Manufacturing method of X70QS seamless line pipe for acid environment

A technology of seamless line pipe and manufacturing method, applied in manufacturing tools, heat treatment equipment, furnaces, etc., to achieve the effects of good HIC resistance, high elongation, and strict control of composition design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

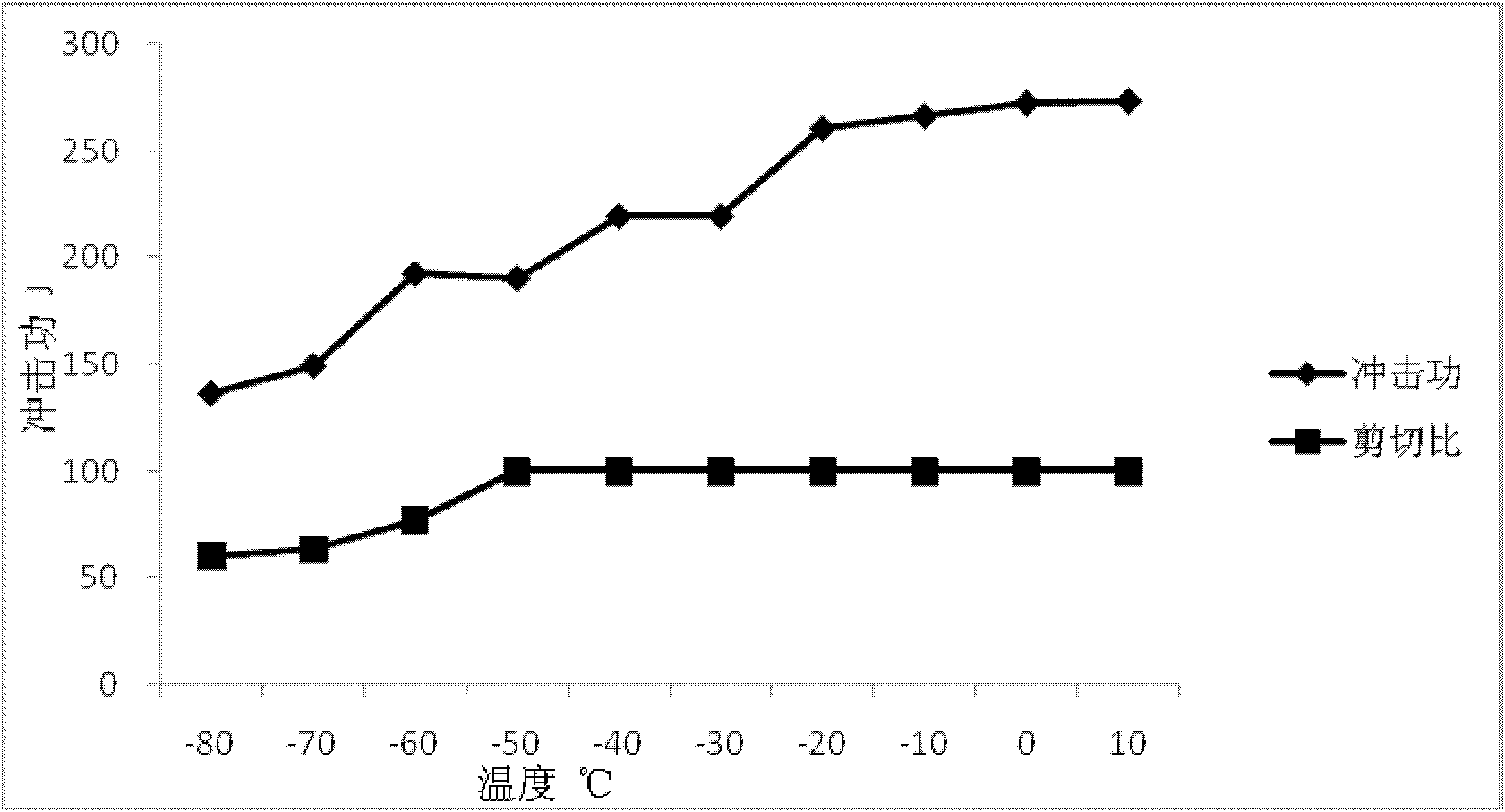

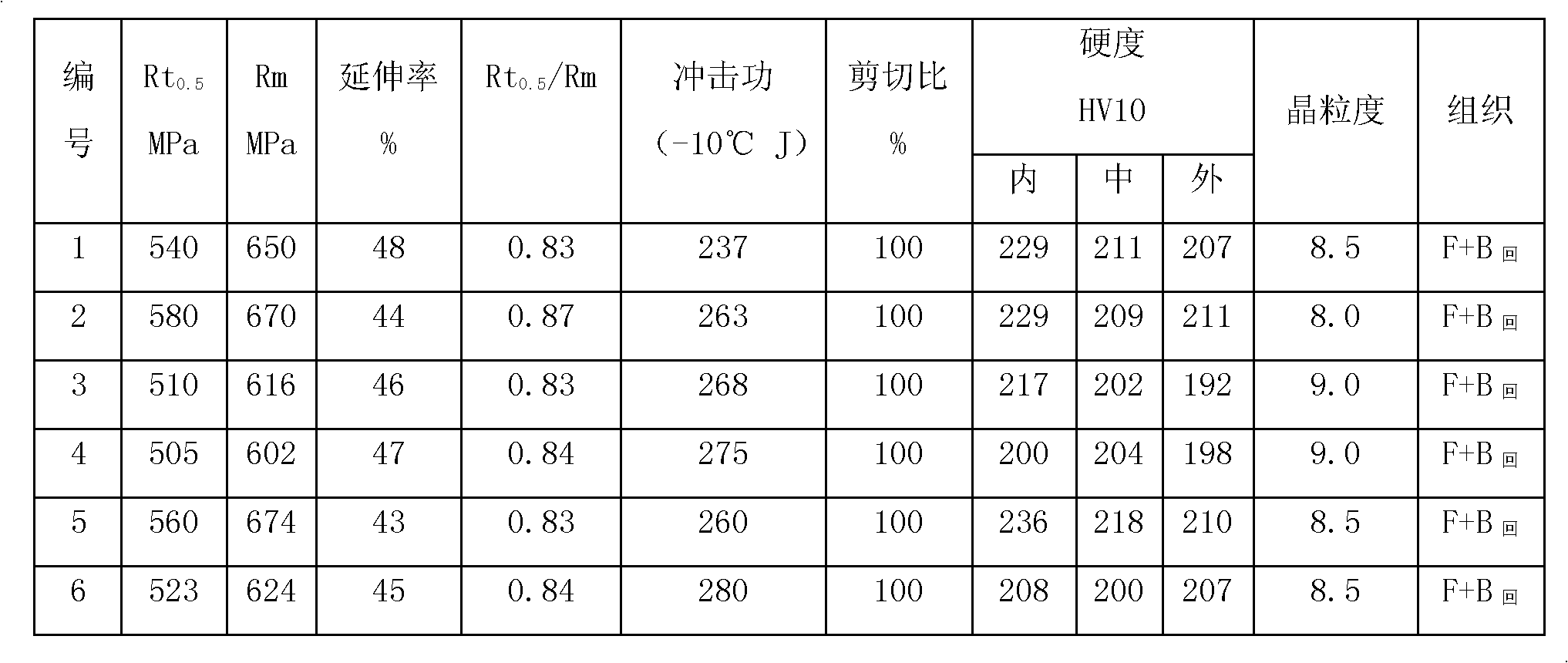

[0023] The manufacturing method of the X70QS seamless line pipe for acidic environment of the present invention will be described in conjunction with the accompanying drawings and examples.

[0024] The technical scheme adopted by the present invention is to provide a method for manufacturing an X70QS seamless line pipe for acidic environments, the method comprising the following steps:

[0025] 1. Steelmaking

[0026] A reasonable chemical composition ratio and a suitable steelmaking process are necessary to obtain a qualified hot-rolled base metal.

[0027] High-quality scrap steel and alloys are used as raw materials, and the composition weight % of the configured steel grades is: C 0.06-0.14%, Si 0.20-0.45%, Mn 1.00-1.30%, P≤0.015%, S≤0.003%, Ni≤0.10%, Cu≤0.20%, Cr 0.05~0.30%, Mo 0.05~0.30%, Al 0.015~0.060%, N 0.003~0.010%, Nb 0.030~0.050%, V 0.05~0.09%, Ca≤0.060%, the balance is Fe and impurities. Carbon equivalent CEpcm≤0.22%, CE IIW ≤0.39%.

[0028] The specific op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com