Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Guaranteed geometry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

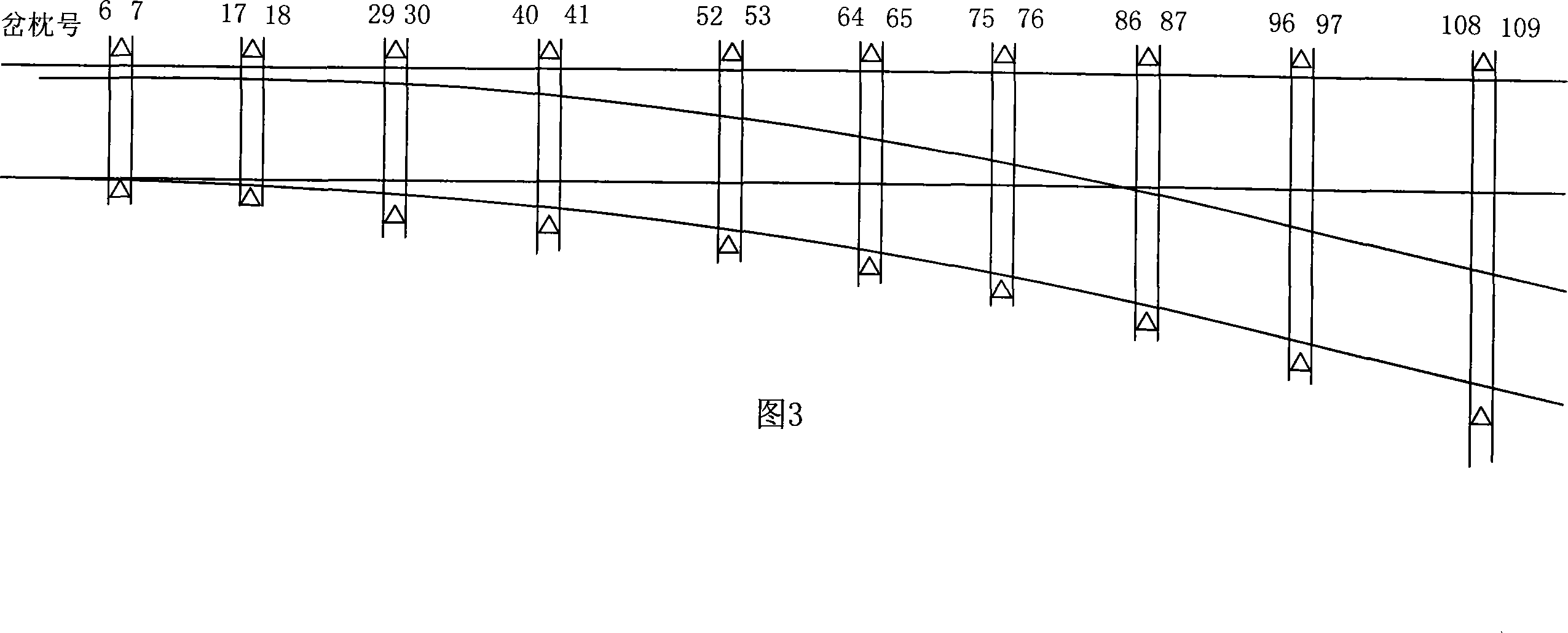

Runway switch laying method for ballast track passenger special line

ActiveCN101173492AHigh adjustment accuracyAvoid deformationRailway track constructionHydraulic equipmentEngineering

The invention relates to an in-situ laying method for the turnouts of ballast track dedicated passenger lines, which is characterized in that: a plurality of temporary track panels are laid at the original positions of the turnouts for transitive purposes, and a piece of large mechanical road maintenance equipment is adopted to tamp the track panels to stabilize the ballast bed; then the temporary track panels are removed, a turnout assembling platform is arranged at the original position of the turnout, and the overall assembly and fine adjustment of the turnout are carried out on the turnout assembling platform. Then a piece of synergic hydraulic equipment is used to jack up the assembled turnout as a whole, the operations of charging ballast and tamping are performed after removing the turnout assembling platform, and the turnout should be repaired and maintained regularly while in service. The invention has the advantages of tremendously improving the adjusting precision of the turnout, effectively preventing the turnout from deforming, enabling the positioning of the turnout to be more accurate, and maintaining the integrity of the turnout.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

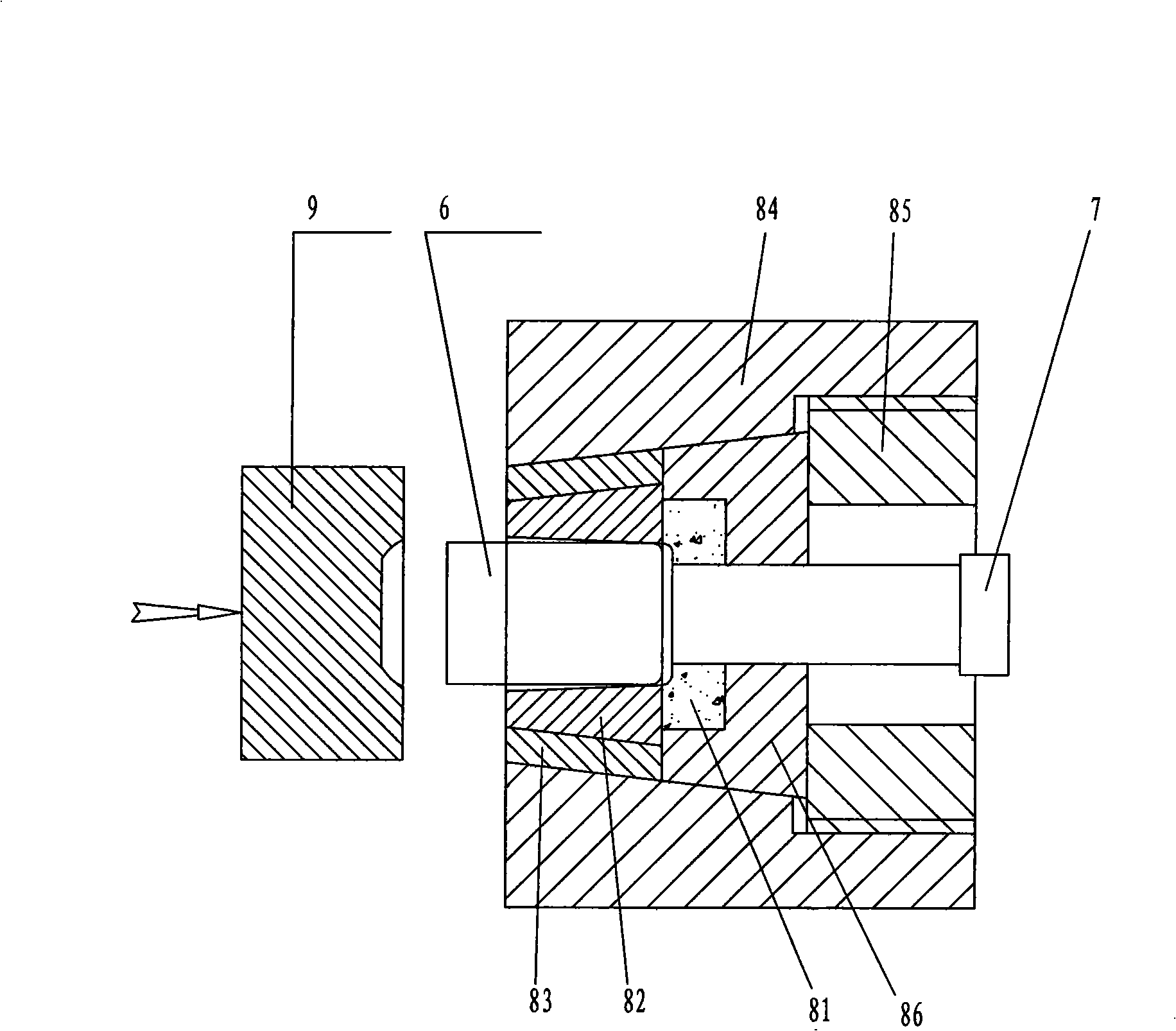

Large size roller cold-upsetting and press-forming method, and cold-upsetting and press-forming mold

InactiveCN101301676AImprove mechanical propertiesGuaranteed geometryForging/hammering/pressing machinesEngine componentsPunchingHigh intensity

The invention relates to a large-dimension roller cold heading punching method and a cold heading punching die. The large-dimension roller cold heading punching method comprises the steps as follows: bar stock is cut as roller material sections by a bar stock cutting die; the roller material sections are punched as roller blanks by the cold heading punching die. The bar stock cutting die is provided with a material feeding wheel, a knife edge die, a cutter and a material baffle; the bar stock is movably connected with the material feeding wheel and the knife edge die; the cutter is arranged at one end of the knife edge die; the material baffle is arranged at one side of the cutter. The cold heading punching die of the invention is provided with a push-off pin, a punching die and a formed punch; the roller material sections and the push-off pin are matched with the punching die; the formed punch is matched with the roller material blanks; the formed punch is connected with a power mechanism. The bar stock of the invention adopts high-carbon chromium bearing steel and the diameter of the roller blank is ranging from 23mm to 28mm. The roller blank processed by the invention can achieve the soft grinding level of turning, the chamfer is naturally formed, the high-strength, high rotation speed and long service life of the finished bearing are ensured, the geometrical dimension and the precision of the roller are ensured, thus realizing the low vibration and silencing of the bearing and reducing the initial manufacture cost at the same time.

Owner:汇洲智能技术集团股份有限公司

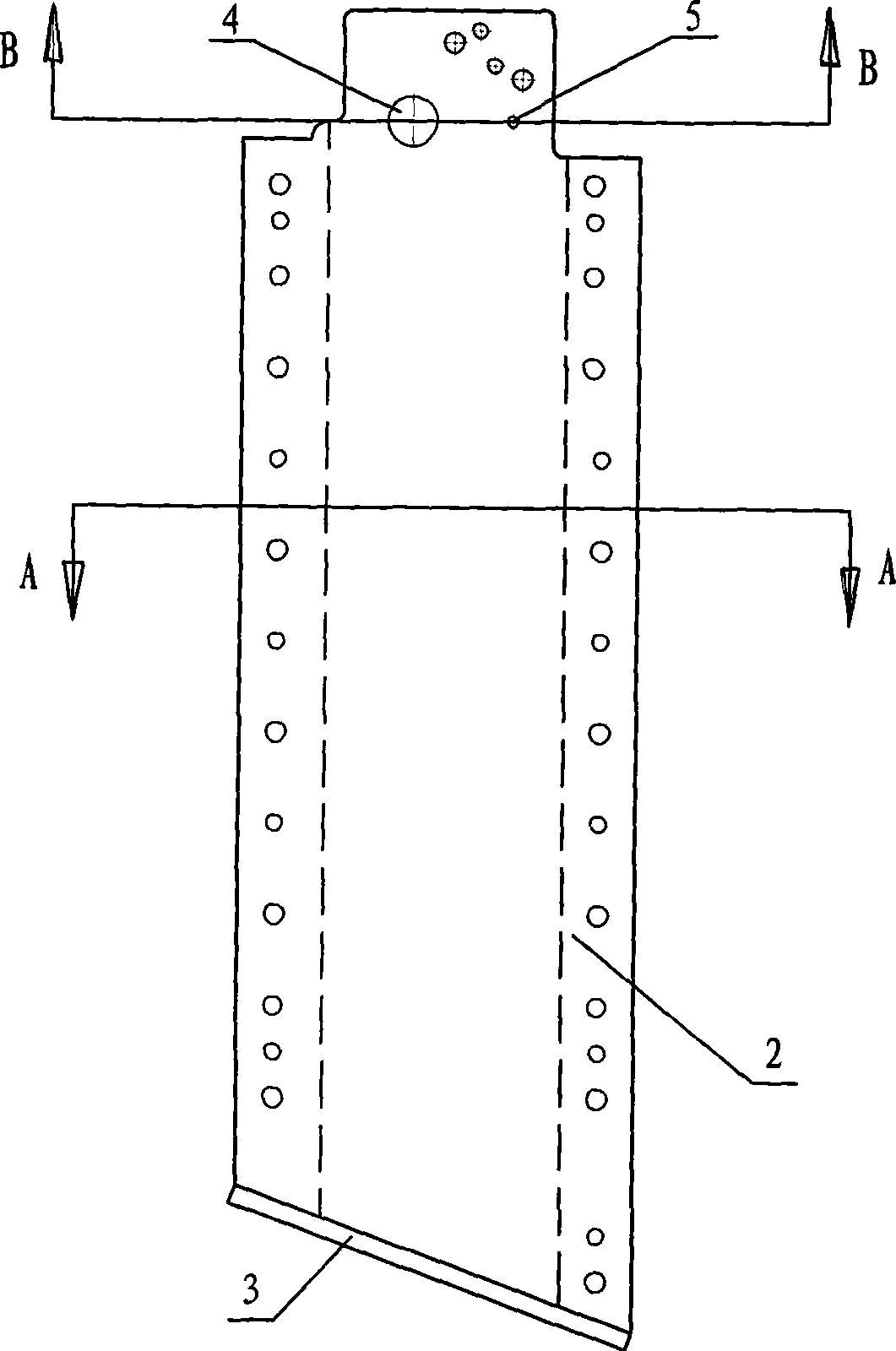

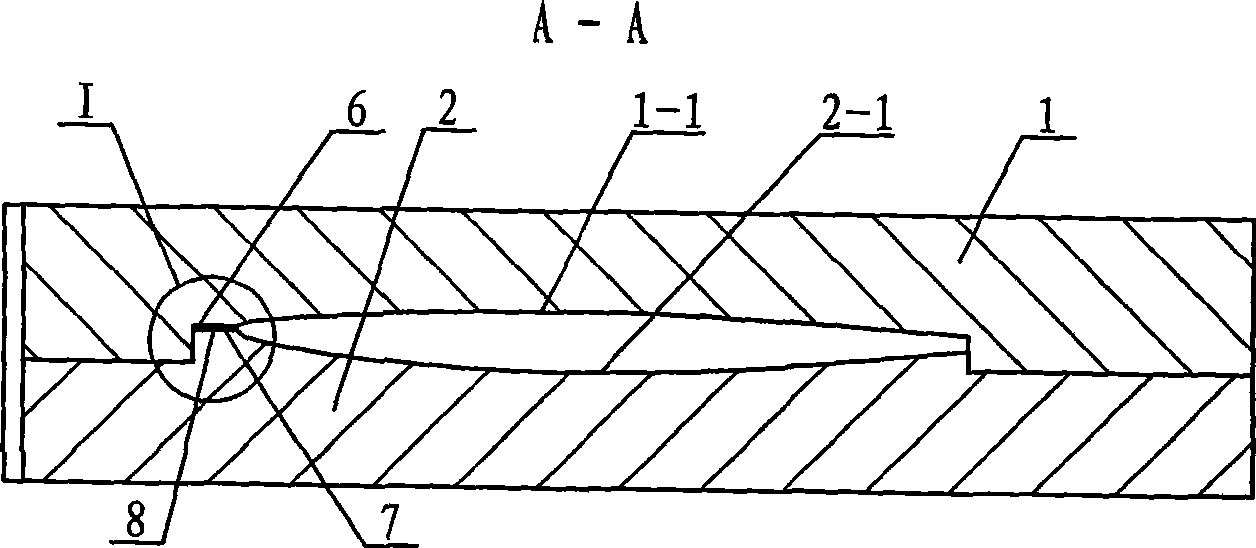

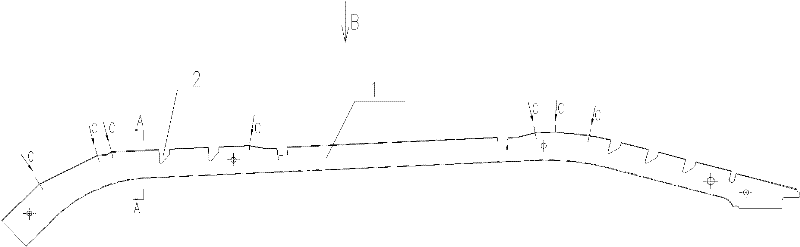

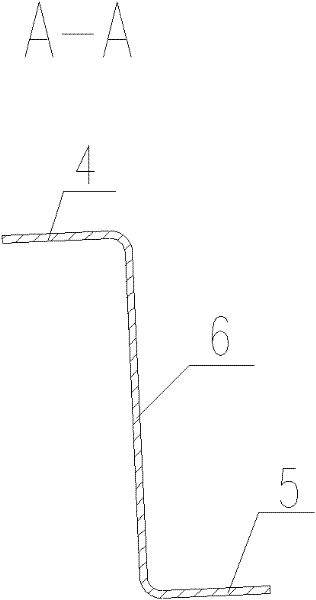

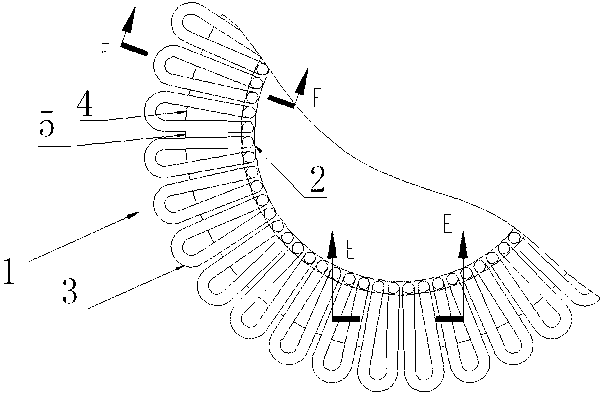

Fibre reinforced resin based composite material fin piece molding mould

InactiveCN101367257AProduct porosity reductionGood surface qualityDomestic articlesPorosityResin-Based Composite

The invention provides a molding die for fiber reinforced resin-based composite vanes. The invention relates to molding die for composite vanes, which aims to solve the problems that the prior composite vane molding die is insufficient in die assembly and too tight to seal die cavities, can not discharge air in a product, can not guarantee the geometrical size of the airfoil surface of a vane and the relative position of a vane handle, and causes that the product is large in porosity or has air holes on surface. A parting surface of an upper die and a lower die is provided with an upper model groove; a parting surface of the lower die and the upper die is provided with a lower model groove; a first positioning pin is arranged in a first positioning pinhole and a third positioning pinhole; a second positioning pin is arranged in a second positioning pinhole and a fourth positioning pinhole; and a gap between the parting surfaces of the upper die and the lower die is configured as a material overflow groove. The material overflow groove can ensure that the upper and lower dies are sufficient in die assembly; die cavities are incompletely sealed; the air in the product can be smoothly discharged; the geometrical size of the airfoil surface of the vane and the relative position of the vane handle are guaranteed; and the product is good in surface quality.

Owner:HARBIN FRP INST

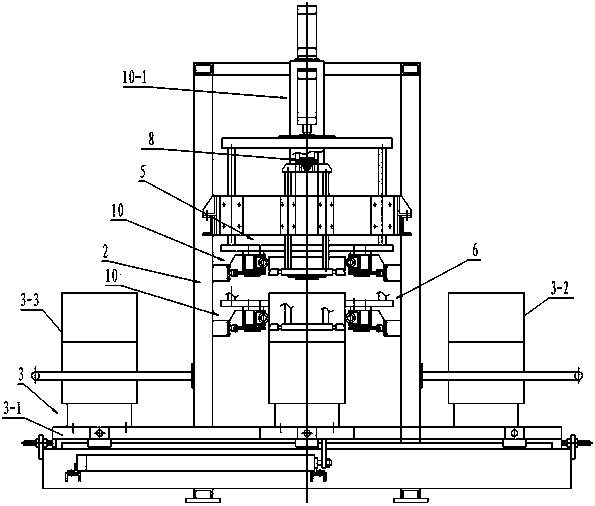

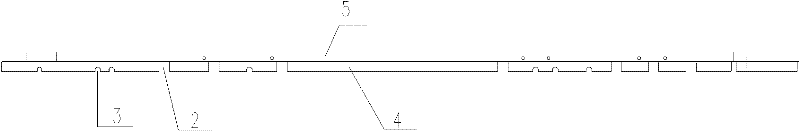

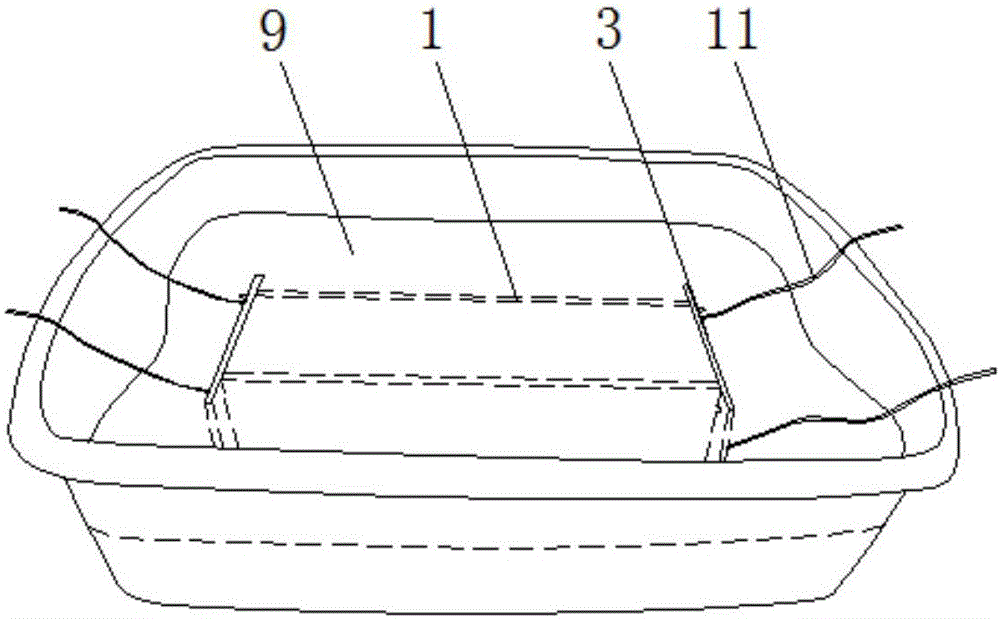

Automatic fastening equipment for refrigerator inner liners

InactiveCN103406464AGuaranteed quality and geometryImprove work efficiencyRefrigerated temperatureMechanical engineering

The invention provides automatic fastening equipment for refrigerator inner liners and solves the problems that fastening of bottom plates and side plates in prior inner liners fails to guarantee geometry and quality and is low in operating efficiency and high in labor intensity. The automatic fastening equipment for refrigerator inner liners comprises a frame, a telescopic loose tool mechanism and a control unit. An upper horizontal pushing and rolling mechanism, a lower horizontal pushing and rolling mechanism, a vertical pushing and rolling mechanism, a horizontal telescopic press plate mechanism and a vertical telescopic press plate mechanism are mounted on the frame. Each of the upper horizontal pushing and rolling mechanism, the lower horizontal pushing and rolling mechanism and the vertical pushing and rolling mechanism is provided with a rolling mechanism. The automatic fastening equipment for refrigerator inner liners has the advantages that fastening of bottom plates and side plates in refrigerators is mechanized and automated, the geometry and quality of refrigerator inner liners is guaranteed, operating efficiency is improved greatly, and labor intensity is reduced.

Owner:QINGDAO XINJINRUN MACHINERY

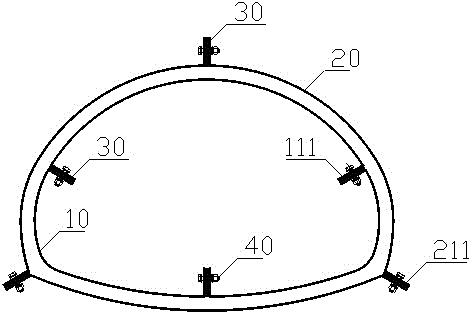

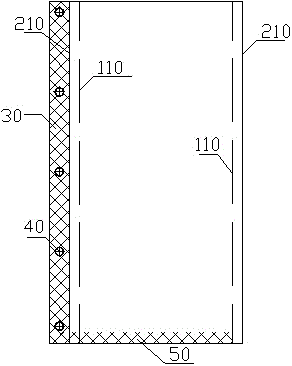

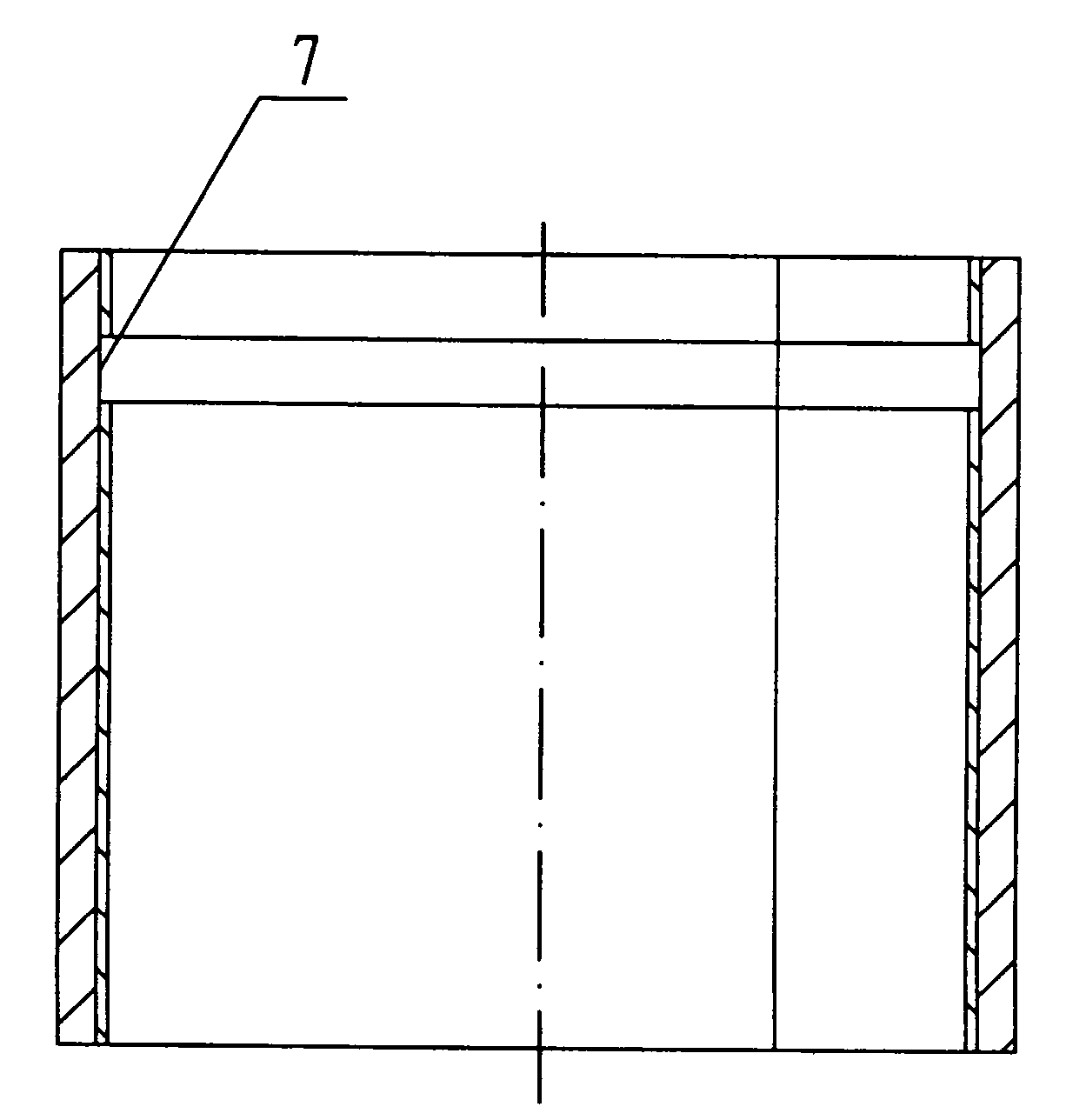

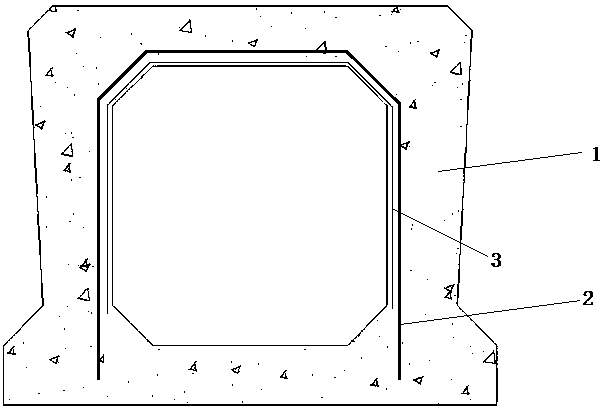

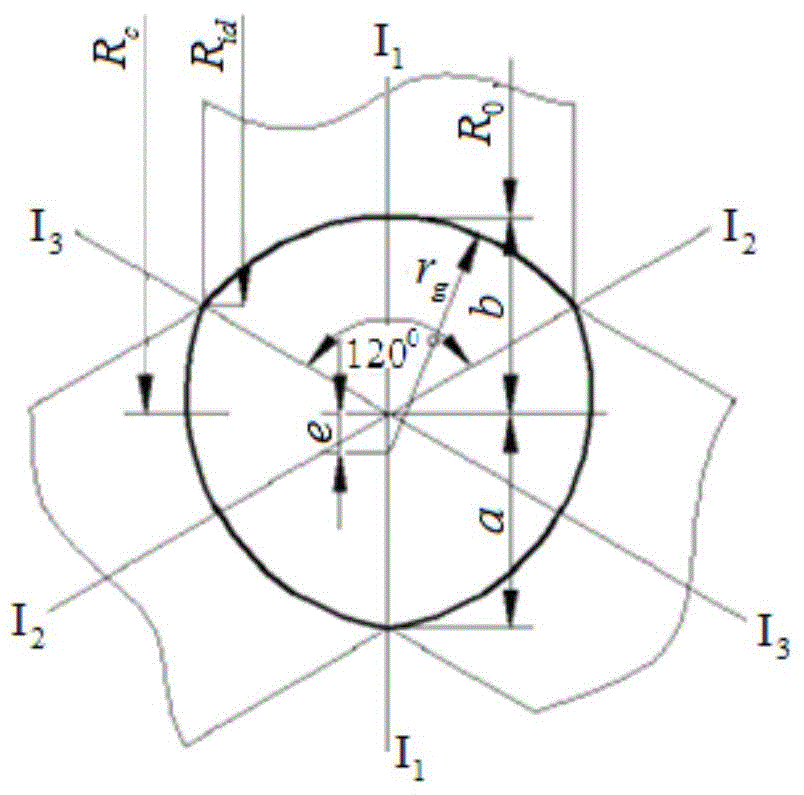

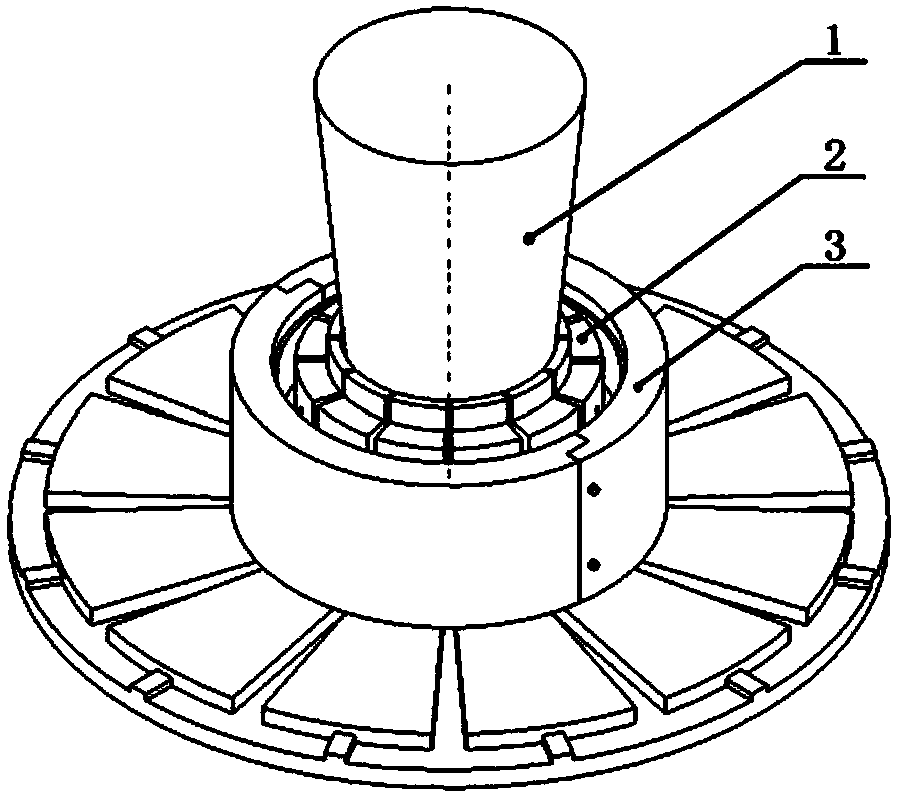

Large-volume lining model pouring device for tunnel model test and method of large-volume lining model pouring device

The invention provides a large-volume lining model pouring device for a tunnel model test and a method of the large-volume lining model pouring device. The large-volume lining model pouring device comprises an inner formwork and an outer formwork, wherein the outer formwork sleeves on the outer side of the inner formwork; the inner formwork is formed by splicing three or more inner mold arc plates; the outer formwork is formed by splicing three or more outer mold arc plates; a grout stop bar is arranged between a spliced position of the adjacent inner mold arc plates and the spliced position of the adjacent outer mold arc plates. Compared with an existing lining model pouring device, the large-volume lining model pouring device disclosed by the invention has the advantages that vertical grout stop bars are used for filling joint seams at the spliced positions of the formworks so as to prevent grout exposure on the side surface during a pouring process and also provide a certain operation space for a subsequent mold dismounting process, so that convenience is provided for demolding of a large-volume lining model; bottom grout stop rings are used for filling the clearance between the inner and outer formworks, so the bottom can be prevented from grout exposure, and mutual positioning between the inner formwork and the outer formwork can be controlled as well so as to guarantee that the geometric dimensioning of the lining mode satisfies design requirements.

Owner:FUZHOU PLANNING DESIGN & RES INST

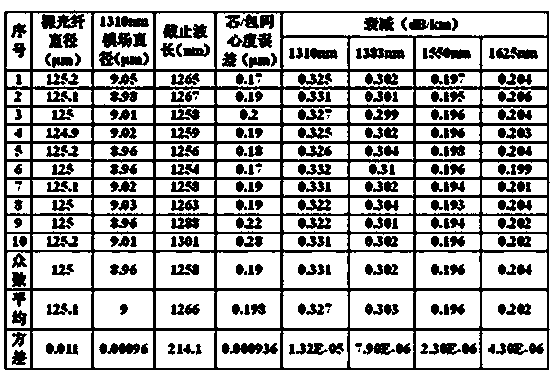

Device and method for manufacturing large-size mandrel loose body

InactiveCN103626392ASolve crackingGuaranteed geometryGlass making apparatusGlass productionTowerLarge size

The invention provides a device and a method for manufacturing large-size mandrel loose body. The device comprises a servo motor, a quartz glass substrate rod, a mandrel loose body, a core blowtorch, a coating blowtorch, a tower, a guide rail, a deposition tank, a diameter measuring device and a weight detecting device, wherein the weight detecting device is installed on a rotating chuck of the servo motor, synchronously slides on the guide rail along with the servo motor, and is used for detecting the total weight of the mandrel loose body; the diameter measuring device is installed on the two sides of the deposition tank and used for measuring the diameter of the loose body in the depositing process.

Owner:JIANGSU HENGTONG PHOTOELECTRIC +1

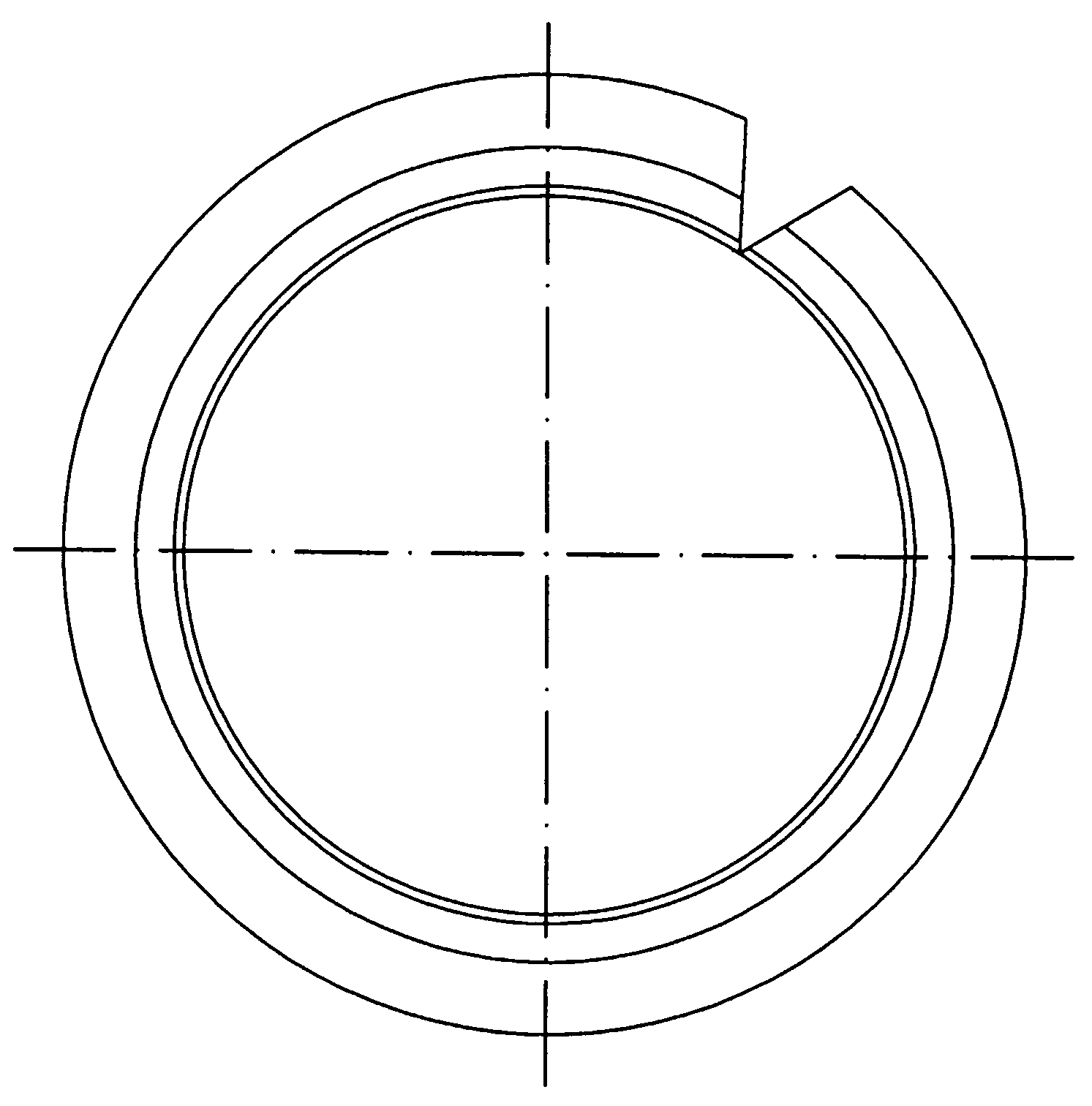

Method for rapidly constructing light formwork of reinforced-concrete-cast-in-place circular draining inspection well

InactiveCN106638697ASolve the problem of insufficient anti-seepageLight textureArtificial islandsUnderwater structuresReinforced concreteRebar

The invention discloses a method for rapidly constructing a light formwork of a reinforced-concrete-cast-in-place circular draining inspection well. The method includes the following construction steps that the inner formwork is installed; reinforcing steel bars of the inspection well are completely bound, and casting of bottom plate concrete is completed; the side boundary of the inner formwork is correctly defined on a concrete bottom plate, holes are drilled in the inner side of the well wall along the side boundary through an electric drill, reinforcing steel bar heads are inserted, and four reinforcing steel bar heads are perpendicularly inserted along the center and used for positioning the position of the inner formwork; the inner formwork is formed by two semicircular light wood formwork bodies, the two semicircular light wood formwork bodies are spliced into a circle on a flat plane, and opposite pulling is carried out with twine tighteners along oppositely-supported positions of the perpendicular abutted seam; after being externally assembled completely, the inner formwork is manually carried and placed into a well chamber and fixed. According to the method, the semicircular light wood formwork bodies are prefabricated and manually carried and installed on site, construction of the draining inspection well is rapid, and the formwork of the reinforced-concrete-cast-in-place circular draining inspection well is formed by splicing steel formwork bodies or narrow-strip wood formwork bodies.

Owner:ANHUI SHUIAN CONSTR GRP CO LTD

Forming process for stand column of stainless steel car body side wall

ActiveCN102672418AThe process steps are simpleReduce manufacturing costMaterials preparationLaser cutting

The invention relates to a forming process for a stand column of a stainless steel car body side wall. The forming process comprises the following steps of: (1) material preparation: processing a whole stainless steel plate into an unfolding shape without being flanged through laser cutting, and remaining flanging capacity and process notches, and a plurality of triangle notches is arranged on the column surface fitting with the side wall panels; (2) compressing: putting the cut plate material in a compressing mould, and forming at one time integrally through mould pressing; and (3) reshaping: carrying out final adjusting and reshaping on the compressed workpiece according to a drawing size, and forming the stand column meeting the requirement of design. The compression forming process at one time integrally is adopted, the process steps are simple, the manufacturing cost is low, the production efficiency is greatly improved, the surface quality and the geometric dimensioning of each position on the stand column are ensured on the premise of ensuring the structural strength of the formed stand column, and the higher requirement of the stainless steel car body side wall of a high-speed motor train unit on the strength of the stand column and the surface quality are completely met.

Owner:CHINA RAILWAYS CORPORATION +1

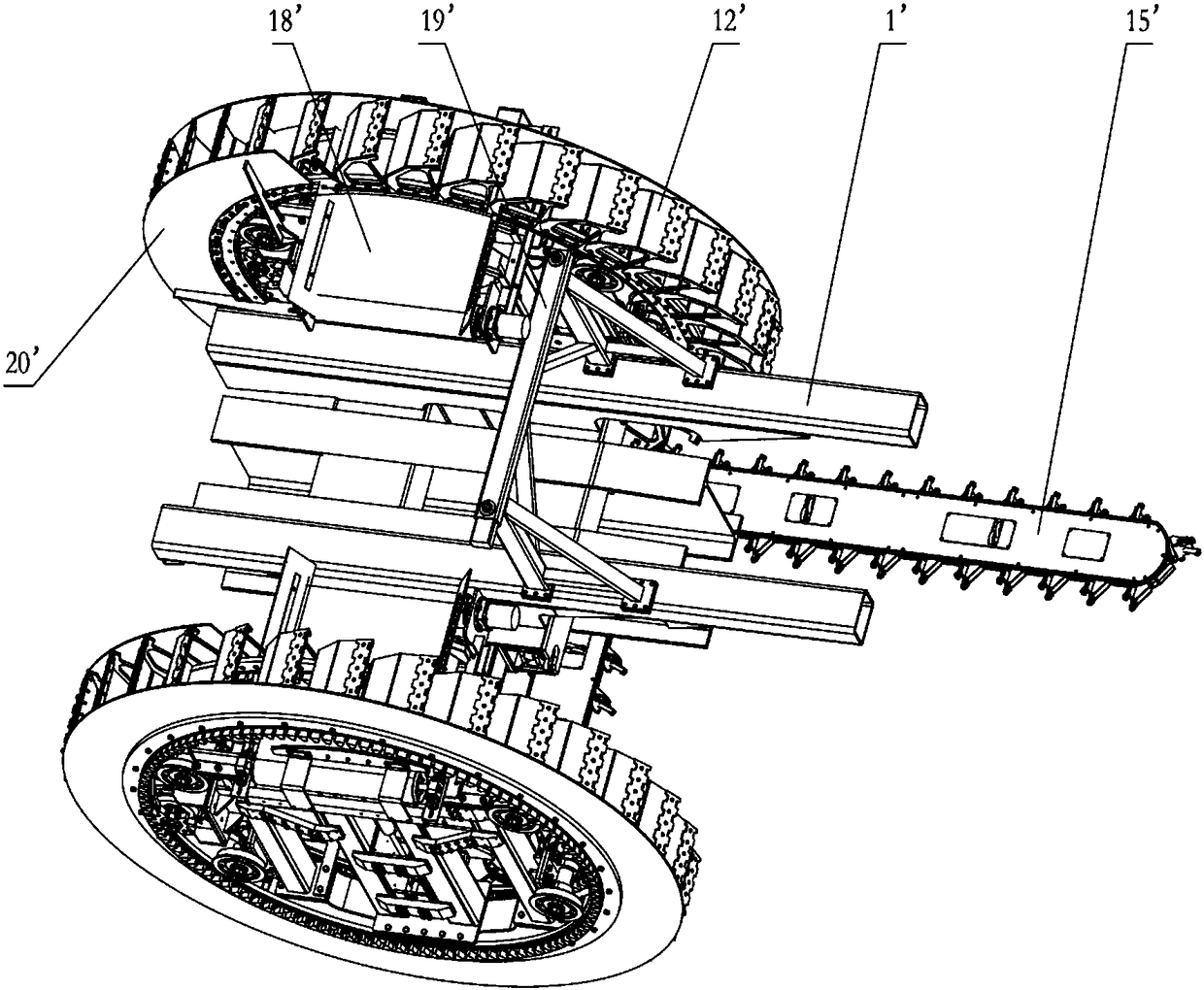

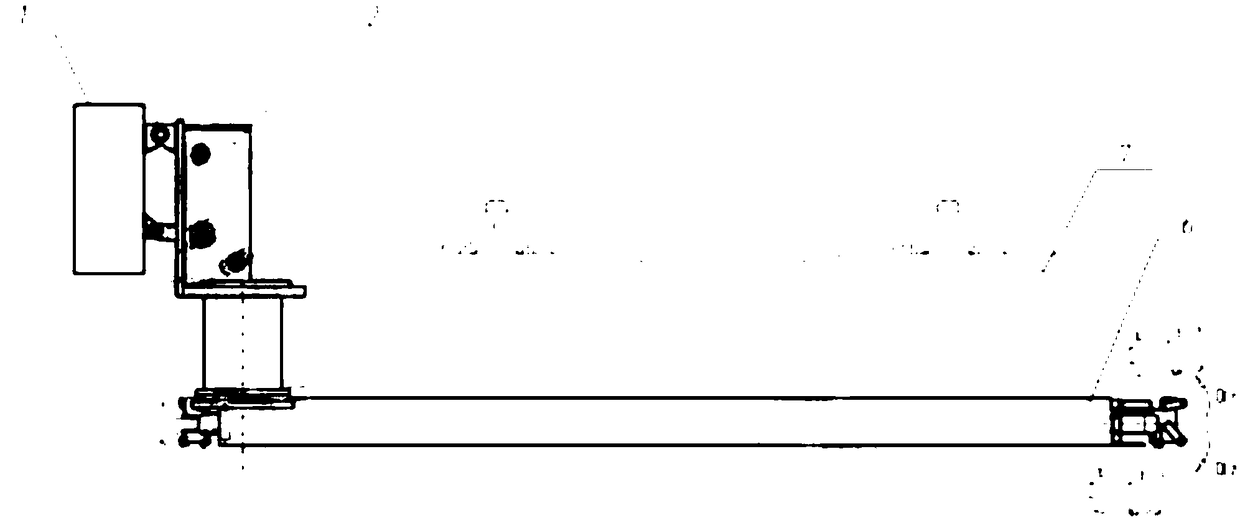

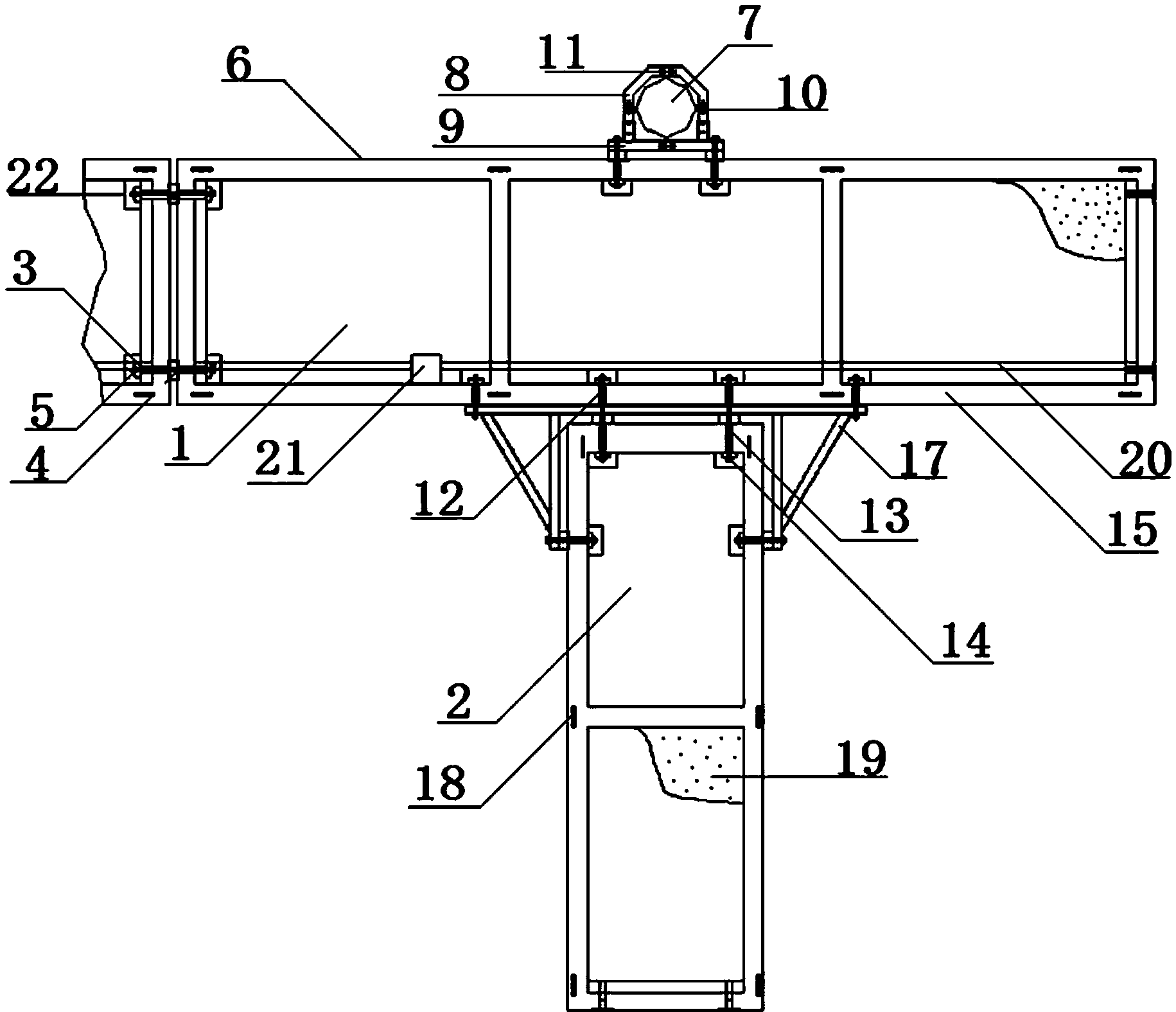

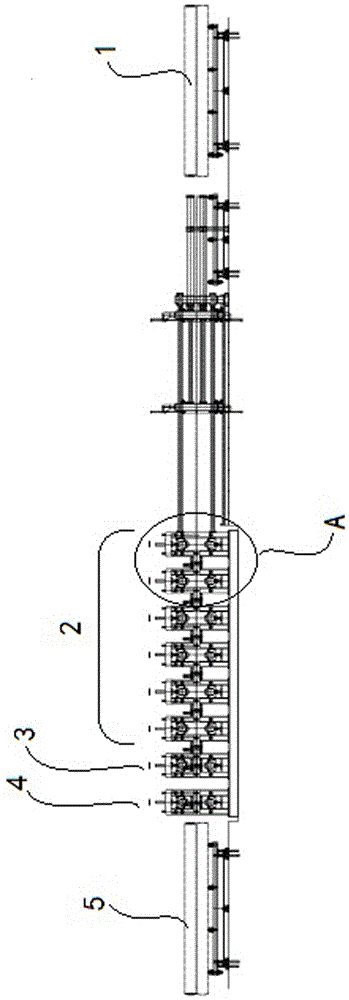

Railway ballast cleaner

InactiveCN108930204AGuaranteed geometryImprove adaptabilityBallastwaySoil-shifting machines/dredgersVehicle frameElectrical control

A railway ballast cleaner comprises a vehicle frame. Cabs are arranged at the two ends on the vehicle frame. An excavation bucket wheel 12' is further arranged in the position, between the cabs at thetwo ends, of the vehicle frame 1' from front to back in the operation direction. The position behind the excavation bucket wheel 12' is connected with a mixed ballast conveyor belt 10'. A screening device 7' is arranged on the lower portion at the tail end of the mixed ballast conveyor belt 10'. A ballast separation device 8' and a main dirty soil conveyor belt 5' are arranged below the screeningdevice 7'. A ballast falling hopper 9' is arranged below the ballast separation device 8'. A loading and unloading storage and transportation box 11' is arranged in front of the ballast falling hopper 9'. A rotary dirty soil conveyor belt 4' is arranged on the lower portion behind the main dirty soil conveyor belt 5'. A backfill conveyor belt 17' is arranged below the ballast falling hopper 9'. Arail lifting device 16' is arranged in the position, behind the excavation bucket wheel 12', of the vehicle frame. The vehicle frame 1' is further provided with a power transmission system 6', an electrical control system, a hydraulic control system, a brake system, a pneumatic system and a walking system. The excavation bucket wheel 12' comprises a multi-degree-of-freedom lateral cutting type knife board 15'. The multi-degree-of-freedom lateral cutting type knife board can be adjusted at multiple degrees of freedom in the X direction, the Y direction and the Z direction in the use process according to the construction requirements, and the geometric dimension of a ballast bed section can be guaranteed.

Owner:CRCC HIGH TECH EQUIP CORP LTD

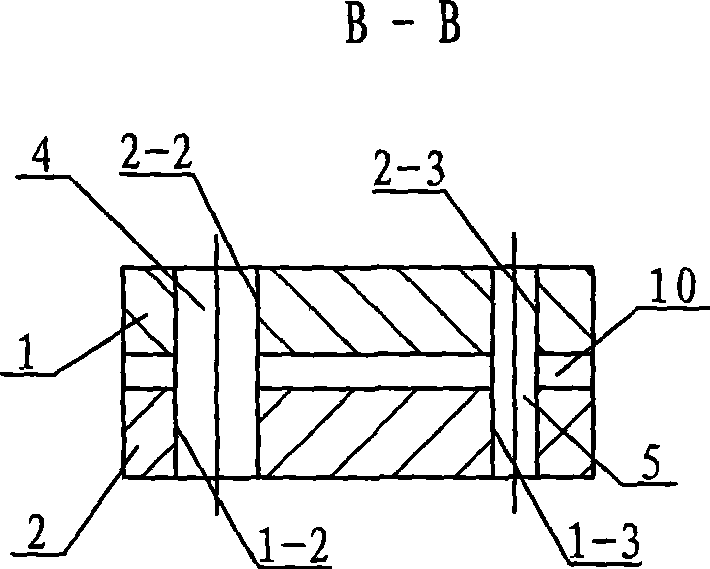

Bimetal liner with flanged flange and manufacturing method of bimetal liner

The invention discloses a bimetal liner with a flanged flange and a manufacturing method of the bimetal liner. The bimetal liner with the flanged flange and the manufacturing method of the flanged flange have the advantages that the structure is simple, the process performance is good, the self-lubricating property is excellent, a copper alloy layer of a flange face cannot crack, and the production efficiency is high. The bimetal liner with the flanged flange comprises a shaft-sleeve-shaped bimetal liner, wherein an outer layer of the bimetal liner is made of steel material, and an inside lining of the bimetal liner is a copper alloy layer; and an outward-flanged flange side is arranged at one end of the bimetal liner and is also in a bimetal structure consisting of the steel material and the copper alloy layer. The bimetal liner is characterized in that the copper alloy layer is not arranged at an outer arc face at a bending part between the bimetal liner and the flange side. As the copper alloy layer is not arranged at the bending part, a situation that the copper alloy layer cracks is avoided in a flanging process. According to a flanging die used in the manufacturing method, the outward-flanged flange side is located in a pit of an upper die, and the outer edge of the flange side is limited by the edge of the pit and cannot extend and deform outwards without limit, so that a phenomenon that the copper alloy layer on the flange side cracks is avoided.

Owner:ZHEJIANG SF OILLESS BEARING +1

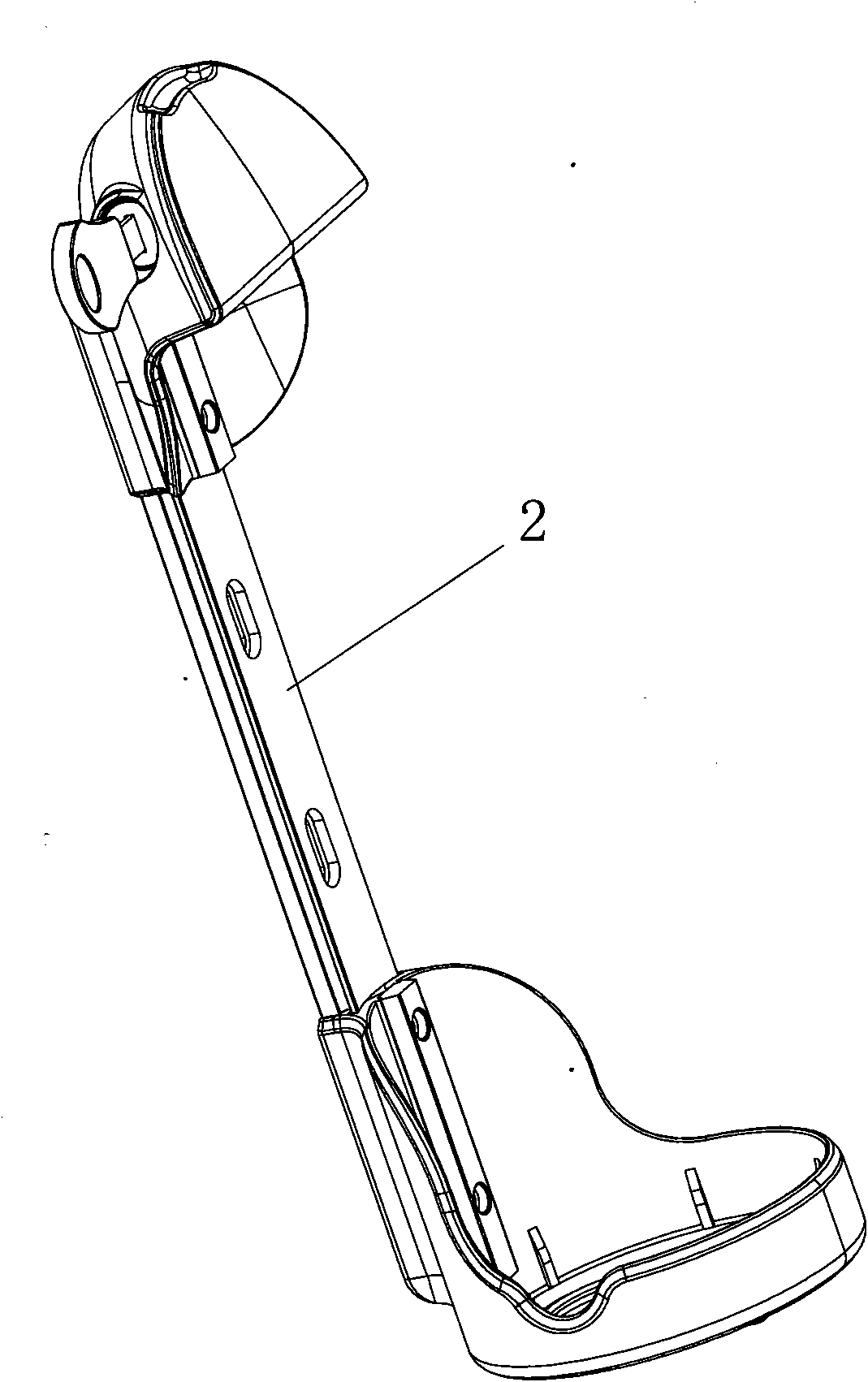

Bicycle battery case set

InactiveCN102376910AImprove waterproof requirementsGood lookingCell component detailsRider propulsionElectronic componentKeyhole

The invention discloses a bicycle battery case set comprising a battery case and a pedestal. The pedestal is fixed on a bicycle frame. The battery case is detachably fixed on the pedestal. The battery case comprises an upper cap, a case body, and a lower cap. A power plug and a power switch are arranged on the lower cap. The pedestal comprises an upper housing coupled with the upper cap, a lower housing coupled with the lower cap, and a base plate used for supporting the case body. A lock body is arranged on the upper housing, and a keyhole is arranged on the upper cap at a place corresponding to the lock body. The battery case set is convenient to install and to detach. With the battery case set, various electronic components can be effectively protected.

Owner:KUNSHAN SHANSHAN PLASTIC TECH CO LTD

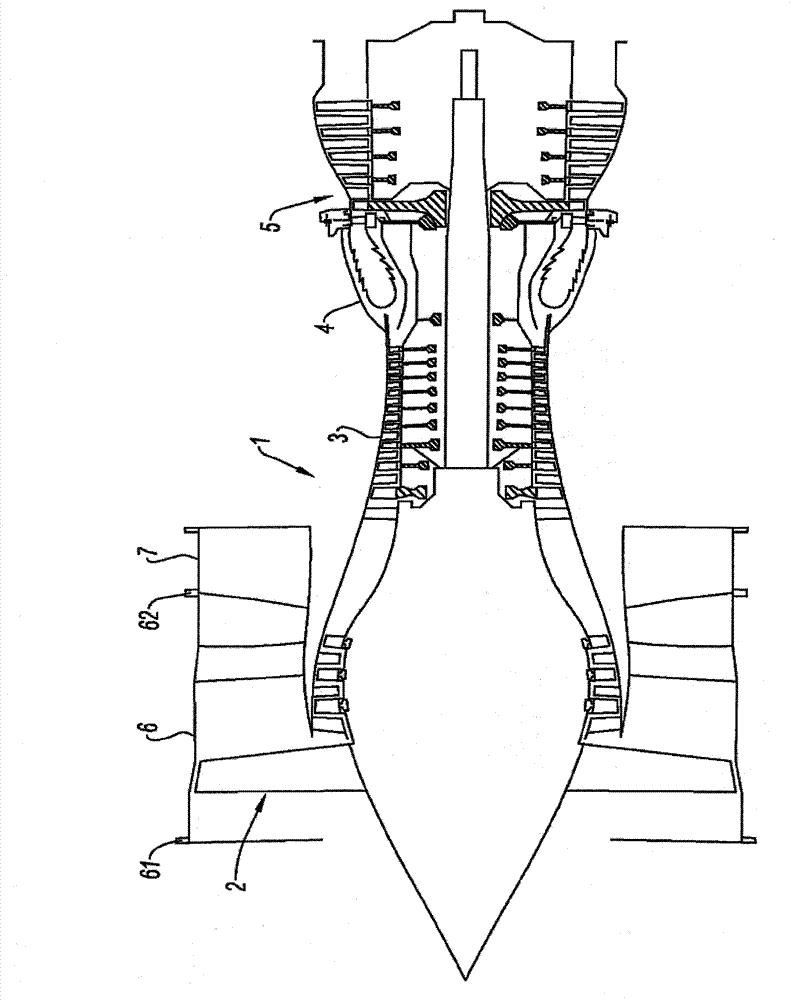

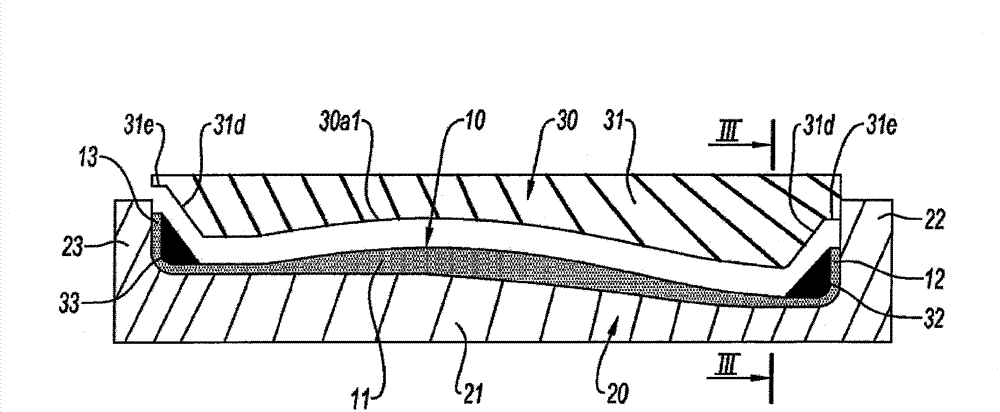

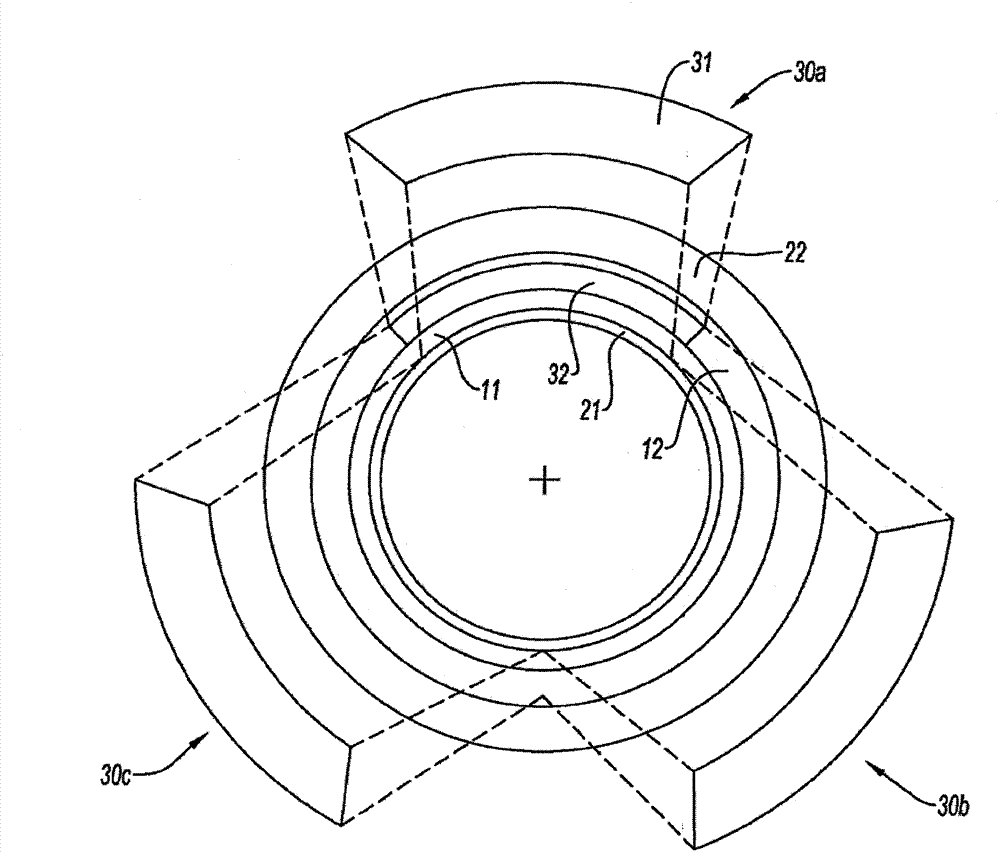

Method for manufacturing article made of composite material

ActiveCN102958681AGeometry Guarantees for Connection RadiiGuaranteed GeometryPump componentsPumpsTurbineTurbojet engine

The invention relates to a method for manufacturing an article made of a composite material consisting of a polymer matrix reinforced by a fibrous structure. The method includes the steps of placing the fibrous structure (10) on a substrate (20) forming a moulding surface, covering the structure with a mating mould (30), and compacting said structure by moving the surface of the mating mould toward the surface of the substrate. The method is characterised in that the substrate (20) includes a cylindrical portion (21) and a wall (22, 23) positioned radially relative to the cylindrical portion (21), and the mating mould includes two portions (31, 32 or 33) which are mobile relative to one another and which are moved toward the axis of the cylindrical portion (21) and towards the radial wall (22, 23) of the substrate (20), respectively. The invention can be used in particular for manufacturing the fan casing of a turbojet engine.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

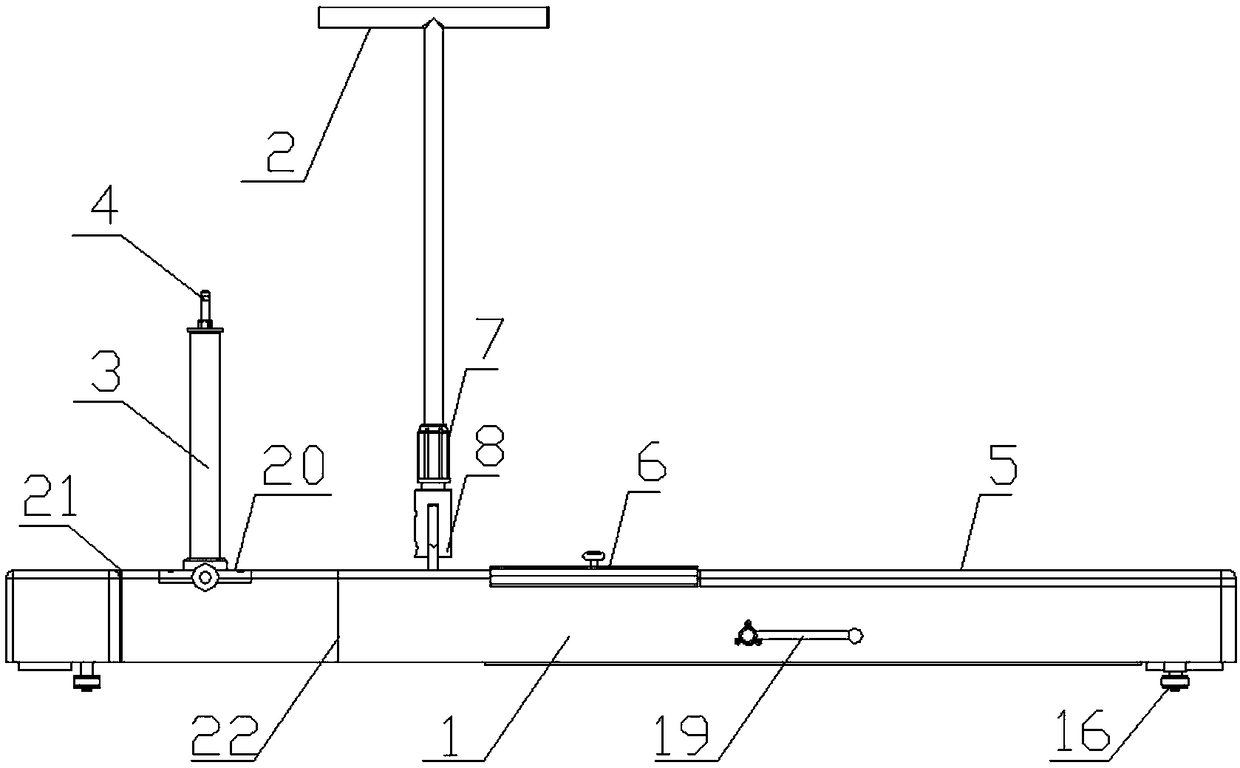

Track geometrical state high-accuracy measurement device

PendingCN108755306AHigh measurement accuracyGuaranteed Accuracy and ReliabilityMeasuring apparatusDistortionTotal station

The invention discloses a track geometrical state high-accuracy measurement device which comprises a main vehicle frame. The main vehicle frame is provided with a walking mechanism, a measurement mechanism, a sensing mechanism and a main control unit. The walking mechanism comprises a first walking wheel, a second walking wheel, a third walking wheel, a first guide wheel and a second guide wheel.The measurement mechanism comprises a prism arranged on the main vehicle frame and a measurement wheel arranged corresponding to the first walking wheel. The sensing mechanism comprises a gauge sensorand tilt angle sensors which are arranged in the main vehicle frame. By the adoption of the track geometrical state high-accuracy measurement device, data of the gauge and the superelevation of a track can be measured in real time, three-dimensional coordinate data of the prism are measured through a total station, the measured data are processed through the main control unit to obtain track geometrical state indexes such as the track direction, the height, the versed sine and the distortion of the track, deviation between a track plane and a design value and deviation between the elevation and a design value, the measurement accuracy of the device is greatly improved, and the accuracy and reliability of a measurement result are guaranteed.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP +1

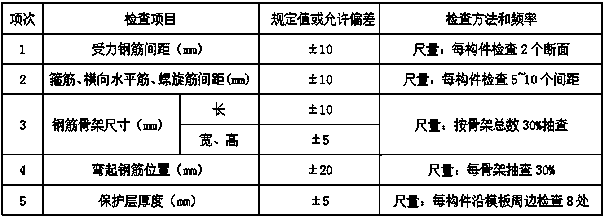

Prefabricated hollow beam slab construction method

ActiveCN109235732APrevent floatingSolve floatingFloorsBuilding material handlingEngineeringSteel bar

The invention discloses a prefabricated hollow beam slab construction method. The method comprises the steps of 1, formwork making; 2, steel bar machining and installing, wherein the tail ends of plain round steel bars should be made into 180-degree semicircular hooks, the bent straight inner diameter of the hooks is not less than 2 .5 d, and the hook ends should have straight segments with a length not less than 3 d; when the tail ends of ribbed steel bars are made into right-angled hooks, the length of straight segments of the hook ends should not be less than 3 d, and the bent diameter of straight hooks should not be less than 5 d; bent-up steel bars should be bent into smooth curves; fixing bars are arranged on the top plate and the web of a hollow beam slab every 0.8-1.5 m, and the fixing bars are fixedly welded to the plain round steel bars or ribbed steel bars or bent-up steel bars intersecting with the fixing bars; 3, prestressed bar making and installing; 4, tensioning; 5, concrete pouring; 6, prestressed bar loosening. In the prefabricated hollow beam slab construction method, the mode of arranging the fixing bars on the top plate and the web of the hollow beam slab is adopted to solve the problem that inflatable core formworks float.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

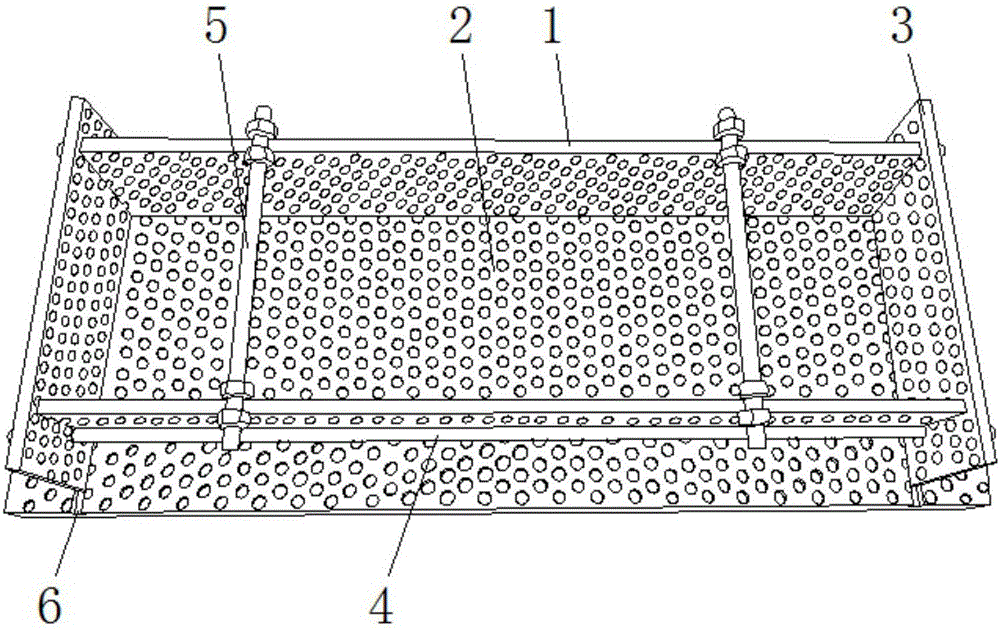

Manufacturing method of biological soil fixation test beam used for constructional engineering

InactiveCN105806688AImprove permeabilityLow costPreparing sample for investigationChemical solutionFixation test

The invention discloses a manufacturing method of a biological soil fixation test beam used for constructional engineering.The manufacturing method includes the following steps that materials are prepared, wherein the materials comprise longitudinal side plates, a bottom plate and end plates; 2, the longitudinal side plates, the bottom plate and the end plates are assembled; 3, a lightweight mold needed for cutting of geotechnical cloth is manufactured, and the geotechnical cloth is cut according to the size; 4, two transverse screws are detached; 5, the cut geotechnical cloth is placed in a rectangular model cavity, and sandy soil is added to a cavity defined by the geotechnical cloth; 6, the distance between the two longitudinal side plates is fixed through the two transverse screws; 7, bacteria are poured into a test piece, and the whole mold is placed in a chemical solution; 8, the rectangular biological soil fixation beam is formed after the reaction is completed.A large number of mechanical performance tests such as the anti-bending performance test need to be conducted on the beam which is produced through the method and needed for building a house before practical engineering application, basic data and scientific reference are provided for practical application of the technology, and safety and reliability of an infrastructure and the house are guaranteed.

Owner:重庆市綦江区全兴建筑工程有限公司

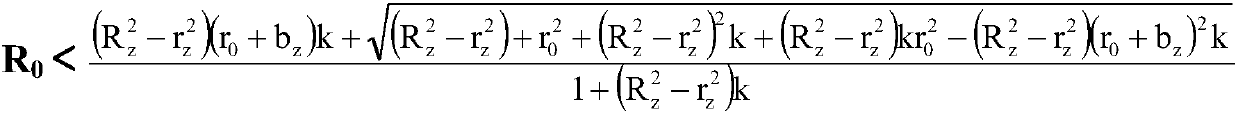

Pass design method for producing seamless steel tubes by utilizing five-rack continuous rolling mill

ActiveCN104550263AOptimize dataGuaranteed mechanical propertiesRoll mill control devicesMetal rolling arrangementsStrip millEngineering

The invention discloses a pass design method for producing seamless tubes by utilizing a five-rack continuous rolling mill. The pass design method comprises the steps of determining the total diameter reduction rate of a continuous rolling mill set, and distributing diameter reduction rates of all racks; then, sequentially calculating pass parameters of each rack; calculating the diameter of a billet tube at the outlet end of each rack; calculating the distance from the pass axis of a roll at the roll outlet side of the continuous rolling mill to the bottom of a pass groove, the distance from the pass axis of a roll at the roll outlet side to the top of the pass groove and the arc radius of roll passes; calculating the ellipticity of each roll pass, calculating the length of each distribution curve, regulating and controlling the ellipticity of a second rack and a third rack within a 10% range, increasing by 1% every time, and finding out the length of the distribution curve with the smallest ellipticity; changing the position of a contact point, which is in contact with the billet tube, of the roll in a rolling deformation area, changing the position within a + / -15% range, increasing by 1% every time, calculating a group of contact arc length values, and obtaining a minimum value of a contact arc length differential value; calculating a longitudinal-horizontal flowing speed ratio of metal deformation of the billet tube. According to the method disclosed by the invention, the mechanical performance of products can be ensured.

Owner:重庆万创无缝钢管制造有限公司

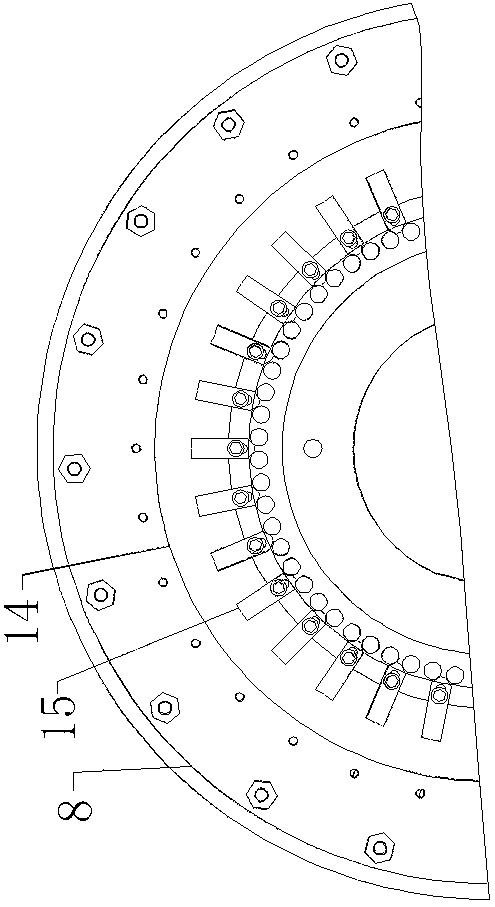

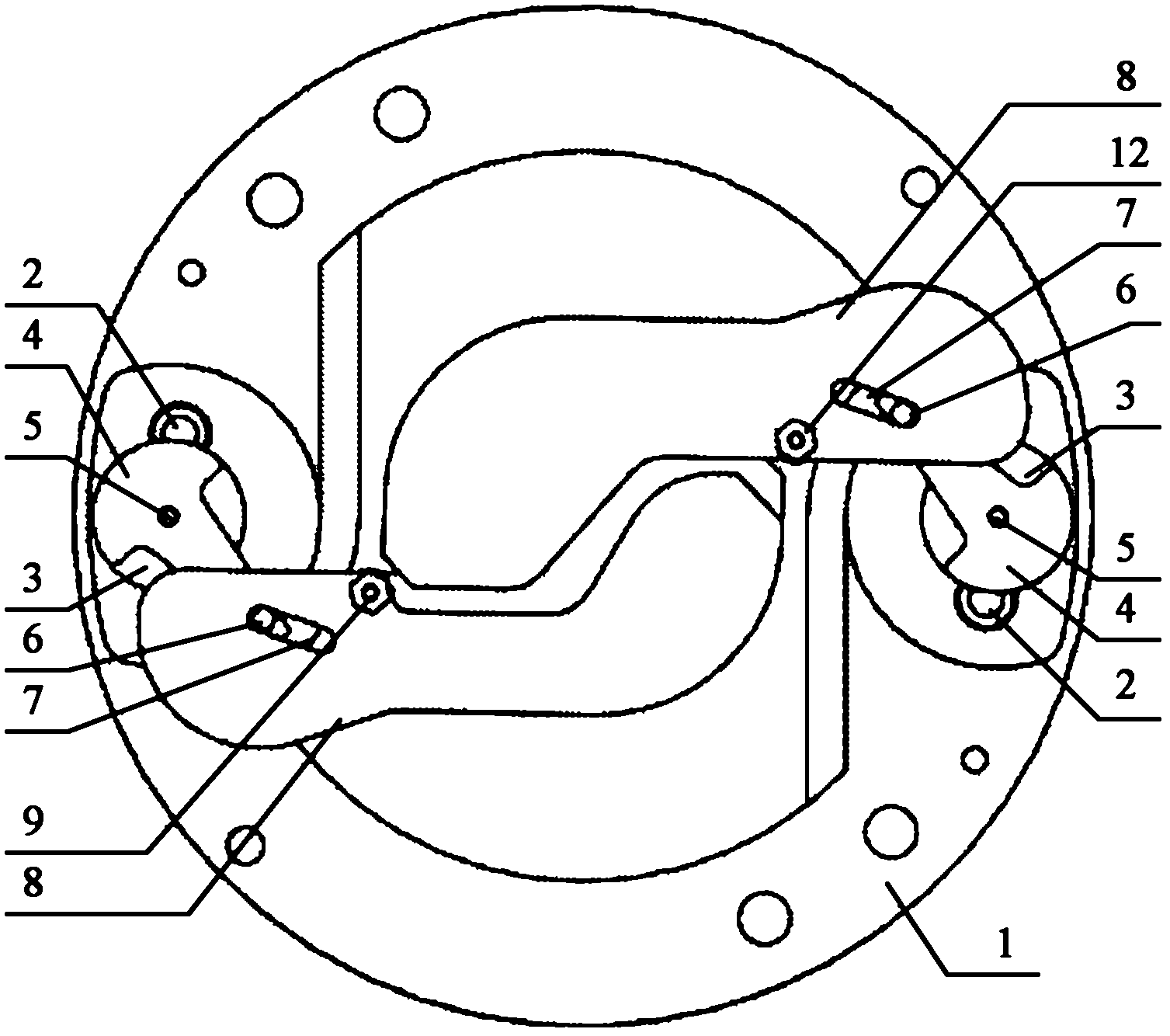

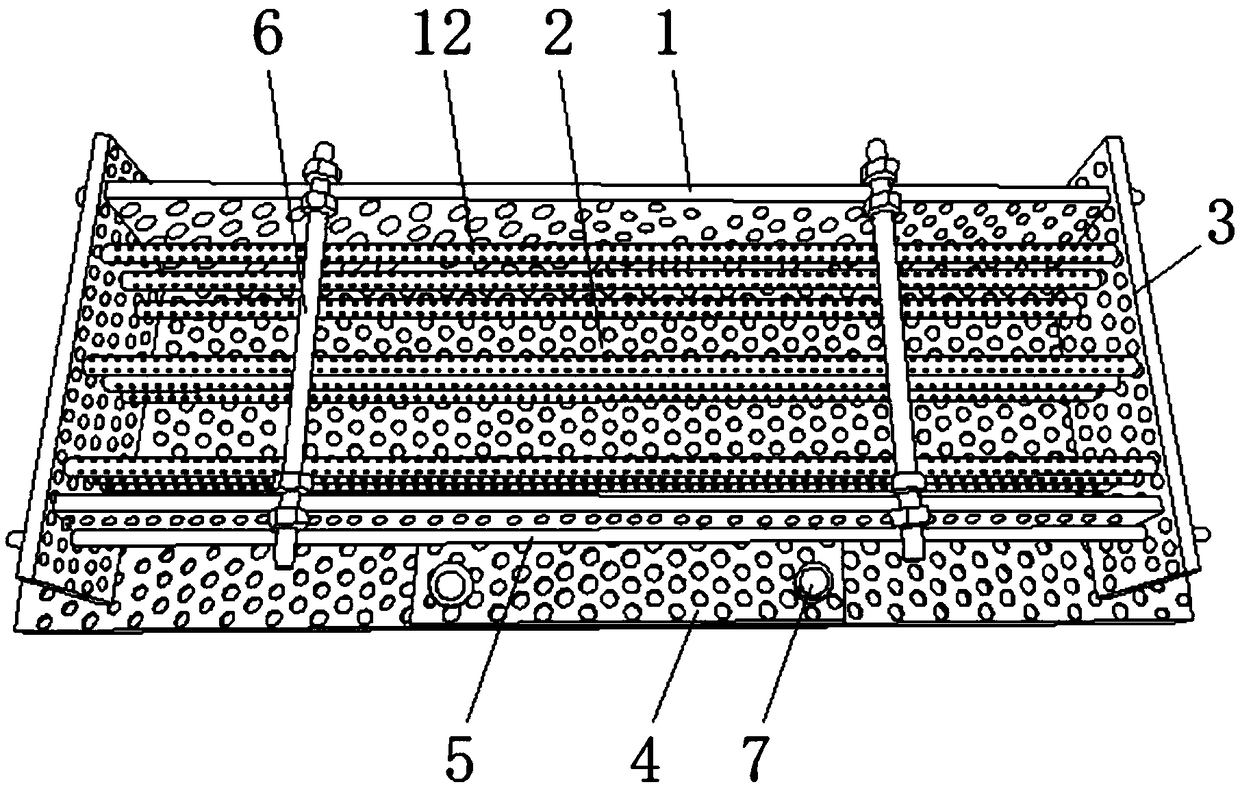

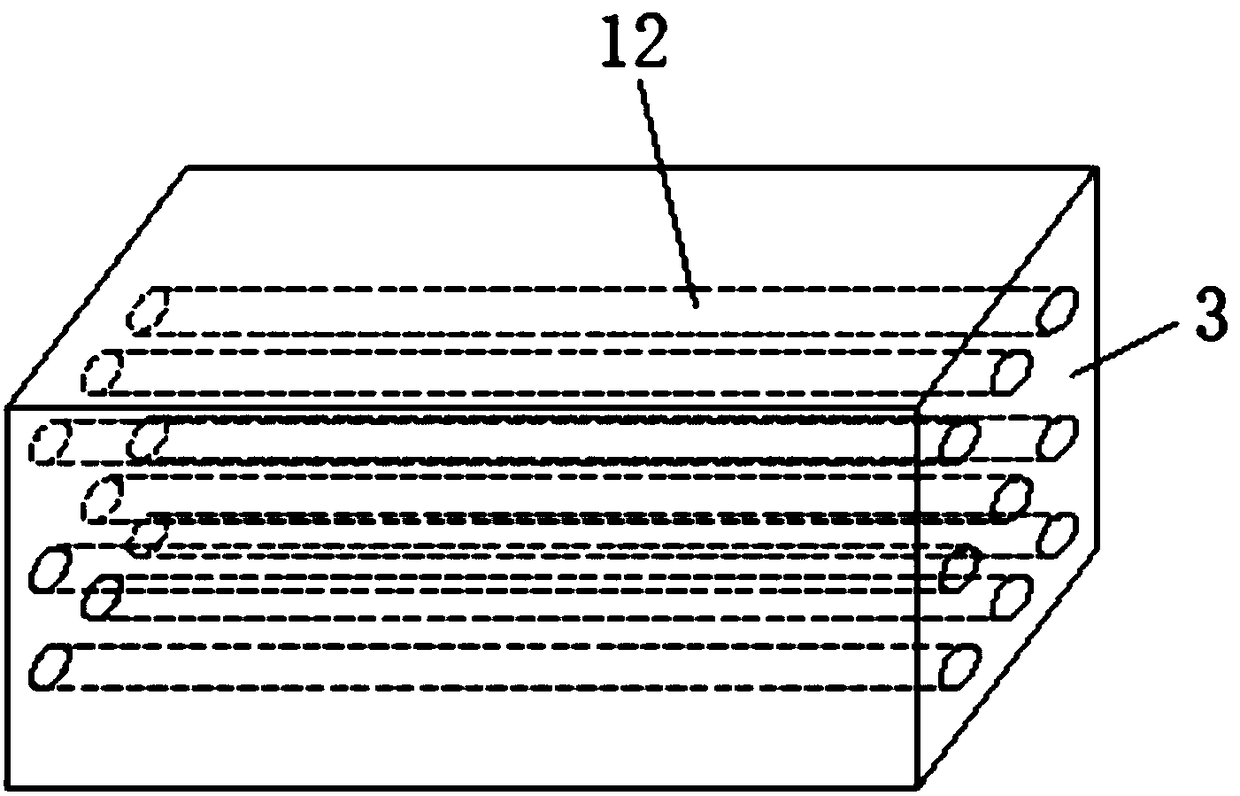

Water wall base cone assembly welding and heat treatment device and method

InactiveCN103157917AGuaranteed GeometryAvoid welding deformationWelding/cutting auxillary devicesFurnace typesButt jointEngineering

The invention relates to a novel efficient gasifier water wall connecting base cone assembly welding and heat treatment method and a device. A water wall base cone 1 is formed by an annular forge piece 2, abnormal-shaped bend pipes 3, first deformed flat steel, second deformed flat steel and an annular deformed flat steel layer 6. The method includes a first step of enabling pipe ports of at both ends of the thirty-two abnormal-shaped bend pipes are in butt joint with two channels adjacent to the annular forge pipe, and then enabling the first deformed flat steel and the second deformed flat steel to be alternatively welded with the inner sides of the abnormal-shaped bend pipes to form a circular abnormal-shaped surface, a second step of enabling a heat-resisting layer of 3 millimeters in thickness to be subjected to bead weld on the connected circular abnormal-shaped surface, and a third step of sending the welded water wall base cone into a furnace to carry out high-temperature tempering processing. The water wall base cone assembly welding and heat treatment device and the method reduce deformation and bend in the welding process of the water wall base cone, and ensure a geometrical shape after the water wall base cone is welded.

Owner:KAIFENG AIR SEPARATION GROUP

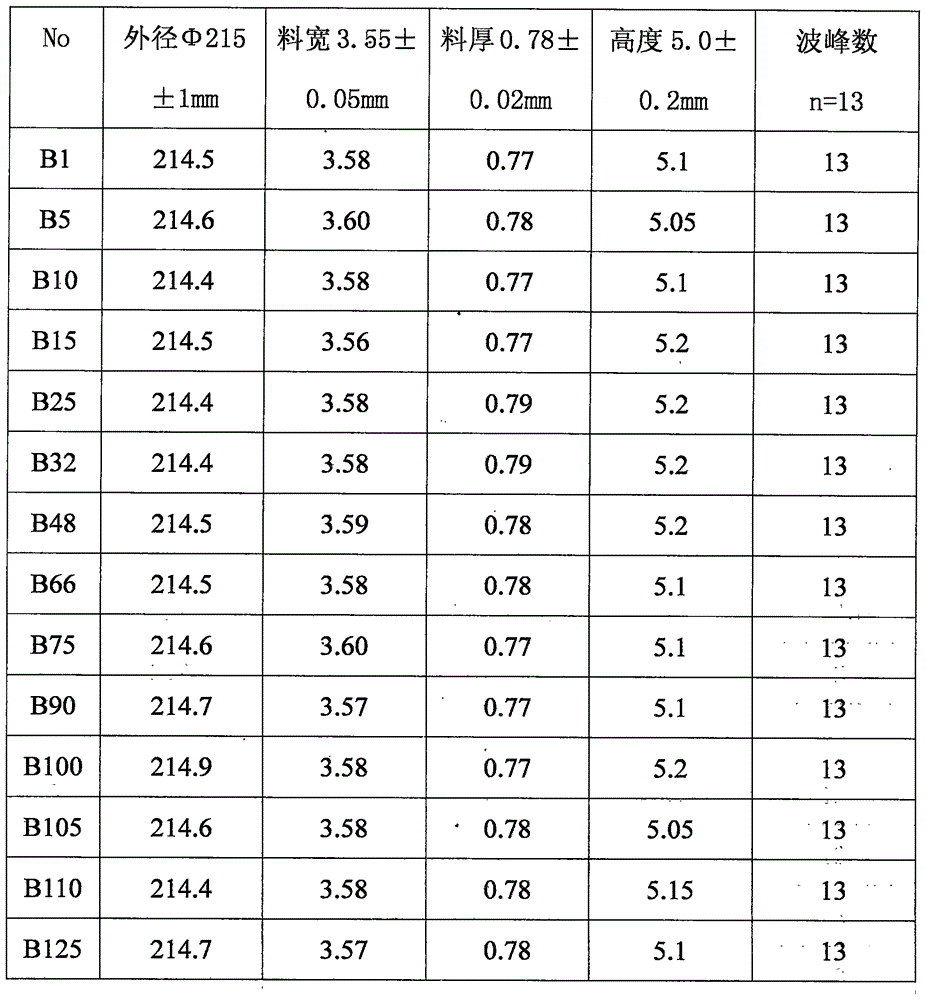

High-efficiency wave spring setting tempering technology

InactiveCN106555044AGuaranteed geometryGuaranteed hardnessFurnace typesHeat treatment furnacesRoom temperatureHardness

The invention aims to provide a high-efficiency wave spring setting tempering technology which can improve the production efficiency while guaranteeing the geometric dimensions and hardness of springs. The concrete technical scheme is as follows: placing compression-molded wave springs in a mould, compressing the wave springs, locking a combined mould, placing the combined mould in a tempering furnace, preheating the combined mould for 60 min at 380 DEG C, taking out the combined mould, and placing the combined mould on a hydraulic machine to further compress and lock the combined mould; and placing the combined mould in the tempering furnace again to reheat the combined mould to 420 DEG C, performing heat preservation for 90 min, taking the combined mould out of the furnace and cooling the combined mould to room temperature.

Owner:沈阳斯普瑞机械加工有限公司

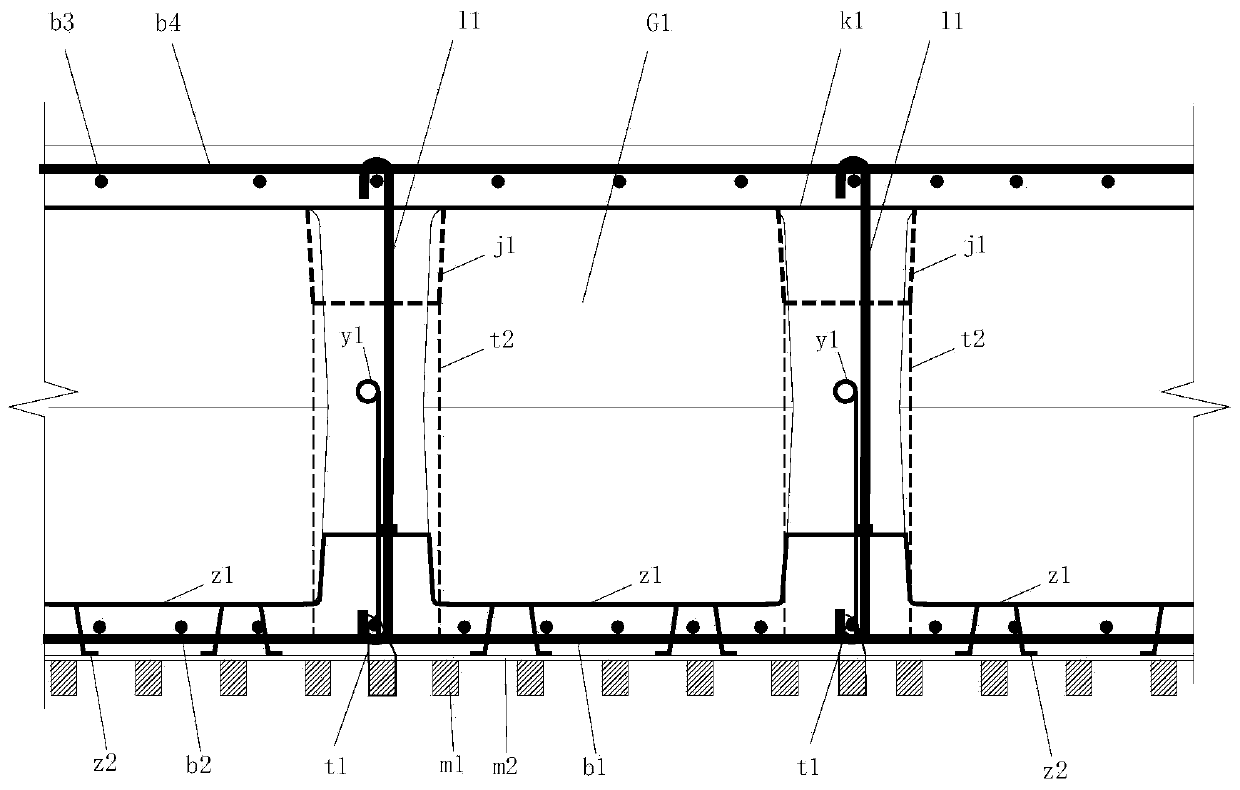

Prestress thick plate hollow floor construction method

The invention relates to a prestress thick plate hollow floor construction method. The method comprises the steps: according to hollow floor design parameters, deepening the geometric dimension and arrangement parameters of a built-in hollow square box; determining arrangement parameters of an anti-floating tie bar; mounting a formwork; locating a hidden beam, a column cap, a multi-ribbed beam, ahigh-injection alloy square box and a reserved embedded facility and performing scribing; installing the hidden beam, column cap ribs, a plate bottom reinforcing steel bar, prestressed ribs and the reserved embedded facility; connecting the plate bottom reinforcing steel bar with the bottom template; laying a hollow square box bottom positioning device; laying a hollow square box; laying an anti-floating steel bar layer, and placing an upper positioning device; connecting the upper positioning device with the plate bottom reinforcing steel bar; placing a plate top reinforcing steel bar cushionblock, laying plate top reinforcing steel bars on the plate top reinforcing steel bar cushion block and performing binding, and tying the plate top reinforcing steel bars and the plate bottom reinforcing steel bars through tie bars; pouring concrete, and performing vibrating and maintaining; performing prestress tensioning, grouting and anchor sealing; and dismantling the formwork. The construction quality of the prestress hollow floor can be improved, and the field construction difficulty is reduced.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Molding structure for green sand mold casting

InactiveCN105880468AHigh strengthGuaranteed geometryFoundry mouldsFoundry coresSand castingMaterials science

The invention provides a molding structure for green sand mold casting. The structure comprises an upper case form and a lower case form, backing sand is placed at the bottom of the lower case form, a built-in casting model is arranged between the upper case form and the lower case form, coated sand covers the periphery of the casting model, and facing sand is arranged on the coated sand which is positioned in the upper case form. The thickness of the coated sand is 3-4mm. The molding structure for green sand mold casting is improved in order to realize quality requirements of products. A common molding structure is used for casting, precision casting effects are realized, and the production cost is lower than the production cost of coated sand casting.

Owner:王德福

Self-locking type shutter device with high impact resistance

The invention relates to a self-locking type shutter device with high impact resistance, which includes an image sensor support, separation blades, acting arms and driving motors, wherein a photosensitive window is arranged at the middle part of the image sensor support; the separation blades are provided with sliding grooves, and can be rotationally mounted on the image sensor support through separation blade shafts, and the separation blades can completely shield the photosensitive window when closed, and are within the range of the image sensor support when opened normally on two sides of the photosensitive window; the acting arms are rotationally mounted on the image sensor support through rotating shafts, and are provided with convex columns which are arranged at one end of each acting arm respectively, pass through the sliding grooves of the separation blades, and can slide along the sliding grooves; the connection lines between the centers of the rotating shafts of the acting arms and the axes of the convex columns are orthogonally intersected with the groove lines of the sliding grooves of the separation blades, or form included angles slight larger than 90 degrees; and the driving motors are mounted on the image sensor support, and are connected with the acting arms for driving the acting arms. The self-locking type shutter device with high impact resistance has the characteristics of self-locking, high impact resistance, high overload resistance and the like in the normally-open state, and capability of realizing non-uniformity correction or exposure control of an image sensor focal plane in the closed state, so that the opening and closing time can be regulated and controlled conveniently according to requirements, the volume is small and the structure is compact.

Owner:中国兵器工业导航与控制技术研究所

Application of modular construction to roll hole construction of furnace wall of annealing furnace

The invention relates to modular construction, in particular to an application of modular construction to roll hole construction of a furnace wall of an annealing furnace. The application modular construction to roll hole construction of the furnace wall of the annealing furnace comprises the steps of: 1, analyzing and optimizing a drawing, decomposing the design and installation characteristics of roll holes of the furnace wall, and drawing a part decomposition drawing of structural deployment of various roll holes; 2, off-line processing an insulating layer backer board and a masonry working layer prefabricating module in a factory, and processing the roll holes or pouring prefabricating modules according to the part drawing; and 3, calculating the modulus of the brick courses of the furnace wall on site according to level of the roll holes, setting a level from the masonry furnace wall to the roll holes, and pairing the prefabricating modules. According to the application modular construction to roll hole construction of the furnace wall of the annealing furnace provided by the invention, the masonry quality of the furnace wall can be improved and the online construction period can be shortened, and the purpose of energy conservation and emission reduction can be realized to control environmental pollution.

Owner:CHINA MCC20 GRP CORP

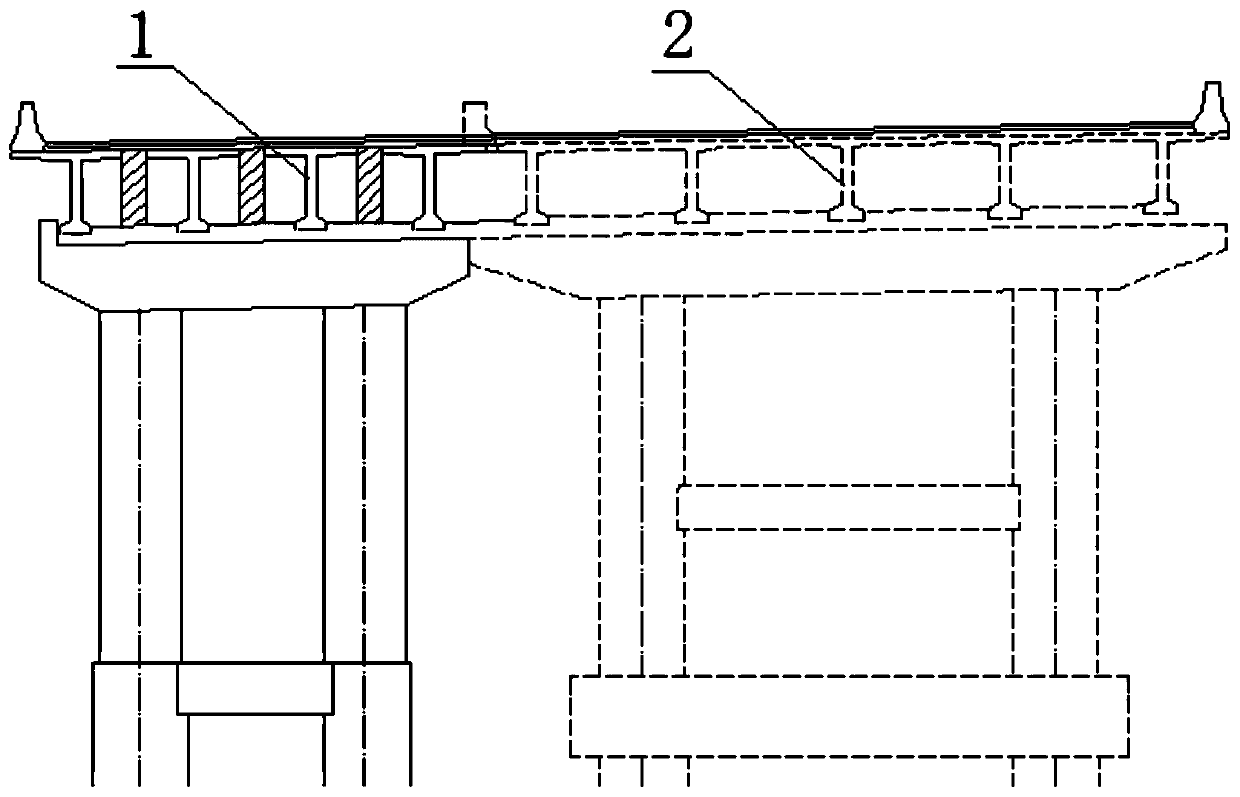

Concrete floating bridge of floating wharf

The invention belongs to the floating bridge field and in particular relates to a concrete floating bridge of a floating wharf. The concrete floating bridge of the floating wharf comprises a main bridge box, an auxiliary bridge box, a connecting rack and a pile type abutment; the main bridge box and the auxiliary bridge box are fixedly lapped on a seafloor pile by use of the connecting rack. The pile type abutment comprises a pile, a pile holder and a bridge box; the pile holder is fixed with the pile and comprises a pile holder main part, a pile holder auxiliary part, a roller and a roller bracket; the roller is fixed on the roller bracket and horizontally fixed on the pile holder. Six faces of the bridge box are all formed by use of reinforced concrete slabs and the reinforced concrete slabs of the bridge box are all coated with a silane anticorrosive material. The concrete floating bridge of the floating wharf is low in cost, high in safety performance, good in wave resistance, good in stability, excellent in durability, high in resistance to freezing and thawing, movable according to requirements and wide in application fields; the concrete floating bridge can be slightly modified into a floating airport for helicopters and a temporary floating wave barrier dam.

Owner:YANTAI KANGRUITE BUILDING MATERIAL

Rolling and bulging composite forming method of high temperature alloy ring piece

The invention discloses a rolling and bulging composite forming method of a high temperature alloy ring piece. The rolling and bulging composite forming method is characterized in that through the design of a rolled blank and a bulged blank and accurate control over the rolling and bulging processes, the defects that in the prior art, the precision is low, or the material utilization rate is not high, and properties are poor are overcome, and the high temperature alloy ring piece meeting requirements is prepared. The preparation method of the high temperature alloy ring piece is mainly used for forming of high temperature alloy ring pieces in the fields such as aviation, aerospace and industrial machinery.

Owner:GUIZHOU ANDA AVIATION FORGING

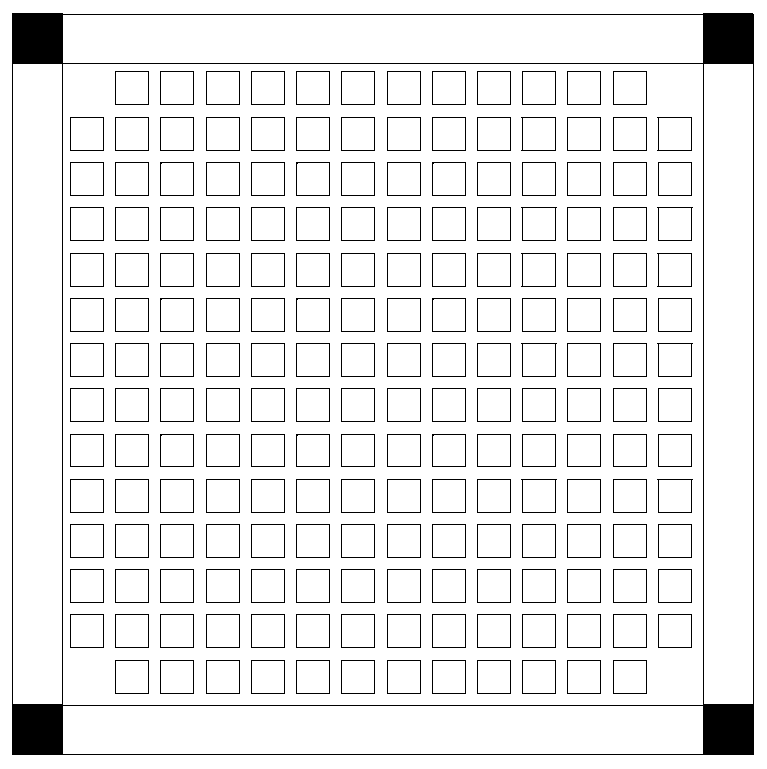

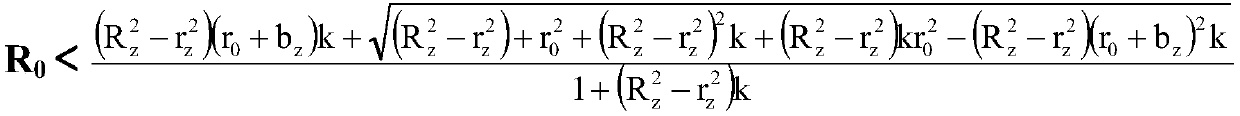

Laser filling method and device for multilayer contour pattern based on contour lines

ActiveCN113793351AReduce search volumeSave time and costImage analysisManufacturing computing systemsGrid patternComputer graphics (images)

The invention relates to a laser filling method and device for a multilayer contour pattern based on contour lines, computer equipment and a storage medium. The method comprises the following steps: performing outer contour inner offset operation on a to-be-filled pattern according to an equidistant offset algorithm to obtain a contour offset pattern; performing grid method environment modeling on the contour offset pattern to obtain a preprocessed grid pattern; performing inner and outer contour discrimination on the grid pattern to obtain a to-be-filled grid; for the to-be-filled grid, constructing a shortest path problem set; and solving the shortest path problem set by using an A* algorithm to obtain an optimal filling path of the to-be-filled grid. By adopting the method, the laser filling efficiency of the pattern can be improved.

Owner:NAT UNIV OF DEFENSE TECH

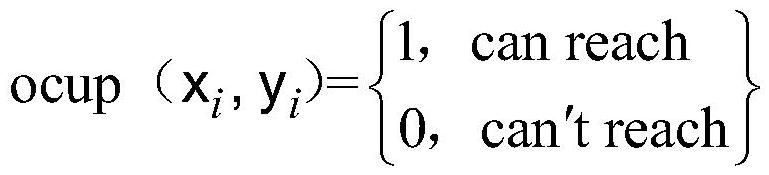

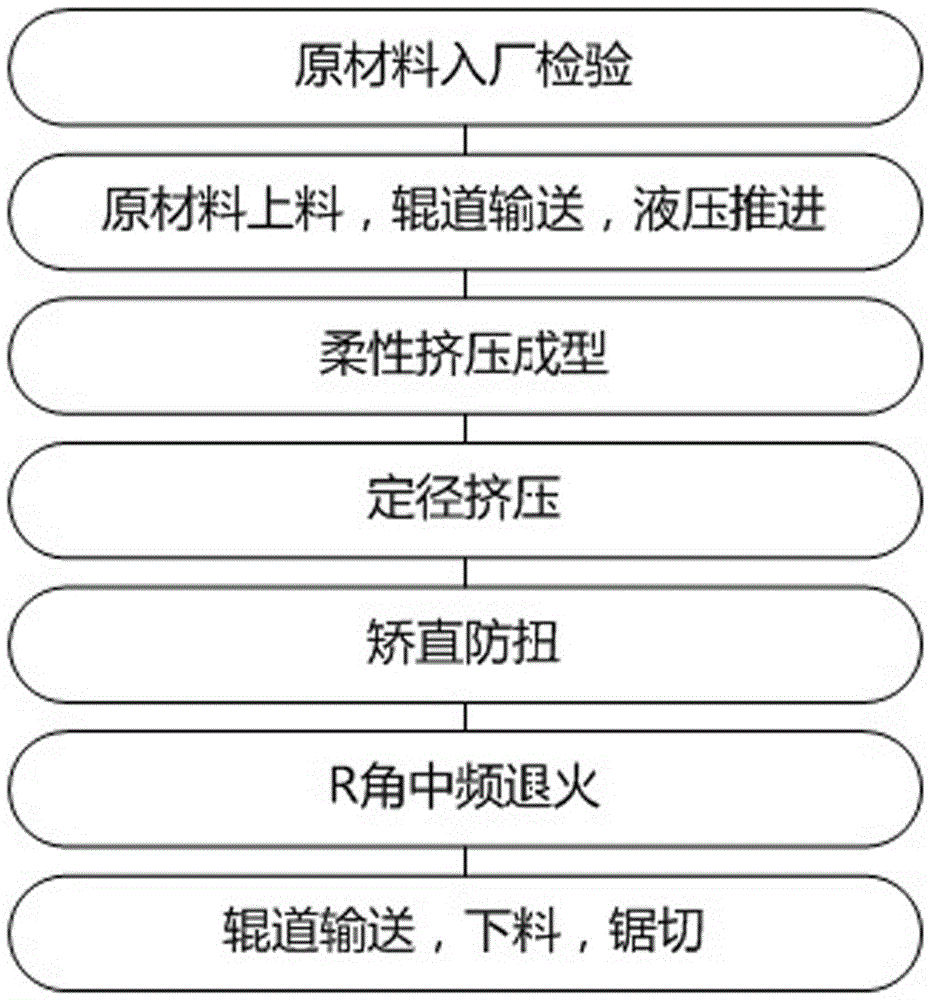

Flexible forming method of secondary forming square tube

The invention relates to a flexible forming method of a secondary forming square tube. The flexible forming method comprises the following steps of S1 performing factory inspection on raw materials; S2 feeding the raw materials, conveying on a roller way, and hydraulically propelling; S3 performing flexible extrusion forming; S4 sizing; S5 straightening to prevent distortion; S6 performing R-angle medium-frequency annealing; S7 conveying on the roller way. The flexible forming method has the advantages that the physical dimension of a steel tube can be guaranteed, the physical properties of the steel tube can be improved, the physical properties of the steel tube can reach the standard in the condition of no heat treatment, the production need is satisfied, and the production cost is reduced.

Owner:HEBEI XINZHONGLIAN SPECIAL STEEL TUBE CO LTD

Method for efficiently forming hollow bricks through high-pressure microorganism solid soil

The invention discloses a method for efficiently forming hollow bricks through high-pressure microorganism solid soil. The method comprises the following steps that 1, a material needed by a die is prepared; 2, organic glass plate with holes is assembled; 3, a light die is manufactured, and geotechnical cloth is tailored according to the size; 4, two transverse screw rods are disassembled; 5, a PVC pipeline is installed in a rectangular die cavity; 6, sandy soil is added to a cavity defined by the geotechnical cloth, and a geotechnical cloth top cover is sewn; 7, by means of the two transversescrew rods, the distance between two longitudinal side plates is fixed; 8, prepared bacteria are poured into a test piece, and then the whole die is placed in a chemical solution, and located under the pressure of two standard atmospheric pressures; and 9, after reacting is carried out for 3 days, biology solid soil hollow bricks are formed. Compared with traditional hollow bricks, the hollow bricks formed efficiently through the high-pressure microorganism solid soil does not need to be inserted and formed at a high temperature, air pollution is reduced, the environment is protected, and themethod is an ecological environment-friendly method.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Expressway T-beam widening structure and method in operation state

PendingCN110485314AEnhance horizontal linkagesOverall goodBridge erection/assemblyBridge strengtheningShaped beamT-beam

The invention discloses an expressway T-beam widening structure and method in an operation state. The problem that in the prior art, it is difficult to guarantee the integrity of new and old bridges through a bridge widening method is solved. The expressway T-shaped beam widening structure in the operating state has the beneficial effects that the transverse connection between an old T-shaped beamand a new T-shaped beam is remarkably improved, and the construction quality is guaranteed. The expressway T-shaped beam widening structure in the operating state comprises the new T-shaped beam arranged on one side of the old T-shaped beam; a first connecting structural part which is connected with an old T-shaped beam flange plate and a new T-shaped beam flange plate; and a second connecting structural part which comprises a plurality of prestress first reinforcing steel bars connected between an old T-shaped beam web and a new T-shaped beam web and second reinforcing steel bar nets arranged between the first reinforcing steel bars, wherein second concrete is poured between third reinforcing steel bar nets formed by the first reinforcing steel bars and the second reinforcing steel bar nets.

Owner:SHANDONG JIAOTONG UNIV

Full-dry nonmetal optical cable

InactiveCN105353483AGuaranteed waterproof performanceGuaranteed mechanical propertiesFibre mechanical structuresMicrometerEngineering

The invention discloses a full-dry nonmetal optical cable in which waterproof substances are not filled. Particularly, a waterproof optical fiber is formed by coating the periphery of the optical fiber inside the optical cable with a waterproof layer, wherein the thickness of the waterproof layer is 10-50 micrometers. According to the optical cable, the environment cannot be polluted during the production and use of the optical cable, an environment-friendly effect is achieved, and meanwhile, the waterproof performance of the optical cable can be guaranteed.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

One-step molding vulcanization technology of hollow-core rubber product

ActiveCN108705791AAvoid secondary damageUniform wall thicknessDomestic articlesHollow coreWork in process

The invention discloses a one-step molding vulcanization technology of a hollow-core rubber product. The one-step molding vulcanization technology comprises the following steps of: step one. preparinga bar material coated with rubber, specifically, the bar material comprises a bar core and a rubber coating layer coating the bar core, and the bar core is made of a phase change material; step two.removing part of both ends of the bar core in a digging manner, then filling the hollow parts of the bar core with rubber compound, and inserting air nozzles in the mixed rubber to obtain a semi-finished product; and step three. putting the semi-finished product in an indirect vulcanizing tank for vulcanization to obtain the hollow core rubber product. According to the one-step molding vulcanization technology, the phase change material is used as the bar core for preparing the bar material coated with the rubber; the phase change material bar core can stably support the rubber coating layer in the molding process, so that the geometric dimensioning of the molded rubber product is ensured; the phase change material bar core is converted into liquid at a high temperature so as to be discharged in the vulcanization process, so that the one-step extrusion molding vulcanization of the hollow rubber product is realized; the geometric dimensioning of the appearance of the prepared hollow core rubber product meets the requirements; the prepared hollow core rubber product has uniform wall thickness; and meanwhile the hidden danger of damage after inflation caused by a mold pressing splicing method is eliminated.

Owner:陕西特种橡胶制品有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com