Photovoltaic cell applied silver paste and preparation method thereof

A technology of photovoltaic cells and silver paste, applied in photovoltaic power generation, cable/conductor manufacturing, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

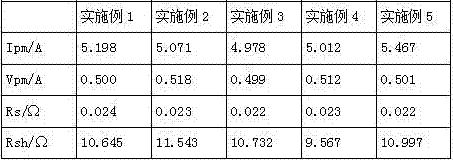

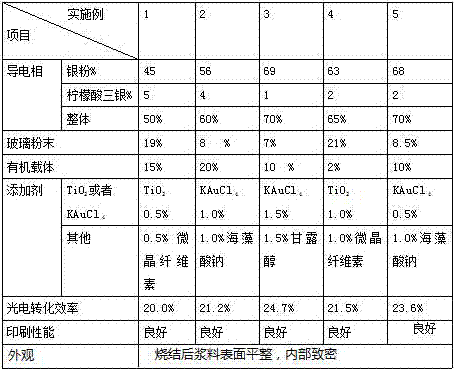

[0032] The preparation method that embodiment adopts in the table 1 is as follows:

[0033] (1) Mix the conductive phase spherical silver powder or flake silver powder with the inorganic phase glass powder plus a 1:1 mixture of absolute ethanol and ethylene glycol;

[0034] (2) Take an appropriate amount of solid powder and mix it evenly with an organic solvent, grind it with a three-roll mill and roll it;

[0035](3) Utilize the screen printing process to prepare the silver film; the present invention adopts the screen printing paste of 350 meshes, and the obtained paste is screen printed on the single crystal silicon wafer coated with reflective film SiNx, at about 180 degrees Celsius Dry at a temperature of 10 minutes;

[0036] (4) Put the printed silver film in a muffle furnace and calcinate it at the sintering temperature and holding time (700-800°C / 3-5s).

[0037] The organic carrier adopted in the present invention is to take ethyl cellulose 5% as thickener, dibutyl p...

Embodiment 6

[0043] Example 6 Effect experiment of additives microcrystalline cellulose, mannitol and sodium alginate

[0044] table 3

[0045] Amount of Microcrystalline Cellulose

0.2%

0.5%

1.0%

1.5%

Rs / Ω

0.024

0.022

0.020

0.023

The speed at which silver powder grows to the silicon surface

basically no reaction

About 10% faster than without adding

About 17% faster than without adding

About 12% faster than without adding

[0046] Table 4

[0047] Dosage / 1.0%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com