Manufacturing method of biological soil fixation test beam used for constructional engineering

A technology of construction engineering and production method, which is applied to the preparation, sampling, and measuring devices of test samples, can solve the problems of not being very economical and practical, the impact of construction period, and long maintenance time, so as to improve the mechanical properties of soil and reduce the Engineering cost, reliable molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] A method for manufacturing a biologically-fixed soil test beam used in construction engineering, the method comprising the steps of:

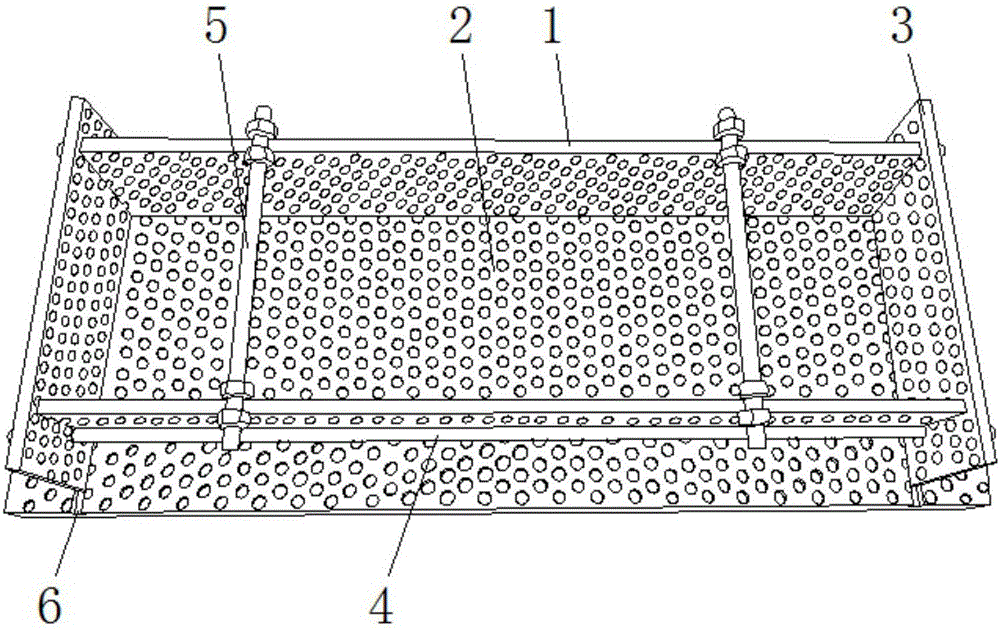

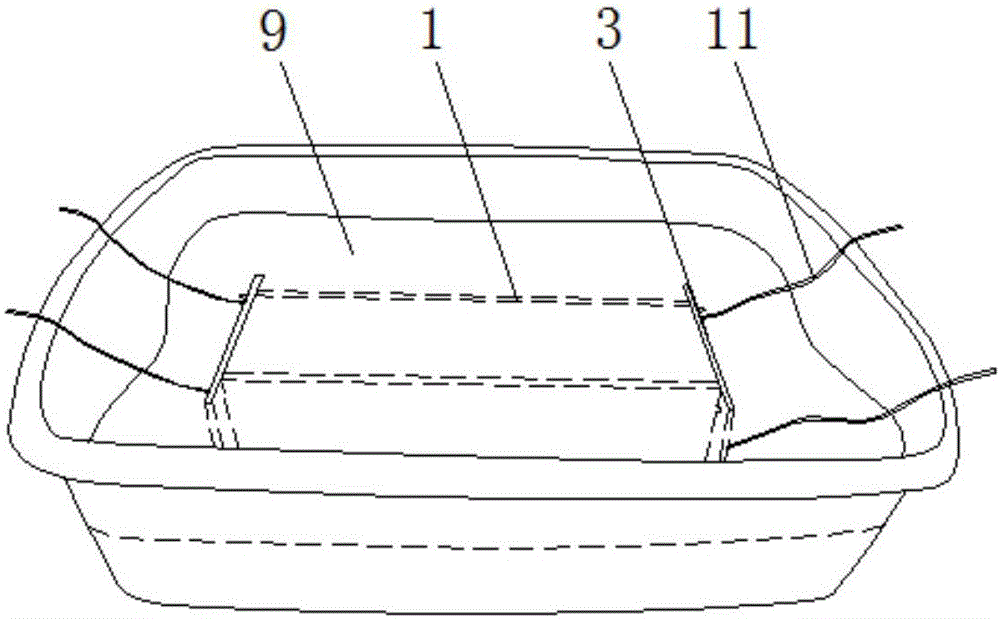

[0035] 1) Prepare the materials required for the mold: Drill holes on the plexiglass flat plate, the holes on the plexiglass are arranged in a dislocation, the diameter of the holes is 5mm, and the distance between the holes is 2.5mm. Cut the plexiglass into plates with a woodworking saw blade, such as figure 1 As shown, the panel comprises two longitudinal side panels 1 , a bottom panel 2 and two end panels 3 . Prepare two vertical screw rods 4 and two horizontal screw rods 5 again, for preventing it from being corroded by chemical substances, the used nuts of two vertical screw rods 4, two horizontal screw rods 5 and the present embodiment are all wound with waterproof plastic paper or water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com