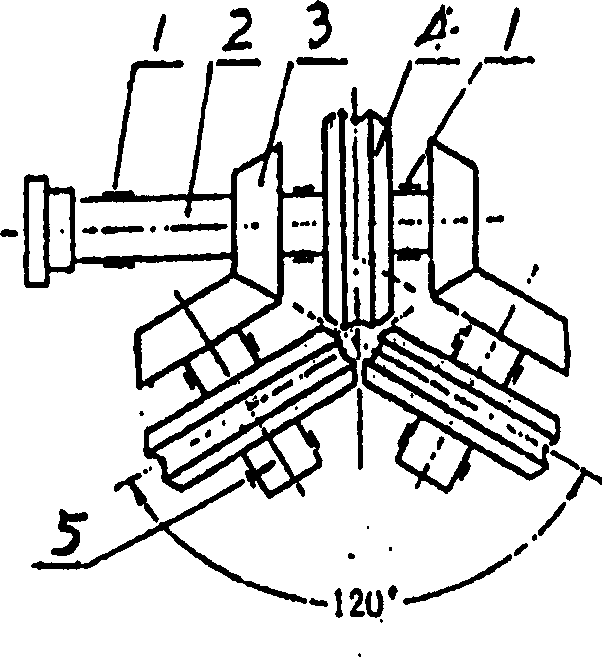

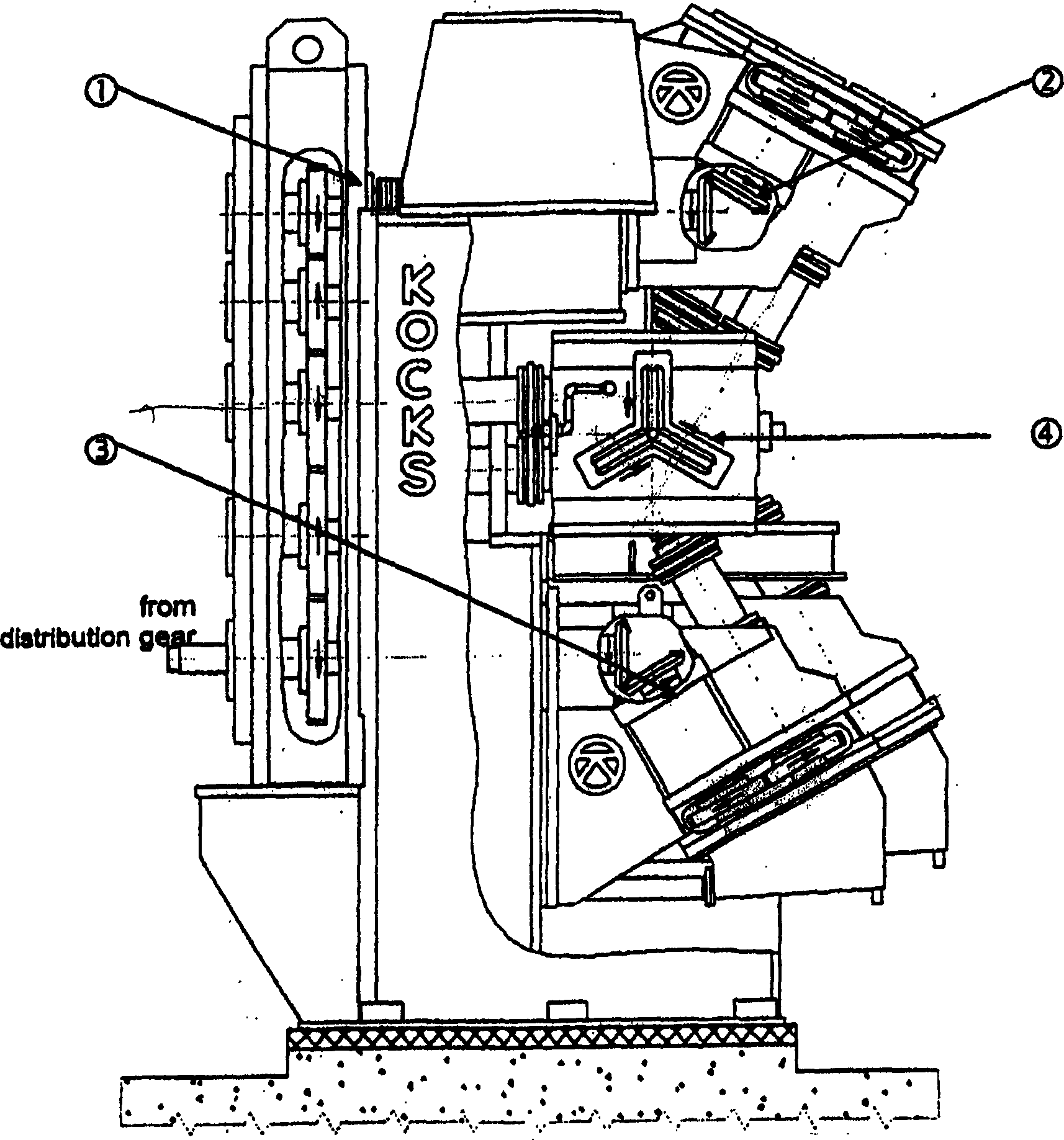

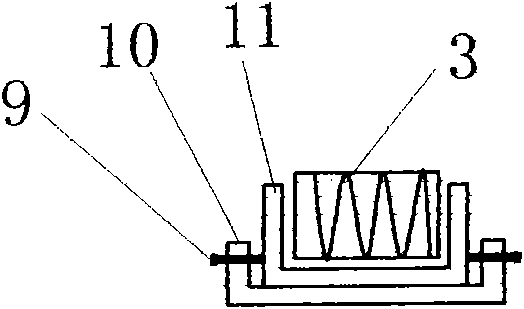

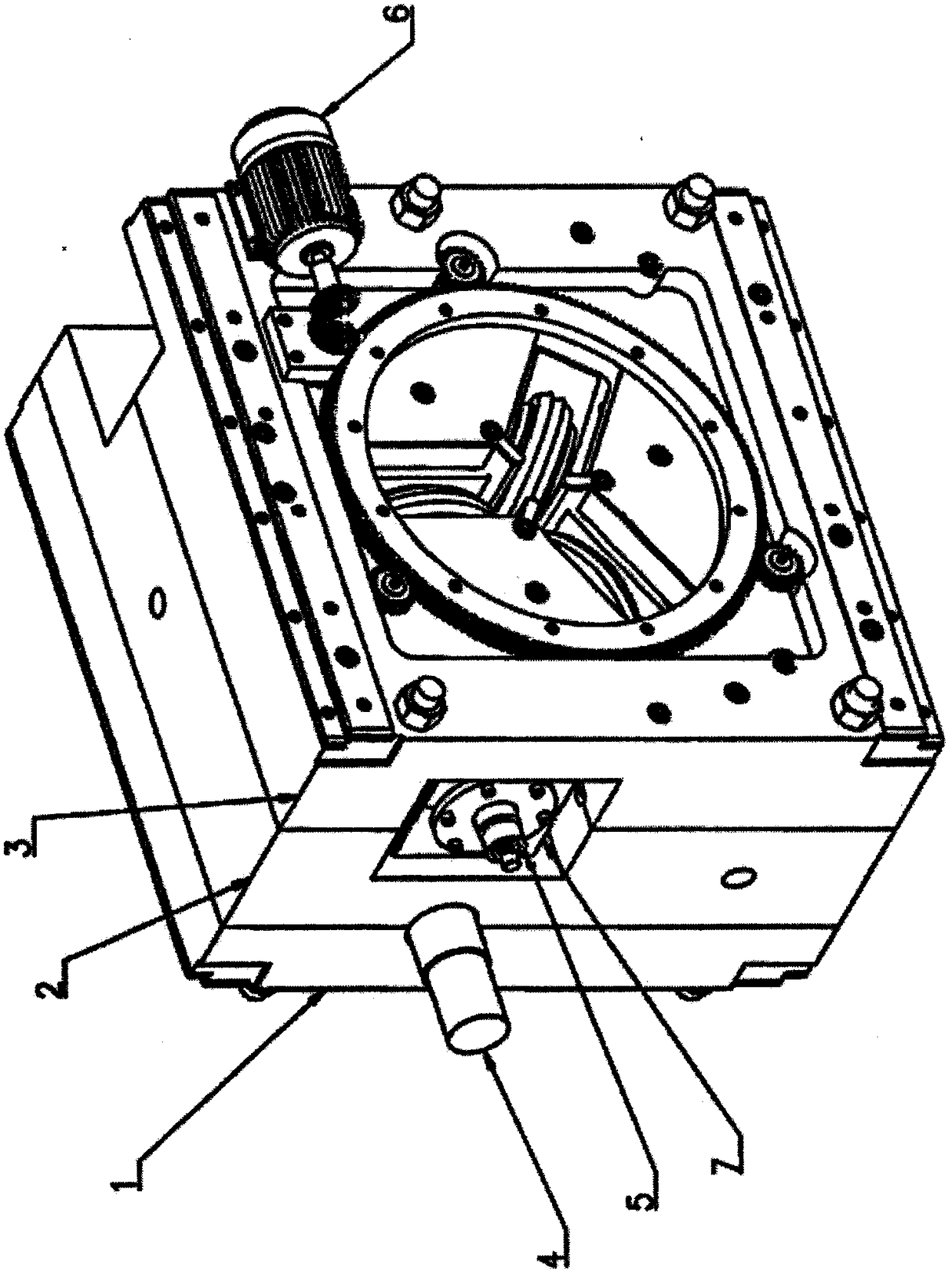

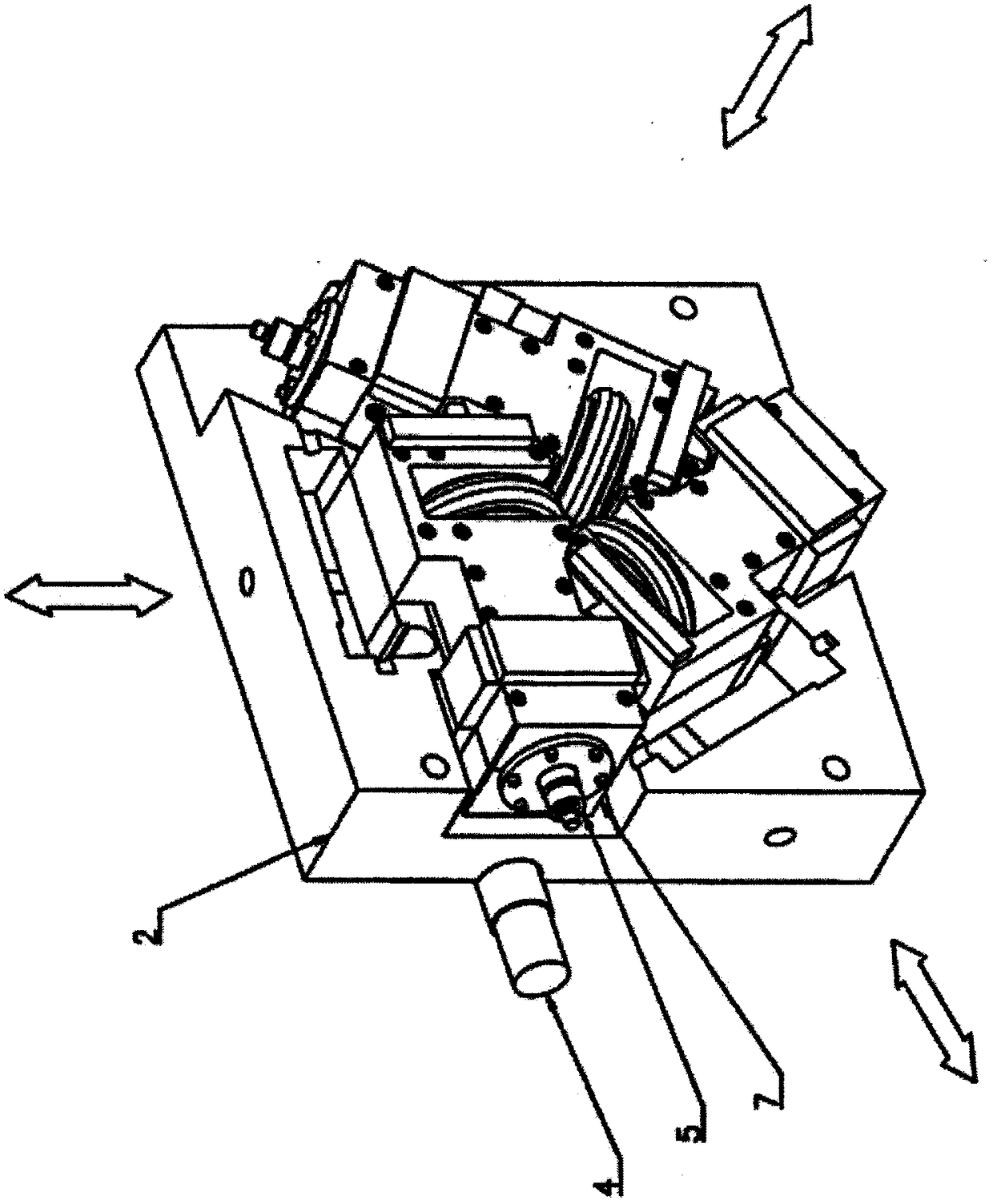

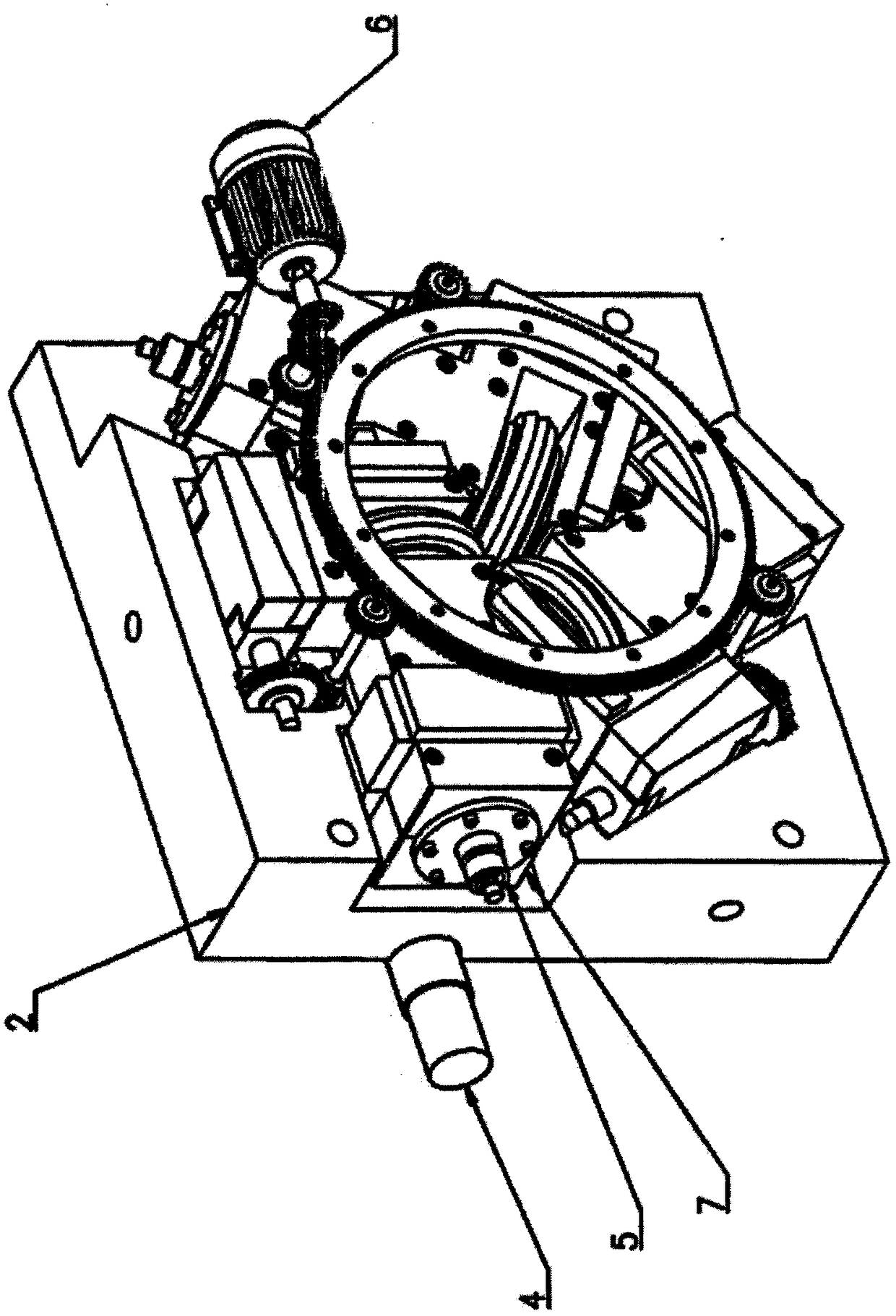

Single-driven input shaft draft-adjustable three-roll mill

InactiveCN1775392AHigh precisionHigh dimensional accuracyMetal rolling stand detailsMetal rolling arrangementsWire rodGear drive

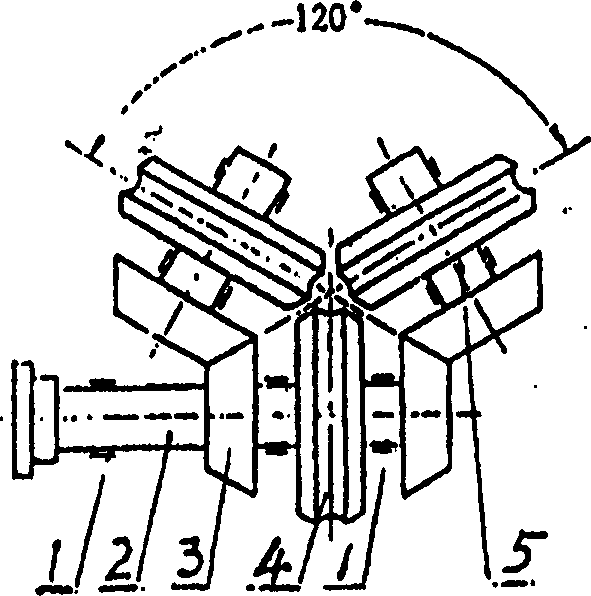

The present invention relates to a three-high rolling mill whose single drive input shaft reduction can be regulated. It includes machine frame, a main driving shaft and two driven shafts which respectively make an angle of 120deg. With said main driving shaft, bevel gears respectively mounted on said three groups of shafts, roll system formed from components of roll collar, etc. and screwdown device and screwdown setting mechanism. Said invention also provides the concrete structure of said main driving shaft and two driven shafts. Said invention can be used for rolling high-speed rod material, wire material and pipe material, its radial adjust size is 12mm.

Owner:北京中冶设备研究设计总院有限公司

A kind of preparation method of back silver paste for crystalline silicon solar cell

InactiveCN102262940ANon-conductive material with dispersed conductive materialCable/conductor manufactureHigh cellSlurry

The invention discloses a method for preparing a back silver paste for a crystalline silicon solar cell, which comprises the following steps: Step 1): preparing an organic vehicle: adding ethyl cellulose resin to a solvent in a constant temperature water bath After dissolving, the organic carrier is obtained by sieve filtration; step 2): preparation of back silver paste: 1.0-5.0% by weight of lead-free glass powder, 56.0-76.0% of flake silver powder, 0.2-2% of inorganic additives 1) Prepared 10%-30% organic vehicle, 3%-12% solvent, 0.1%-1% plasticizer and 0.1-1% dispersant are mixed evenly, and dispersed to 20 μm on a three-roll machine Hereinafter, the back silver paste for the crystalline silicon solar cell is obtained. The paste has excellent printability, good ohmic contact with silicon wafer and aluminum after sintering, good solderability, and high battery conversion efficiency.

Owner:IRICO

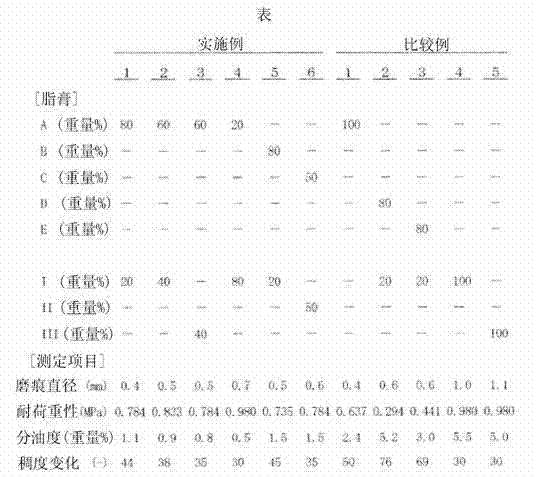

Lubricating grease composition and method for producing the same

InactiveUS20110218128A1Excellent abrasion resistanceLow costBase-materialsCarboxylic acidDicarboxylic acid

Disclosed is a lubricating grease composition comprising a complex metal soap thickener of aliphatic dicarboxylic acid and monoamide monocarboxylic acid, and a fluororesin powder contained in a base oil mixture of a non-fluorine-based base oil and a fluorine-based base oil, which are incompatible with each other. The lubricating grease composition can be produced by kneading, preferably kneading by a three-roll mill, a non-fluorine-based grease and a fluorine-based grease, the non-fluorine-based grease being prepared by stirring a non-fluorine-based base oil, aliphatic dicarboxylic acid, and monoamide monocarboxylic acid under heating, and adding metal hydroxide thereto to form a complex metal soap in the non-fluorine-based base oil; and the fluorine-based grease being prepared from a fluorine-based base oil and a fluororesin powder.

Owner:NOK KLUEBER CO LTD

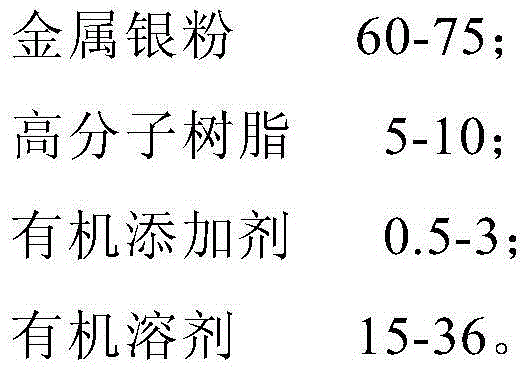

Quick-dry type silver paste used for PCB through hole and preparation method for quick-dry type silver paste

ActiveCN105788700AImprove wear resistanceGood solvent resistanceNon-conductive material with dispersed conductive materialCable/conductor manufacturePolyesterSolvent

The invention relates to quick-dry type silver paste used for a PCB through hole and a preparation method for the quick-dry type silver paste. The raw materials of the silver paste comprise the following components in parts by weight: 60-75 parts of metal silver powder, 5-10 parts of macromolecule resin, 0.5-3 parts of organic additives and 25-35 parts of organic solvent. The quick-dry type silver paste is prepared by the steps of weighing the macromolecule resin and the organic solvent and pouring the macromolecule resin and the organic solvent into a stirring vessel, stirring until the mixture is transparent; then carrying out filtering and impurity removing through a 300-400-mesh polyester net to obtain a carrier; weighing the metal silver powder, the carrier and the organic additives, and putting the weighed mixture in a high-speed dispersion machine to carry out high-speed dispersion to obtain uniform paste; grinding the paste by a three-roll mill; enabling the fineness of the silver paste to be less than 15[mu]m through adjustment of gaps of the rolling mill; enabling the viscosity of the silver paste to be within a range of 10-20Pa.S through fine tuning of the solvent; and filtering the paste by a 300-mesh stainless steel net to obtain the quick-dry type silver paste used for the PCB through hole. Compared with the prior art, the silver paste prepared by the method can be dried rapidly without being cured at a high temperature, and the production efficiency is high.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

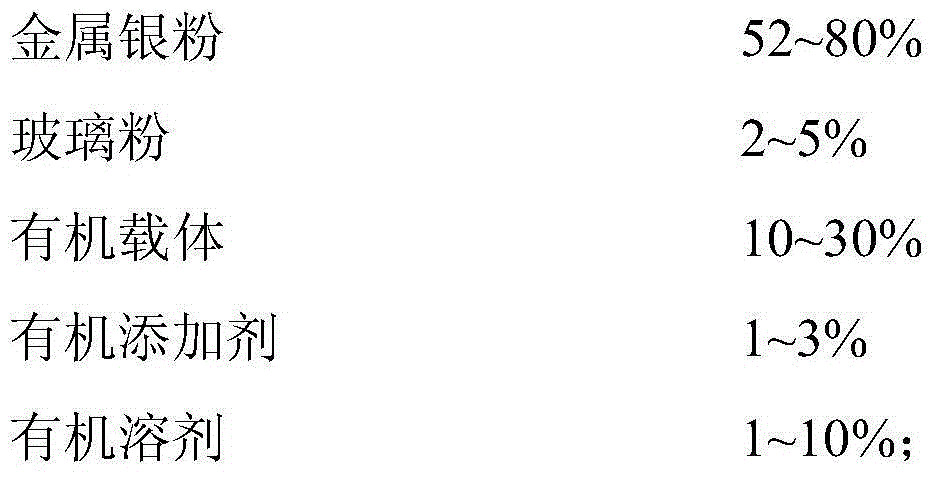

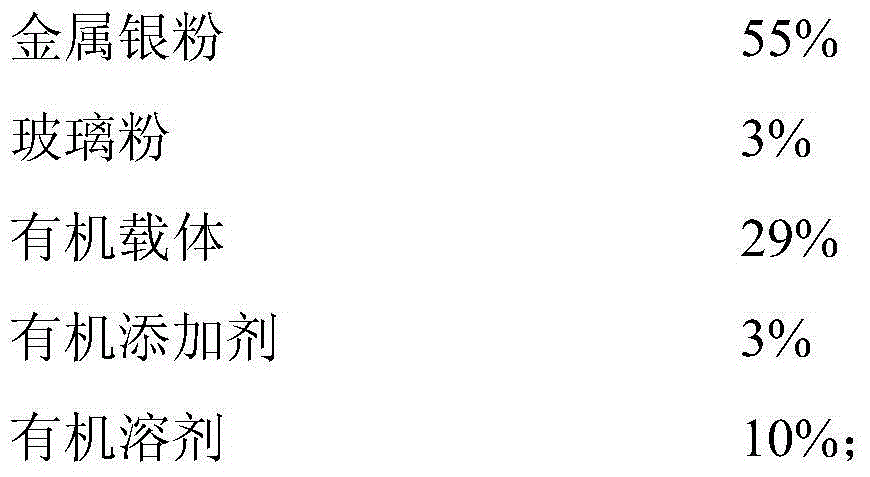

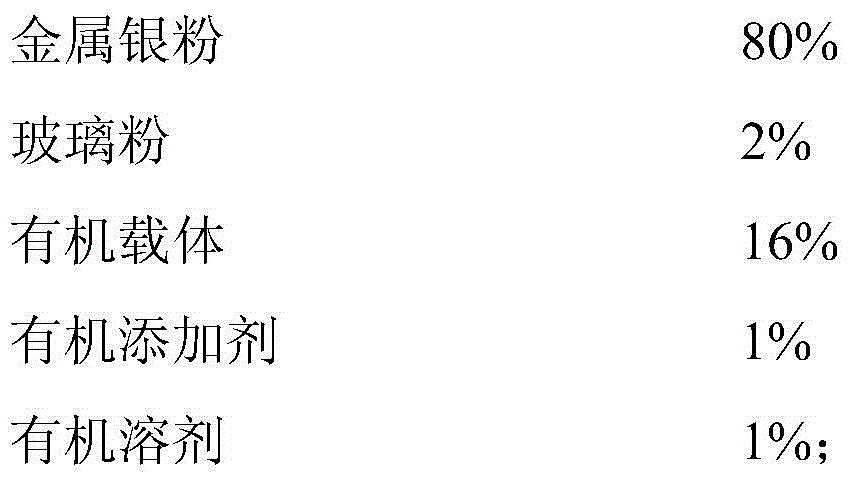

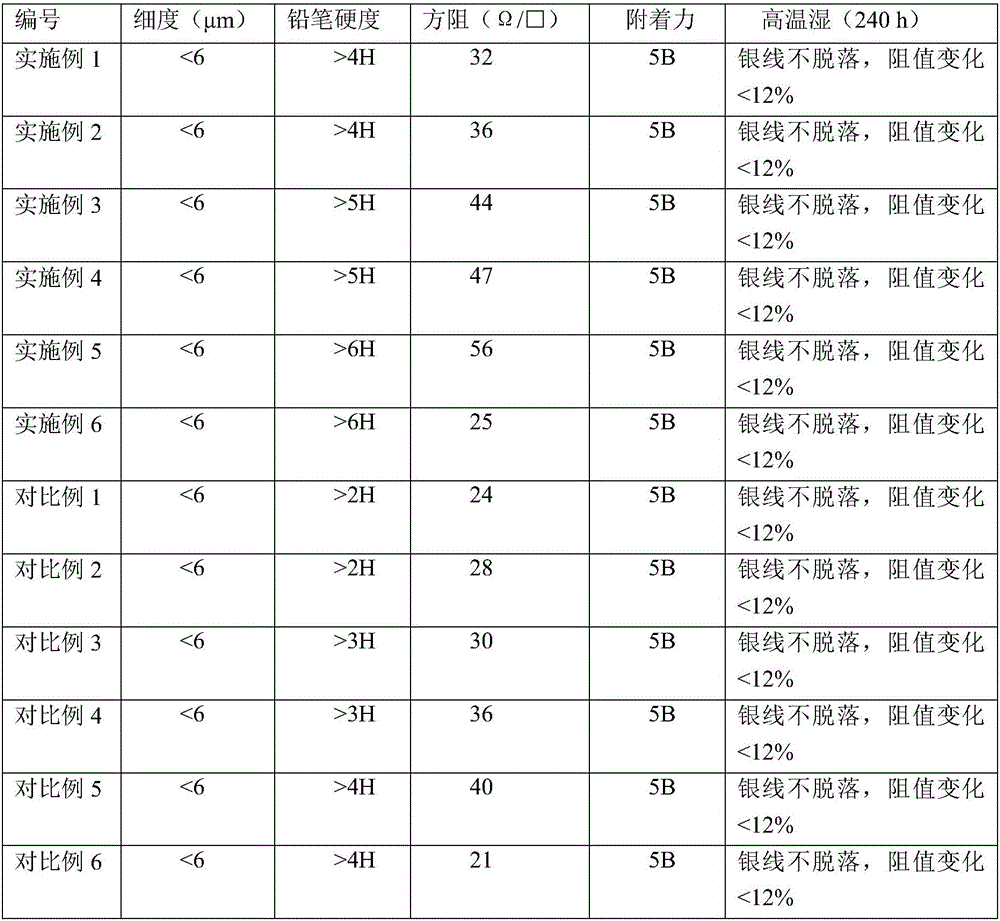

High-temperature and high-humidity resistant electrode silver paste for ZnO piezoresistor and preparation method for electrode silver paste

ActiveCN105788699AReduce contact resistanceImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteOrganic solvent

The invention discloses high-temperature and high-humidity resistant electrode silver paste for a ZnO piezoresistor. The conductive silver paste comprises the following components in percentage by weight: 52-80% of metal silver powder, 2-5% of glass powder, 10-30% of organic carrier, 1-3% of organic additives and 1-10% of organic solvent; the preparation method for the electrode silver paste comprises the steps of uniformly mixing the organic carrier and the organic solvent to prepare a uniform colloidal solution; then adding the other components in sequence; and enabling the mixture to be mixed through a mixer, grinded through a three-roll mill, and the like to obtain the high-temperature and high-humidity resistant electrode silver paste for the ZnO piezoresistor. Compared with the prior art, the electrode silver paste for the ZnO piezoresistor prepared by the invention is high in adhesive force, high in circulation volume, high in voltage resistance, low in ohmic contact resistance, high in flatness, excellent in structural compactness, and excellent in high-temperature and high-humidity resistance.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

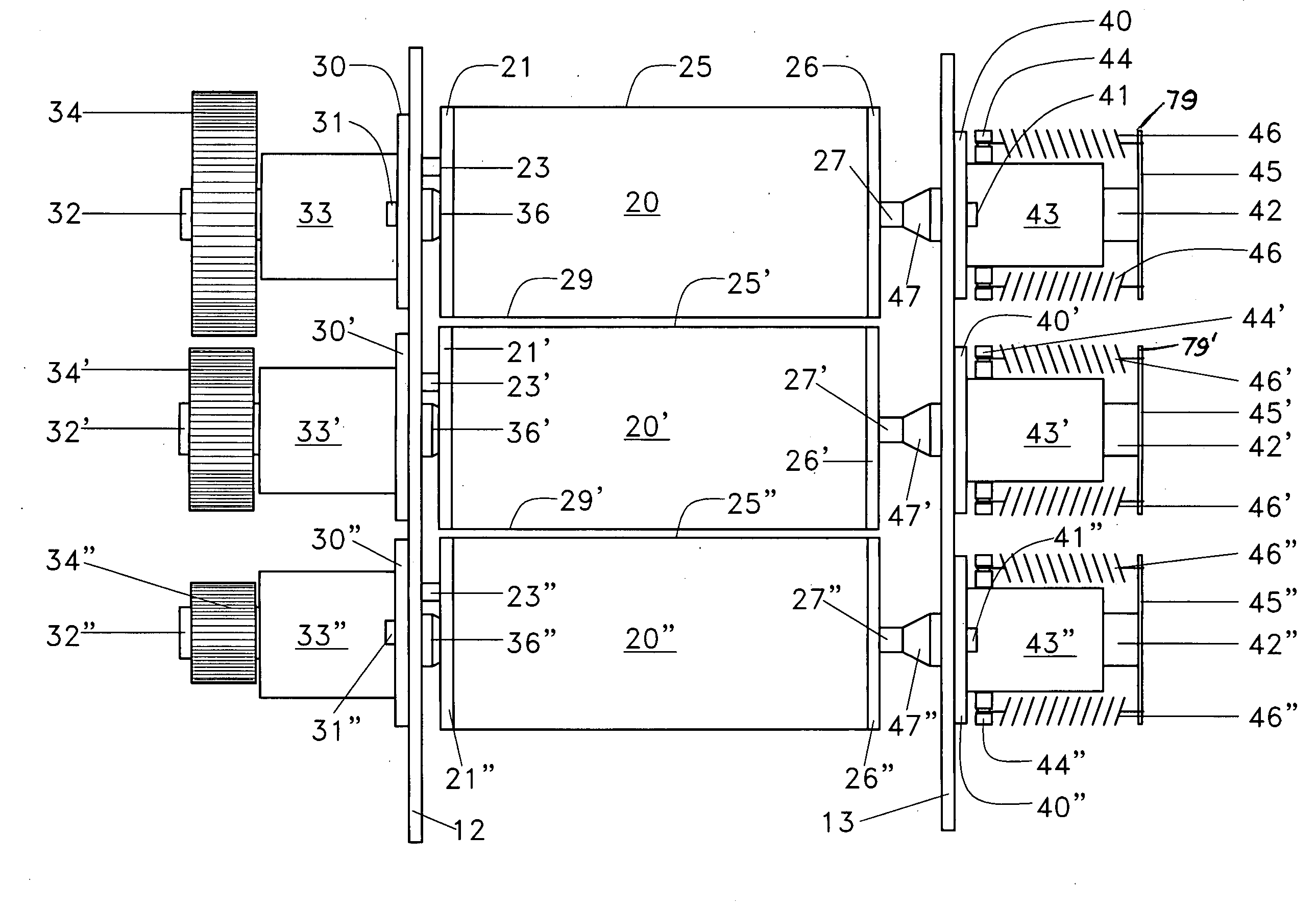

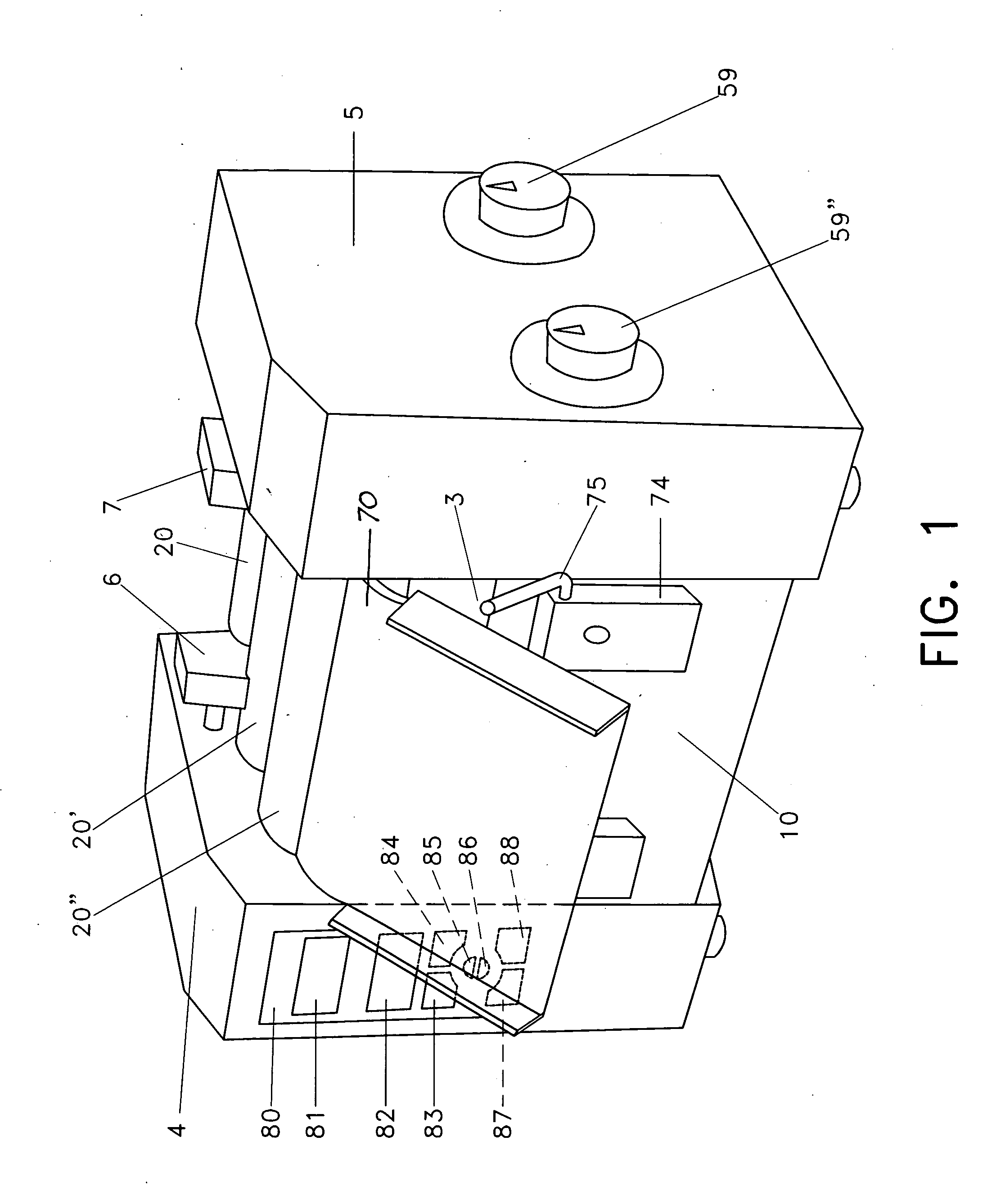

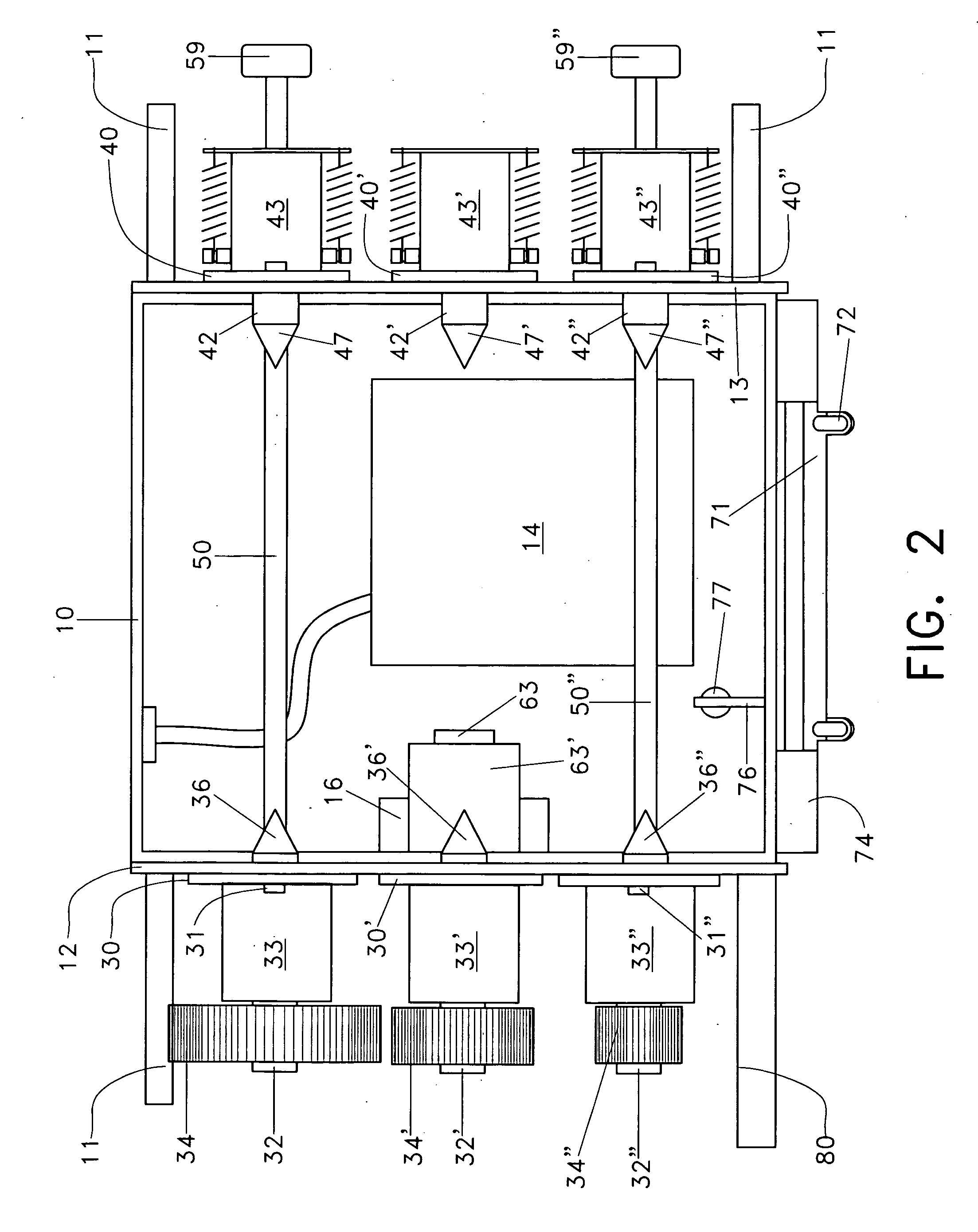

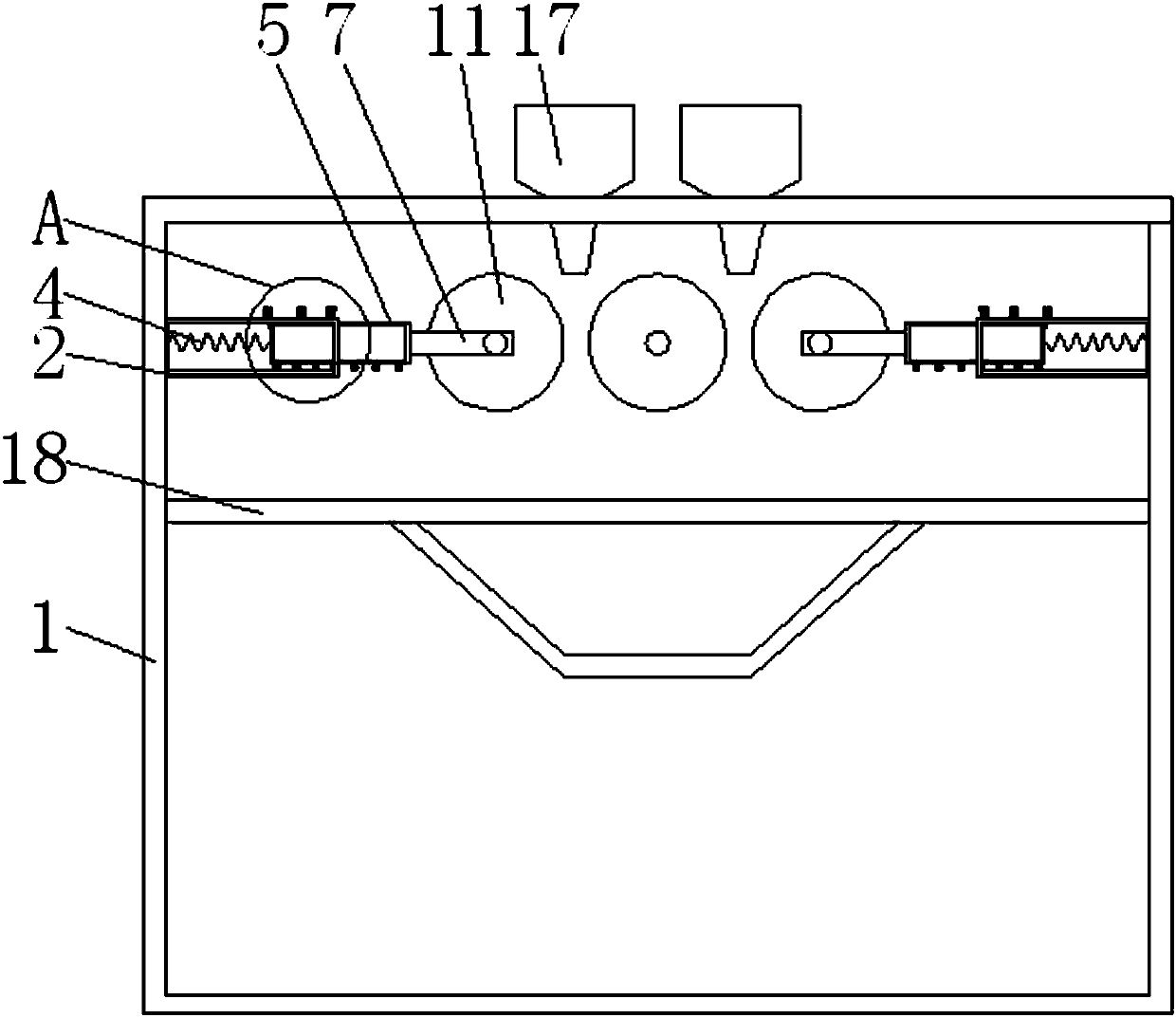

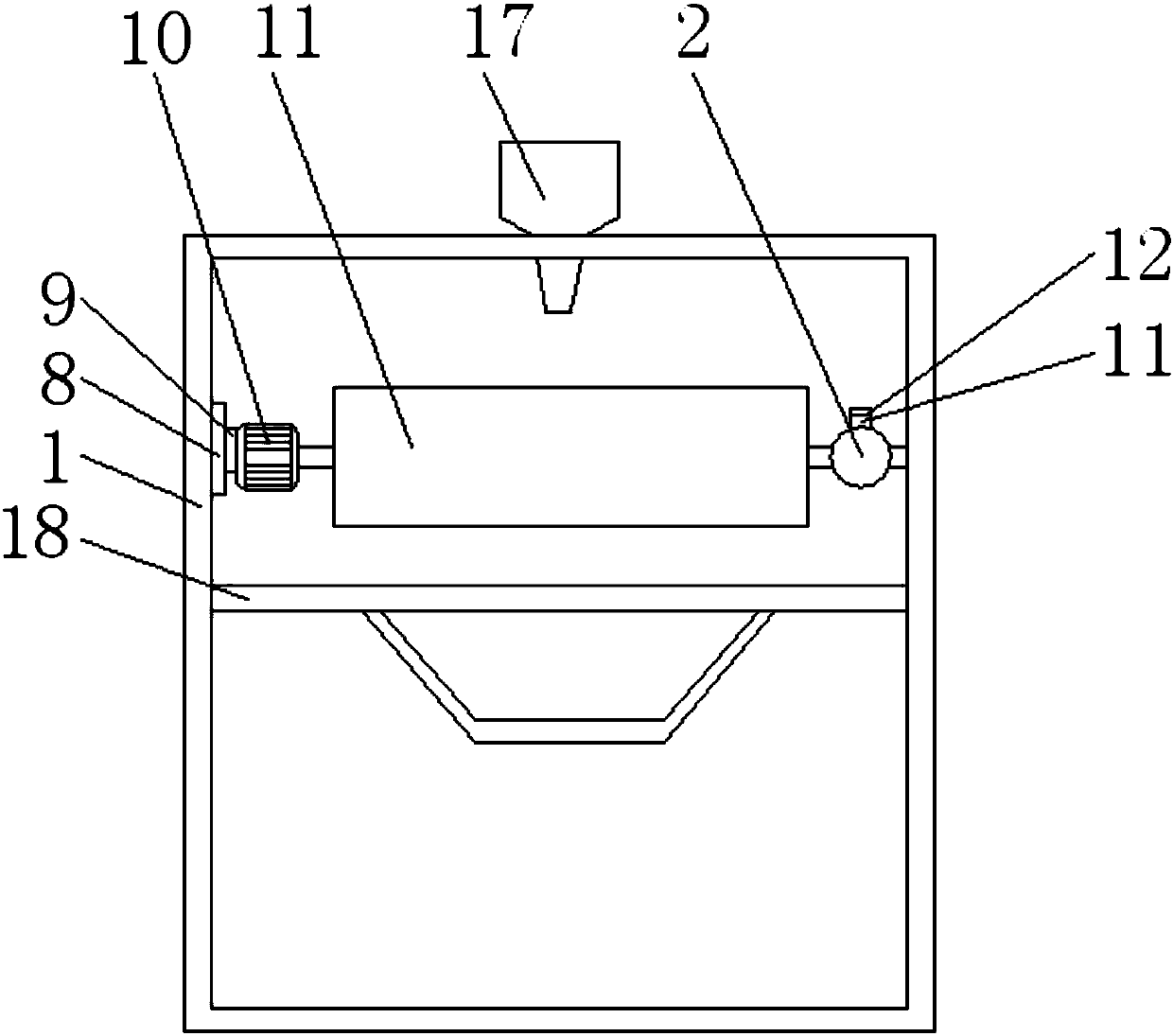

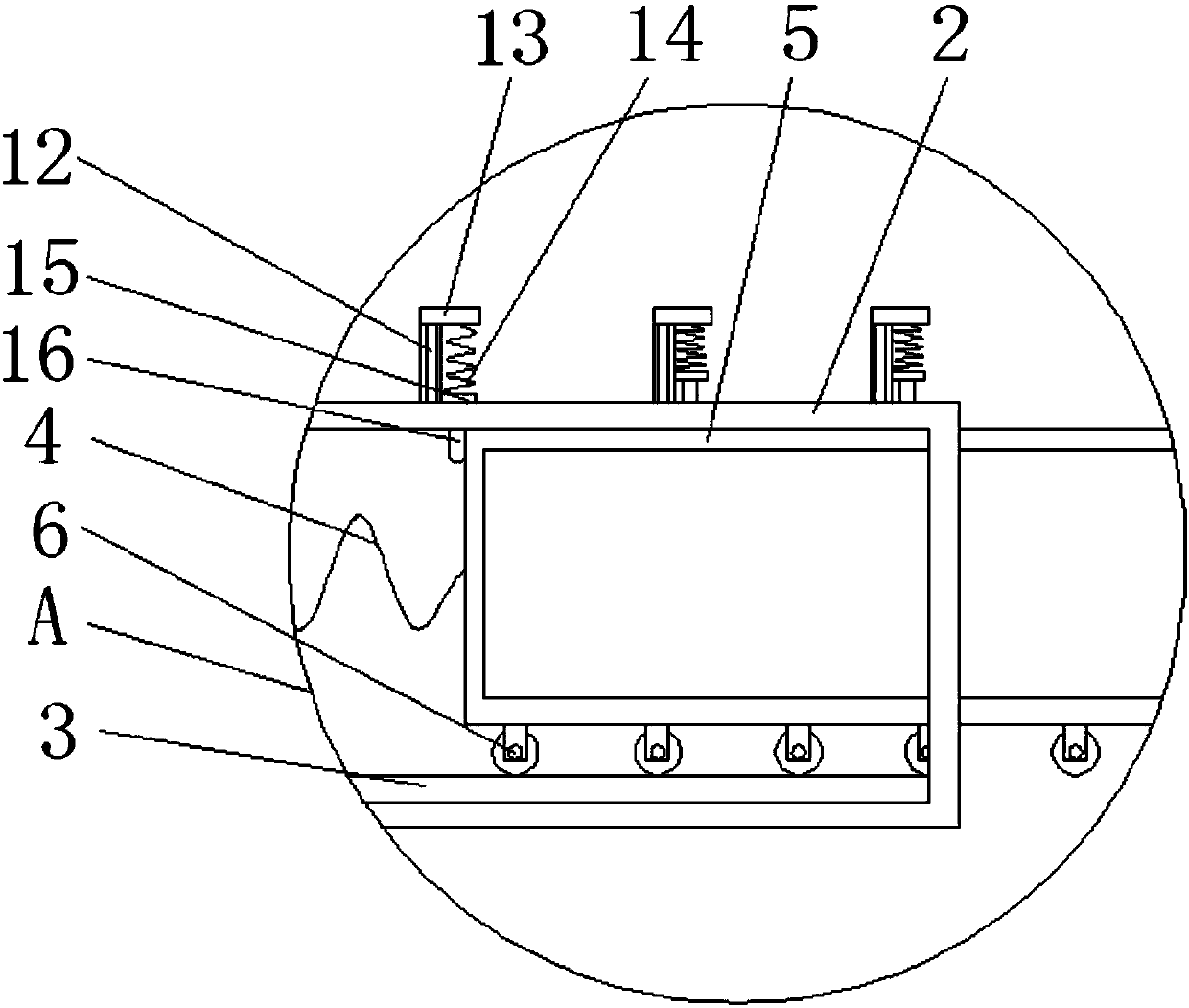

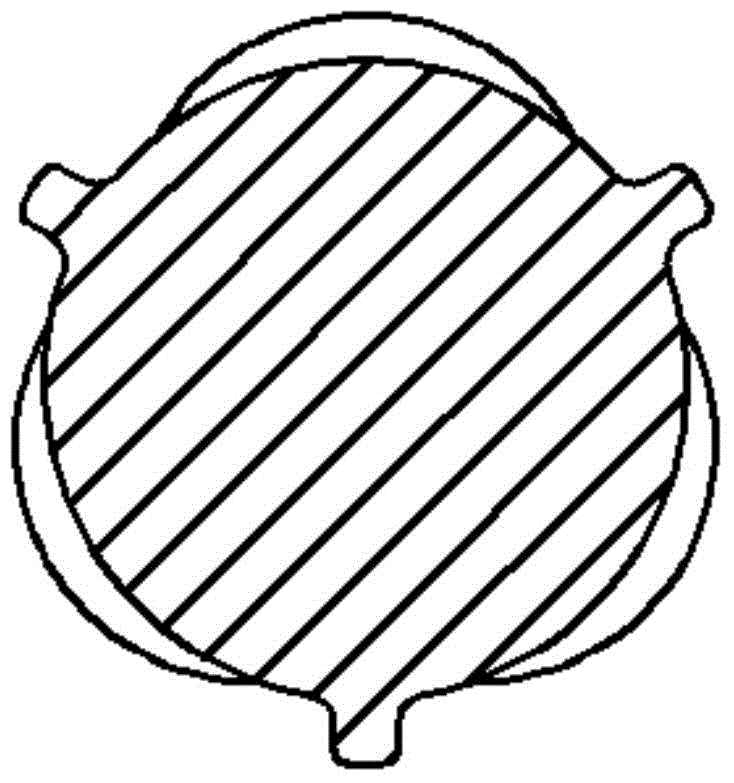

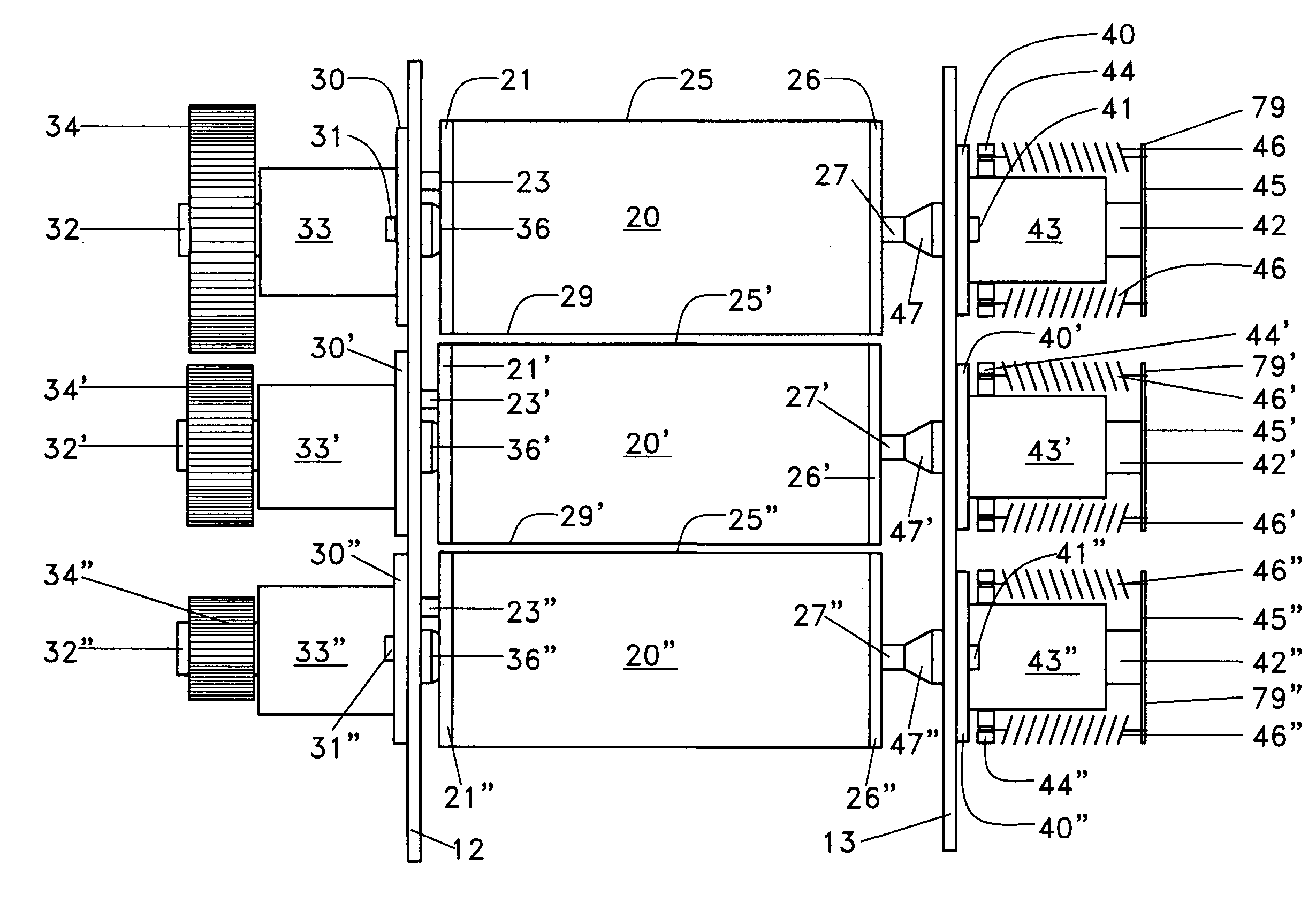

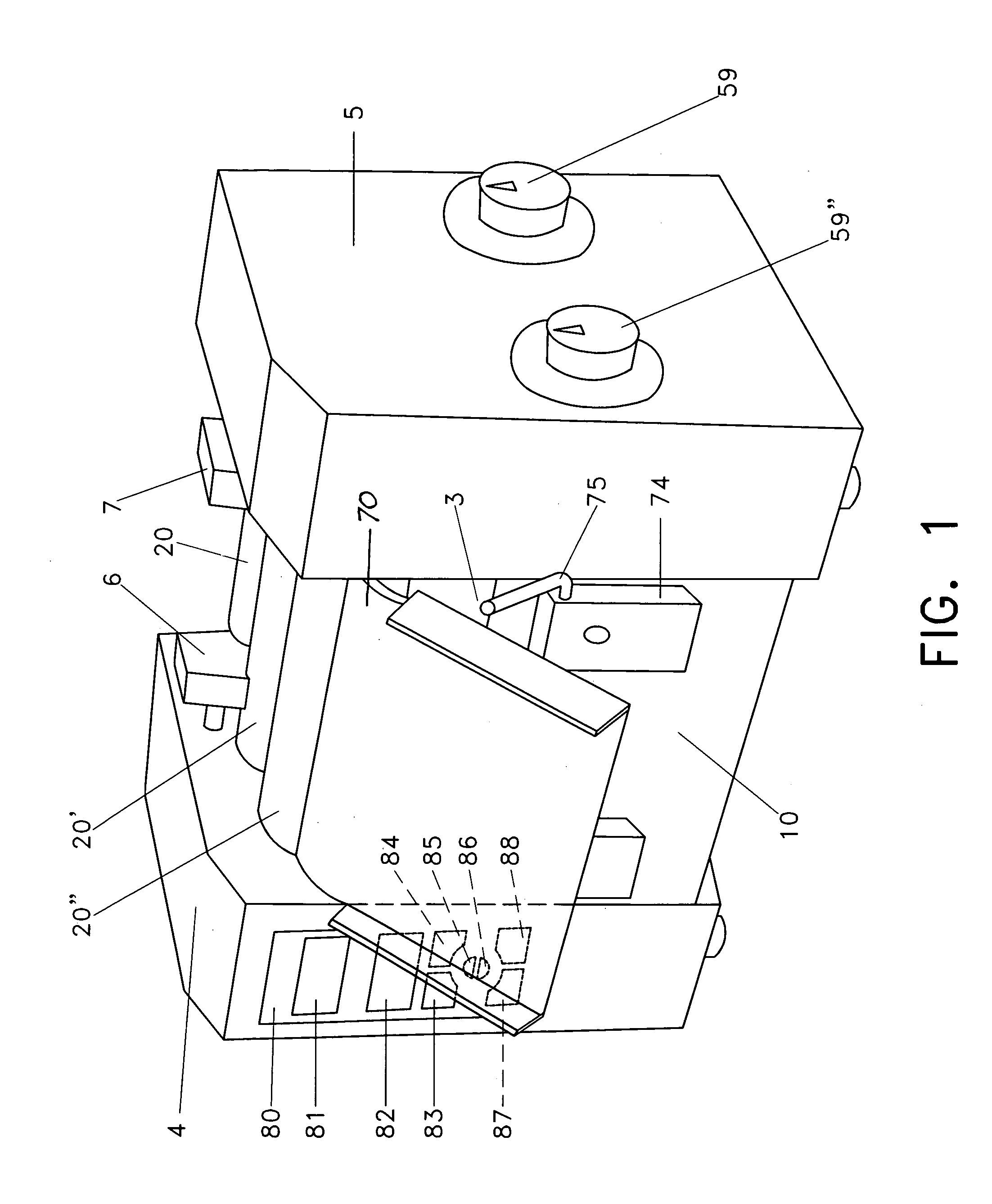

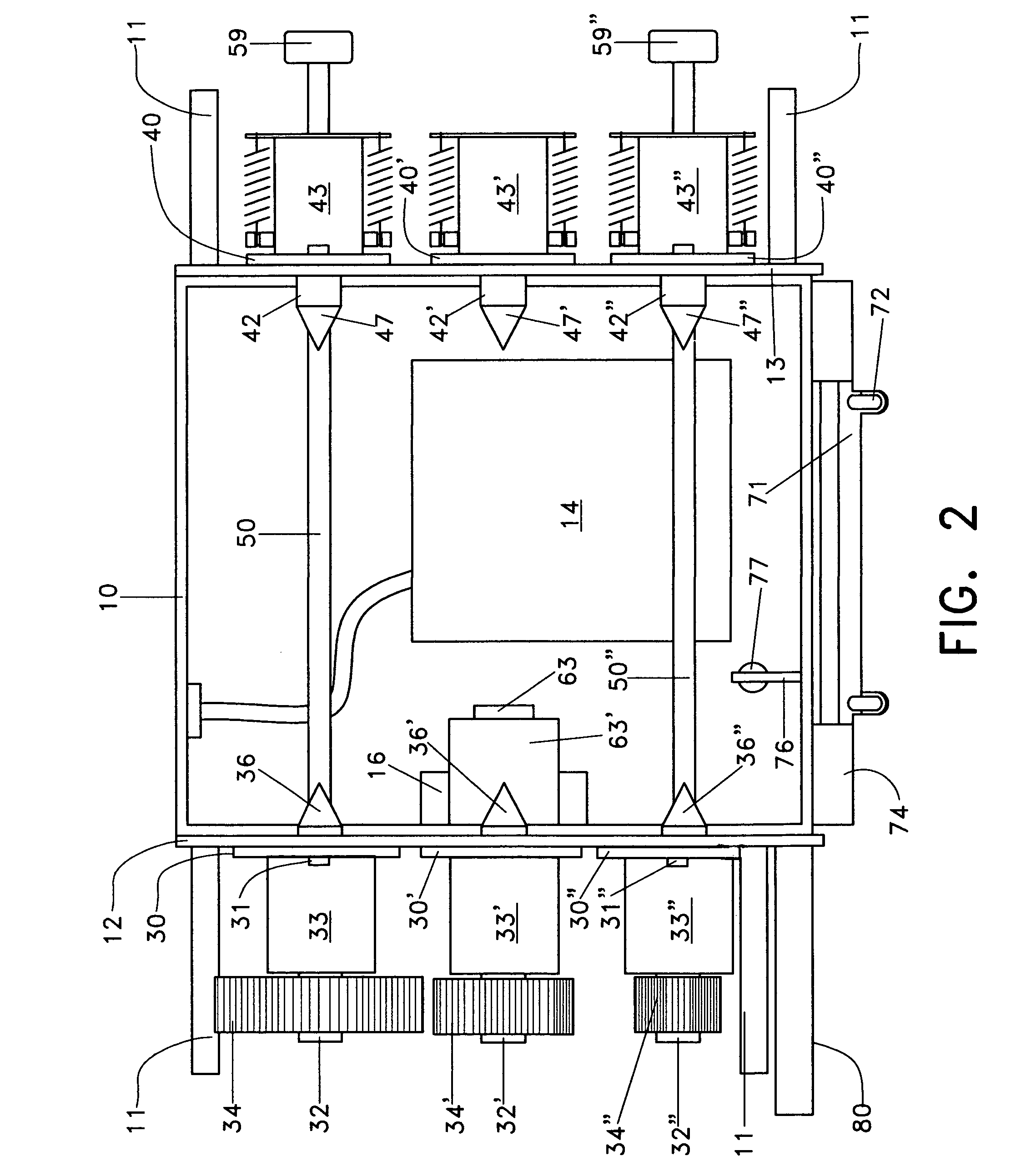

Three roll mill

A three roll mill having a feed roll, a center roll, and an apron roll with that are driven so that their cylindrical surfaces move in the same direction but different speeds in each nip. One end of each roll is engaged by a drive shaft at a first side of the mill, whereas the other end of each roll rotates freely at a second side of the mill. Each roll can be removed individually and without tools by moving the roll away from the first side against a spring force in the second side. This disengages the roll from its drive shaft, whereupon it can be lifted out of the mill.

Owner:SMITH JEFFREY P

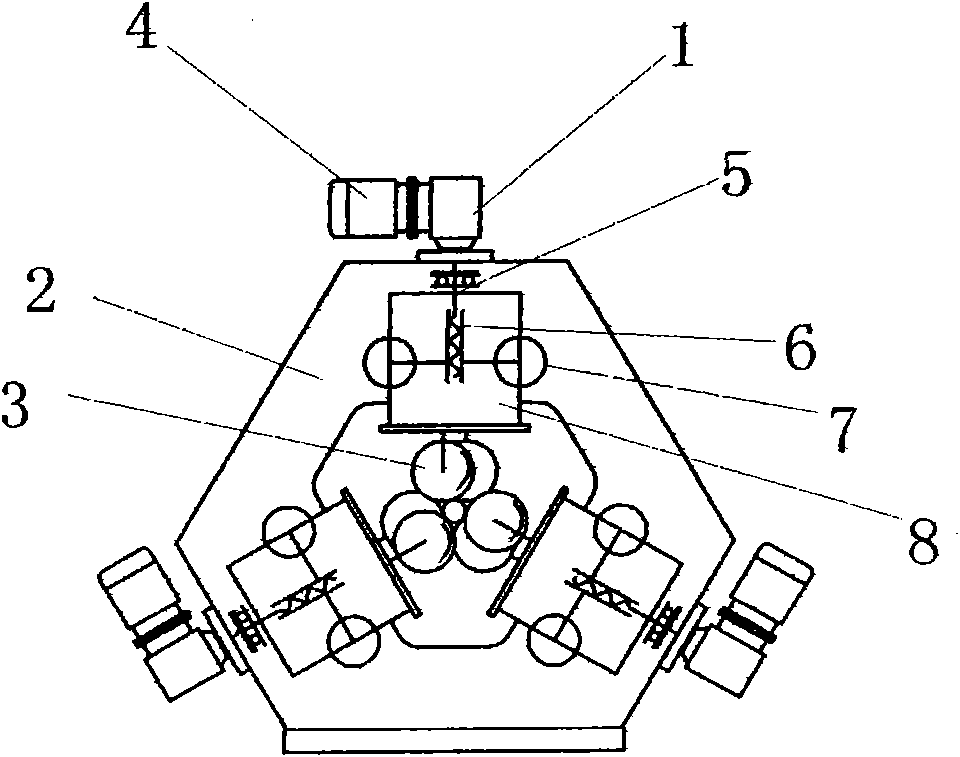

A three-roll spiral groove rolling mill

ActiveCN102274852AReasonable designReduce manufacturing costMetal rolling stand detailsMetal rolling arrangementsChinese charactersPulp and paper industry

The invention relates to a three-roller spiral pore type rolling mill which comprises a roller device and a frame, wherein the roller device comprises three roller components which are mounted on the frame in the shape of a Chinese character 'pin'; each roller component is composed of a roller, a roller pressing adjusting mechanism, a roller axial adjusting mechanism and a roller feeding angle adjusting mechanism; the roller pressing adjusting mechanism, the roller axial adjusting mechanism and the roller feeding angle adjusting mechanism which are arranged on the roller device are used for realizing the pressing adjustment, axial adjustment and feeding angle adjustment of the roller; and the roller component is organically combined with a phase angle adjusting mechanism, thereby being suitable for the rolling of various parts. Besides, the three-roller spiral pore type rolling mill has the advantages that the whole design is reasonable and the manufacturing cost is low.

Owner:芜湖精艺铜业有限公司

Nitrogen oxide sensor-used platinum-rhodium electrode paste and preparation method thereof

ActiveCN102798652APrinting changeChange appearanceMetal/metal-oxides/metal-hydroxide catalystsMaterial electrochemical variablesPlatinumNitrogen oxide sensor

The present invention discloses nitrogen oxide sensor-used platinum-rhodium electrode paste and a preparation method thereof. The platinum-rhodium electrode paste is prepared from the following raw materials by mass percentage: 1-10 wt% of an inorganic binder,10-20 wt% of an organic binder, 10-50 wt% of ultrafine rhodium powder, 30-60 wt% of ultrafine platinum powder, and 5-10 wt% of zirconium dioxide. The preparation method comprises: (1) preparing the inorganic binder, (2) preparing the organic binder, (3) weighing the organic binder, the inorganic binder, the ultrafine rhodium powder, the ultrafine platinum powder and zirconium dioxide by taking the preparation of 100 g of platinum-rhodium electrode paste as a reference, adding to the container in accordance with the principle of from less to more, stirring sufficiently for uniform dispersion on adding each material, then grinding by a three-roll mill, removing agglomerated particles, and then stirring for dispersion to obtain the uniformly dispersed paste. The paste is good in printing, drying, and sintering performances and good in adhesion after sintering at high temperature.

Owner:WUXI LONGSHENG TECH

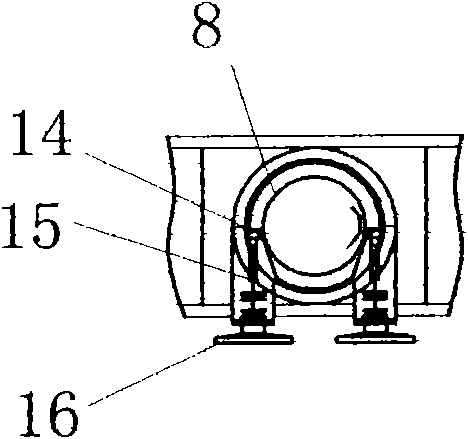

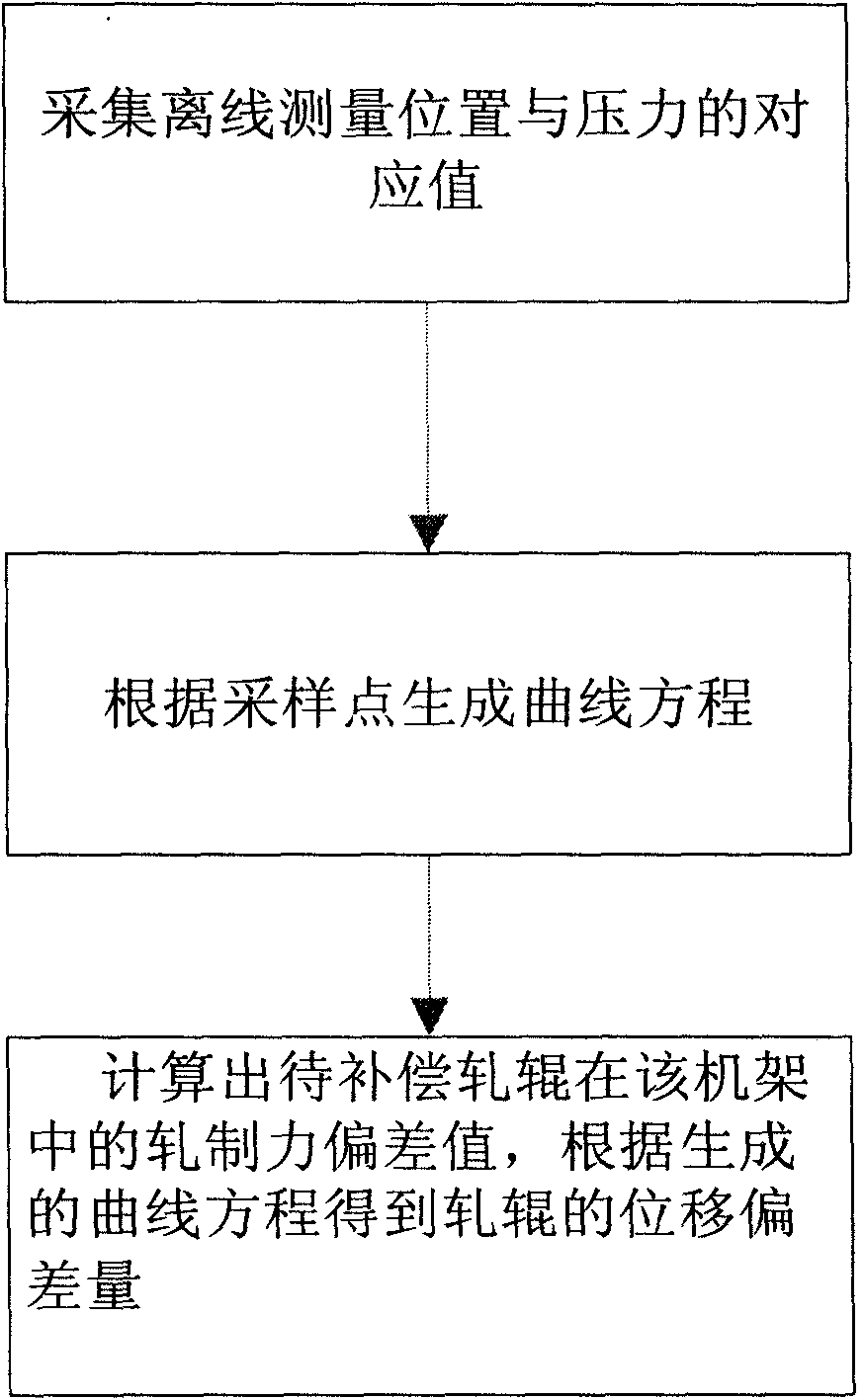

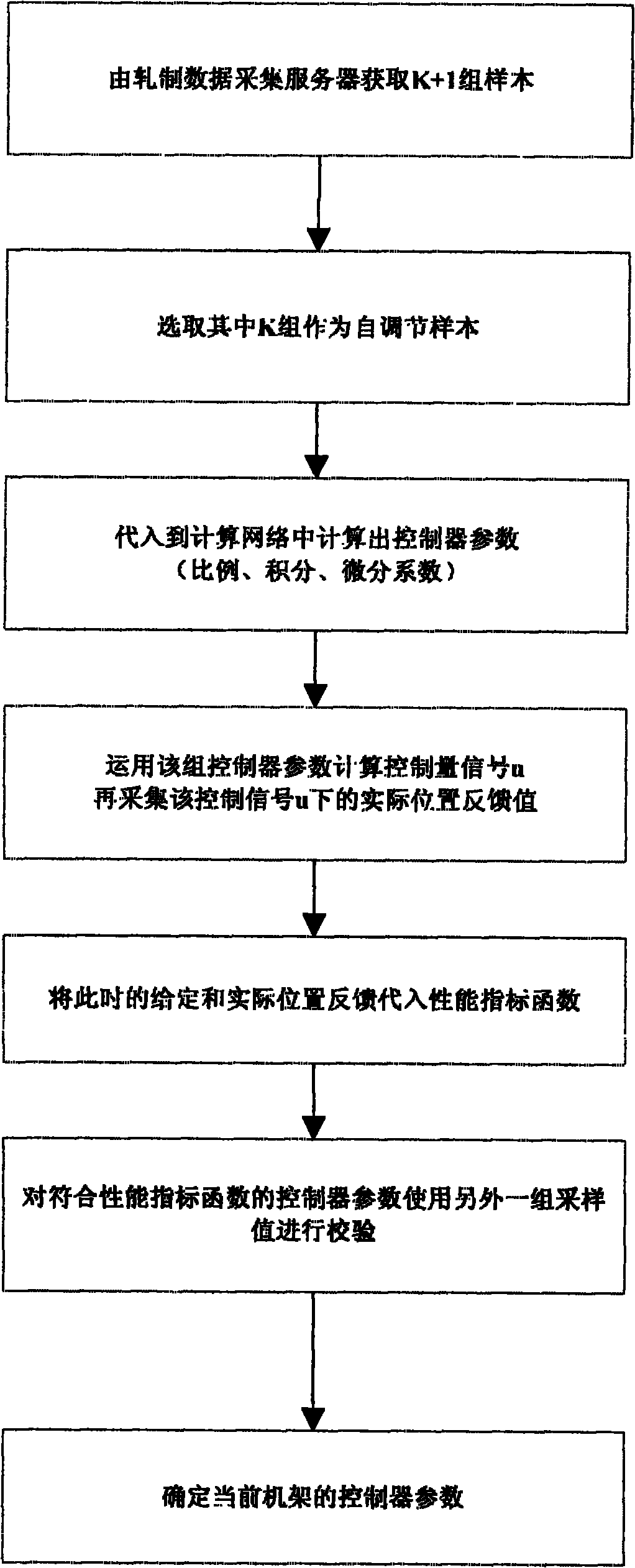

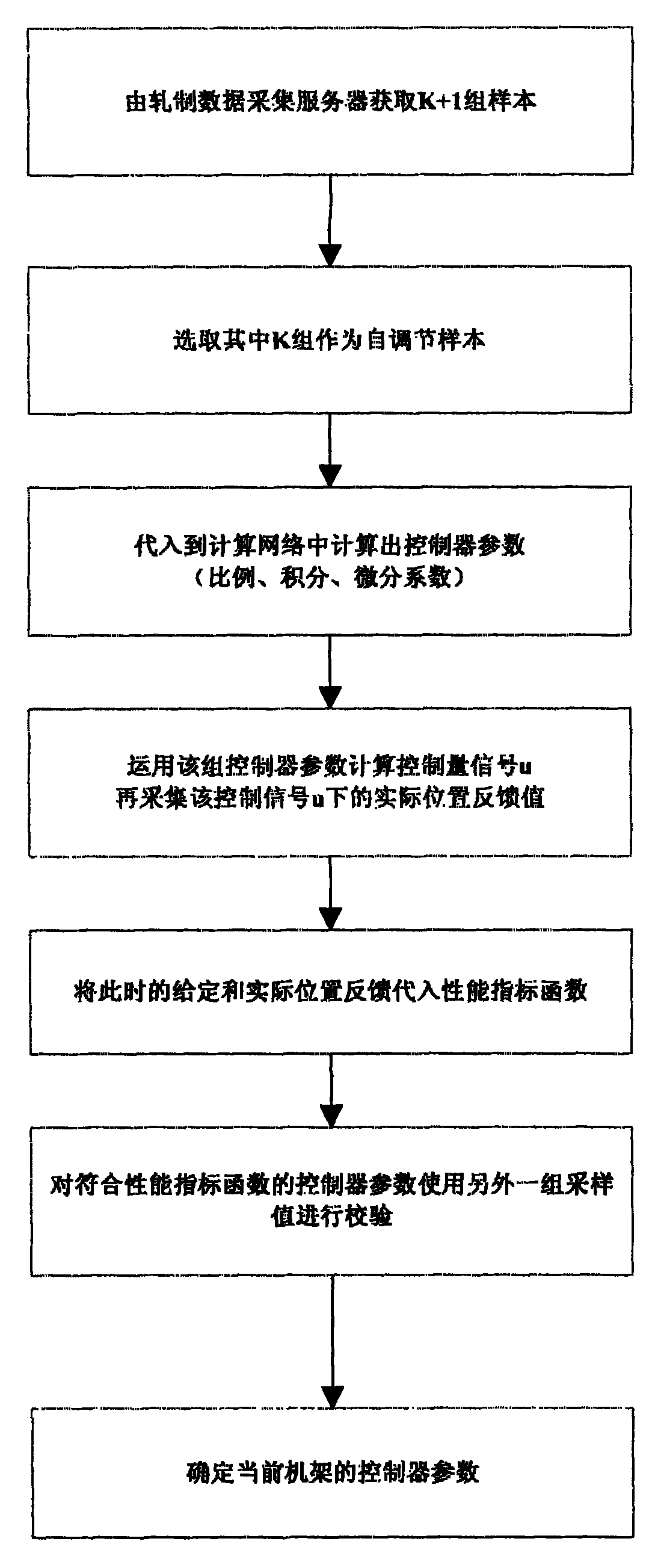

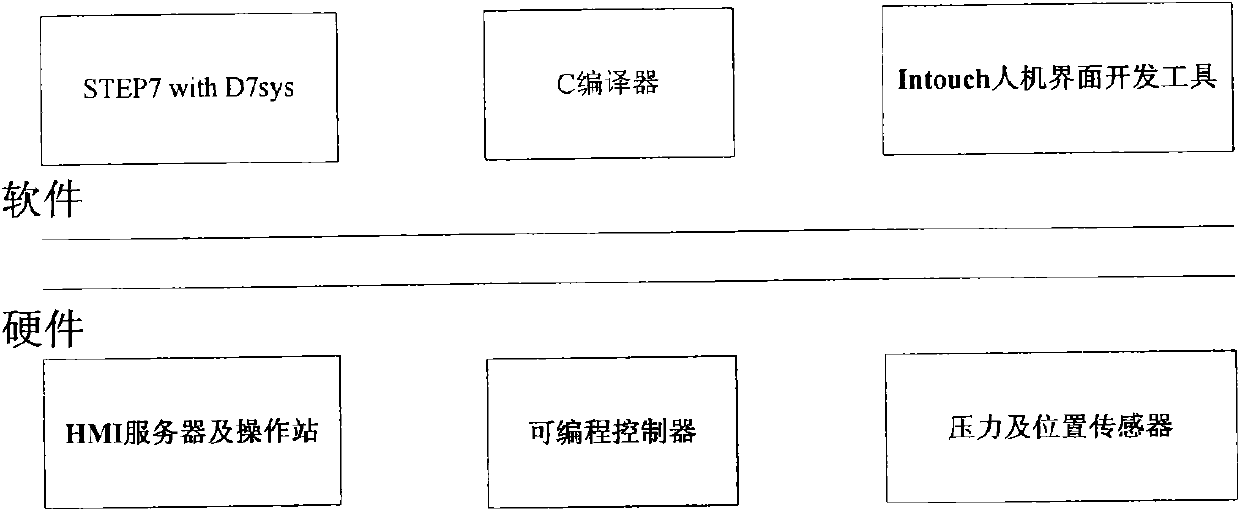

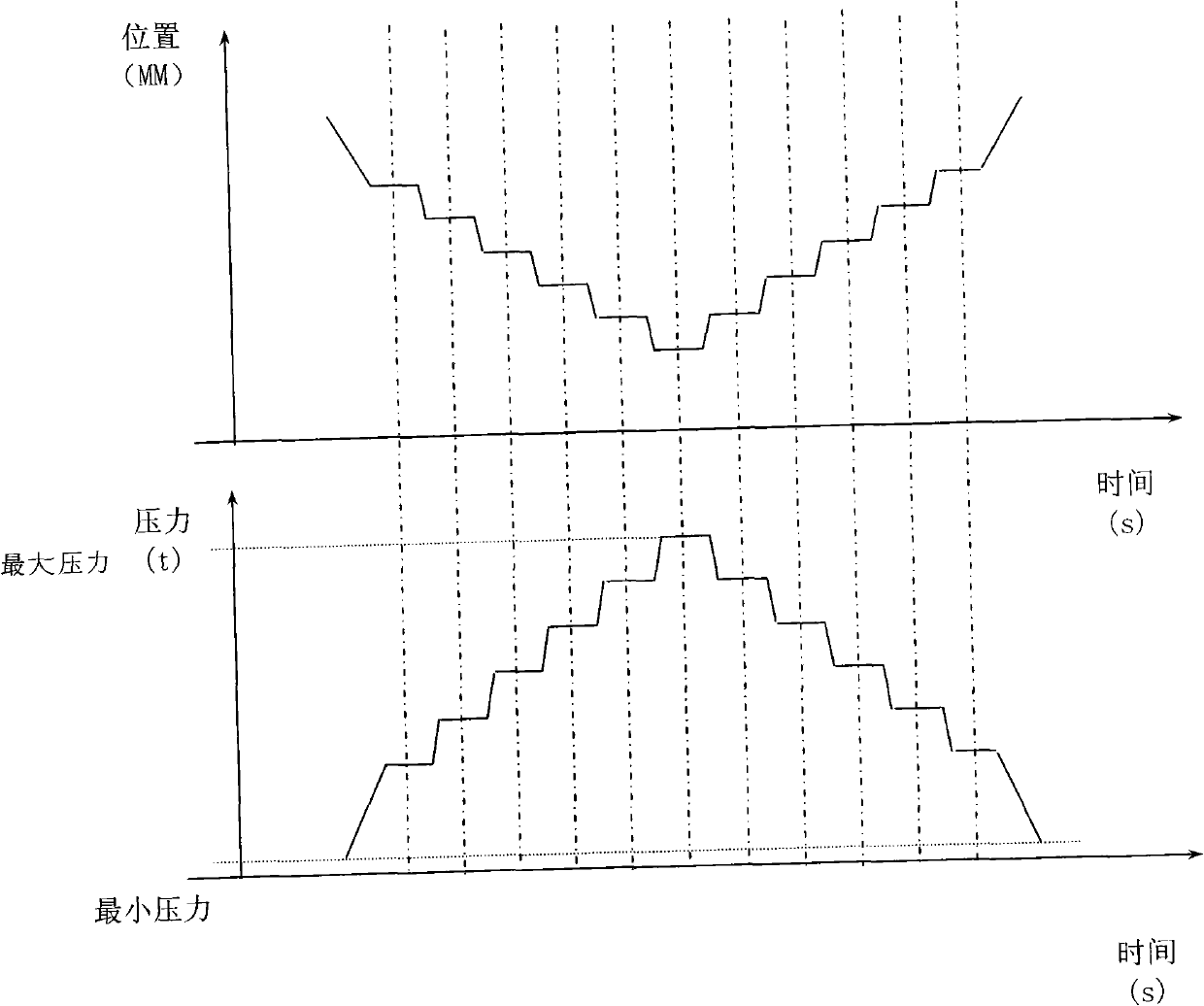

Method for adjusting three-roll mill roll gap controller

InactiveCN101927269ASolve the problem of position offsetAvoid uneven forceRoll force/gap control deviceAdaptive controlControl signalEngineering

The invention discloses a method for adjusting a three-roll mill roll gap controller. The roll gap controller is characterized in that the adjusting method comprises the steps of: A. deducing controller parameters Kp, Ki and Kd through a neural network and calculating control signals by increment control equations for adjusting the controller; and B. Balancing a rolling force: acquiring corresponding values of a off-line measuring position and pressure, calculating rolling force deviation of the roll to be compensated on a stand according to a curvilinear equation generated from a sampling point, and compensating the control signals through the calculated displacement deviation. The invention uses the neural network to calculate proper controller parameters so as to make the control more accurate. Meanwhile, the roll gap controller adopts a centering compensating method, thus the roll gap controller can avoid position deviation of roll gap resulted under the action of rolling pressure. In addition, the adjusting method for balancing rolling force solves the problem of uneven load distribution in different directions of a pipe so as to achieve uniformity of wall thickness of a product and improve productivity of the product.

Owner:CISDI ENG CO LTD

Lubricating grease composition and manufacturing method therefor

ActiveCN102186958AImprove wear resistanceImprove load resistanceThickenersAdditivesCarboxylic acidDicarboxylic acid

Disclosed is a lubricating grease composition that includes a composite metal soap thickener of aliphatic dicarboxylic acid and monoamide monocarboxylic acid, and a fluorine resin powder in a base oil mixture comprised of a non-fluorine series base oil and a fluorine series base oil which are mutually incompatible. This lubricating grease composition is manufactured by kneading, preferably with a three-roll mill, a non-fluorine series grease which is prepared by heating and agitating a non-fluorine series base oil, aliphatic dicarboxylic acid, and monoamide monocarboxylic acid, and adding a metal hydroxide thereto to form a composite metal soap in the non-fluorine series base oil, and a fluorine series grease which is prepared from a fluorine series base oil and a fluorine resin powder.

Owner:NOK KLUEBER CO LTD

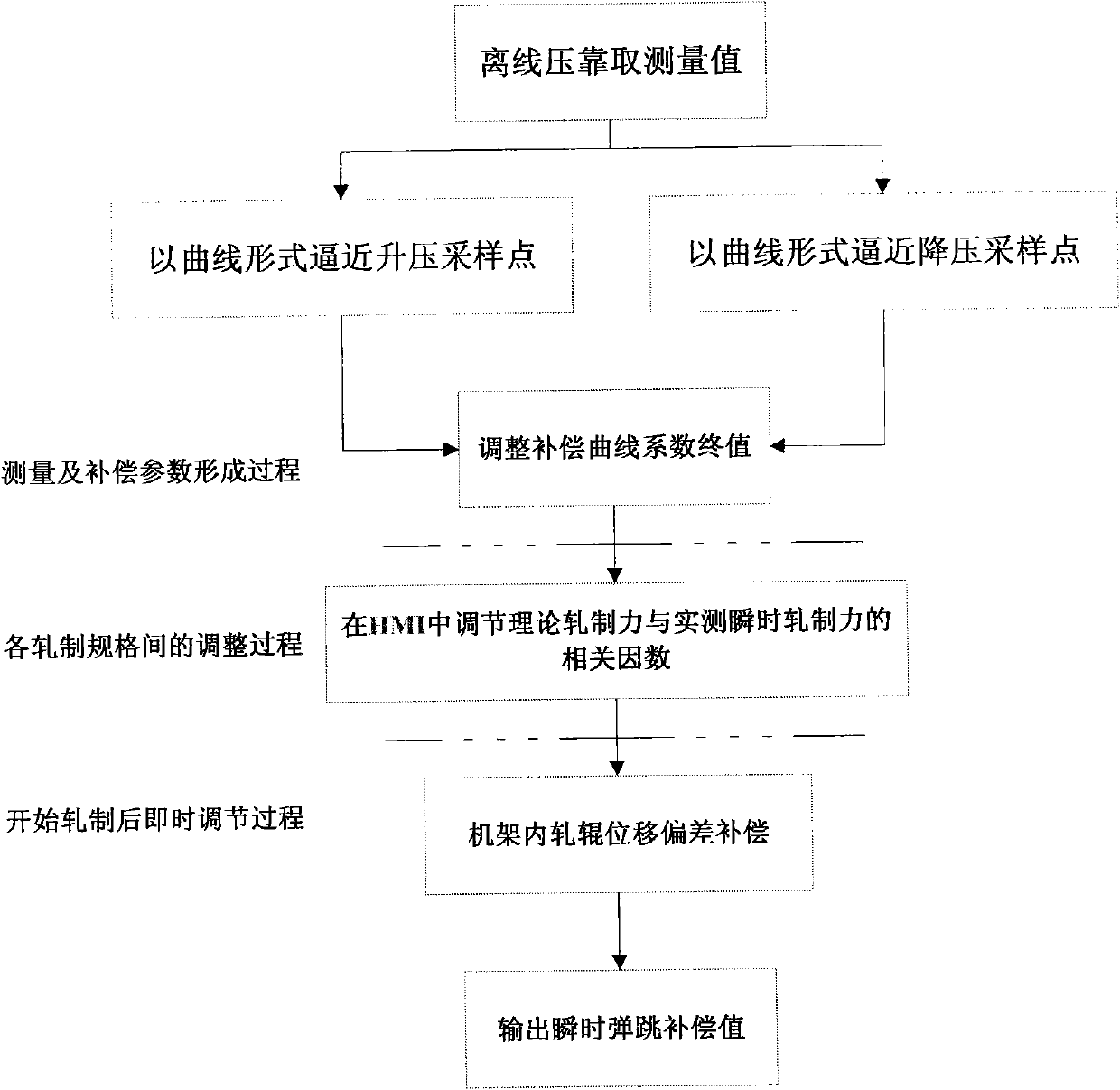

Compensation method of seamless steel pipe three-roll mill

InactiveCN101658863AEasy to track and controlImprove portabilityRoll force/gap control deviceRolling equipment maintainenceElastic curveEngineering

The invention belongs to the technical field of forming and particularly relates to a compensation method of seamless steel pipe three-roll mill. The method comprises: 1, an equation of an elastic curve: T(x)=sigma ciphii; 2, a three-roll centering compensation method; 3, disturbance influence reduction method; and 4, elastic deformation compensation input adjustment method. The compensation method of the invention solves an elastic deformation problem of a seamless steel pipe three-roll mill and takes the characteristics and the influences of smooth adjustment into consideration. Simply, a smooth curve approximation mode of elastic deformation compensation can be used in three-roll mills and also can be used in production processes of other various mills, such as other hot rolling processes, cold rolling processes and the like.

Owner:CISDI ENG CO LTD

Foaming sound-proof acrylic resin vehicle bottom protective plastisol and preparation method thereof

The invention relates to foaming sound-proof type acrylic resin car-bottom protection plastisol and the preparation process thereof. The foaming sound-proof type acrylic resin car-bottom protection plastisol comprises components with following percentage by weight, 4-8% volatile solvent, 20-40% plasticizing agent, 20-35% acrylic polymer, 5-20% polyurethane resin, 0.2-1.5% foaming agent, 0.2-1.5% thixotropic agent and 15-45% filling. The preparation process comprises mixing raw materials under controlled temperature, stirring, grinding with a three roll mill, stirring under -0.05-0.1MPa, screening and obtaining finished products. The plastisol of the invention has excellent sound-proof effect, less construction usage, safe construction condition and low cost.

Owner:长春依多科化工有限公司

High-thermal-conductivity conductive adhesive prepared from nano-silver modified carbon nanotubes and preparation method of conductive adhesive

InactiveCN110079266ALower transport barrierImprove transmission efficiencyNon-macromolecular adhesive additivesEpoxy resin adhesivesHeat conductingModified carbon

The invention relates to a high-thermal-conductivity conductive adhesive prepared from nano-silver modified carbon nanotubes and a preparation method of the conductive adhesive and belongs to the technical field of composite preparation. The high-thermal-conductivity conductive adhesive prepared from nano-silver modified carbon nanotubes is prepared from raw materials as follows: 20-35 parts of aresin carrier, 65-80 parts of silver powder and 1-5 parts of the nano-silver modified carbon nanotubes. The carrier and the silver powder with the particle size of 5 mu m are fully dispersed and mixedby a three-roll mill, the nano-silver modified carbon nanotubes, the dispersant and the defoaming agent are added, mixed slurry is obtained and then mixed by a centrifuge, and the high-thermal-conductivity conductive adhesive is prepared. According to the method, the carbon nanotubes modified with nano-silver are added to silver adhesive, heat conducting bridge linking is formed among micro-silver particles, nano-silver on surfaces of the carbon nanotubes and silver particles are sintered and linked, a large number of heat conducting paths are established, the carrier transport potential barrier among filler is reduced, and the transport efficiency of phonons and electrons among filler interfaces is substantially improved.

Owner:KUNMING UNIV OF SCI & TECH

A two-stage lateral transmission three-roll rolling mill

The invention belongs to the technical field of mechanical engineering and relates to a two-stage lateral transmission three-roll rolling mill. The system includes: machine base transmission side cover, machine base, machine base roll side cover, transmission shaft, roll, roll gap adjustment mechanism, roll bearing seat. The present invention is a three-roll rolling mill with two-stage lateral input transmission power. When the roll gap is adjusted, the rolls are perpendicular to the line connecting the center of the transmission shaft gear and the center of the roll gear. After the roll gap is adjusted, the difference between the center moments of the two gears within the allowable tolerance range of the central moment. Three roll chocks that move vertically to the rolled piece and the roll gap adjustment mechanism are designed and arranged in conjunction with the roll gap adjustment method. The roll gap adjustment mechanism synchronously drives the wedge to move to increase or decrease the roll gap. The invention inputs transmission power on the sides of the three rollers, cancels the C-shaped module, simplifies the power input of the rolling mill, and reduces equipment weight and energy consumption.

Owner:BEIJING WANTAI MACHINERY EQUIP

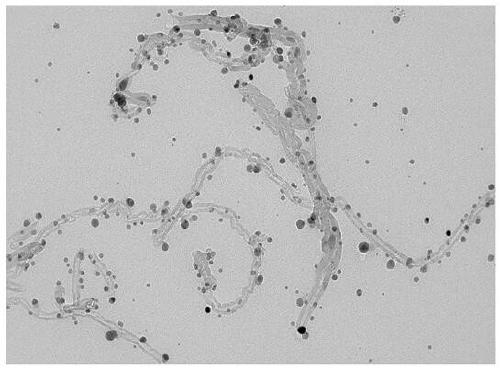

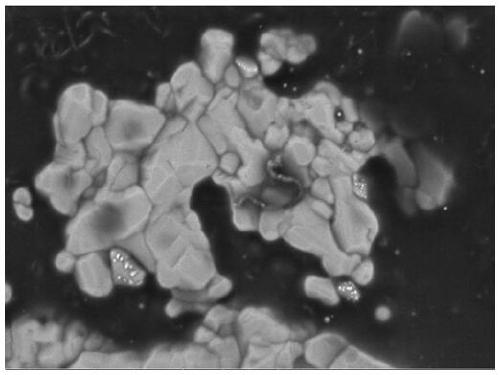

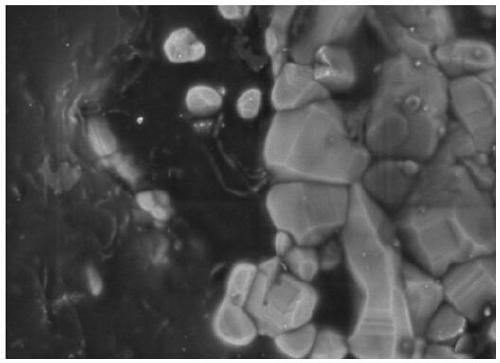

Grease composition and process for producing the same

A grease composition, which comprises a mixture of mutually incompatible thickener-containing non-fluorine-based base oil and thickener-containing fluorine-based base oil, the base oils being in a morphological structure, where one of the base oils is homogeneously dispersed in a particulate state in the other base oil, can be produced by kneading the mixture through a three-roll mill at least twice. By forming a morphological structure, one of the mutually incompatible non-fluorine-based base oil and fluorine-based base oil is homogeneously dispersed in a particulate state in the other base oil, that is, by forming a microscopically dispersed state, the following effects can be obtained (1) less oil separation (smaller degree of oil separation) at elevated temperatures, (2) distinguished shearing stability, (3) low and stable friction coefficient, and (4) less abrasion.

Owner:NOK KLUEBER CO LTD +1

Three-roller grinder capable of adjusting drum distance

InactiveCN107837865AImprove convenienceSpacing is easy to adjustGrain treatmentsEngineeringChemical milling

The invention relates to the technical field of chemical grinding machines and discloses a three-roller grinder capable of adjusting the drum distance. The three-roller grinder comprises a drum body.A column body I is fixedly installed on the top of the side face of an inner cavity of the drum body. A supporting plate is fixedly installed on the bottom of an inner cavity of the column body I. A spring I is fixedly installed on the side face of the inner cavity of the column body I. One end of the spring I is movably connected with a column body II movably sleeved with the inner cavity of thecolumn body I. A rolling shaft is fixedly installed on the bottom of the column body II. The rolling shaft is movably connected with the upper surface of the supporting plate. According to the three-roller grinder capable of adjusting the drum distance, by means of cooperation among a supporting rod, the column body II and the rolling shaft, materials are ground according to different needs, whenthe distance between drums is adjusted, the distance between the drums does not need to be adjusted manually, resilience of the spring I is utilized, the drums move automatically, and then convenienceof the whole device is improved.

Owner:黄敬匀

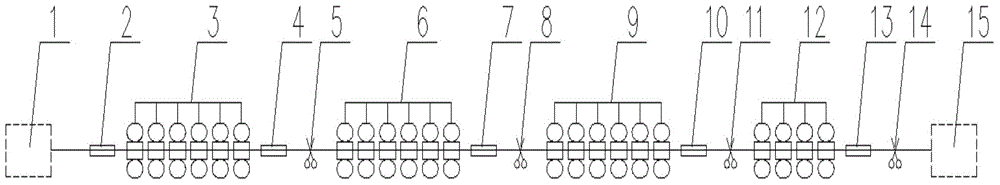

Production process device for rebar with ribs at three sides

ActiveCN103978030ALarge rolling capacityWork treatment devicesMetal rolling arrangementsProduction lineTemperature control

The invention discloses a production process device for a rebar with ribs at three sides. The device comprises a preprocessing procedure, a rough mill unit, first shearing equipment, a middle mill unit, second shearing equipment, a finishing mill unit, third shearing equipment, a diameter reducing and fixing unit, fourth shearing equipment and a postprocessing procedure which are arranged in sequence; the rough mill unit, the middle mill unit, the finishing mill unit and the diameter reducing and fixing unit all adopt a three-roll mill; crescent-shaped rib grooves matched with the shapes of rib parts at the surface of the rebar with the ribs at three surfaces are marked at the last three-roll mill of the finishing mill unit. The high strength three-roll mills are arranged in the full production line, the rolling capacity is large, large compression in one single path can be realized and guarantee is provided for producing a fine grain rebar; in addition, temperature control water tanks are arranged at multiple positions of the production line, so a rolled piece is subjected to online temperature control and cooling by mediums such as air and water, and the ordered production of the threaded rebar with high strength level can be realized by matching the reasonable temperature window of the rolled piece and the large compression process of the mills.

Owner:CISDI ENG CO LTD +1

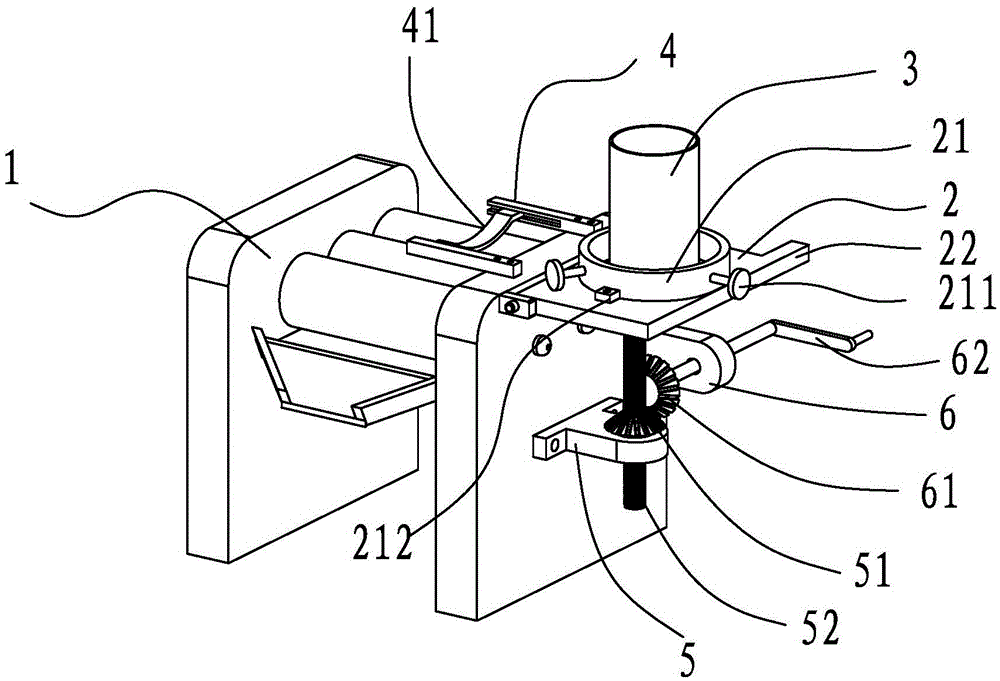

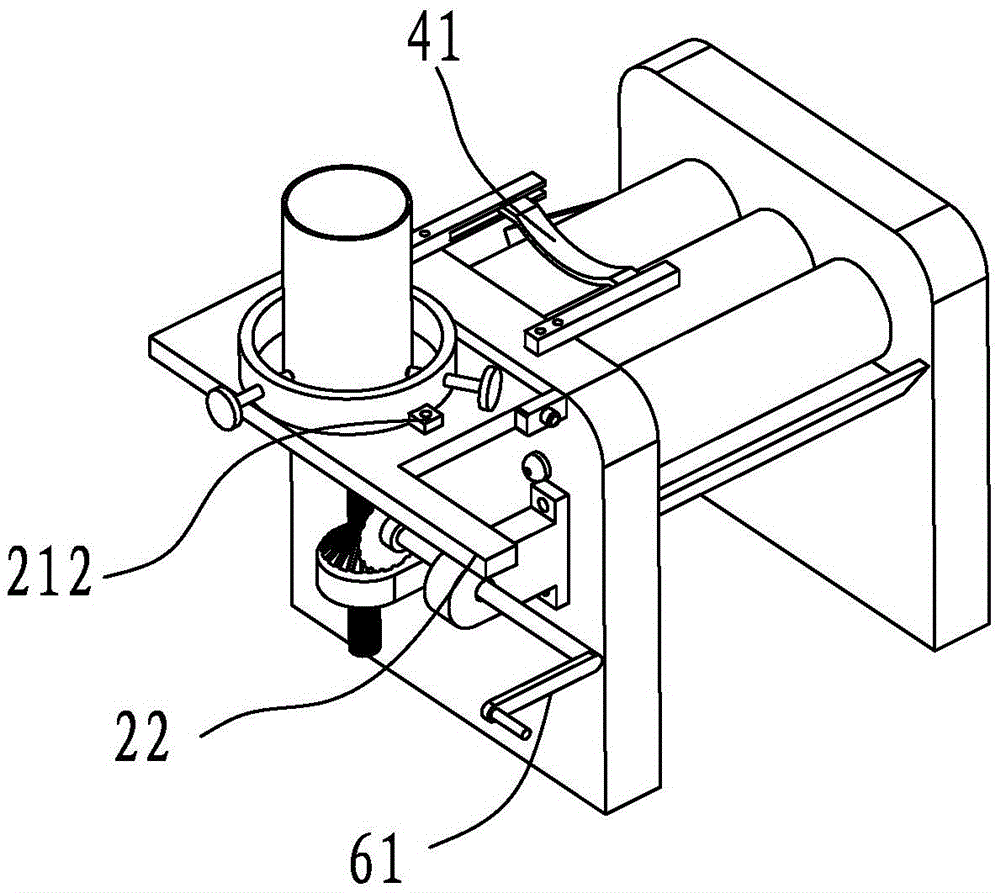

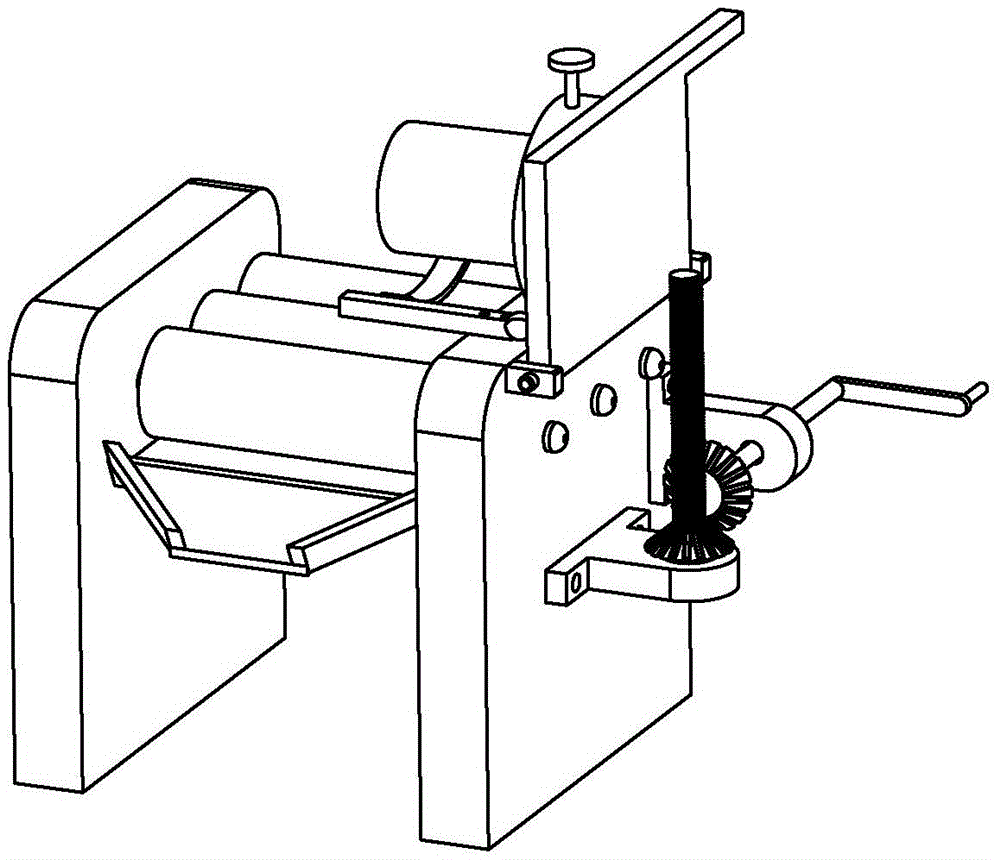

A feeding mechanism for a three-roller mill

The invention discloses a feeding mechanism of a three-roller grinding machine. The feeding mechanism comprises a grinding machine main body, wherein the outer side surface of the grinding machine is articulated to a feeding support plate, the rear side of the feeding support plate extends to form a handheld part, a limit steel ring is fixed to the center of the feeding support plate, a material barrel is arranged in the limit steel ring, more than two fastening screws are arranged on the periphery of the limit steel ring, two parallel steel strips are fixed on the inner side surface of the grinding machine and above three rollers, a sliding rail is arranged on the inner side surface of each steel strip, and a holding frame for supporting the inclined material barrel is arranged between the two sliding rails. Therefore, an operator can pour materials with less effort, and the working efficiency is improved.

Owner:CHANGXING HUAQIANG ELECTRONICS

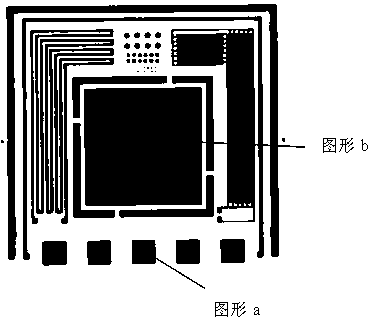

Conductive silver paste for fine line silk-screen printing for capacitive type touch screen

ActiveCN105788702ASmooth edgesImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureFine lineDefoaming Agents

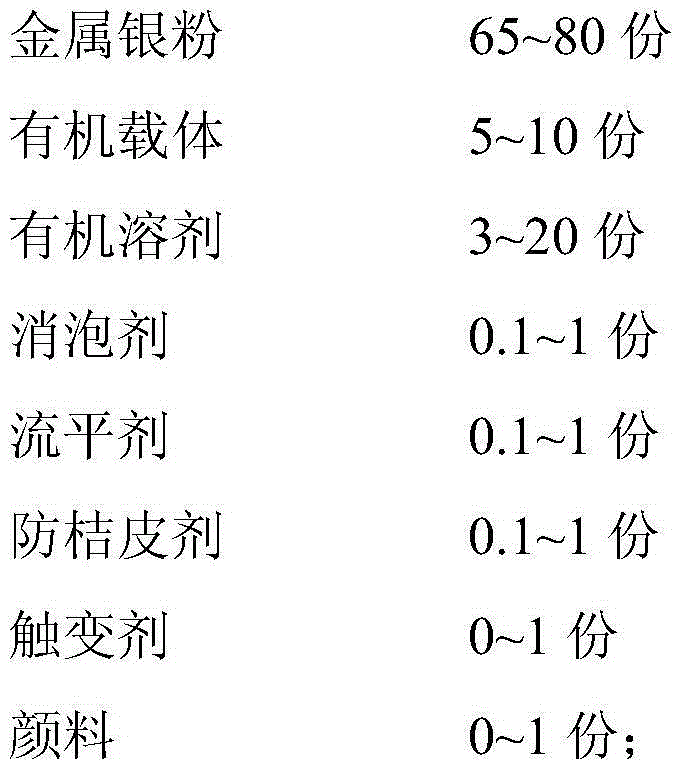

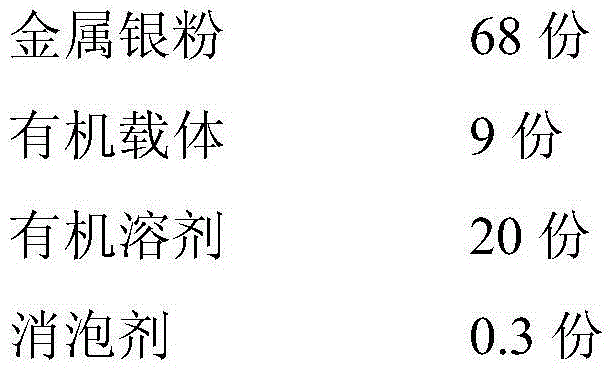

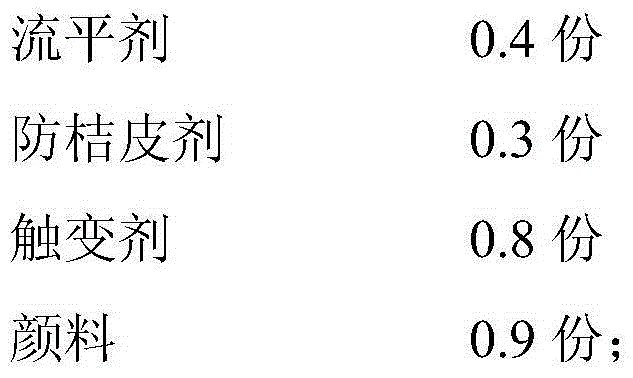

The invention relates to conductive silver paste for fine line silk-screen printing for a capacitive type touch screen. The conductive silver paste comprises the following components in parts by weight: 65-80 parts of metal silver powder, 5-10 parts of organic carrier, 3-20 parts of organic solvent, 0.1-1 parts of defoaming agent, 0.1-1 parts of leveling agent, 0.1-1 parts of anti-skinning agent, 0-1 parts of thixotropic agent and 0-1 parts of pigment; the preparation method for the conductive silver paste comprises the steps of mixing the organic carrier and the organic solvent to prepare a uniform colloidal solution; then adding the other components in sequence; and enabling the mixture to be mixed through a mixer, grinded through a three-roll mill, filtered, and the like to obtain the conductive silver paste for the capacitive type touch screen. Compared with the prior art, the conductive silver paste is simple in preparation process; the prepared conductive silver paste is low in volume resistance, high in adhesive force, high in surface hardness, corrosion resistance, and oxidization resistance, wherein the adhesive force between the conductive silver paste and a PET substrate can reach 5B level, and the surface hardness can reach greater than 3H; and in addition, the conductive silver paste also has an excellent ohmic contact performance.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

Method for the production of a magnetic layer on a substrate and printable magnetizable varnish

InactiveUS20100129540A1Improve magnetic propertiesHigh strengthInorganic material magnetismThick magnetic filmsScreen printingStrontium

The current invention relates to a method for the production of a magnetic layer on a substrate, comprising the production of a printable varnish, containing 60 weight-% of neodym iron boron powder, 10 weight-% of ferrite powder, preferably strontium hexaferrite powder, 1.4 weight-% of a catalyst, 1.1 weight-% of a dispersing additive, and as the remainder a matrix, preferably an epoxy polyol matrix. These agents are mixed by means of stirring or kneading, and rolled in a three-roll mill. Preferably, they are applied to a substrate by screen printing, and subsequently pre-cured at 80 to 120° C. for six to twelve hours, and then cured at 200° C. to 220° C. for three hours.

Owner:BOURNS INC

Three roll mill

A three roll mill having a feed roll, a center roll, and an apron roll with that are driven so that their cylindrical surfaces move in the same direction but different speeds in each nip. One end of each roll is engaged by a drive shaft at a first side of the mill, whereas the other end of each roll rotates freely at a second side of the mill. Each roll can be removed individually and without tools by moving the roll away from the first side against a spring force in the second side. This disengages the roll from its drive shaft, whereupon it can be lifted out of the mill.

Owner:SMITH JEFFREY P

Touch screen silver paste and preparation method thereof

ActiveCN106683747AEasy to prepareIncrease productivityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteZirconium hydride

The invention discloses touch screen silver paste and a preparation method thereof. The touch screen silver paste is prepared from the following components in parts by weight: 40-60 parts of silver powder, 10-30 parts of zirconium hydride, 10-15 parts of polymer resin, 15-28 parts of an organic solvent and 2-5 parts of an additive. The preparation method comprises the following steps of firstly preparing an organic carrier; and adding the silver powder, the zirconium hydride and the additive to the organic carrier, fully mixing evenly, rolling by using a three-roll mill, filtering and removing insoluble substances. Through the addition of the zirconium hydride, the powder filling amount of the touch screen silver paste is not reduced while the usage amount of the silver powder is reduced by 15%-30%, the conductivity is ensured, the hardness and the scratch resistance are improved and the cost is reduced; and meanwhile, the touch screen silver paste is simple in preparation method and high in production efficiency. The touch screen silver paste does not contain a harmful heavy metal ion or halogen and meets the environmental protection requirements.

Owner:湖南省国银新材料有限公司

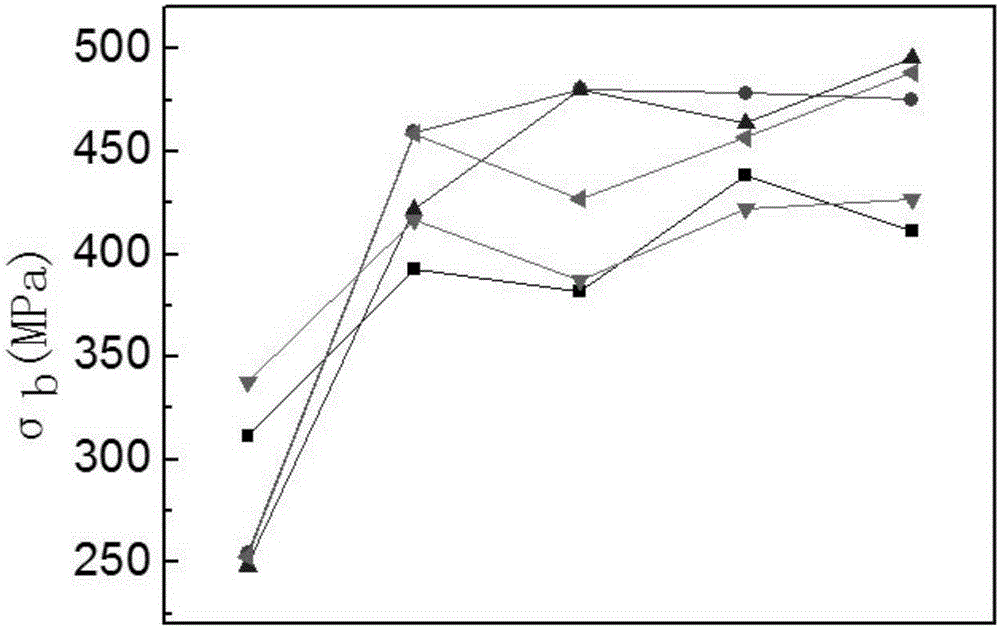

Heat treatment method for high-strength large-size aluminum alloy thick-wall ring part with controllable elongation

The invention relates to a heat treatment method for an aluminum alloy thick-wall ring part, in particular to a heat treatment method for a high-strength large-size aluminum alloy thick-wall ring part with controllable elongation and aims at solving the problem that a thick-wall ring part is low in alloy strength. The heat treatment method comprises the steps of cutting a 2A14 aluminum alloy thick-wall ring part, preserving the temperature at 490-500 DEG C, conducting quenching treatment and solid solution, and obtaining the aluminum alloy thick-wall ring part; 2, adopting a three-roll mill for conducting hot rolling on the aluminum alloy thick-wall ring part; 3, then conducting cold rolling treatment on the aluminum alloy thick-wall ring part obtained after the hot rolling; 4, conducting aging treatment for 2-5 hours at the temperature of 150-200 DEG C. According to the method, the formation of a theta'' phase is inhibited through a cold deformation method, the aging process is controlled so that the core portion of an aluminum alloy thick-wall ring can have high strength, the tensile strength of the aluminum alloy thick-wall ring part obtained after the heat treatment reaches 480 MPa, the yield strength reaches 460 MPa, and the elongation of the aluminum alloy thick-wall ring part is controllable within a certain range.

Owner:HARBIN INST OF TECH

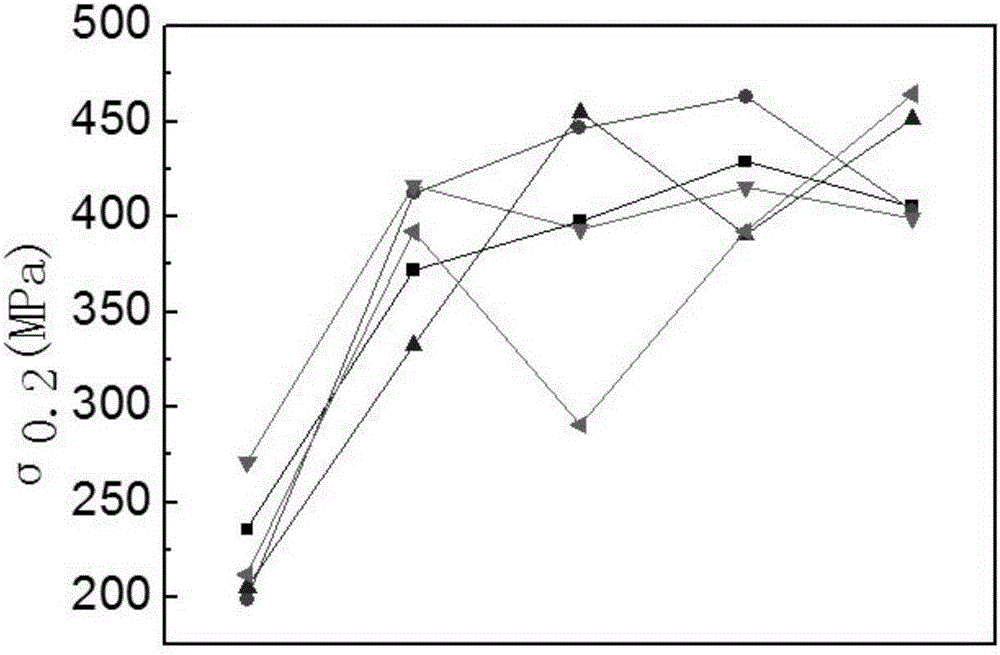

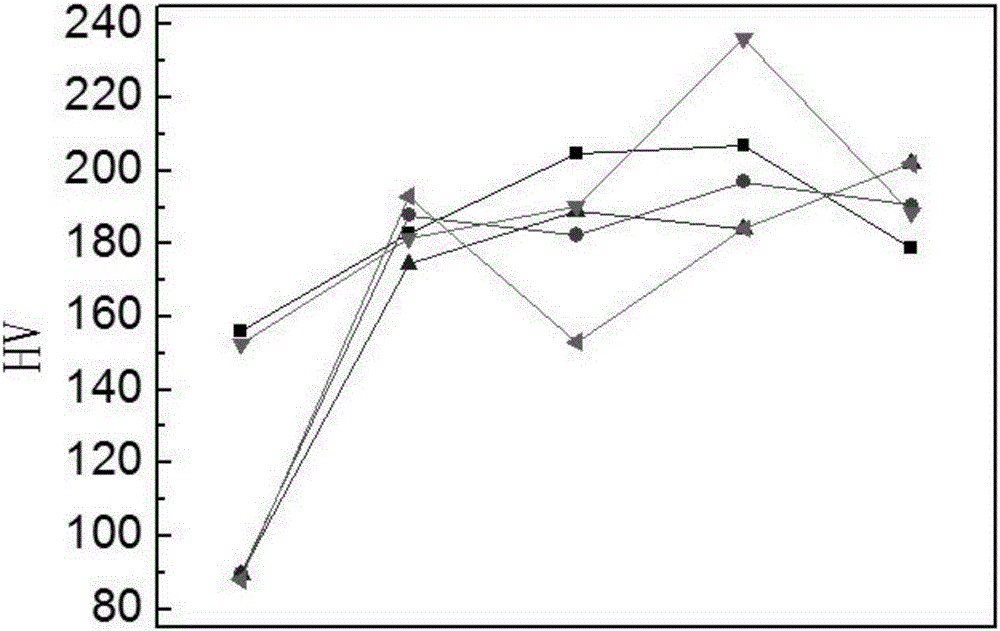

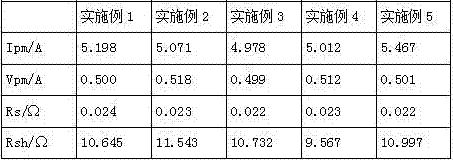

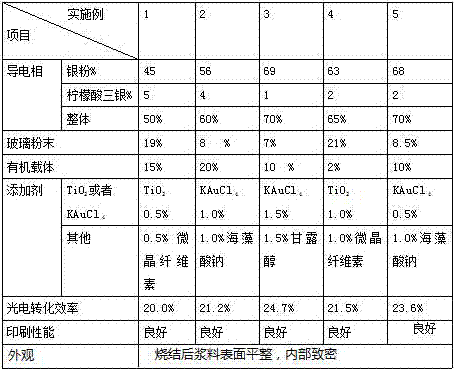

Photovoltaic cell applied silver paste and preparation method thereof

ActiveCN107240435AGood printabilityNarrow widthNon-conductive material with dispersed conductive materialPhotovoltaic energy generationMannitolMuffle furnace

The invention relates to photovoltaic cell applied silver paste and a preparation method thereof. The silver paste comprises the following components: 50-70% of conductive phase, 10-25% of glass frit, 10-25% of organic carrier and 1-3% of additive. The above proportions are in mass percent, wherein the conductive phase is a mixture of silver powder and tri-silver citrate. The additive is a mixture of TiO2 or KAuCl4 with any one the following elements: microcrystalline cellulose, sodium alginate and mannitol. The method comprises: (1) adding the mixture of the ethyl alcohol absolute and the ethylene glycol to the conductive phase and the glass frit; (2) taking the organic carrier to mix with the organic solvent and grinding it with a three-roll mill; (3) preparing a silver film through the screen printing technology; and (4) placing the printed silver film in a muffle furnace and calcining it at a temperature from 700-800 degrees for three to five seconds. The silver paste of invention has a good printing performance and a low contact resistance with the silicon wafer. After the sintering of the silver paste, the electrode has a narrow width and a high thickness and can achieve good compactness, reducing the use amount of silver paste greatly. The overall cost is also low.

Owner:JURONG GCL SYST INTEGRATION TECH CO LTD

Low-silver back electrode slurry for chip resistors and preparation method for low-silver back electrode slurry

InactiveCN109524149ALow production costImprove compactnessNon-conductive material with dispersed conductive materialCable/conductor manufactureHigh resistanceSlurry

The invention discloses a low-silver back electrode slurry for chip resistors and a preparation method for low-silver back electrode slurry. The preparing method includes the steps of preliminarily mixing ultrafine silver powder, metal oxide, the glass powder modifier and partial organic carriers by a mixer; homogenizing the primary mixture by a three-roll mill until all the powders are well dispersed to form a slurry semi-finished product; secondarily mixing the slurry semi-finished product and the remaining organic carriers by the mixer; subjecting the paste to low-pressure rolling through athree-roll mill to be sufficiently dispersed, and then sieving through a 250-mesh sieve and carrying out vacuum defoaming to prepare a finished slurry. The back electrode slurry solves the problems of high resistance of a slurry sintered film and low adhesion to the alumina substrate under the condition of low silver content, and the production cost of a chip resistor product is reduced.

Owner:西安宏星电子浆料科技股份有限公司

Steel tube rolling process

InactiveCN107737810AIncrease productivityIncrease profitMetal rolling arrangementsHeating furnaceMaterial Perforation

The invention relates to a steel pipe rolling process, which includes the following steps: heating, heating the tube blank in a heating furnace to above 1150°C; piercing, and piercing the heated tube blank through a piercing machine to make a capillary tube; Heating, sending the perforated capillary into an inclined-bottom heating furnace for short-term heating; rolling, putting the capillary after the second soaking on the stop mandrel, and then passing through a three-roll cross-rolling machine for shrinkage Diameter, wall reduction, extension and rolling to form a waste tube; stripping, the rolled waste tube is released from the restraining mandrel; sizing and shaping, sizing and shaping to form a hot finished tube; cooling, hot finished tube Cooling through the stepping cooling bed; the finished product is collected, which solves the production problem that the production of thin-walled seamless steel pipes cools quickly during the rolling process and is difficult to re-roll, and changes the production of thin-walled seamless steel pipes by cold drawing instead of hot rolling. Unreasonable product structure can reduce energy consumption, reduce equipment investment costs, and improve the efficiency of producing seamless steel pipes.

Owner:孙超

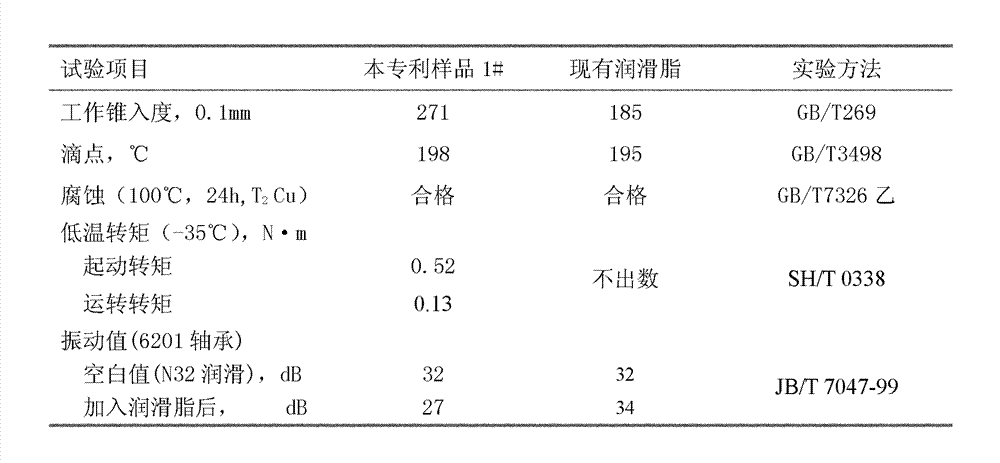

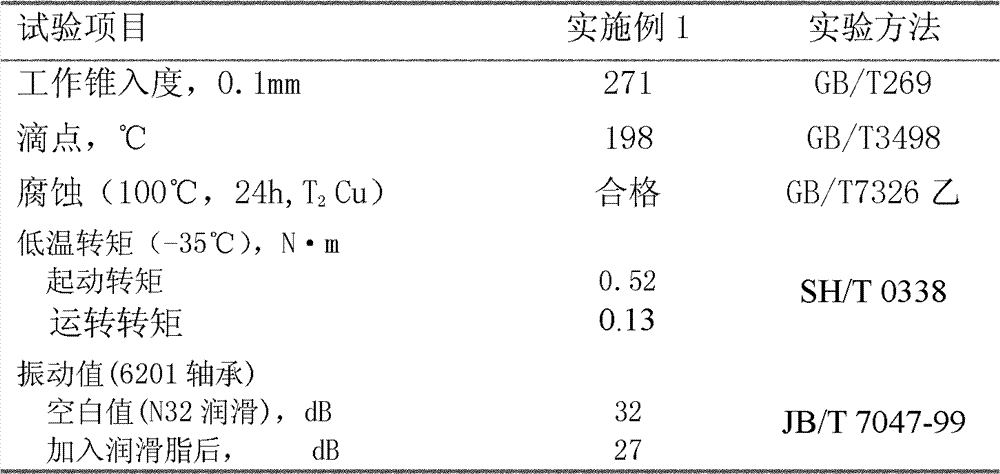

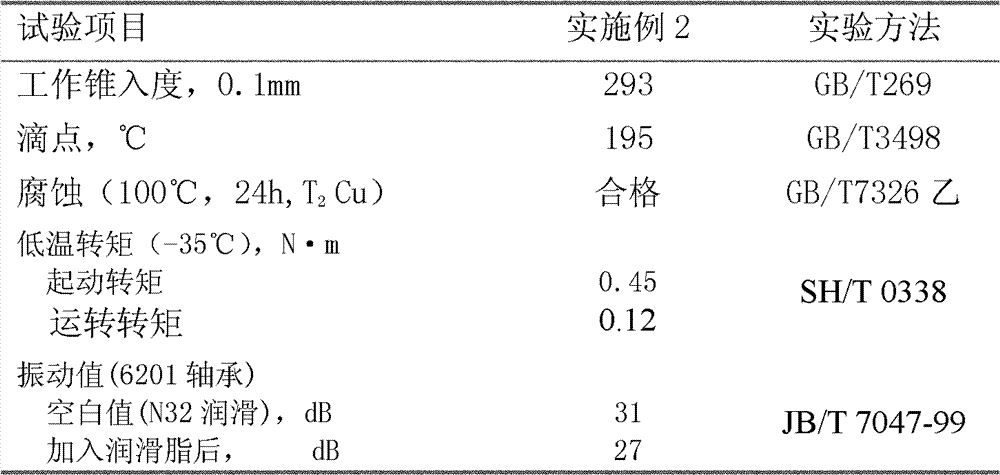

Lithium-based low-noise lubricating grease composition and preparation method thereof

ActiveCN102021069BReduce vibration and noise performanceTransparent appearanceLubricant compositionLow noiseLithium hydroxide

The invention relates to a lithium-based low-noise lubricating grease composition and a preparation method thereof. The lubricating grease composition comprises 60-70% of base oil A, 10-20% of base oil B, 5-15% of thickening agent and 1-5% of additive; the preparation method comprises the following steps: adding 40-60% of the base oil A into a reaction kettle; adding fatty acid; heating to 80-85 DEG C; adding the aqueous solution of lithium hydroxide; heating to 90-100 DEG C to start saponification; after the saponification is finished, raising temperature to 210-215 DEG C; cooling in the reaction kettle with the rest base oil A, wherein the cooling temperature is controlled between 140 and 190 DEG C; adding the base oil B to reduce temperature to 90-100 DEG C, and then adding the additive C; when the temperature is reduced to 70-80 DEG C, adding the additive D; and when the temperature is reduced to 30-60 DEG C, performing oil pressing with a three-roll mill to obtain the finished product. The lubricating grease has high performance in reducing vibration noise, and the vibration value can be reduced by 2-5 decibels; meanwhile, the indexes such as high-temperature performance and low-temperature performance of the lubricating grease reach a relatively good index range, and the finished product of lubricating grease also has transparent appearance.

Owner:CHINA PETROLEUM & CHEM CORP

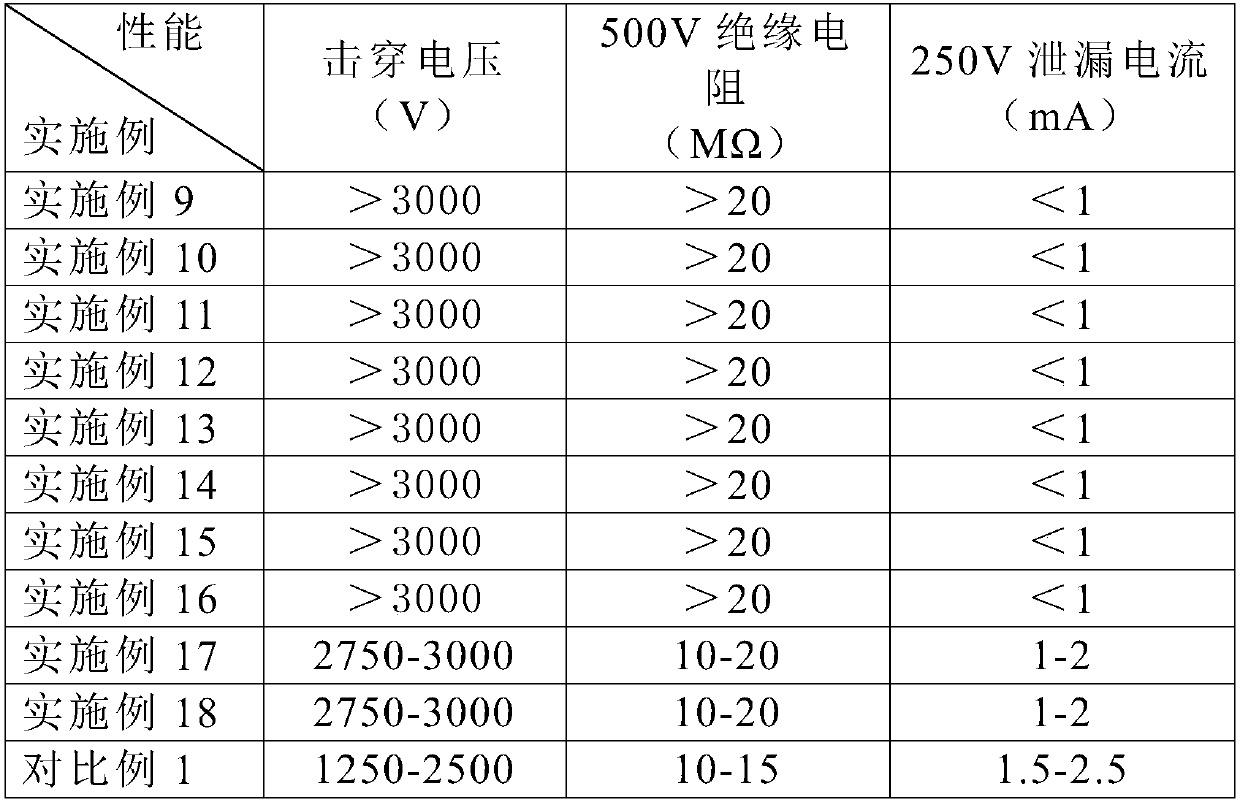

Composite oxide microcrystalline glass, insulating medium slurry and preparation method and application thereof

ActiveCN108682478AImprove compactnessImprove adhesionQuartz/glass/vitreous enamelsMetallic oxidesSlurryLow leakage

The invention relates to composite oxide microcrystalline glass, and an insulating medium slurry and preparation method and application thereof, and belongs to the technical field of thick film circuits. The composite oxide microcrystalline glass is SiO2-B2O3-Cs2O-P2O5-MnO2-Co2O3- Ta2O5-CeO2-Er2O3 composite oxide microcrystalline glass; the insulating medium slurry includes an organic carrier andan inorganic main phase composed of the composite oxide microcrystalline glass. The preparation method of the insulating medium slurry includes: mixing raw materials according to a ratio; heating themixture to 1100-1700 DEG C for 1-24 hours; performing water quenching, drying, and ball milling; mixing the mixture with the organic carrier in proportion; and finally using a three-roll mill to perform rolling repeatedly, and obtaining a thick film circuit insulating medium slurry. The slurry is used for a high-power thick-film circuit insulating dielectric layer of a stainless steel substrate, has a large expansion coefficient, good adhesion, high insulation and resistance, high breakdown voltage, and low leakage current.

Owner:NINGBO POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com