Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Guaranteed geometric accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional building fine geometric reconstruction method integrating airborne and vehicle-mounted three-dimensional laser point clouds and streetscape images

PendingCN111815776AGuaranteed geometric accuracyEfficient extractionInternal combustion piston engines3D modellingPoint cloudModel reconstruction

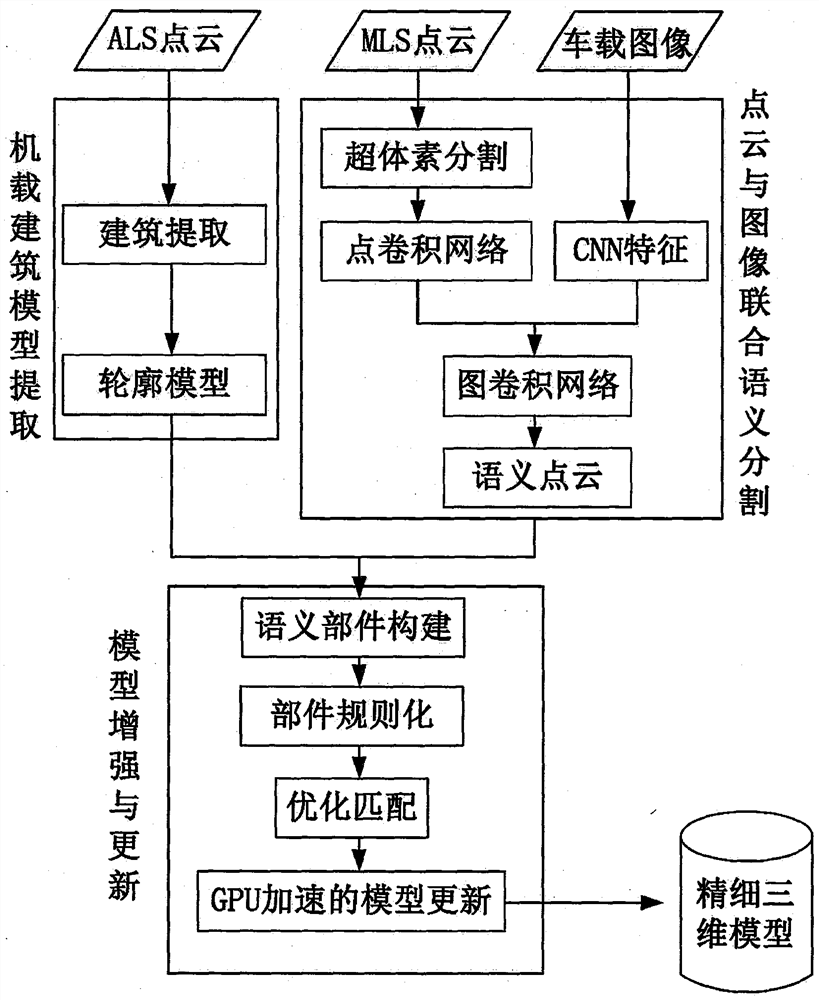

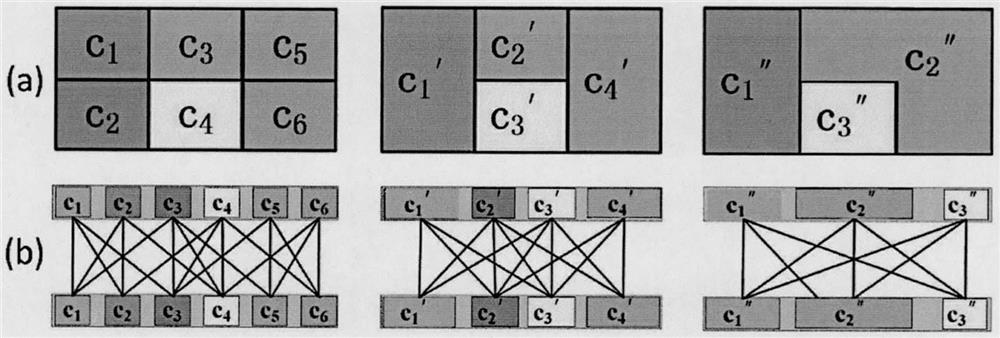

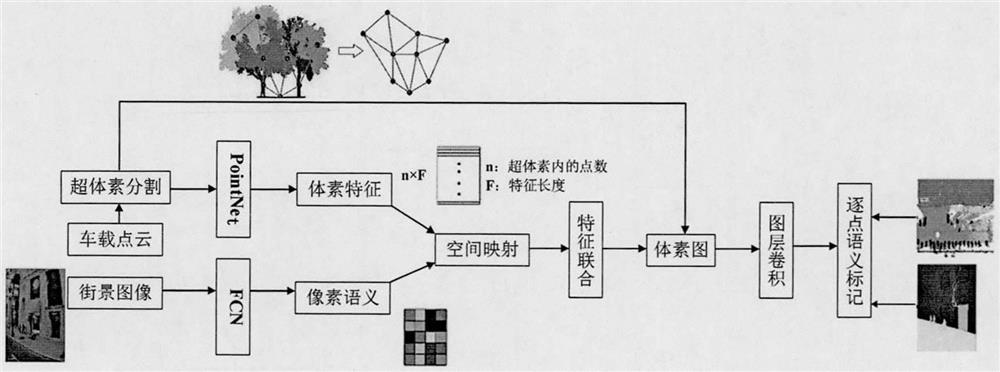

The invention provides a three-dimensional building fine geometric reconstruction method integrating airborne and vehicle-mounted three-dimensional laser point clouds and streetscape images. The method comprises the following steps: (1) a quick modeling method based on airborne laser data; (2) combining the semantic segmentation framework of the vehicle-mounted point cloud and the image; and (3) amodel automatic enhancement algorithm fusing multi-source data. According to the method, airborne laser point cloud, vehicle-mounted laser point cloud and streetscape images are taken as research objects, model reconstruction, model enhancement and updating are taken as targets, joint processing of point cloud and image data of different platforms is realized, and the fusion potential of variousdata is fully mined. The final research result will perfect the fusion and fine modeling framework of vehicle-mounted-airborne data, promote the development of the point cloud data semantic segmentation technology, and serve the emerging application fields of unmanned driving and the like.

Owner:山东水利技师学院

Large-area complex-terrain-region unmanned plane sequence image rapid seamless splicing method

InactiveCN104156968AAvoid blind matchingNarrow searchImage analysisLevenberg–Marquardt algorithmTerrain

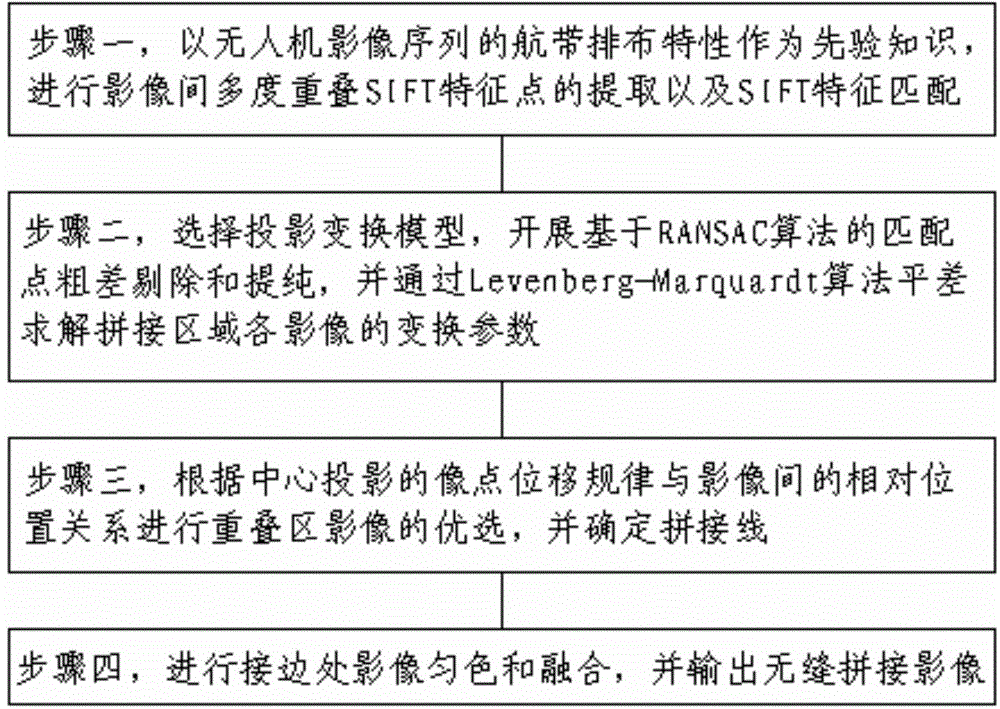

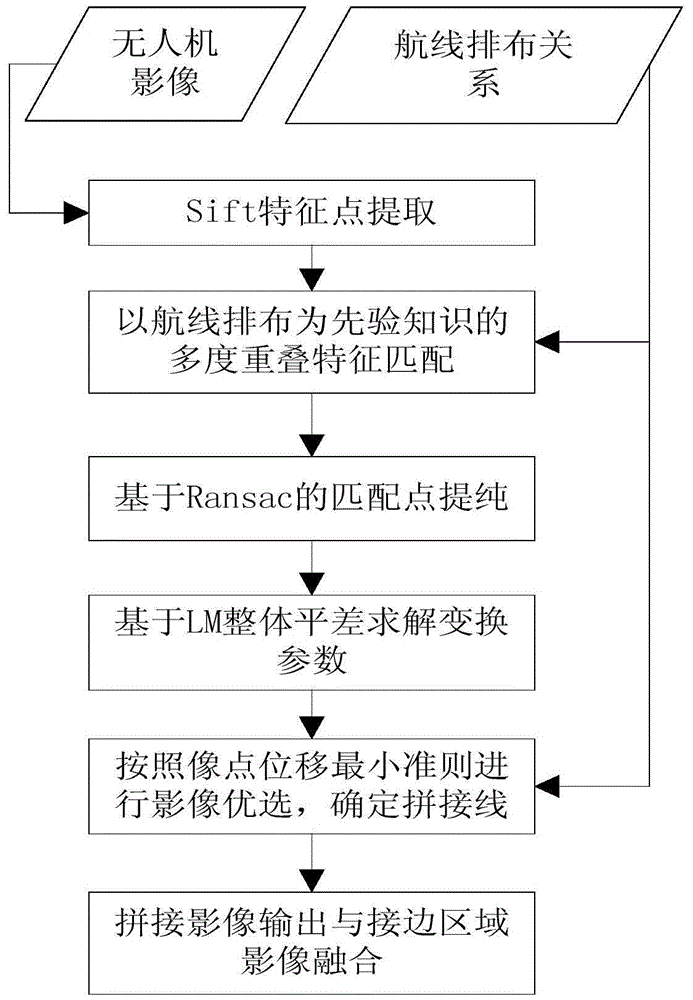

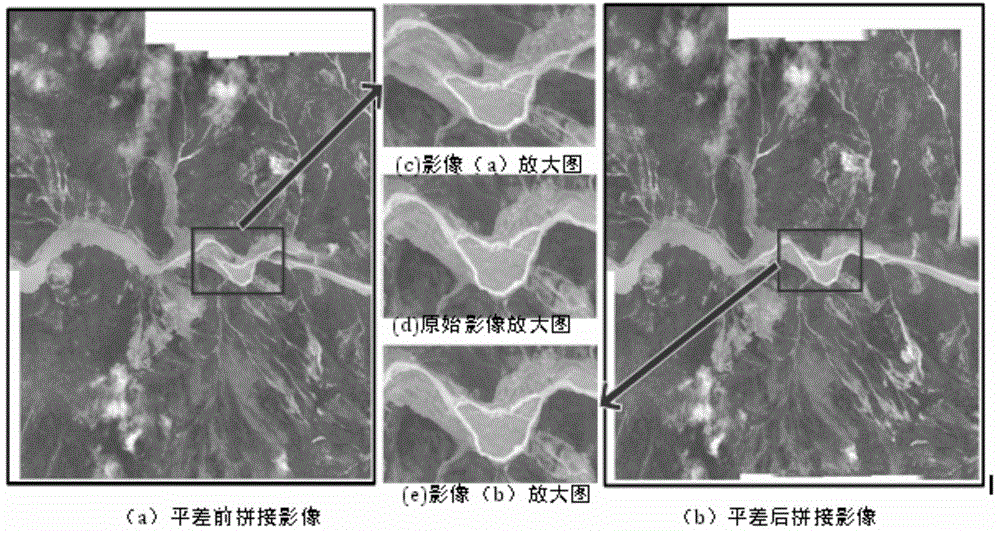

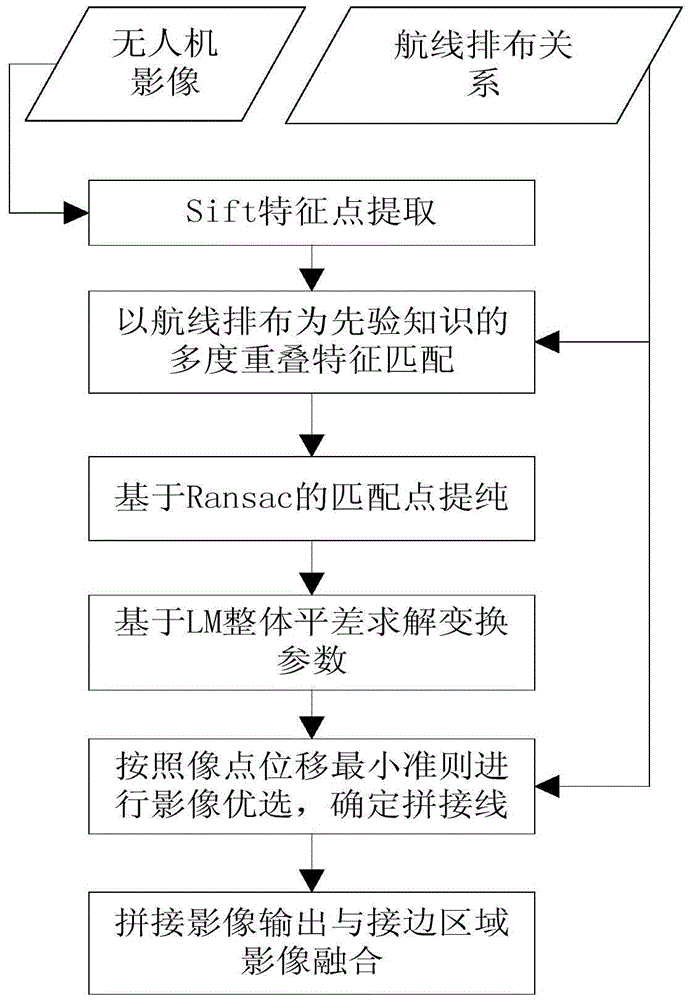

Provided is a large-area complex-terrain-region unmanned plane sequence image rapid seamless splicing method which comprises the following steps: to begin with, with air strip arrangement features of unmanned plane image sequence being prior knowledge, carrying out inter-image multiple-overlap SIFT feature point extraction and matching; then, carrying out matching point gross error removing and purifying based on random sample consensus algorithm, and solving transformation parameters of each image in spliced regions in an adjustment manner through an Levenberg-Marquardt algorithm; next, carrying out overlapped region image optimized selection according to the relative position relationship between central projection image point displacement rules and the images, and determining splicing lines; and finally, carrying out image uniform-coloring and fusion at the edge-connection places, and outputting spliced images, thereby realizing mass unmanned plane image seamless splicing. The seamless splicing method helps to improve the extraction efficiency of the SIFT feature points, guarantee the geometric accuracy of the spliced images, and eliminate the tiny color difference at the two sides of the image splicing line, and thus the spliced images with natural color transition and good natural object and landform continuity are obtained.

Owner:SHANDONG LINYI TOBACCO

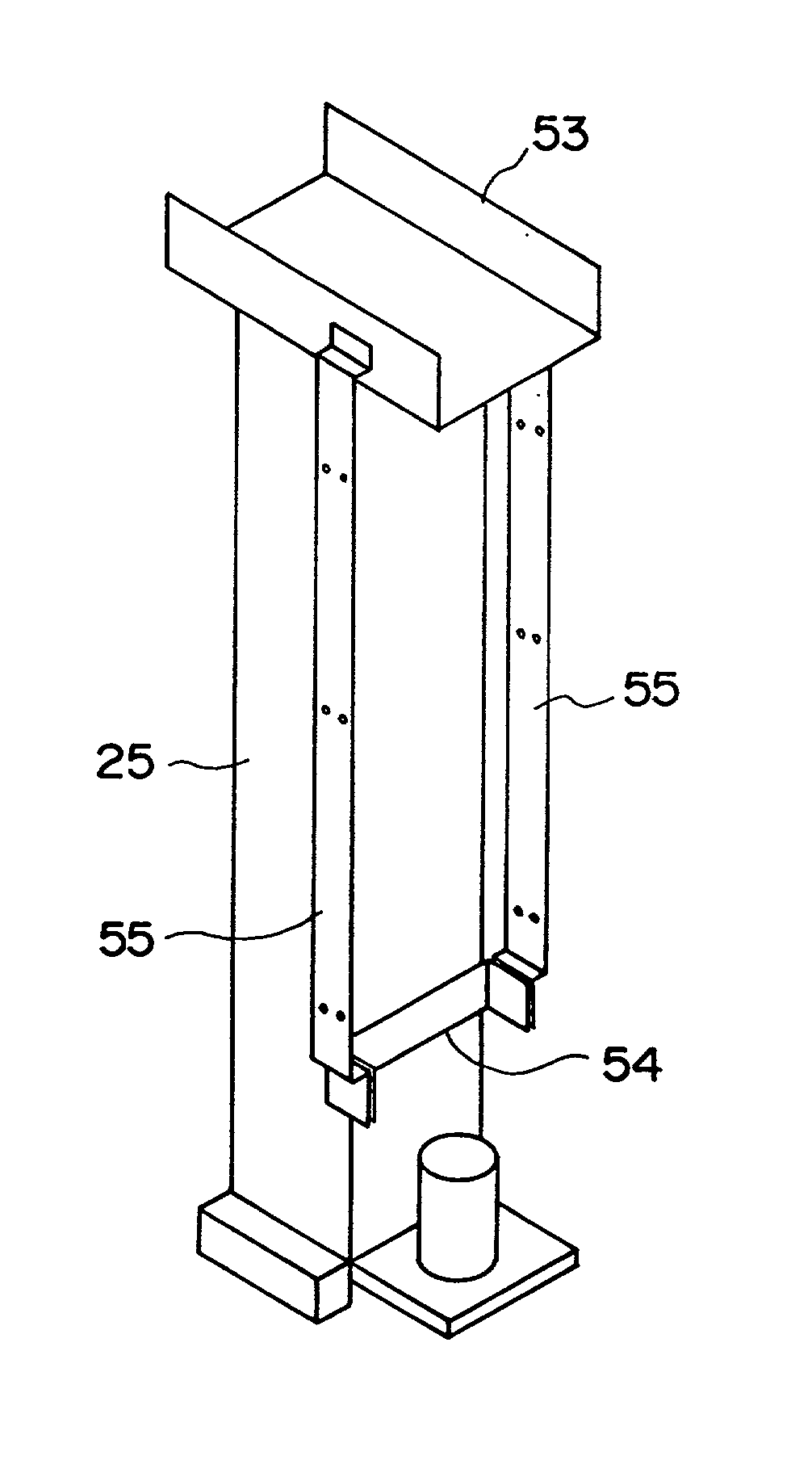

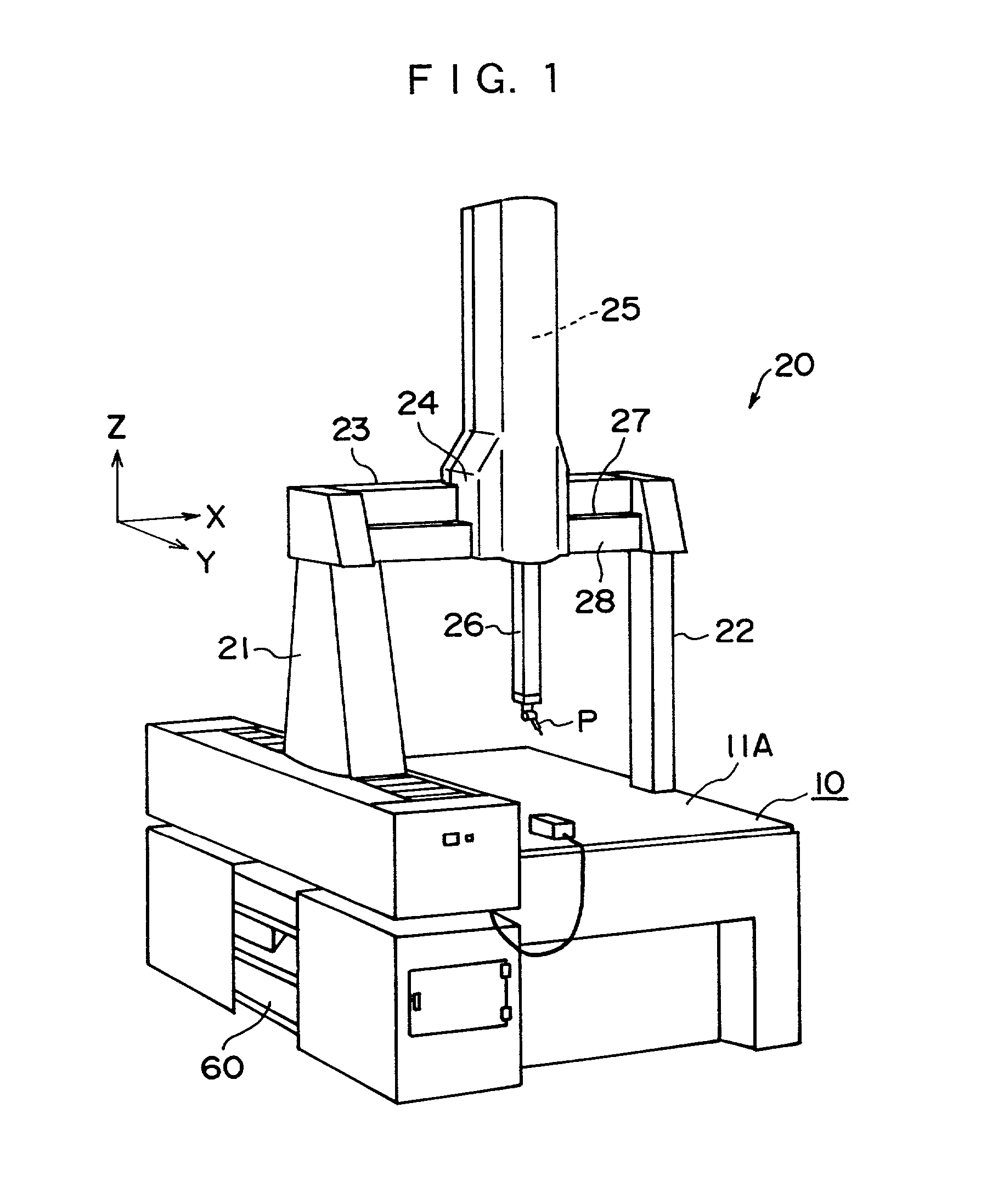

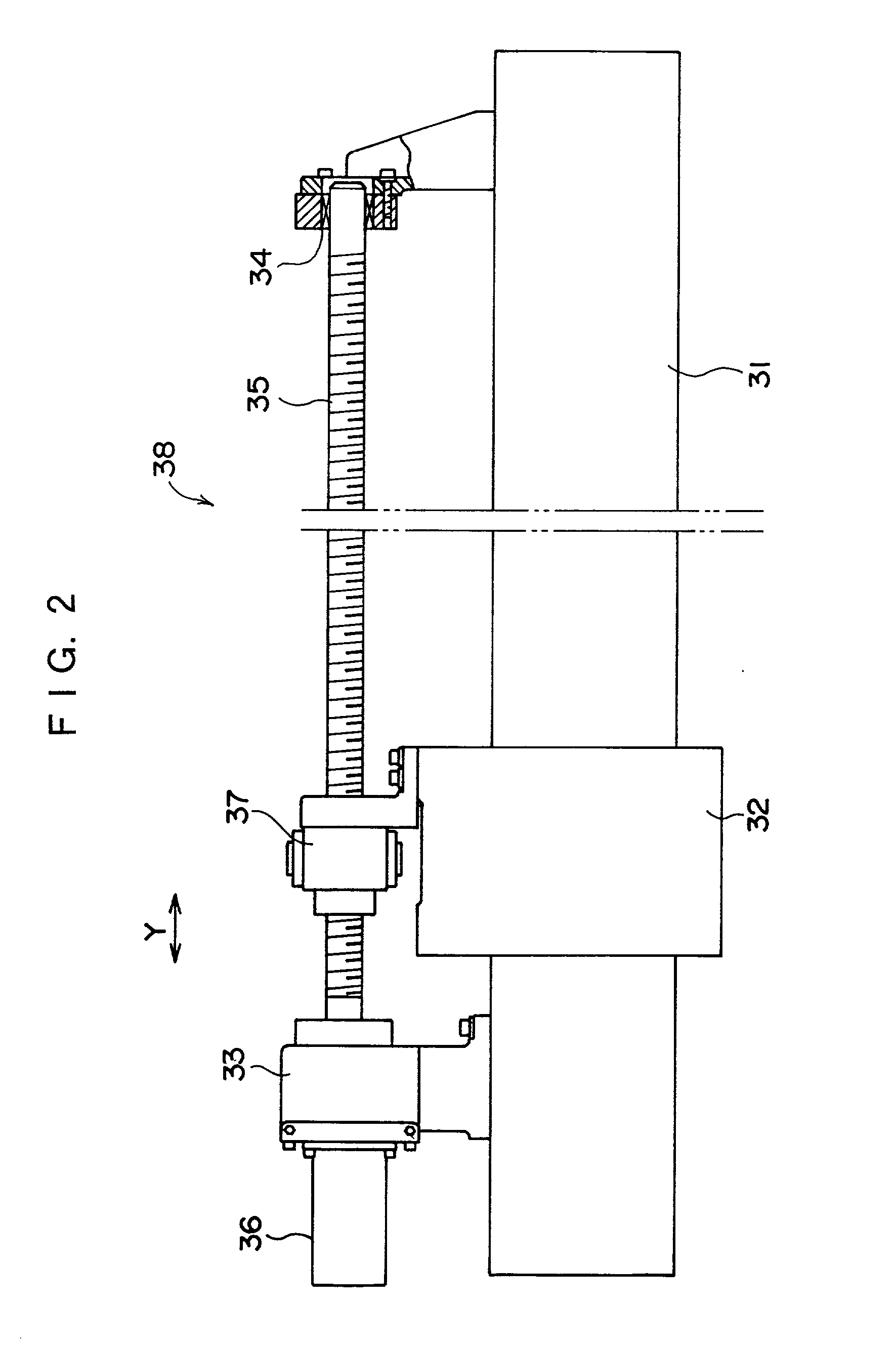

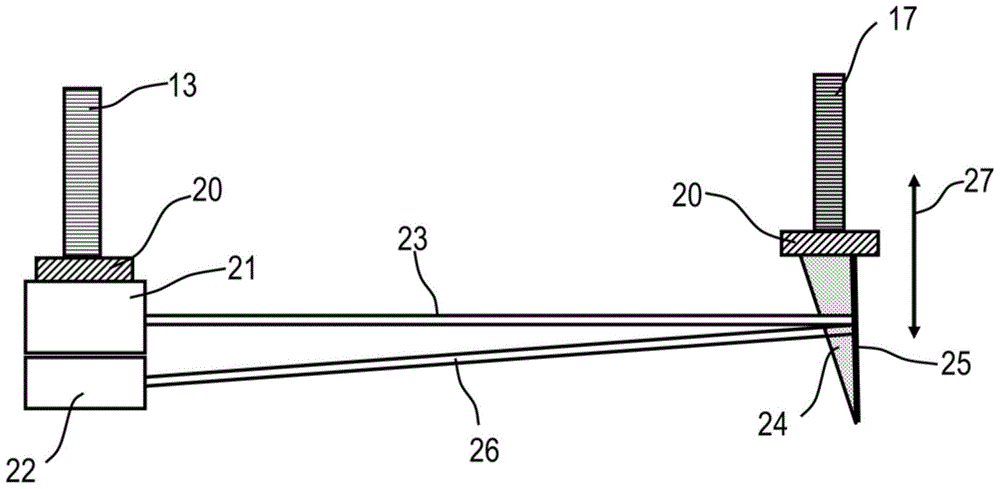

Measuring machine

InactiveUS6370787B1Uniform temperature distributionLarge thermal conductivityUsing electrical meansElectric/magnetic contours/curvatures measurementsEngineeringAlloy

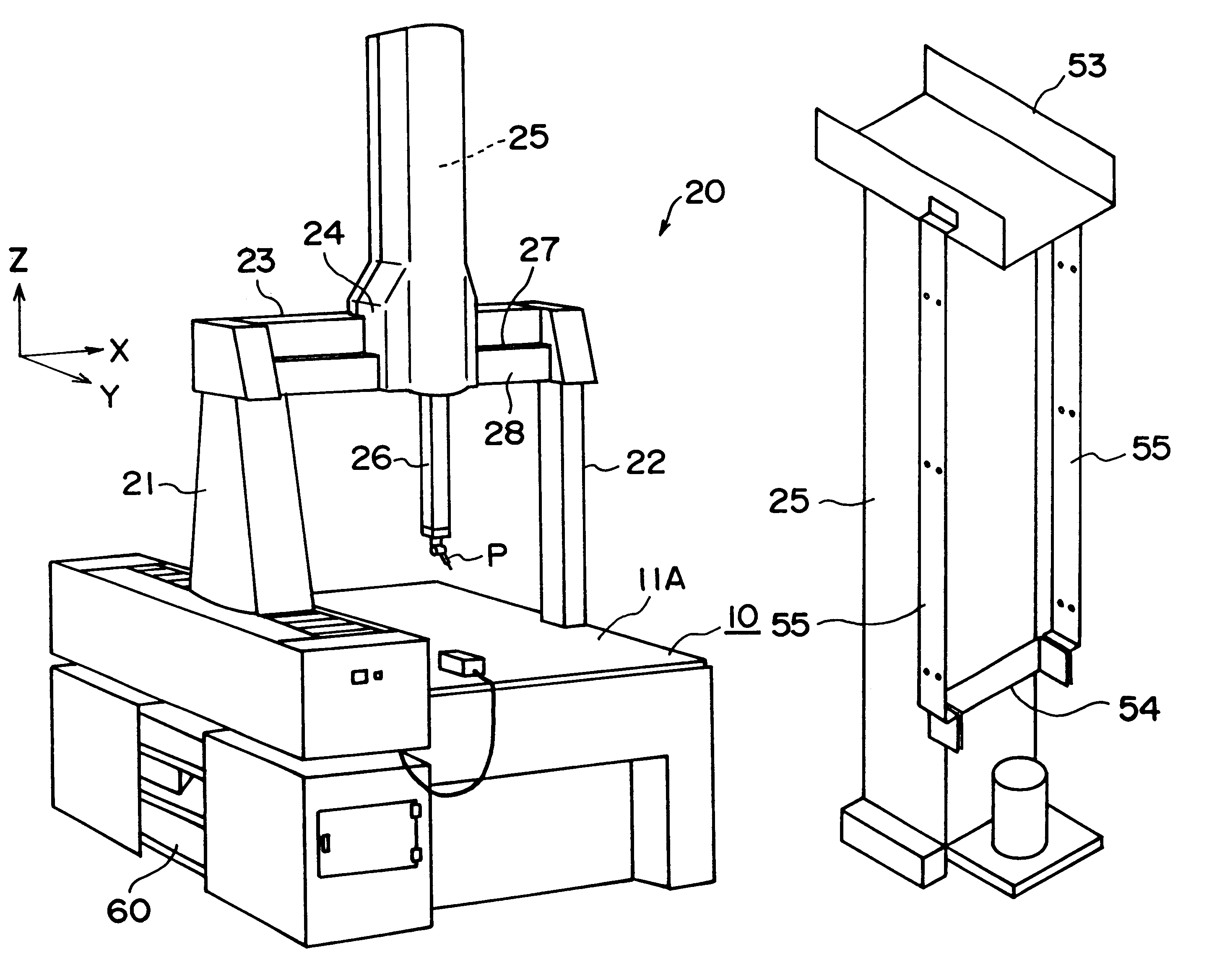

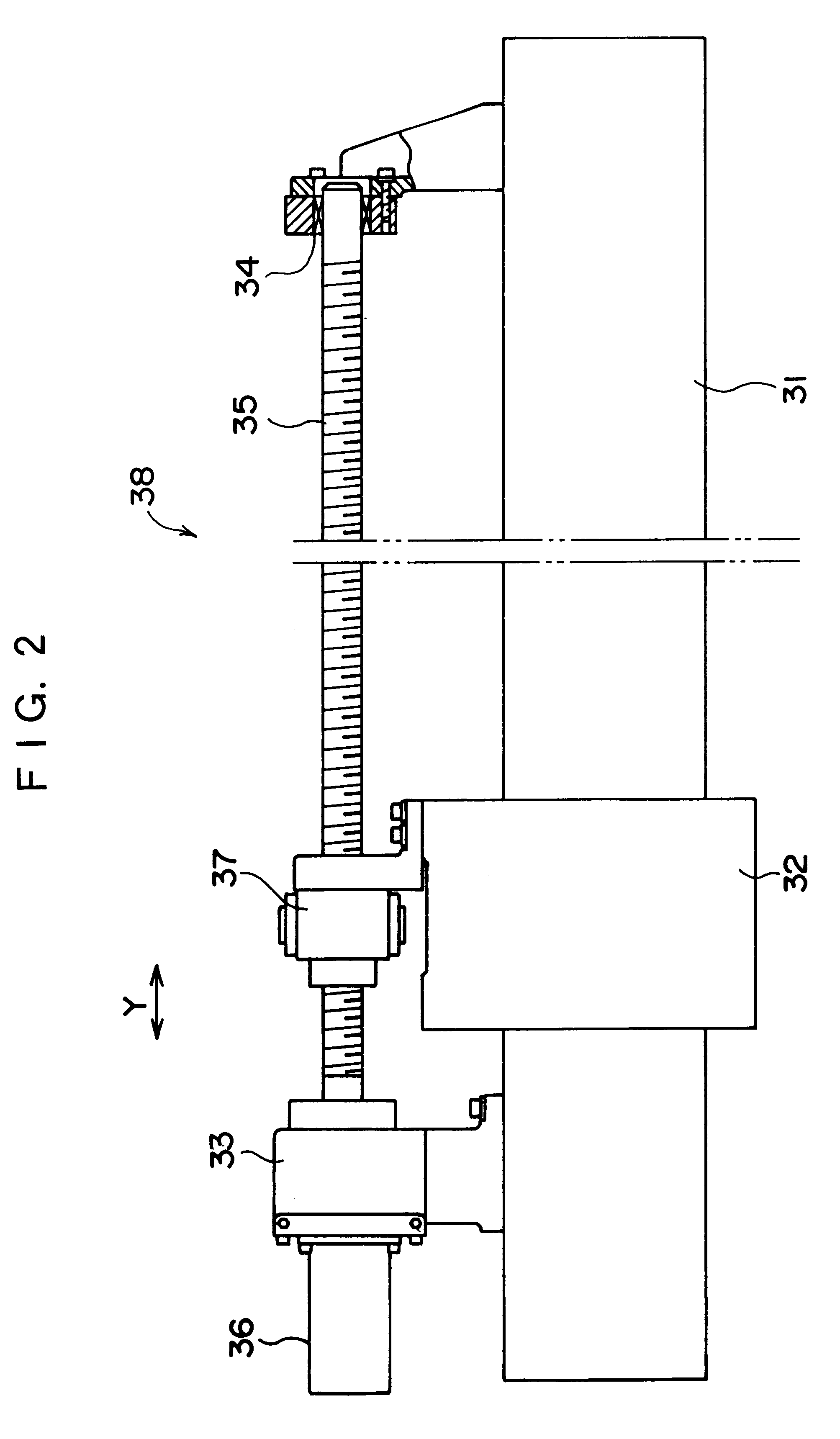

A measuring machine having a base (10), a touch signal probe (P), a moving mechanism (20) for retaining the touch signal probe (P) movably in three-dimensional directions, and a controller (60) for controlling a movement of the moving mechanism (20) and for acquiring coordinates value of respective axes based on a contact signal from the touch signal probe (P) to measure a dimension etc. of a workpiece based on the coordinates value is provided. Main structural members structuring the moving mechanism (20), more specifically, a column (21), a supporter (22), a X-beam (23), a Z-axis structure (25) and a Z-axis spindle (26) are made of aluminum or aluminum alloy including aluminum as main component, which has large thermal conductivity, thereby making temperature distribution uniform to improve geometrical accuracy.

Owner:MITUTOYO CORP

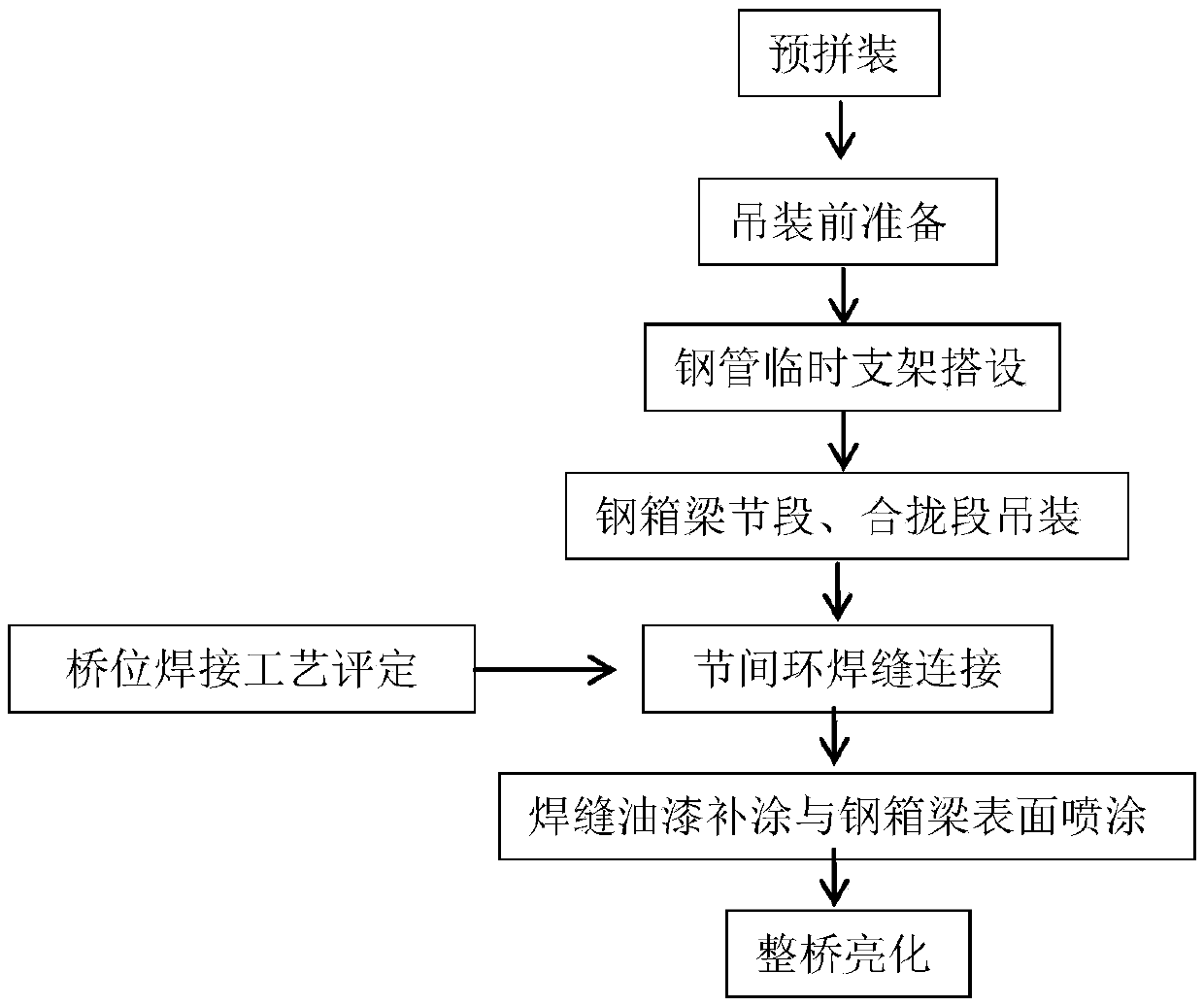

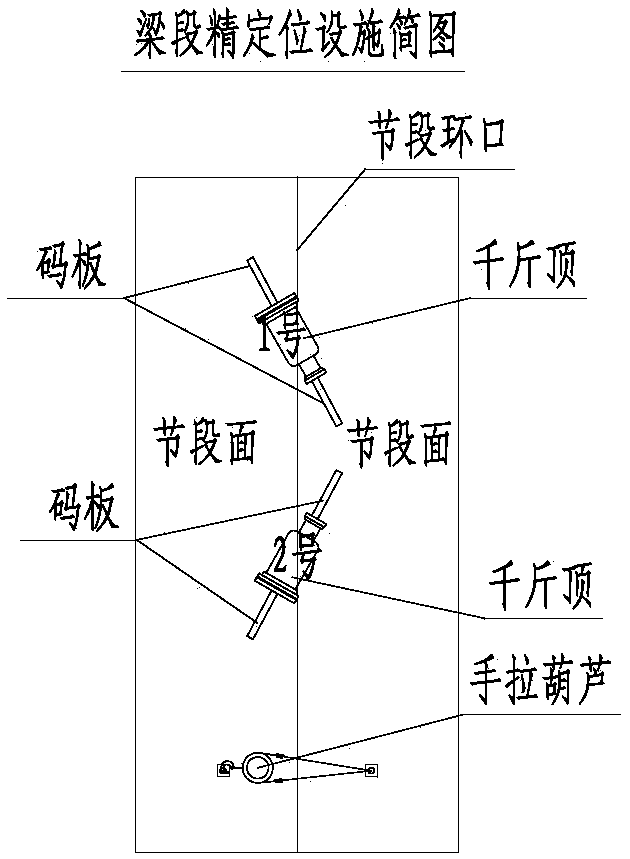

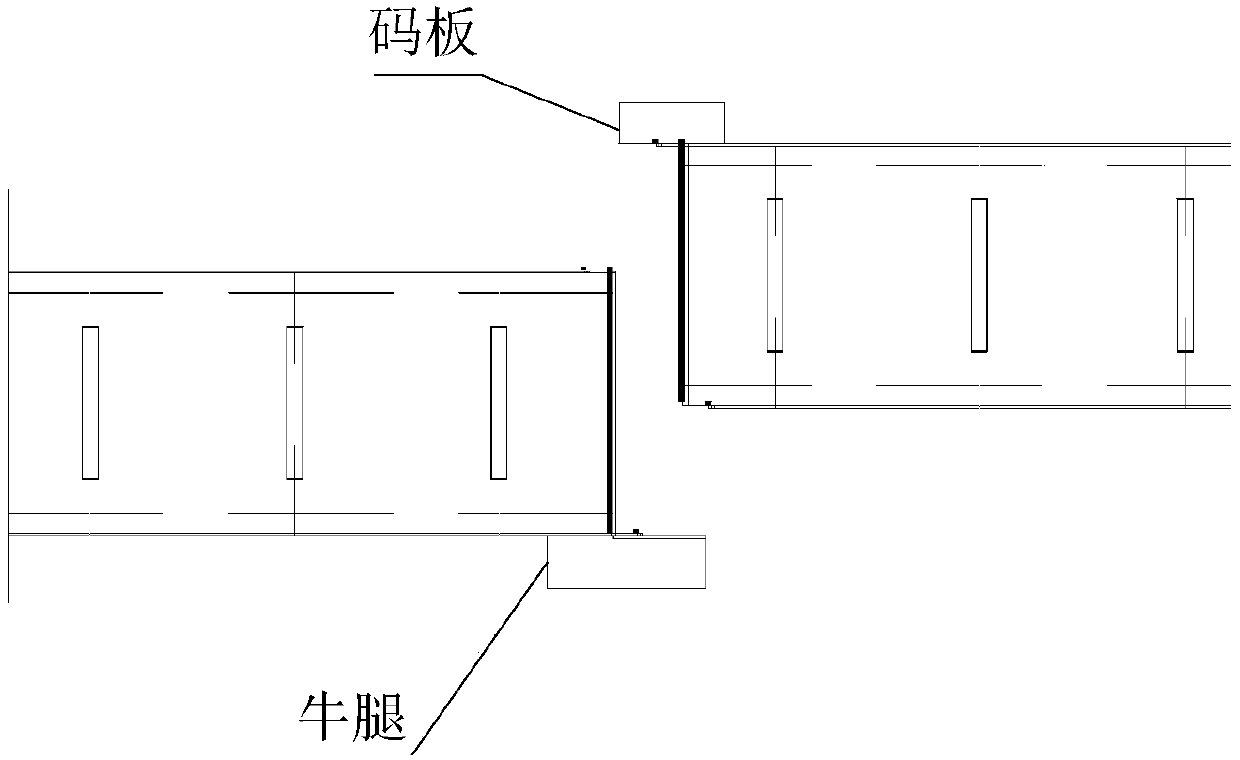

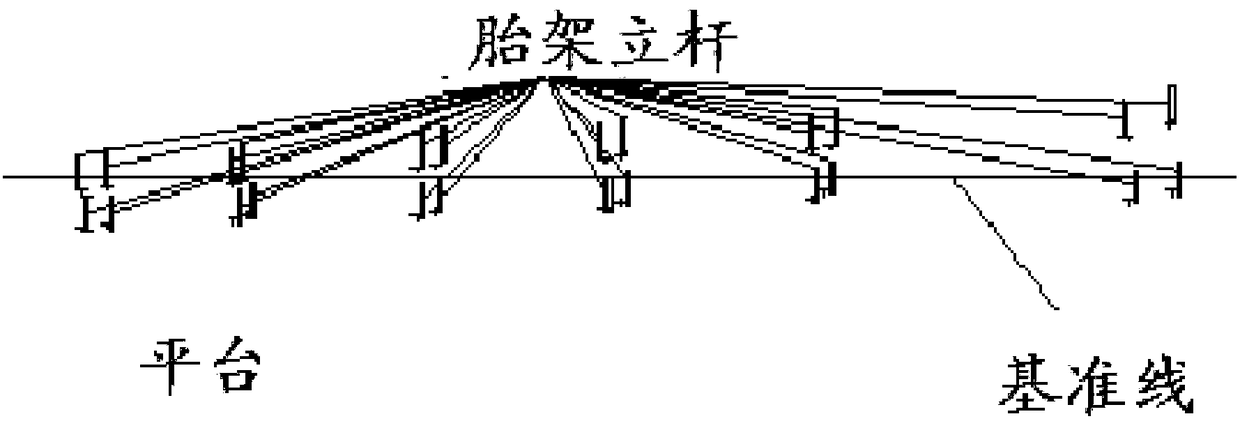

Limited bracket construction method of large-span S-shaped steel box girder

InactiveCN109594474ASmall footprintReduce the impactBridge erection/assemblyBridge materialsEngineeringSteel box girder

The invention discloses a limited bracket construction method of a large-span S-shaped steel box girder. The steel box girder comprises 14 small sections of prefabricated steel box girders; and the 14small sections of prefabricated steel box girders are assembled into seven large sections at a construction site, and then the seven large sections are hoisted and fixed. The construction method comprises the following specific steps of: prefabricating and assembling the steel box girders, constructing temporary brackets in water, hoisting and positioning steel box girder section blocks, connecting steel box girder interfaces, constructing closure sections and welding the collar extension of the steel box girders. According to the limited bracket construction method, a prefabricated assemblymode is used during construction; a floating crane is used for assembly, so that the occupation and pollution of a water area under a bridge are reduced; the parallel operation of multiple processes speeds up the construction progress and shortens the construction period; the temporary brackets are arranged only at circular seams of large-section girder joints; and the brackets occupy small space,thereby facilitating the navigation under the bridge in the construction state and reducing the influence on the navigation under the lake-across construction bridge and surrounding social environments.

Owner:合肥市公路桥梁工程有限责任公司

Decarburization cleaner

ActiveCN101538511AReduce consumptionEasy to useOrganic detergent compounding agentsSurface-active detergent compositionsDissolutionSolvent

The invention discloses a decarburization cleaner. Perchloroethylene and methylen chloride or dichloropropane without flammable risk are used as decarburization solvents of the invention; on the basis of the permeability and dissolution of the solvents, the surfactant sodium alkyl sulfonate is compounded, thus promoting and improving the dirt-removing power, and trolamine is taken as antirusting agent without affecting the activity of the surfactant. The invention also discloses a formula and a preparation method of the decarburization cleaner. No heating or stirring is needed in using the invention, excellent using effect can be achieved by soaking at room temperature, energy consumption can be reduced remarkably. The pH value is neutral, thus having no corrosion on the surface of the material. The product has the characteristics of low toxicity, non-combustion and the like, thus the safety is improved greatly. The invention can be recycled only by simple filtering, thus saving using cost.

Owner:SHANGHAI JIUSHENG IND

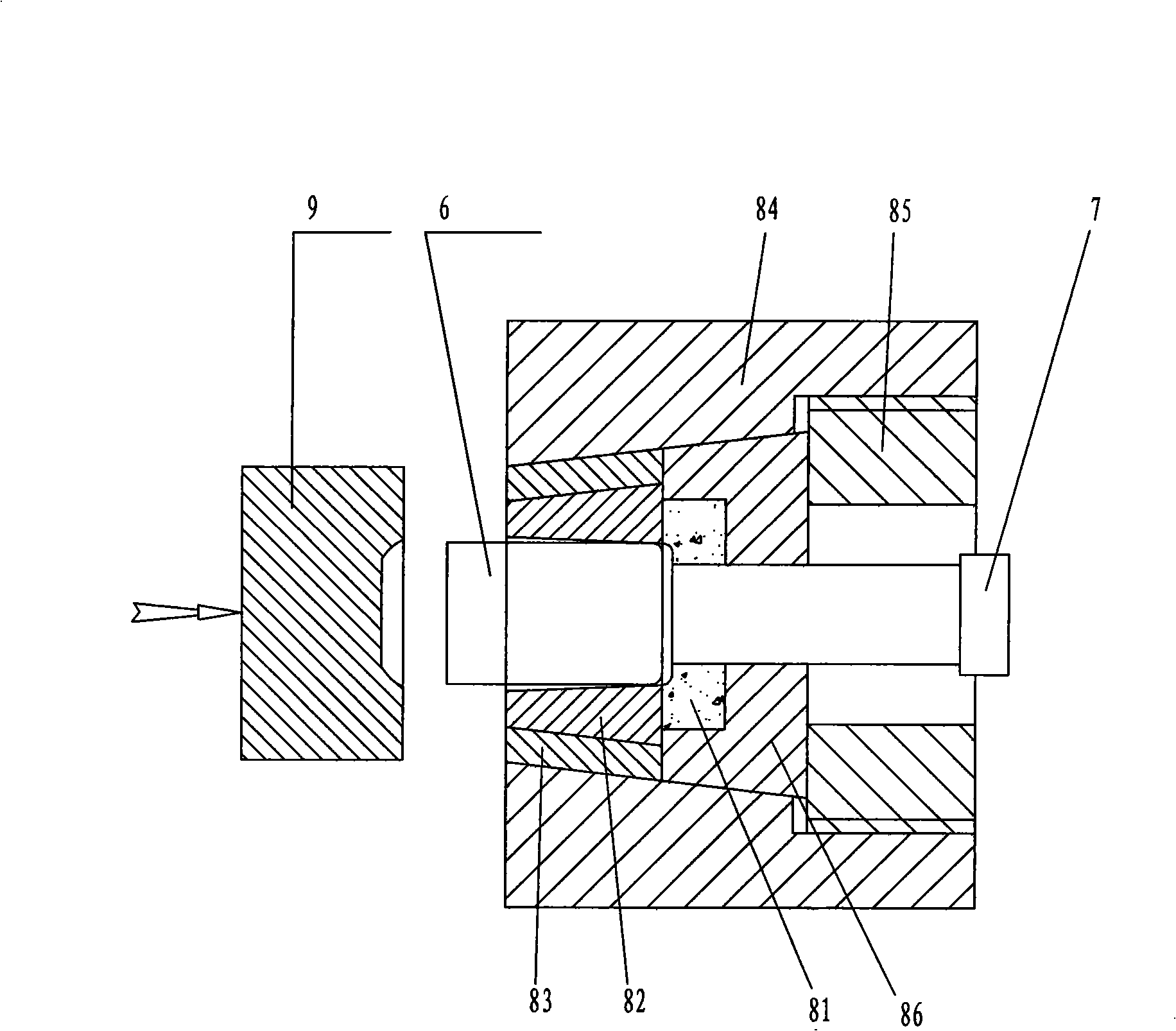

Large size roller cold-upsetting and press-forming method, and cold-upsetting and press-forming mold

InactiveCN101301676AImprove mechanical propertiesGuaranteed geometryForging/hammering/pressing machinesEngine componentsPunchingHigh intensity

The invention relates to a large-dimension roller cold heading punching method and a cold heading punching die. The large-dimension roller cold heading punching method comprises the steps as follows: bar stock is cut as roller material sections by a bar stock cutting die; the roller material sections are punched as roller blanks by the cold heading punching die. The bar stock cutting die is provided with a material feeding wheel, a knife edge die, a cutter and a material baffle; the bar stock is movably connected with the material feeding wheel and the knife edge die; the cutter is arranged at one end of the knife edge die; the material baffle is arranged at one side of the cutter. The cold heading punching die of the invention is provided with a push-off pin, a punching die and a formed punch; the roller material sections and the push-off pin are matched with the punching die; the formed punch is matched with the roller material blanks; the formed punch is connected with a power mechanism. The bar stock of the invention adopts high-carbon chromium bearing steel and the diameter of the roller blank is ranging from 23mm to 28mm. The roller blank processed by the invention can achieve the soft grinding level of turning, the chamfer is naturally formed, the high-strength, high rotation speed and long service life of the finished bearing are ensured, the geometrical dimension and the precision of the roller are ensured, thus realizing the low vibration and silencing of the bearing and reducing the initial manufacture cost at the same time.

Owner:汇洲智能技术集团股份有限公司

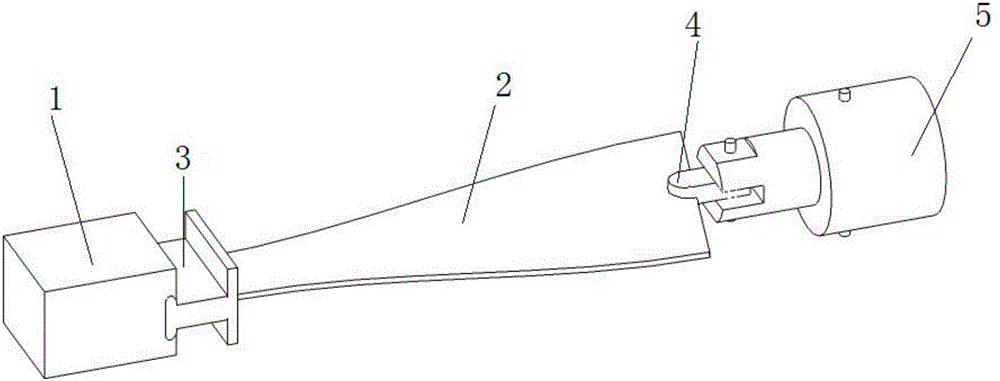

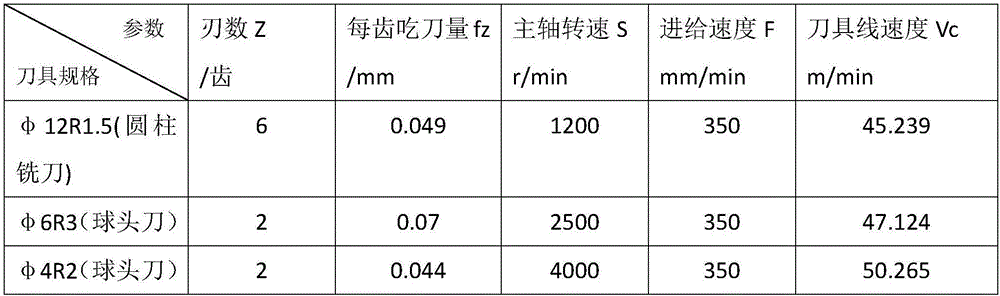

Numerical control processing method and device for complex molded surface of rotor blade of air compressor

The invention discloses a numerical control processing method and device for a complex molded surface of a rotor blade of an air compressor. The processing method comprises the steps of clamping the blade, selecting a milling cutter, and determining the milling mode of the blade and the milling sequence of the blade, wherein the back end of the blade is clamped through tightening; the milling cutter adopts a cylindrical cutter; the milling mode of the blade is spiral surrounding milling; and the milling sequence of the blade is that firstly, the edge is cut, then, a blade body is milled, then, a margin plate is milled, and finally, a root is milled. According to the processing method, the deformation in processing is reduced, the geometric accuracy and positional accuracy of the blade are guaranteed, the service life of the cutter is prolonged, the integrity of the blade surface is improved, the processing efficiency is improved, and the problems of overcutting and disorder of a cutter path are solved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Double-station automatic grinding and cutting machine for ceramic green body tubes

InactiveCN106625132ASave land areaAccurate locationGrinding carriagesBelt grinding machinesSurface grindingSilo

The invention provides a double-station automatic grinding and cutting machine for ceramic green body tubes. The machine includes a machine frame, a storage silo, a feeding mechanism, a delivery mechanism, a ceramic green body tube grinding station and a ceramic green body tube cutting station; the ceramic green body tube grinding station is on the left side of the cutting station; the left side of the feeding mechanism is provided with the storage silo, a feeding air cylinder is located at the tail end of the storage silo, and the tail end of a storage silo supporting beam is fixedly provided with a guide plate for ceramic green body tube dropping; the delivery mechanism includes a delivery bracket driving air cylinder and a double-V-shaped groove delivery bracket which are fixed together, and the side of the double-V-shaped groove delivery bracket is fixedly provided with a guide slider; the grinding station includes a core-free supporting wheel, a magnetic-driving device and an abrasive belt grinding device; the cutting station includes a core-free supporting wheel, a magnetic-driving device and a cutting device and further includes a workpiece discharging mechanism. The machine has the advantage that ceramic green body tube surface grinding and ceramic green body tube two-end excess material cutting can be achieved with one machine.

Owner:ZHEJIANG UNIV

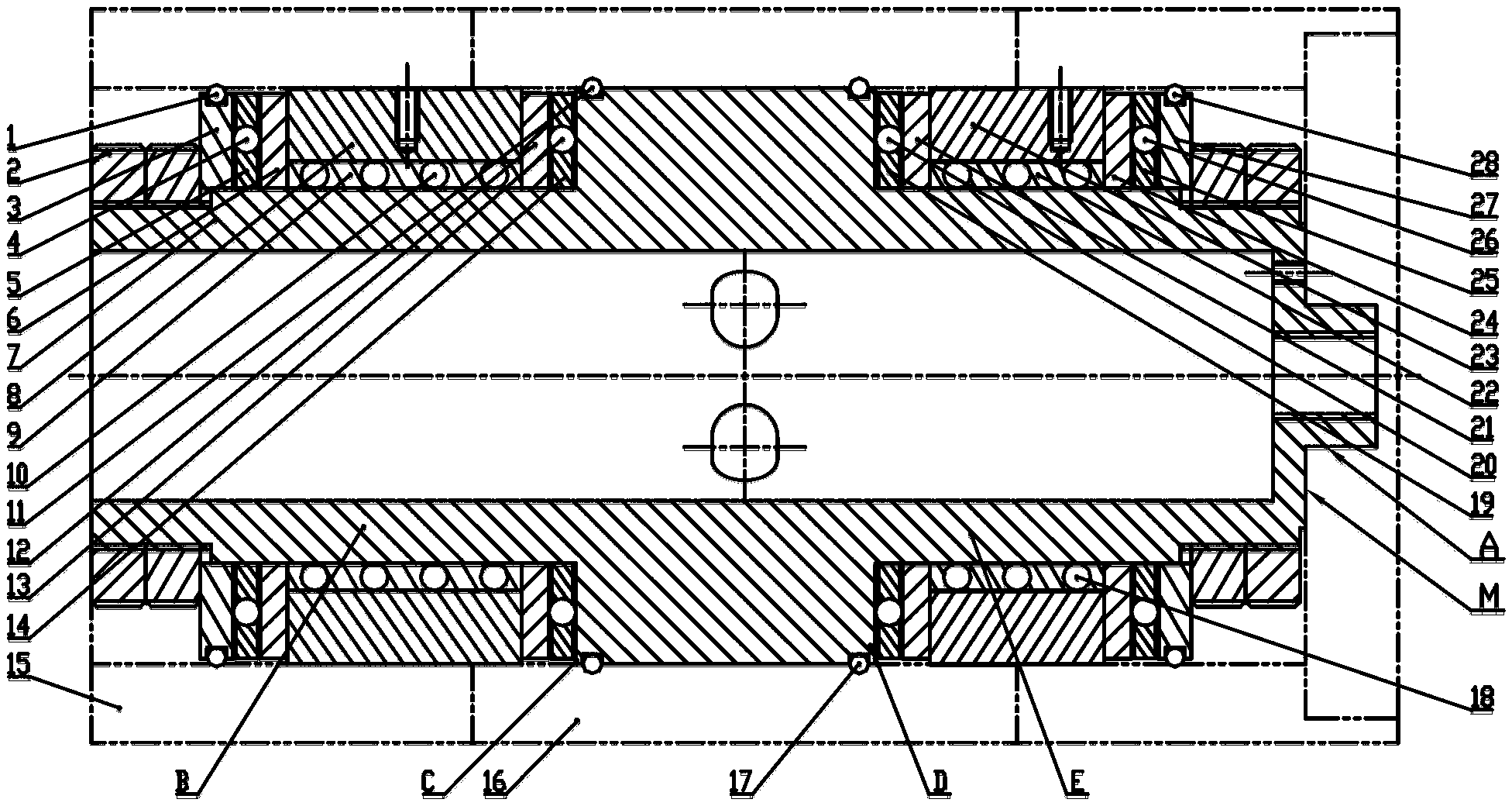

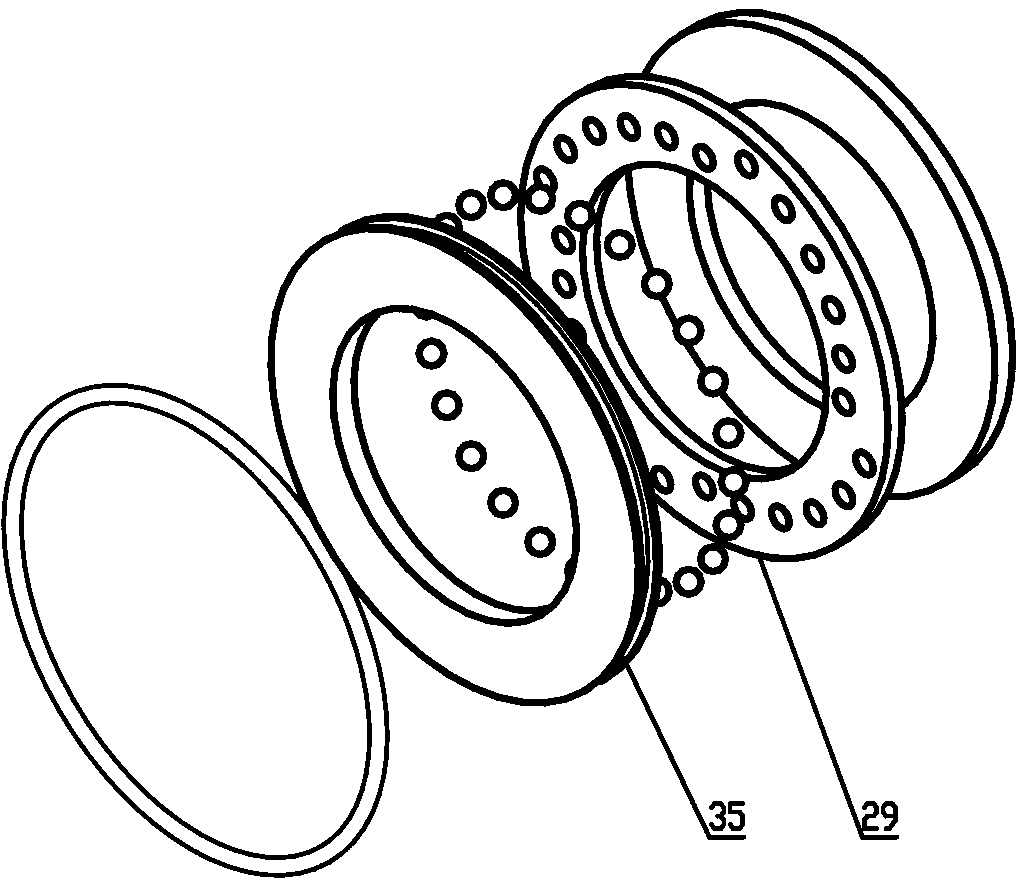

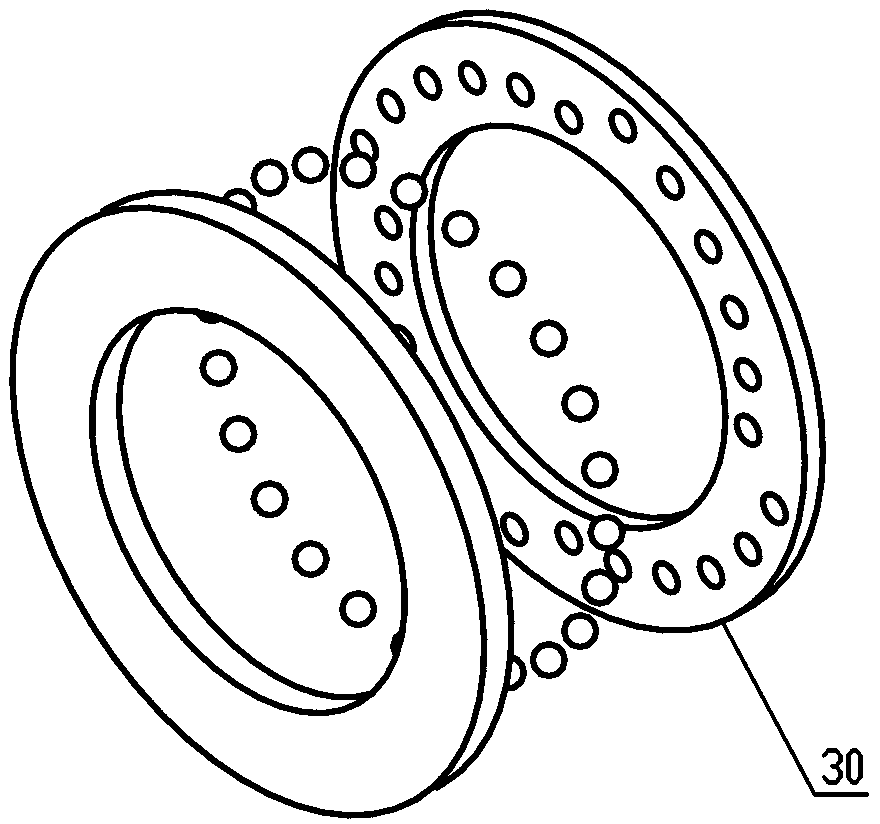

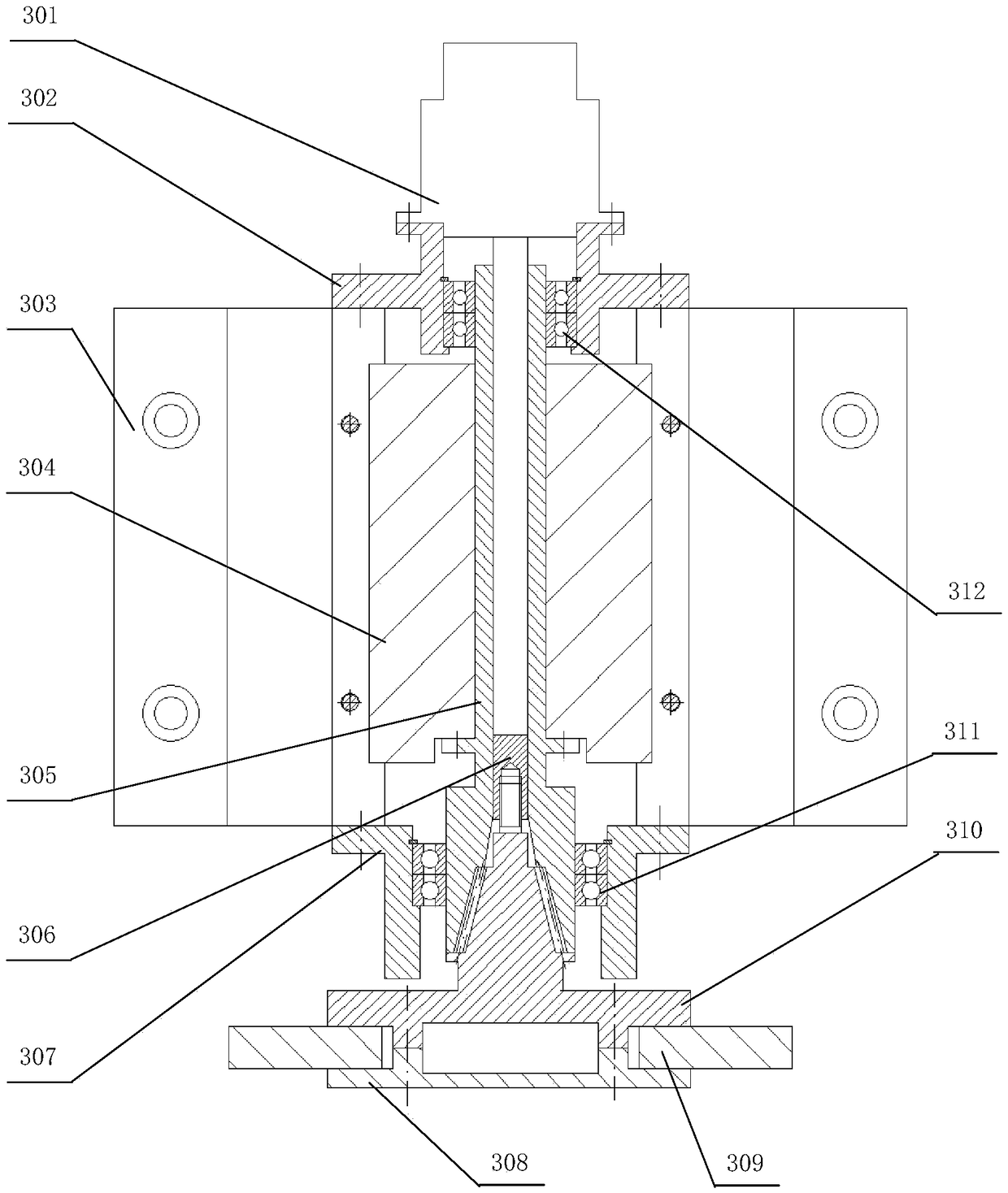

Middle driving type dense bead shaft system mechanism

InactiveCN103016548ADagang/Inertial RatioGuaranteed dimensional accuracyBearing unit rigid supportNumerical controlDrive shaft

The invention belongs to the field of a numerical control precise measuring device, and relates to a middle driving type dense bead shaft system mechanism. The middle driving type dense bead shaft system mechanism comprises four axial thrust dense bead shaft systems and two radial dense bead shaft systems, a transmission shaft and a locking member. The four axial thrust dense bead shaft systems are arranged on both sides of a middle step shaft. The radial dense bead shaft systems are respectively arranged between the two axial thrust dense bead shaft systems. The end faces of the bearing retainer rings of the axial thrust dense bead shaft systems close to the radial dense bead shaft systems and the end faces of the radial dense bead shaft systems and a retaining frame which are coplanar are coplanar. The transmission shaft is in threaded connection with a revolving member through a screw and maintains a relatively unchanged position relation with the revolving member through a cylindrical pin. The shaft sleeve is in threaded connection to a fixed piece through a screw. The maximum rigidity / inertia ratio is guaranteed, the resistance to overturn is strong, the revolving precision is high, the stress is uniform, and the positioning precision can reach 1'. The processing difficulty is reduced, and the size and geometric accuracy of a ball working rollaway nest are easy to guarantee.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

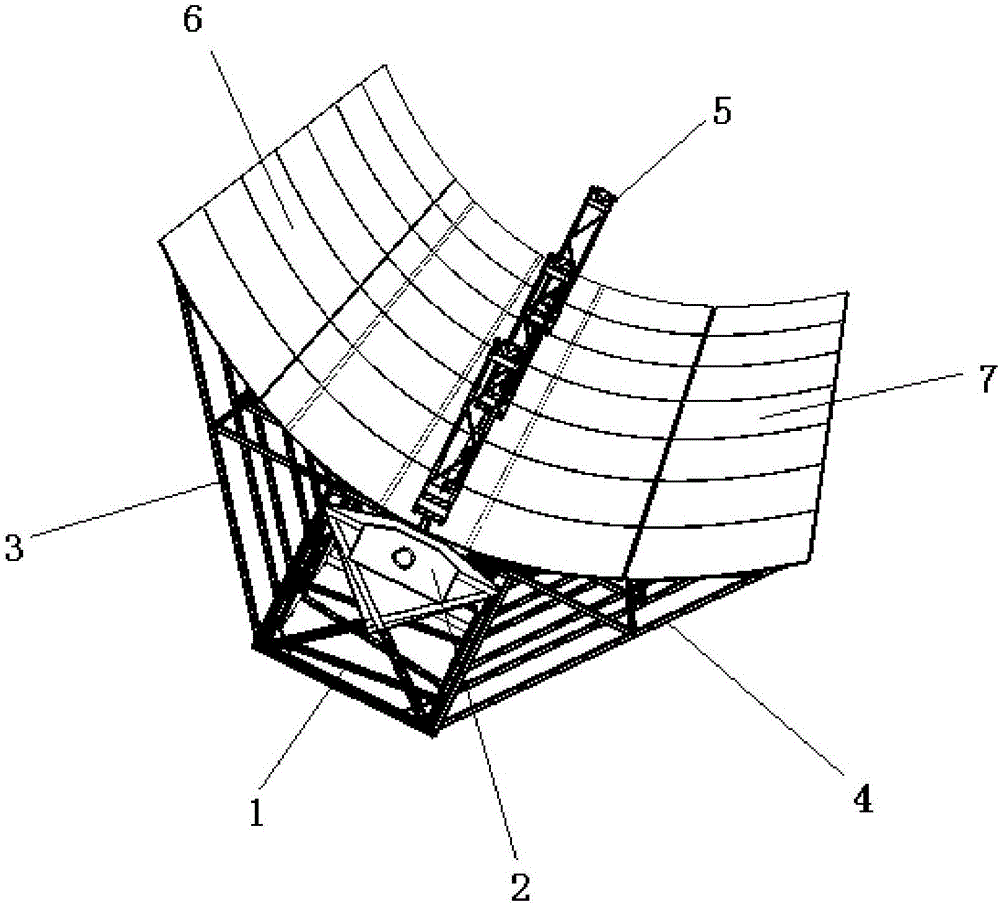

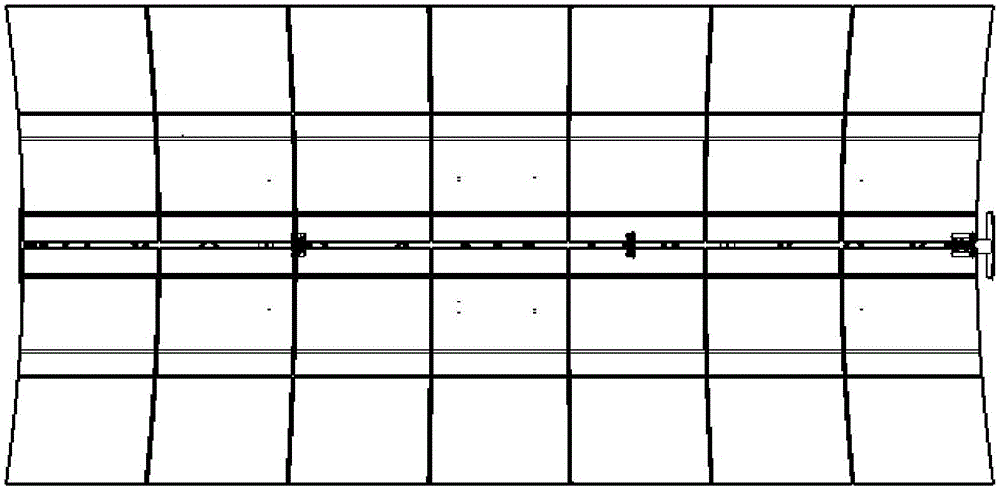

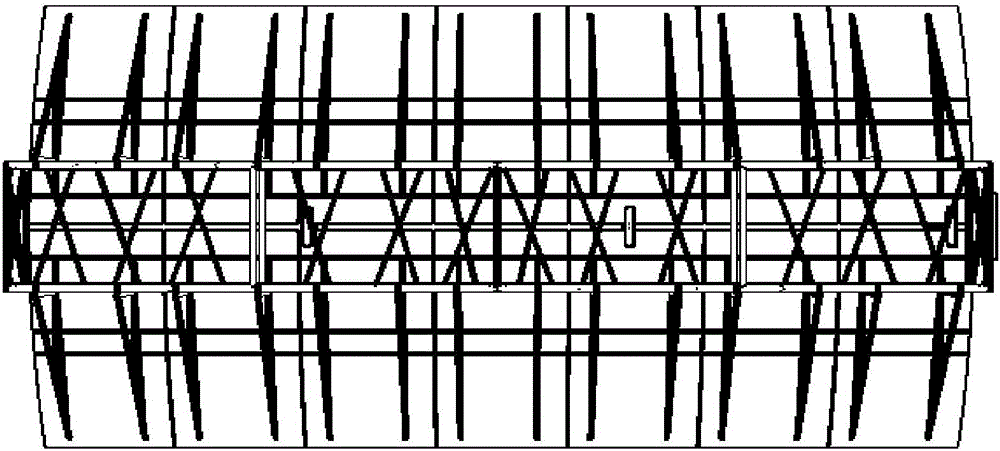

Trough type solar heat collector bracket and mounting method thereof

InactiveCN106839455ALow costGuaranteed geometric accuracyPhotovoltaic supportsSolar heating energyEngineeringSolar heat

The invention provides a trough type solar heat collector bracket and a mounting method thereof. The trough type solar heat collector bracket comprises a torque frame body, a transmission shaft, a connecting end plate (2), a first reflector support arm (3), a second reflector support arm (4) and a heat collecting pipe bracket (5). The trough type solar heat collector bracket has the advantages that a complicated clamping rack does not need to be built, so that site assembly difficulty and transporting cost are reduced; and at the same time, the geometric precision of a heat collector is ensured, and the purposes of reducing the structural weight of the heat collector and facilitating maintenance are also achieved. A feasible scheme is provided for the design optimization of the trough type heat collector, and the reduction of the whole building cost of a solar power plant is also facilitated.

Owner:中广核太阳能开发有限公司 +1

Close shot large span digital photogrammetry system and method

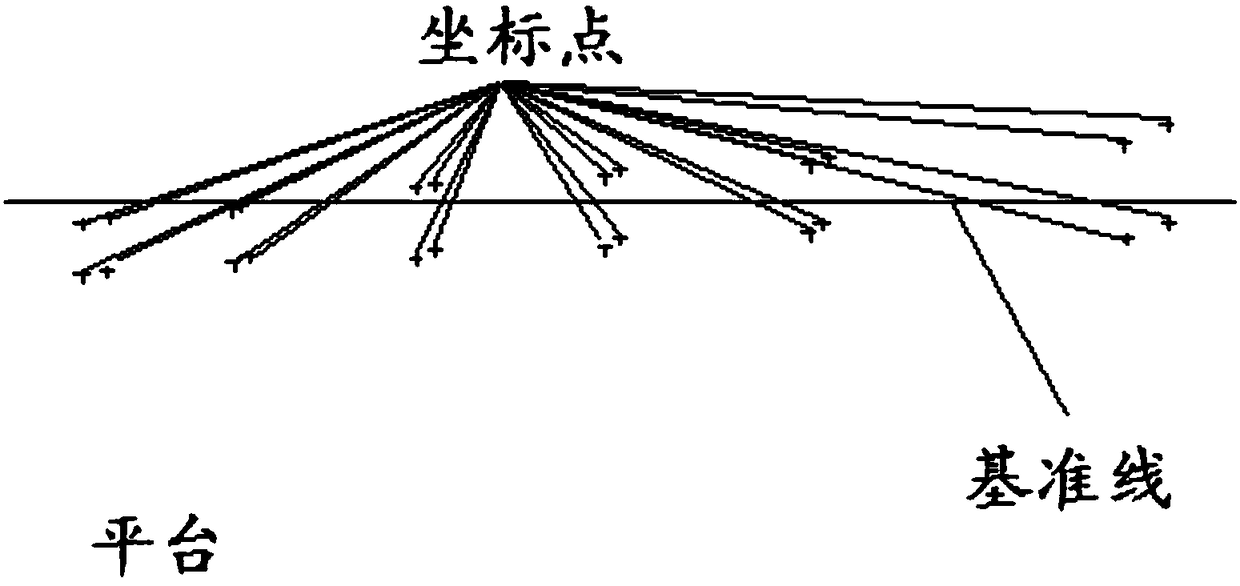

ActiveCN103424104AGuaranteed geometric accuracyHigh precisionPicture taking arrangementsEngineeringDigital photogrammetry

The invention discloses a close shot large span digital photogrammetry system and method. The system comprises a rectangular collecting platform, guide rails, cameras, a three-dimensional calibrating board and a two-dimensional control filed. The three-dimensional calibrating board comprises a plurality of calibrating marks distributed evenly, each calibrating mark comprises a cylindrical type wooden stick and a round wooden board on the top surface of each cylindrical type wooden stick, the cylindrical type wooden sticks of all the calibrating marks are different in height, and the cylindrical type wooden sticks of the calibrating marks located in the middle of the three-dimensional board are higher than those located on the peripheral of the calibrating marks. The two-dimensional control field comprises a plurality of control point marks distributed on the end face of the edge of the rectangular collecting platform, the control point marks form the control points of the two-dimensional control field, and each control point mark comprises a round wooden board. The close shot large span digital photogrammetry system and method can enable images to achieve the fidelity of high-precision geometrical information.

Owner:CHINA TOPRS TECH

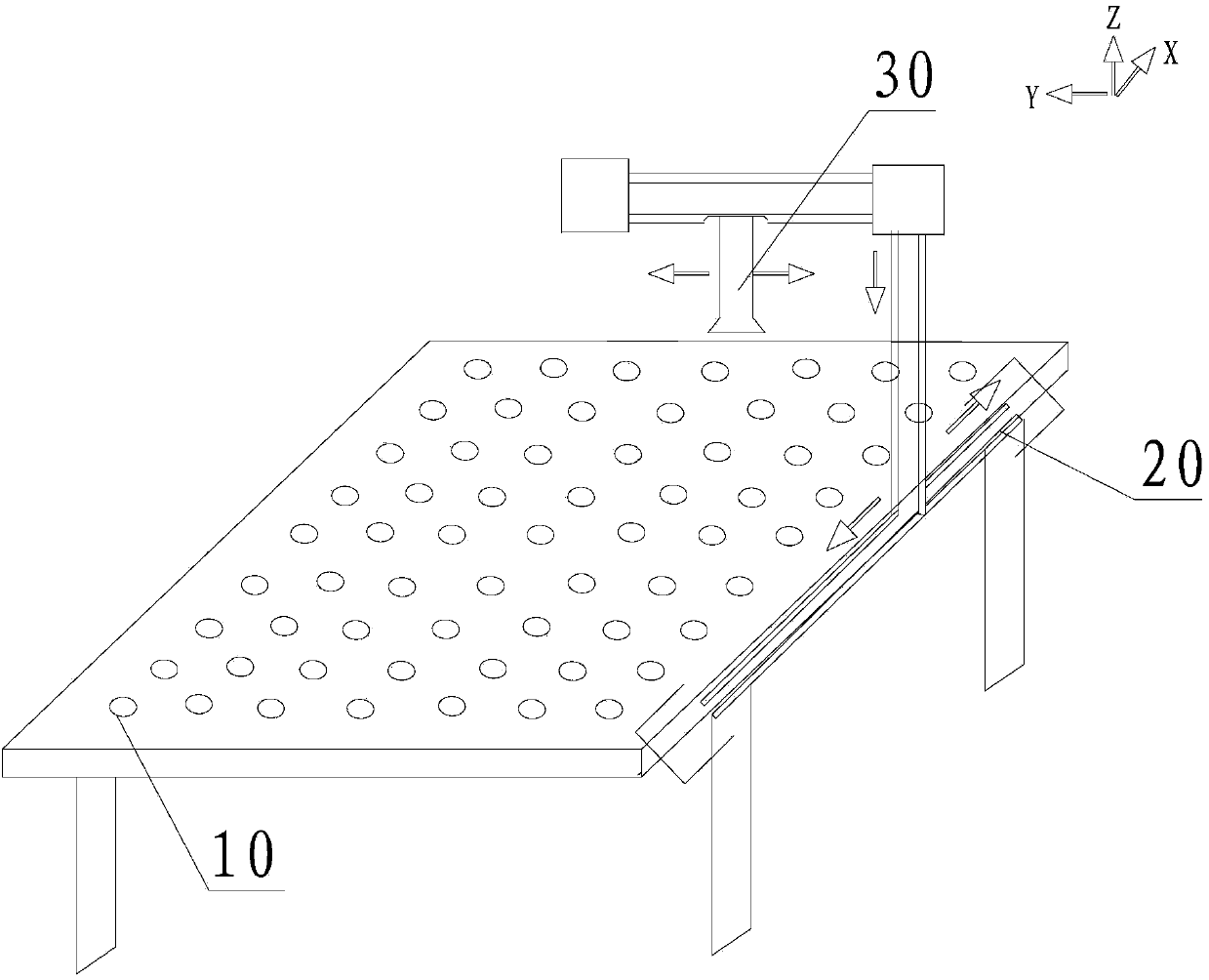

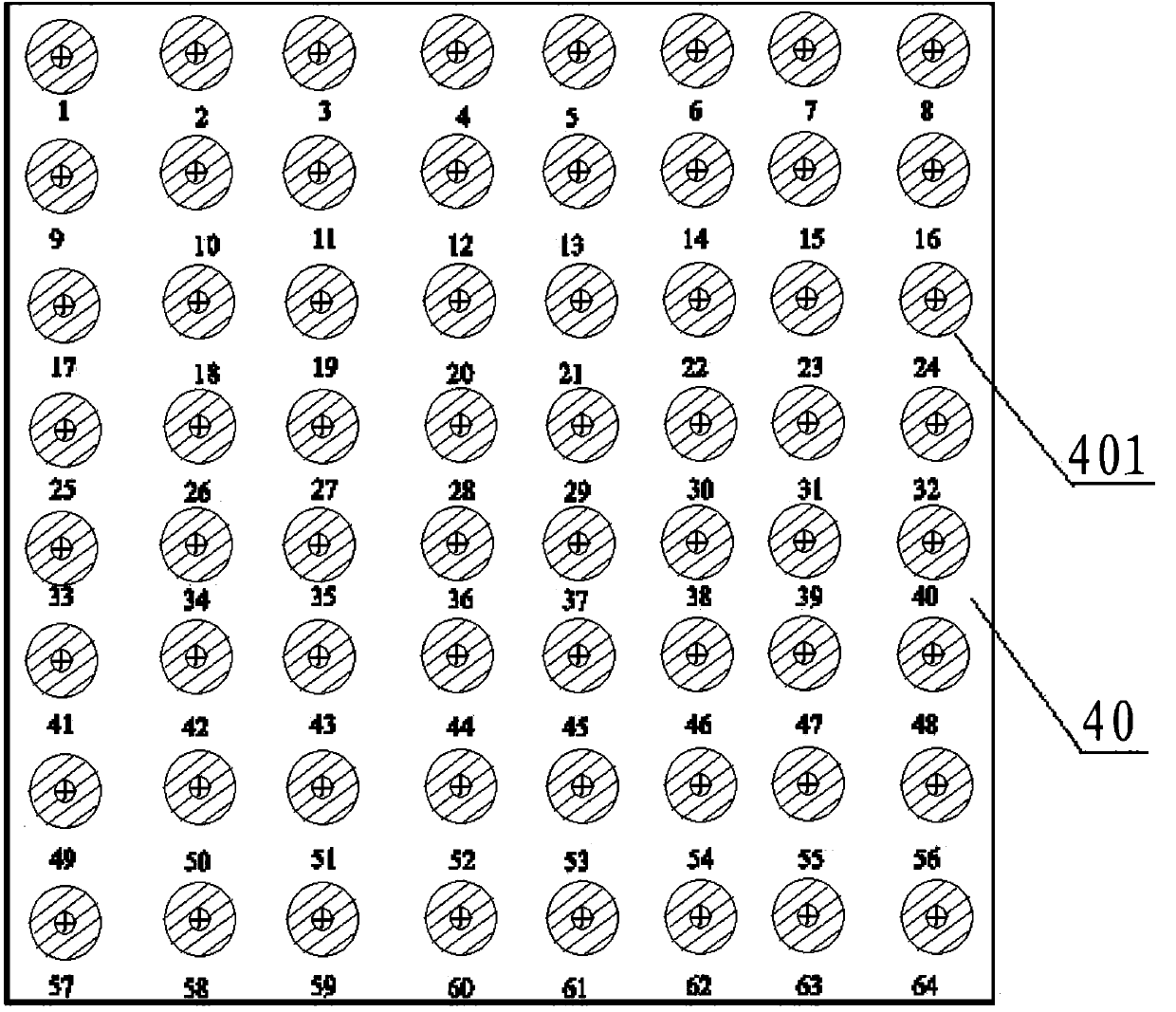

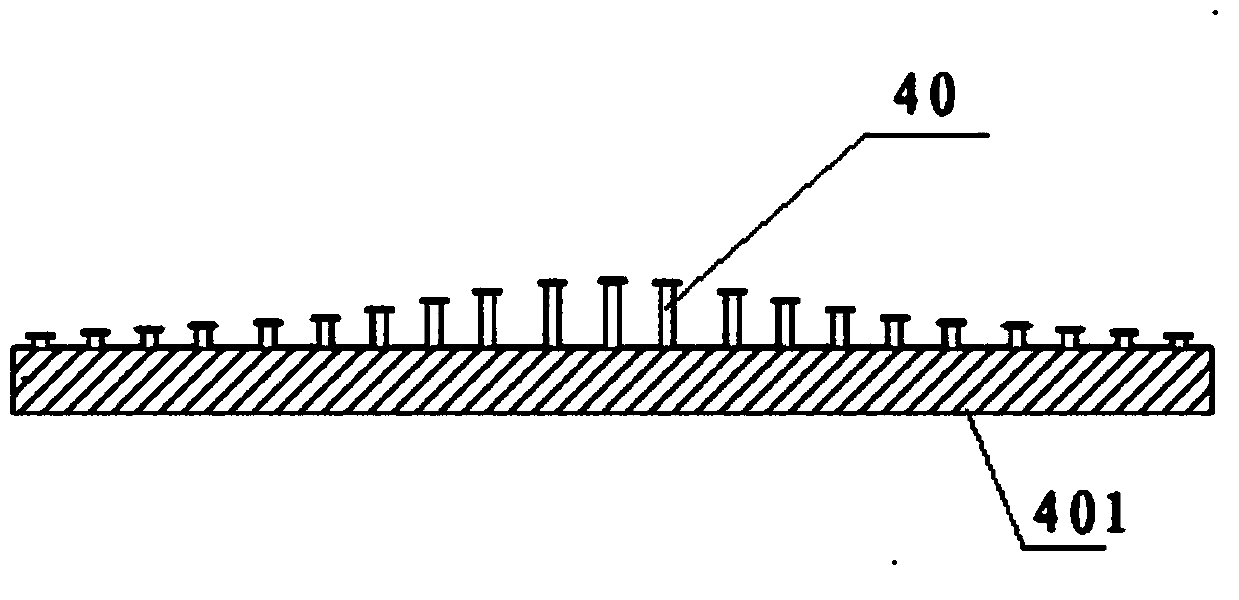

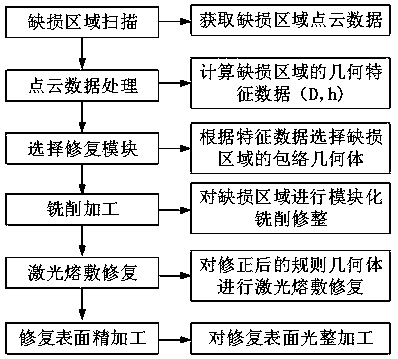

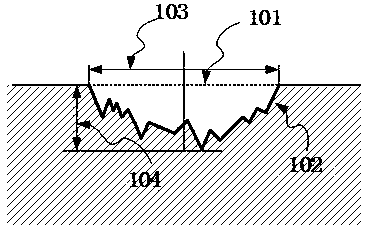

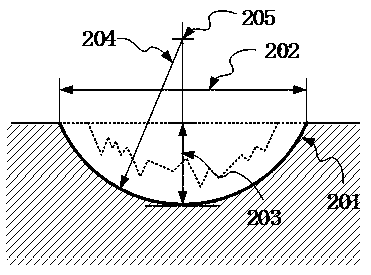

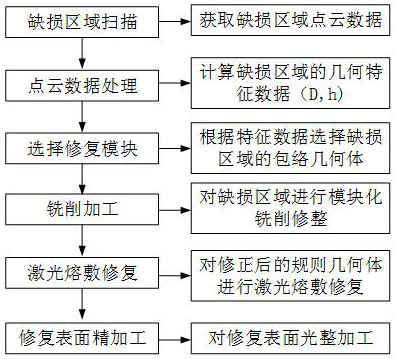

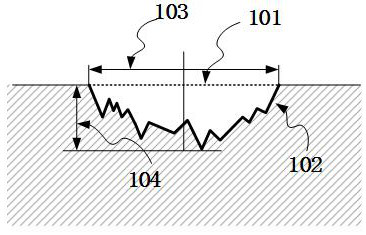

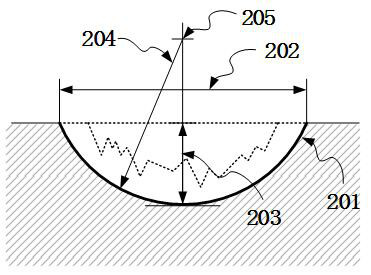

Modularization type material addition and reduction composite repairing method for defective region of component surface

ActiveCN110640146AImprove repair efficiencyImprove restoration qualityAdditive manufacturing apparatusIncreasing energy efficiencyPoint cloudStructural engineering

The invention provides a modularization type material addition and reduction composite repairing method for a defective region of a component surface and relates to the technical field of machining. The main process of the method comprises the following steps of: implementing three-dimensional scanning on the defective region of the component surface and acquiring point cloud data of a to-be-repaired region; calculating the characteristic parameters of the defective region according to the point cloud data; selecting a corresponding geometric module according to the characteristic parameters;implementing modular milling and removal on the defective region to obtain a regular to-be-repaired region; implementing modular laser melt-coating repairing on the to-be-repaired region; and precisely milling the laser-repaired surface to end the repairing. By adopting a material addition and reduction composite way, the method provided by the invention repairs a complicated irregular defective appearance into a regular geometry; on the basis, the modular to-be-repaired geometry is subjected to laser melt-coating repairing; and the operation route is conveniently and quickly planned, so the overall repairing efficiency is improved. Beside, the precise milling for the laser melt-coating region can maintain the repairing precision of the contour of the repaired surface, and the use performance of the repaired surface is also improved.

Owner:NANJING INST OF TECH

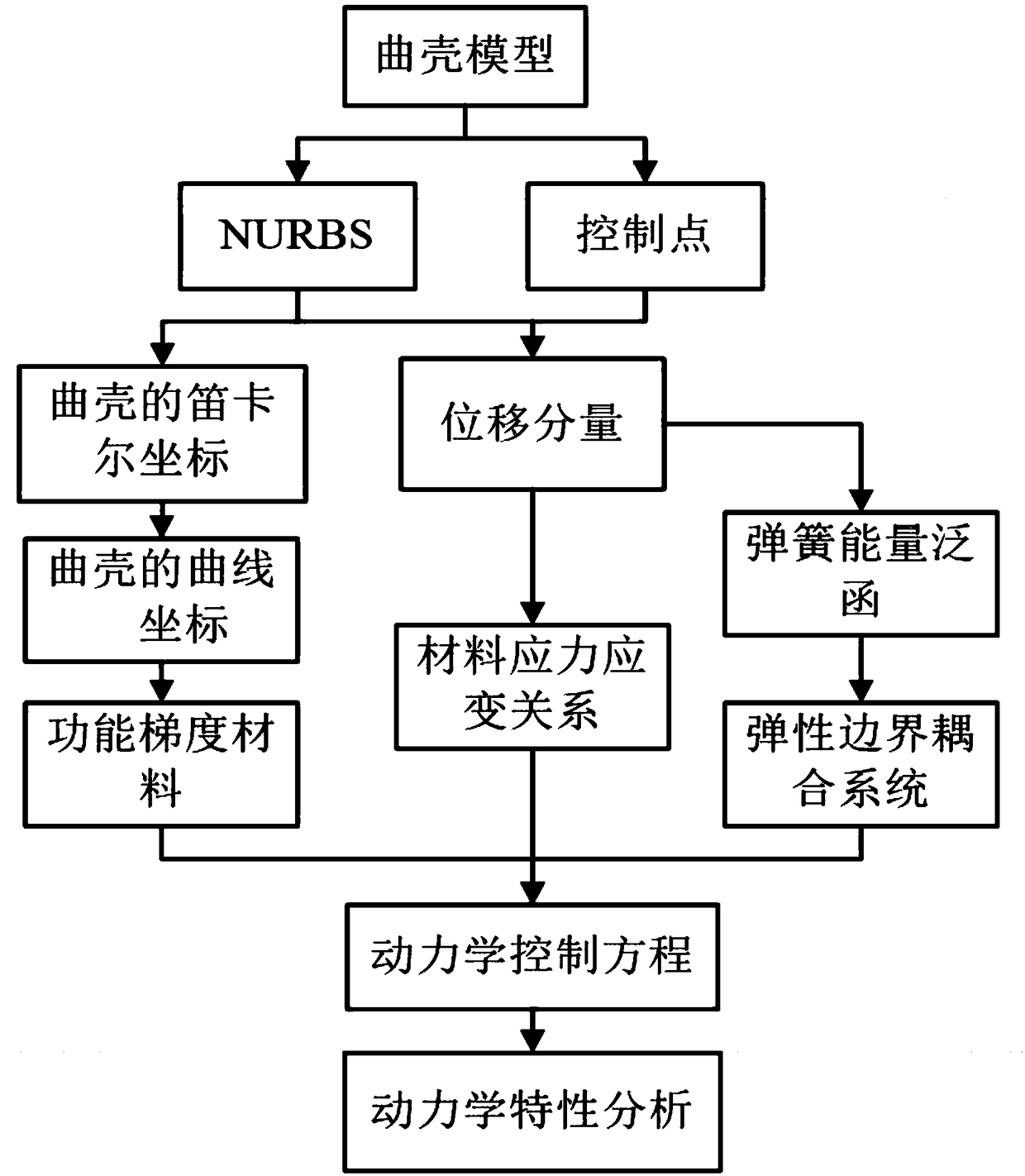

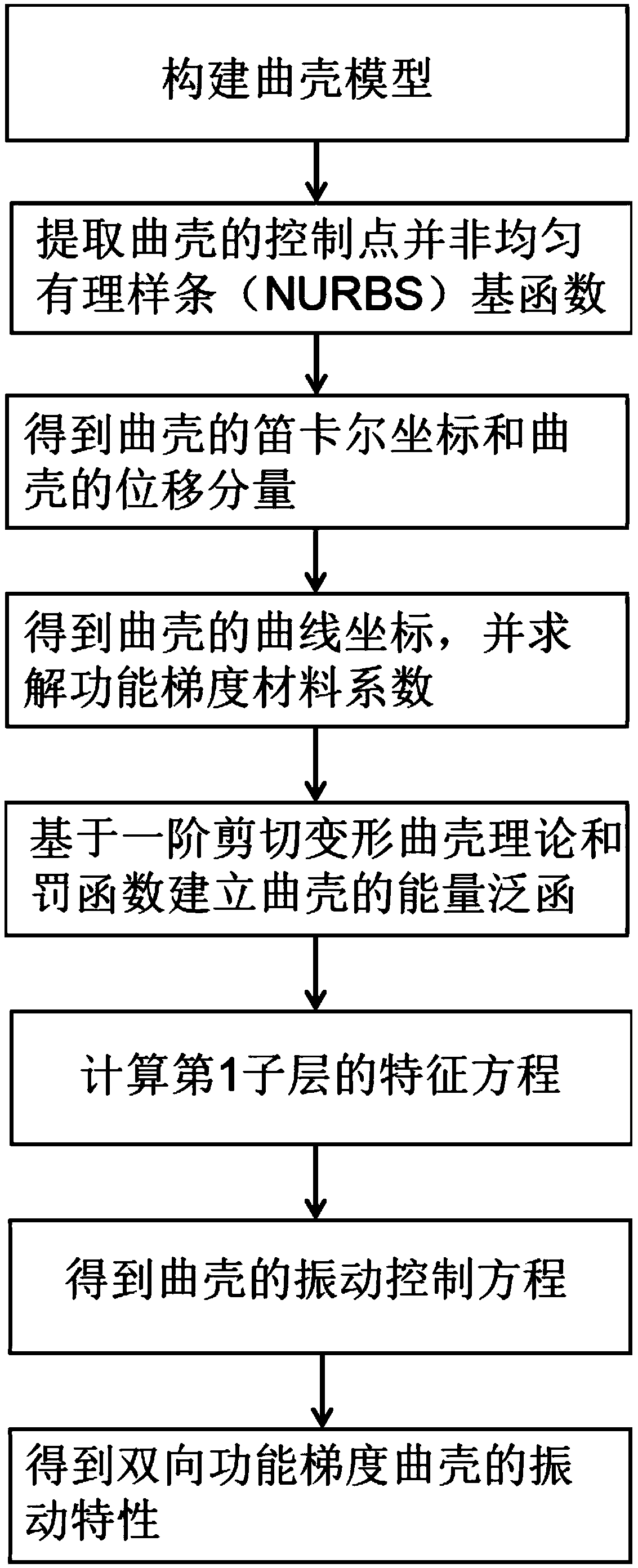

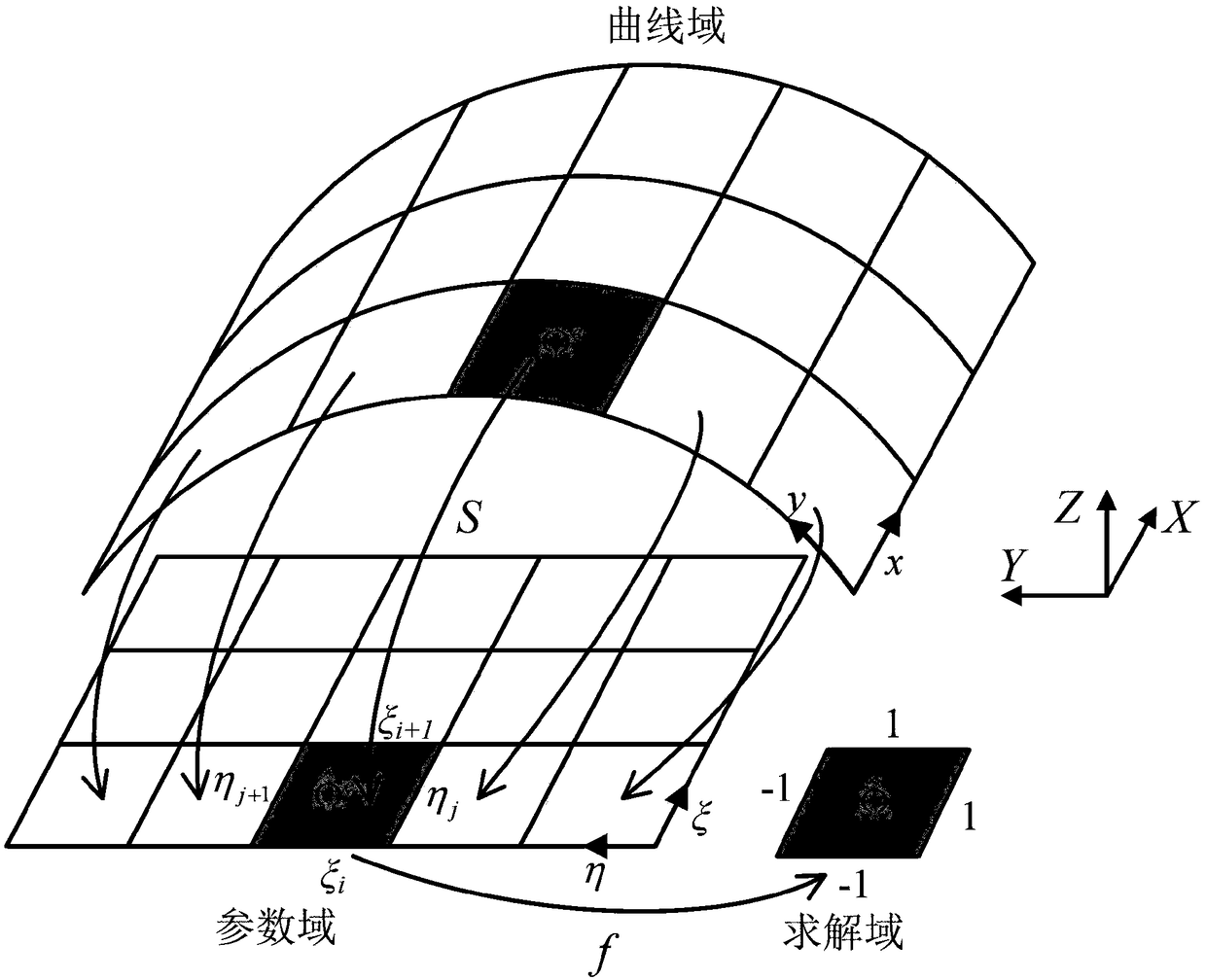

Method for vibration analysis of bi-directional functionally gradient curved shell

ActiveCN109117504AGuaranteed geometric accuracyImprove computing efficiencyGeometric CADDesign optimisation/simulationGeometric controlStructural dynamics

The invention belongs to the field of structural dynamics, and relates to a bidirectional functionally gradient curved shell vibration analysis method. The invention utilizes NURBS function to describe unknown domain and geometric model, thus ensuring geometric accuracy and geometric structure response analysis, considering axial and circumferential functional gradient transformation material influence, and realizing different refinement according to actual requirements, thereby improving computational efficiency. In addition, for different curved shell structures, boundary conditions and material properties, only the corresponding geometric control points and spline functions, boundary constraints and material exponential parameters need to be set without reprogramming one by one, which greatly reduces the computational cost.

Owner:HARBIN ENG UNIV

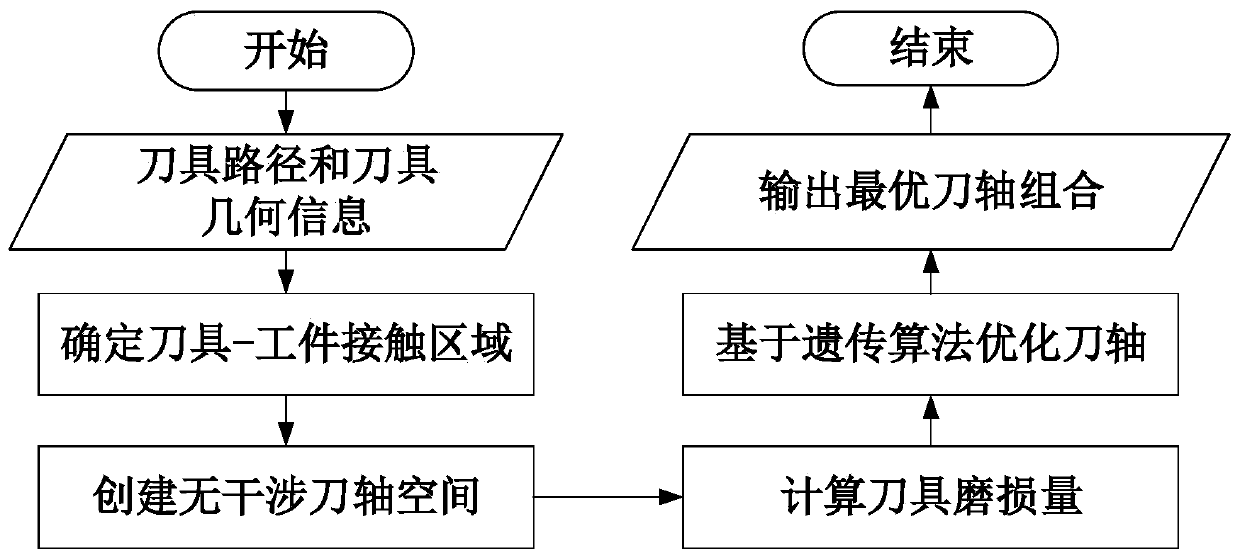

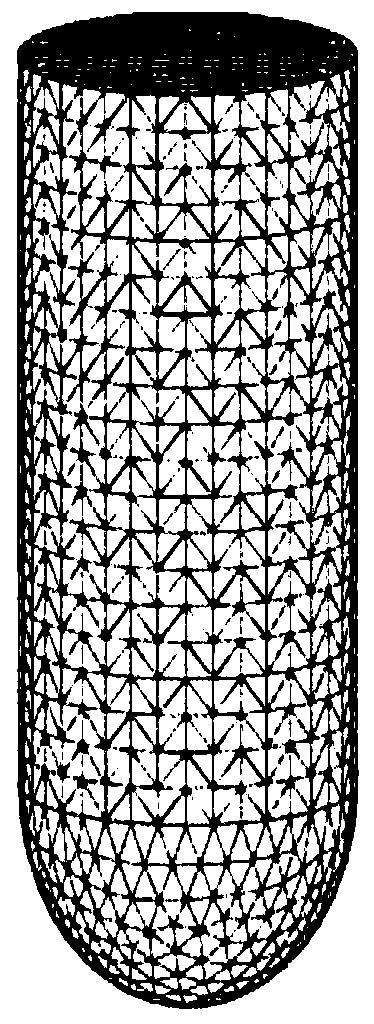

Cutter shaft optimization method for curved surface numerical control machining ball-end milling cutter abrasion control

The invention provides a cutter shaft optimization method for curved surface numerical control machining ball-end milling cutter abrasion control. The method comprises the following steps: firstly, constructing a cutter-workpiece meshing area at each cutter location point according to an input cutter path and geometrical information, and calculating an interference-free cutter shaft space at eachcutter location point; dividing the cutting edge of the cutter into a plurality of cutting intervals along the axial direction of the cutter; calculating the cutting length of each cutting interval ofthe cutter at each cutter location point under an initial cutter shaft according to the obtained cutter-workpiece meshing area to obtain the cutting length of the whole part machined by each cuttinginterval of the cutter edge, and calculating cutter abrasion loss of each cutting interval according to the abrasion rate; and finally, by adopting a fixed cutter shaft strategy, calculating cutter shaft direction in which the cutter abrasion is uniformly distributed in each cutting interval of the cutting edge from the non-interference cutter shaft space of each cutter location point. The methodis high in practicability and operability; and cutter abrasion is evenly distributed by adjusting the cutter shaft, and the problem that the cutter loses efficacy too fast due to the fact that the cutter abrasion is concentrated in a local area can be effectively solved.

Owner:NANJING UNIV OF TECH

Large-modulus rack machining method

The invention relates to a large-modulus rack machining method, which relates to the field of the machining, in particular to a large-modulus rack machining method. The method comprises the following steps: forging a blank; roughly machining the blank, controlling small cutting output, feeding a cutter for multiple times, and controlling the deformation of a workpiece; tempering, to be specific, controlling the tempering hardness to reach 217 to 255 HBW; semi-finishing the workpiece, to be specific, semi-finishing a centre hole in an upper flat end surface of a boring machine, machining a square surface and a hoisting hole, and controlling the machining allowance to be 2mm to 3mm; aging the workpiece; finishing the workpiece, to be specific, finishing the centre hole on the upper flat end surface of the boring machine, finish turning an outer circle on a 1680 machine tool, strictly controlling the cutting output, feeding the cutter for multiple times, controlling the deformation of the workpiece, finally milling the square surface, the hoisting hole and the overall length of the workpiece on a 13m numerical-control gantry milling machine to reach the requirement of a drawing, installing a cutter disc on a universal milling head, respectively machining each toothed surface, and controlling the size of each part of the tooth by utilizing a toothed tooth distance template. By adopting the method, the product quality is improved, various technical indexes such as size precision, geometric precision and surface roughness are enabled to meet the design requirement and the application performance requirement, and the requirement of a component on the machine tool can be lowered.

Owner:SHAANXI QIYUAN TECH DEV

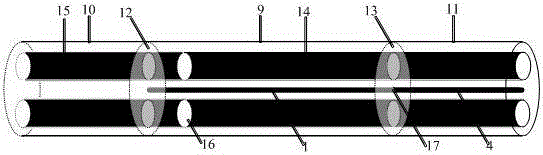

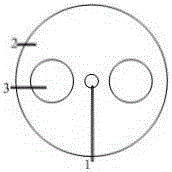

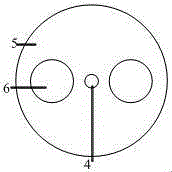

Wire drawing method of high-stress active polarization-maintaining fiber prefabricated rod

ActiveCN105293892AImprove the utilization lengthGuaranteed geometric accuracyGlass making apparatusRare earth ionsPolarization-maintaining optical fiber

The invention relates to a wire drawing method of a high-stress active polarization-maintaining fiber prefabricated rod. The method comprises the following steps: depositing a rare-earth ion-doped active fiber prefabricated rod by virtue of a CVD process; respectively preparing a quartz rod and a fiber prefabricated rod; welding the active fiber prefabricated rod between the quartz rod and the fiber prefabricated rod; forming two holes in the entire welded prefabricated rod; respectively inserting two fine quartz rods into two inner holes II of the quartz rod and two inner holes I of the active fiber prefabricated rod, and enabling the two stress rods to tightly contact the two fine quartz rods; connecting a supporting pipe to the prefabricated rod, then placing the prefabricated rod into a heating furnace of a wire drawing tower, after the prefabricated rod is heated and softened, and sealing the upper ends of the two inner holes I of the active fiber prefabricated rod by virtue of the fine quartz rods, so that liquefied boron rod can be prevented from overflowing from the inner holes I. By adopting the wire drawing method, the using length of the active polarization-maintaining prefabricated rod can be effectively increased, and the deformation amount of an optical fiber can be maximally reduced.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Measuring machine

InactiveUS20020020073A1Uniform temperature distributionLarge thermal conductivityElectric/magnetic contours/curvatures measurementsUsing electrical meansEngineeringAlloy

A measuring machine having a base (10), a touch signal probe (P), a moving mechanism (20) for retaining the touch signal probe (P) movably in three-dimensional directions, and a controller (60) for controlling a movement of the moving mechanism (20) and for acquiring coordinates value of respective axes based on a contact signal from the touch signal probe (P) to measure a dimension etc. of a workpiece based on the coordinates value is provided. Main structural members structuring the moving mechanism (20), more specifically, a column (21), a supporter (22), a X-beam (23), a Z-axis structure (25) and a Z-axis spindle (26) are made of aluminum or aluminum alloy including aluminum as main component, which has large thermal conductivity, thereby making temperature distribution uniform to improve geometrical accuracy.

Owner:MITUTOYO CORP

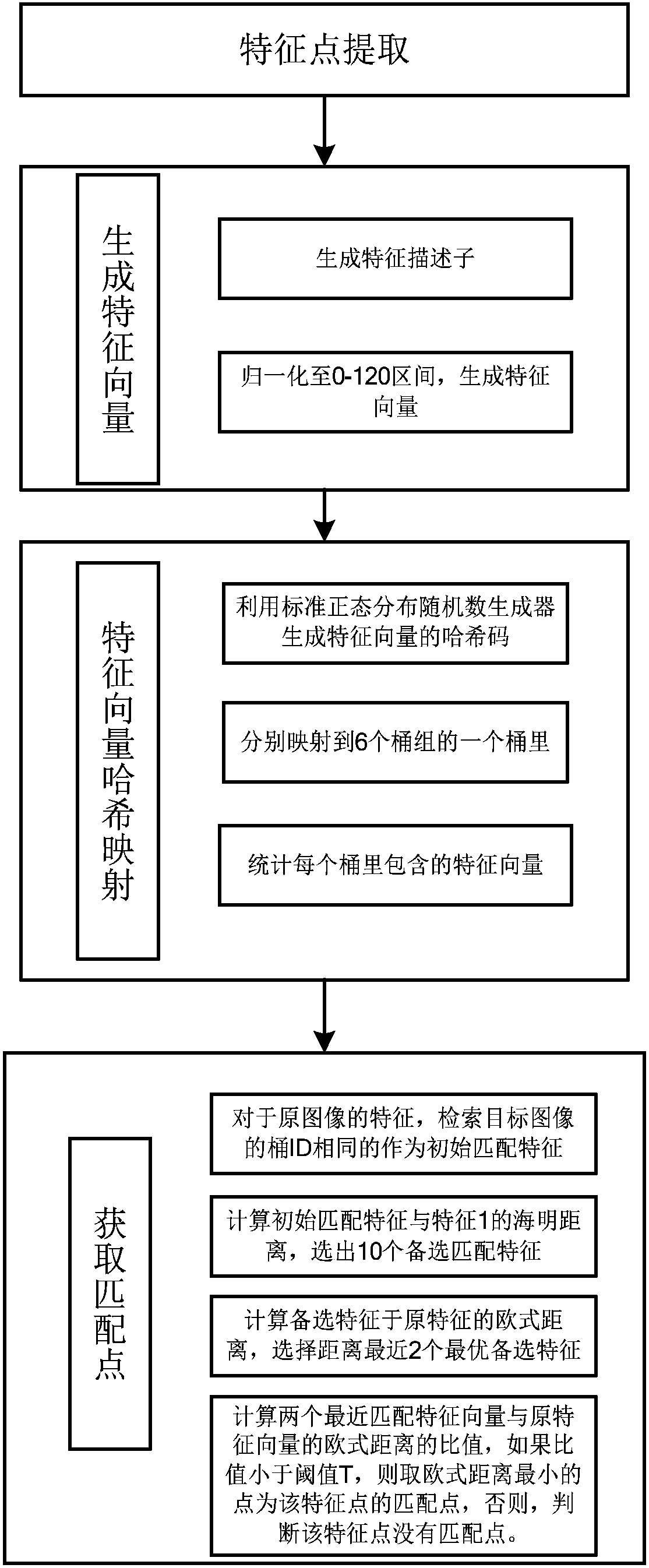

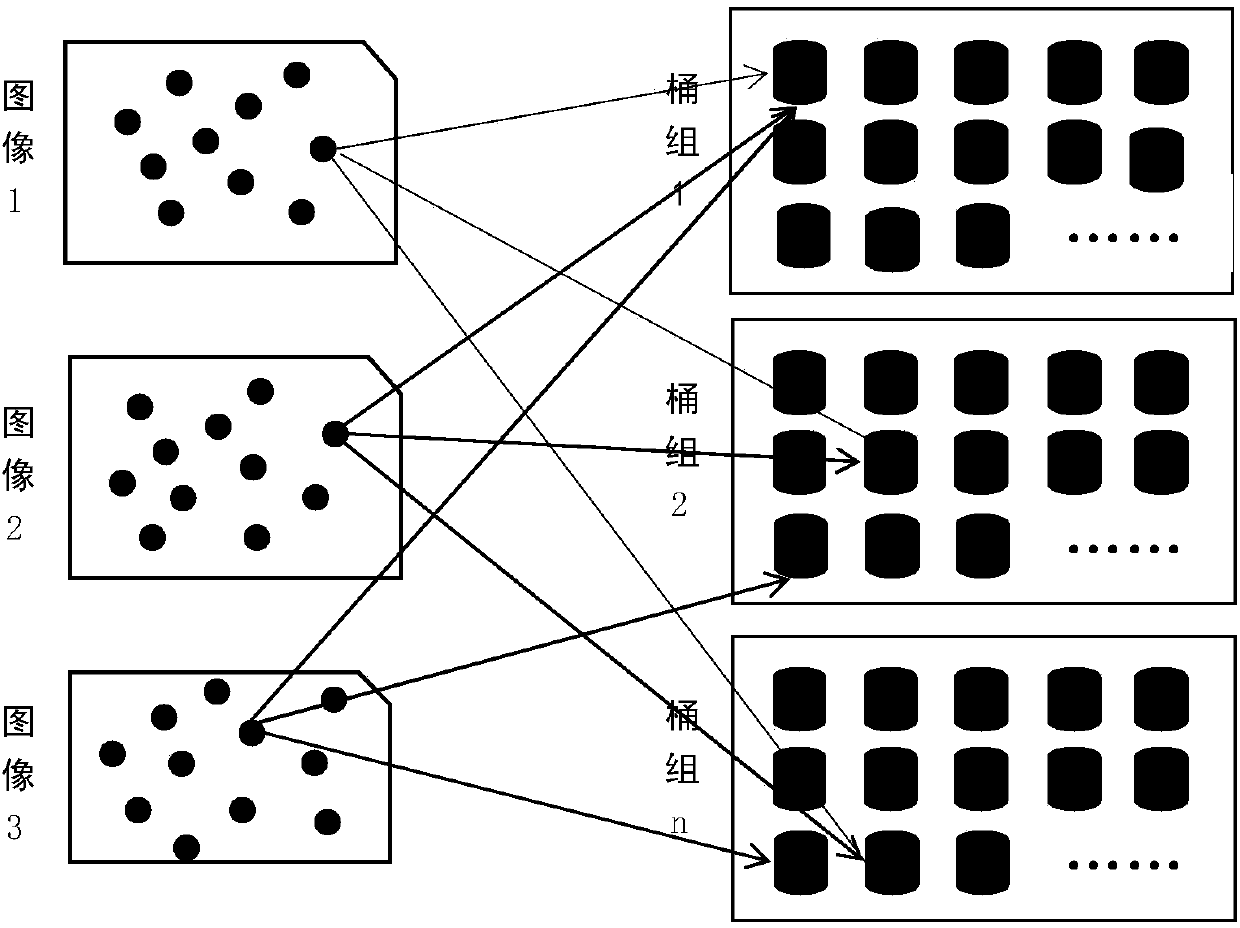

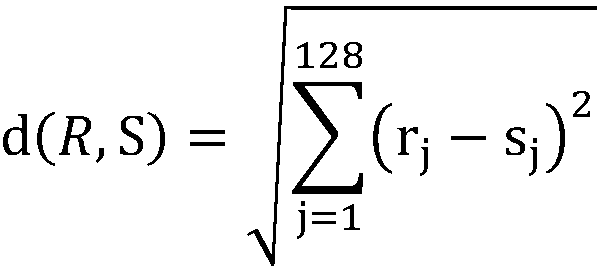

A Hash algorithm-based large-scale image matching method

InactiveCN109902700AQuick matchImprove matching efficiencyCharacter and pattern recognitionFeature vectorEuclidean vector

The invention discloses a Hash algorithm-based large-scale image matching method. The method comprises the steps of 1) extracting all feature points of an original image and a target image; 2) extracting a feature descriptor at each feature point, and distributing a direction value to the feature point to generate a feature vector; 3) mapping all the feature vectors to a hash table by using a hashalgorithm, enabling each feature vector to correspond to one hash feature code, and respectively distributing the hash feature codes to a plurality of bucket groups by using a mapping function; And 4) selecting the feature vector of one feature point from the original image as an original feature, and matching the original image with the target image by using the feature vector in the hash tableto obtain matched homonymous points. According to the method, quick and accurate matching of large-scale images can be achieved, the matching efficiency of the large-scale images is effectively improved, and meanwhile the geometric accuracy of large-area image matching can be guaranteed.

Owner:BEIJING AEROSPACE TITAN TECH CO LTD

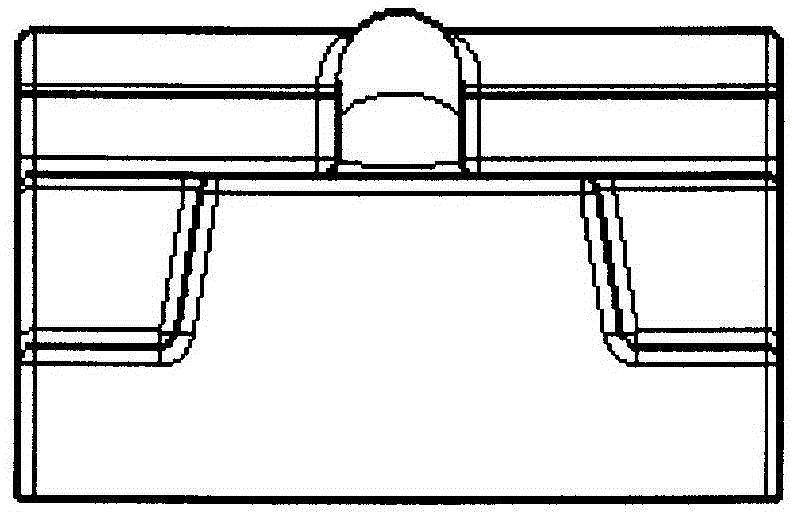

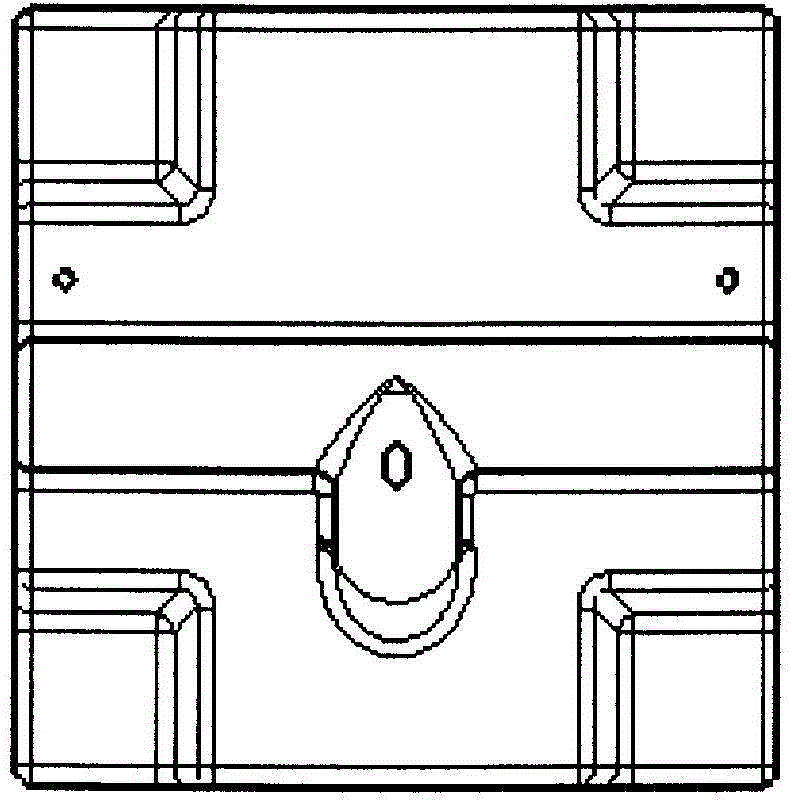

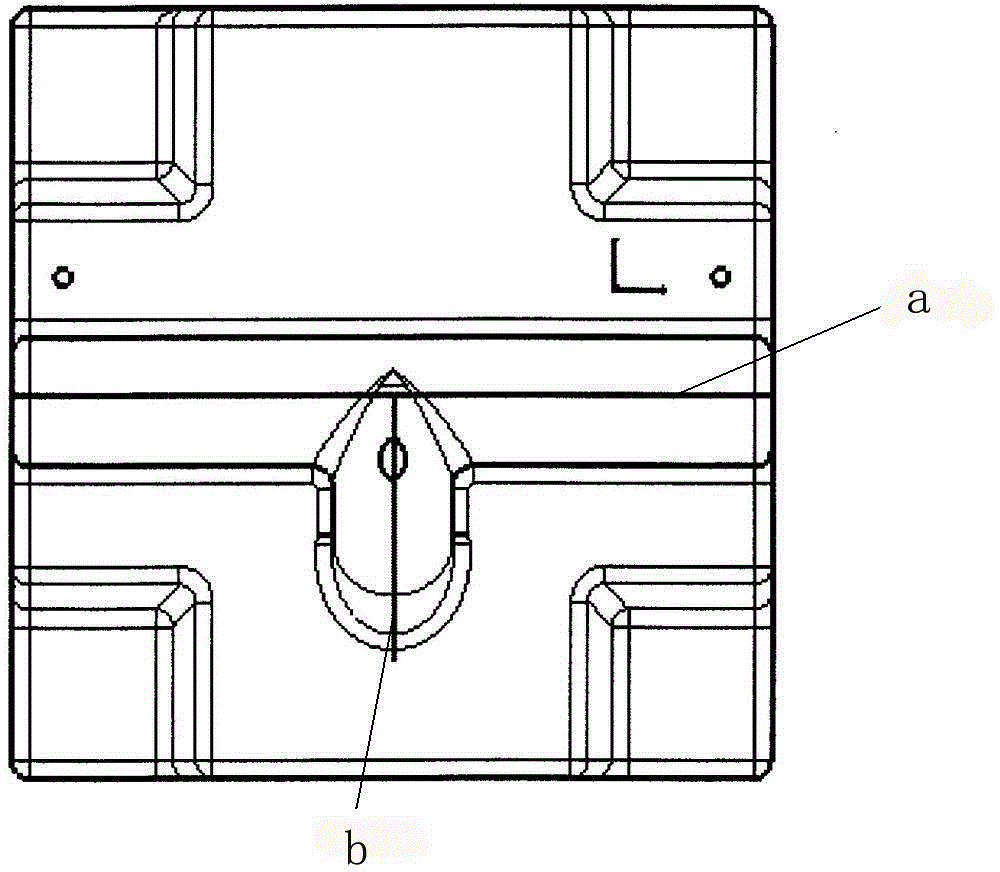

Machining method for mold with protrusion

ActiveCN104588983ASolve processing problemsGuaranteed geometric accuracyNumerical controlMilling cutter

The invention provides a machining method for a mold with a protrusion. The machining method includes the following concrete steps of bottom surface machining, profile numerical control machining, polishing by a bench worker, and delivering and inspecting. According to the profile numerical control machining, guiding lines need to be firstly made, then the Contour-driven command in CATIA V5 is used, the guiding lines divide a main profile into three parts, rough machining, semi-finish machining and finish machining are performed on each part, and after profile machining is completed, whether step machining is performed or not is determined according to the remaining quantity of a step surface; in layering machining, a Profile Contouring command in CATIA V5 is used for layering machining through an end mill, for example, horizontal layering or vertical layering is performed or horizontal layering and vertical layering are performed at the same time, and the non-working surface of the step is in flush joint through the end mill. By the adoption of the machining method, the machining problems of the mold with the protrusion can be effectively solved, machining time is shortened, and the geometric accuracy of the mold is effectively guaranteed.

Owner:SHENYANG AIRCRAFT CORP

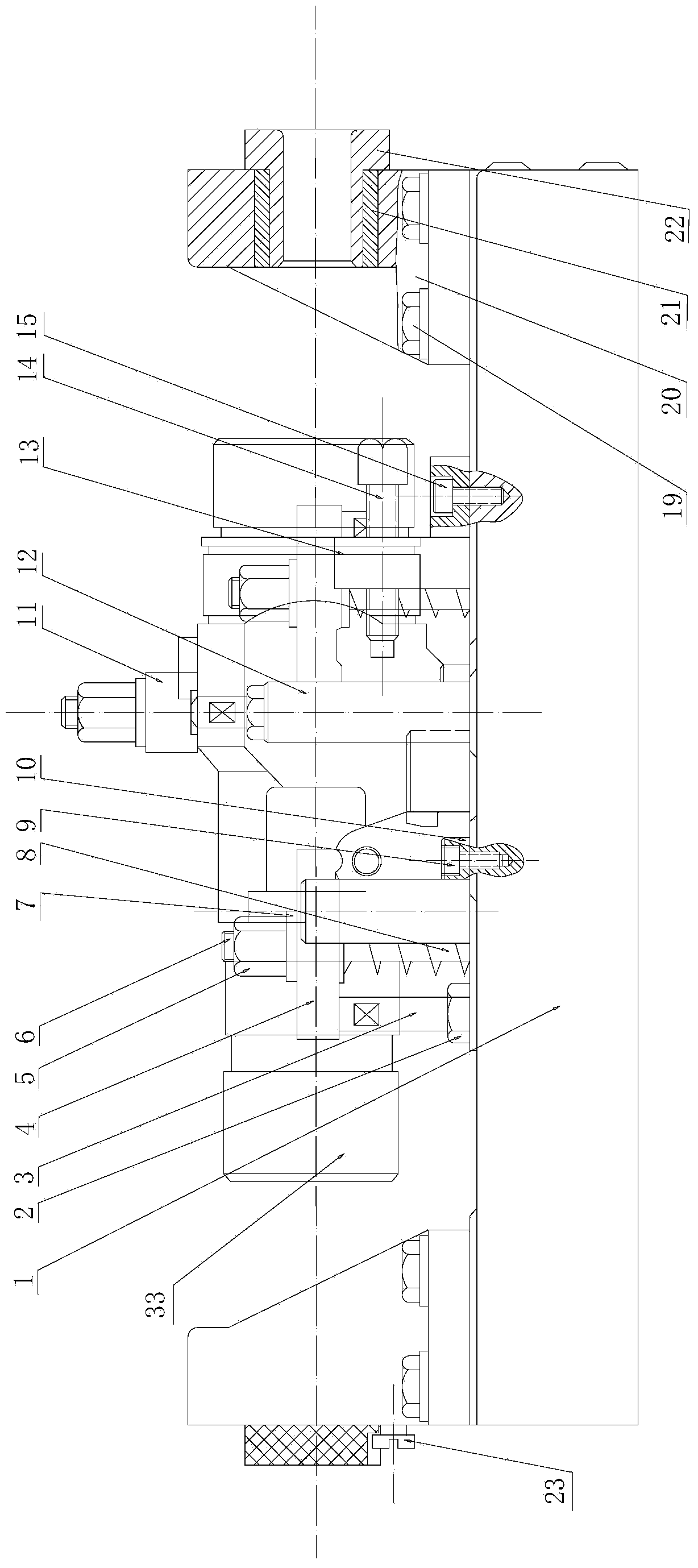

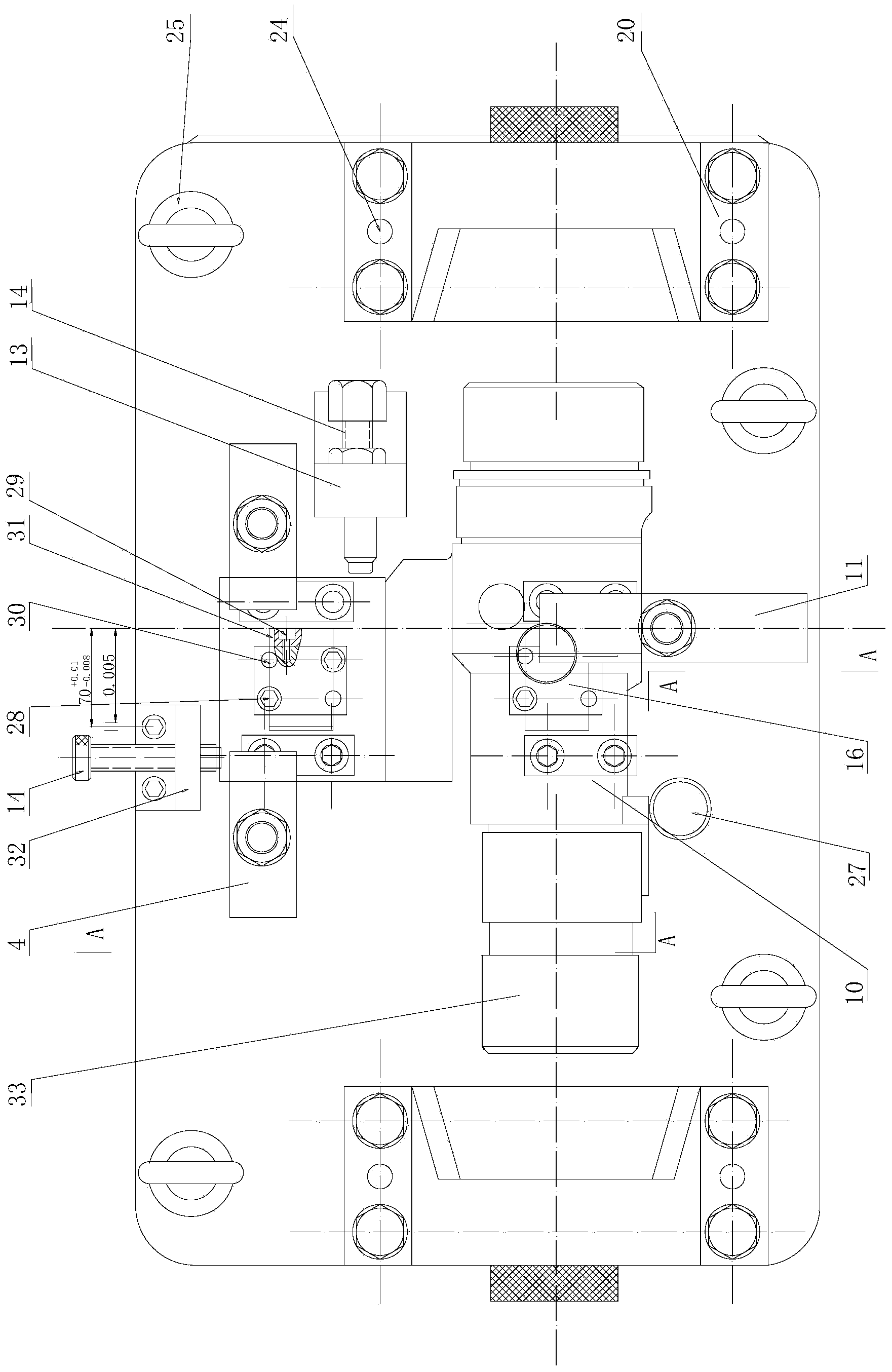

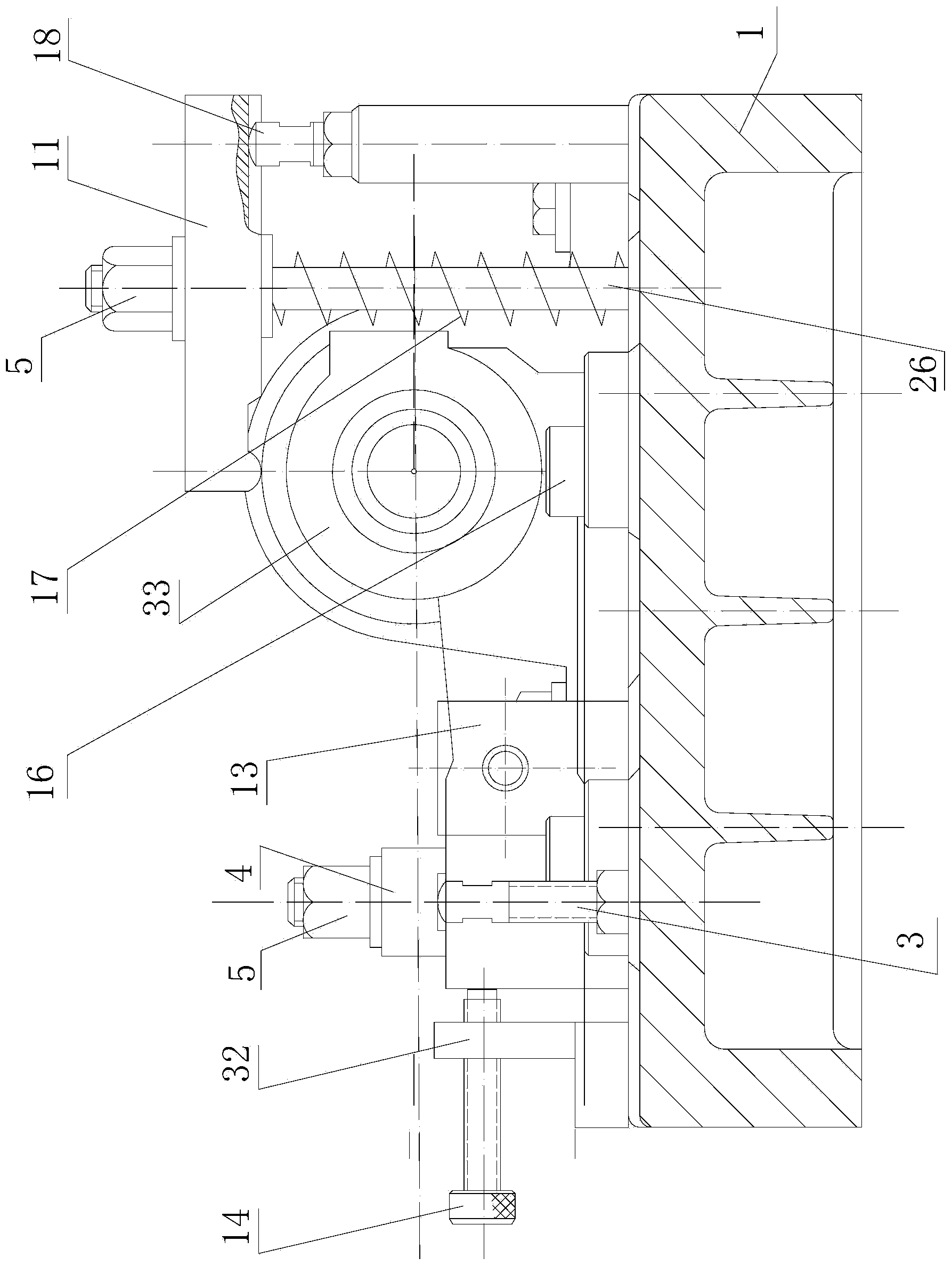

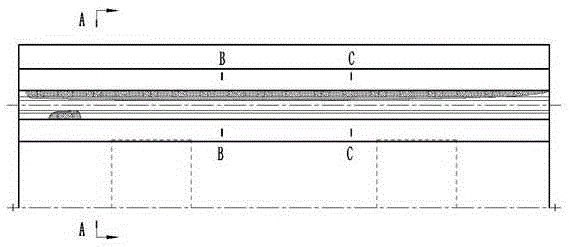

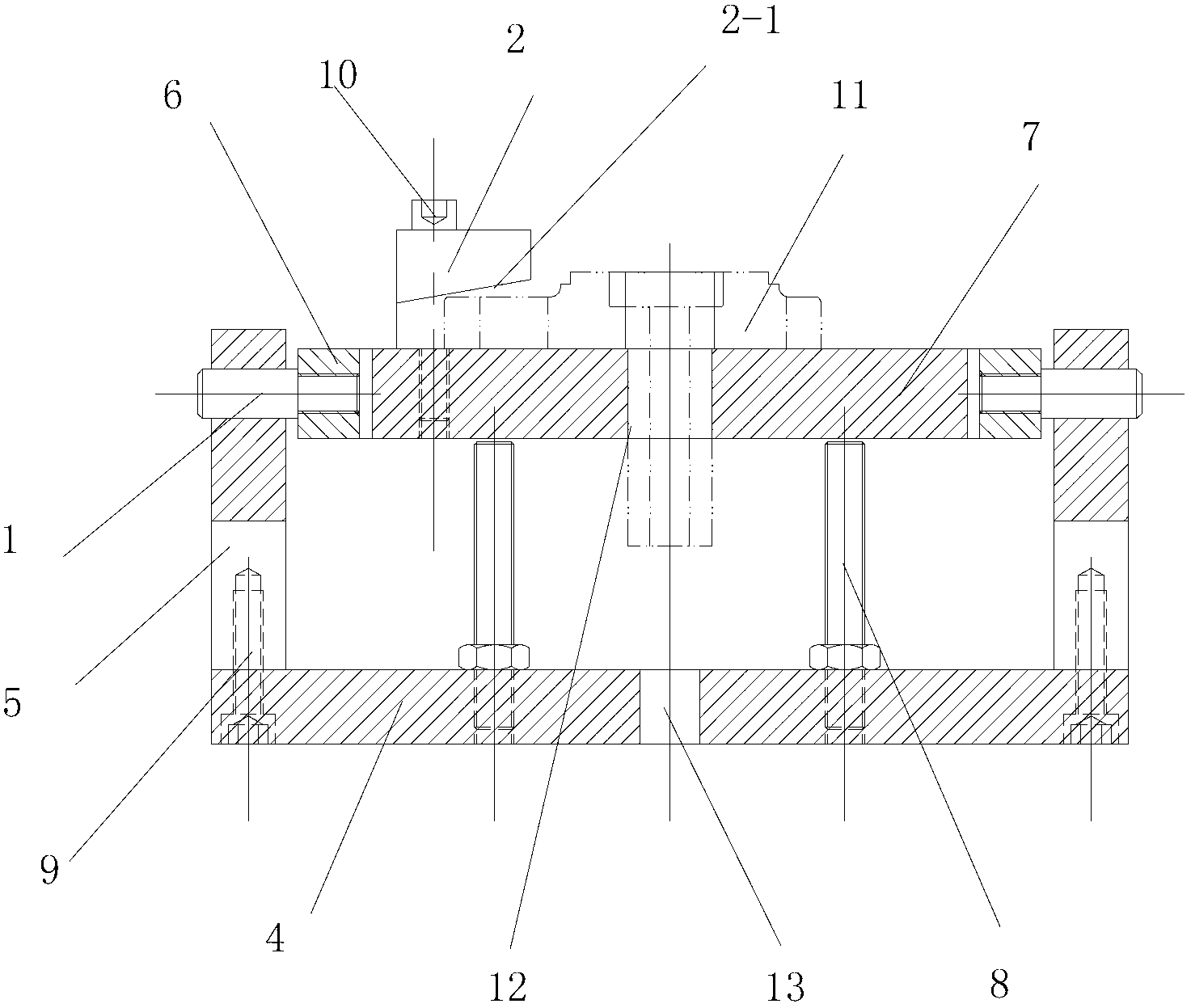

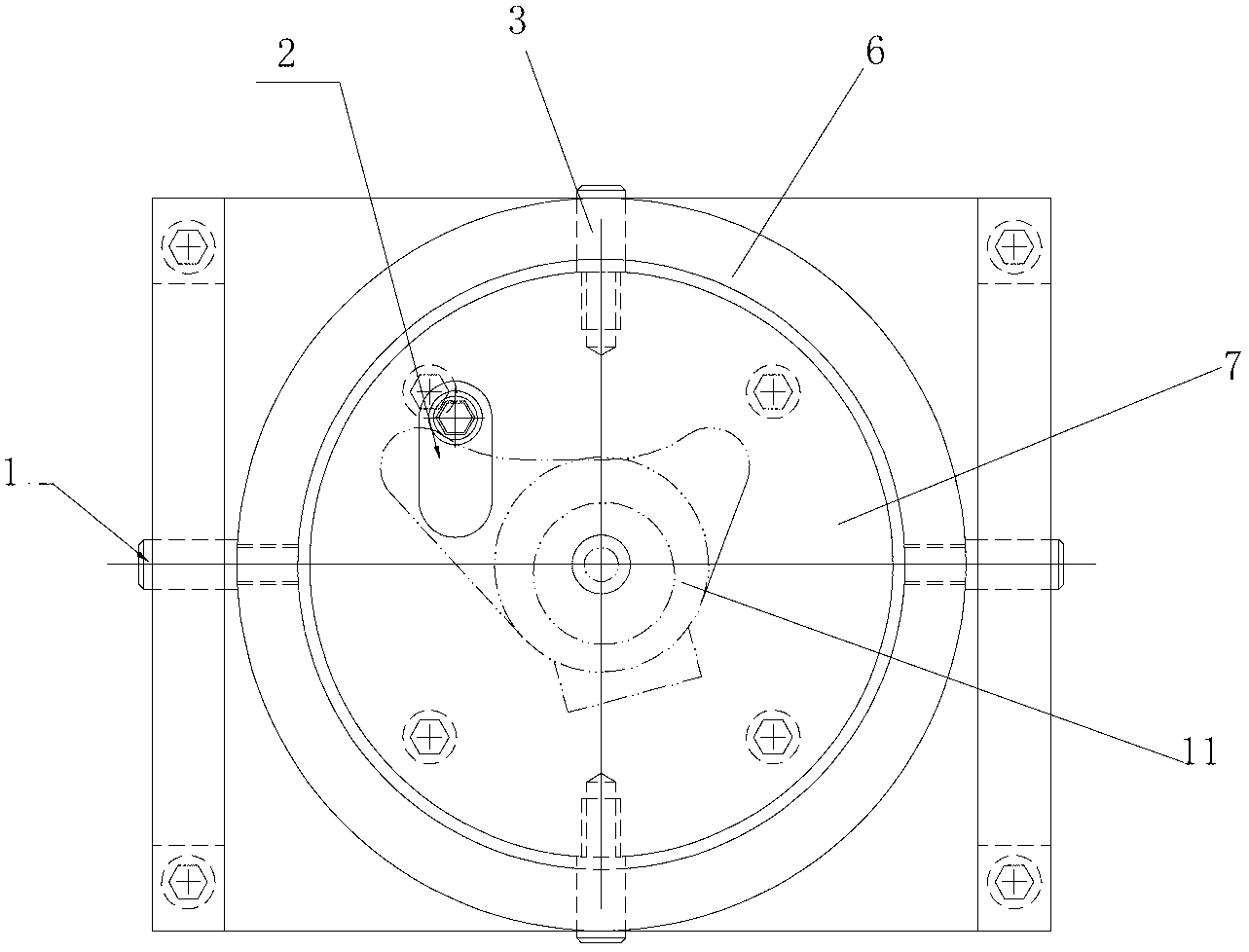

Boring clamp for machining gear milling machine special-shaped oil cylinder and machining method

InactiveCN103522097AGuaranteed tightnessGuaranteed positionPositioning apparatusBoring/drilling componentsEngineeringMachining process

The invention relates to a boring clamp for machining a gear milling machine special-shaped oil cylinder and a machining method. The boring clamp is characterized in that the boring clamp comprises a clamp base, supporting plates arranged on the clamp base and a locating frame arranged between each set of supporting plates, wherein locating supporting plates matched with rectangular grooves in the bottom of the special-shaped oil cylinder are mounted on the locating frames; the boring clamp comprises a first screw frame and a second screw frame which are mounted on the upper end face of the clamp base, the first screw frame corresponds to one side face of the rectangular body of the special-shaped oil cylinder, the second screw frame corresponds to the other side face of the rectangular body of the special-shaped oil cylinder, and the first screw frame and the second screw frame are provided with first adjusting screws and boring rod supports, wherein the boring rod supports are symmetrically arranged on the two sides of the upper end face of the clamp base; the boring clamp further comprises locating pins, a pressing plate used for pressing the periphery of the special-shaped oil cylinder and a rectangular body upper end face pressing plate. The boring clamp has the advantages that machining precision and production efficiency of holes of the special-shaped oil cylinder can be greatly improved, and operation is simple, aligning only needs to be conducted at one time when the boring clamp is used for machining a batch of workpieces, and the boring clamp is especially suitable for production of batches of special-shaped oil cylinders; the special-shaped oil cylinder can be prevented from being deformed in the hole machining process, and geometric dimensioning precision of the machined special-shaped oil cylinder can be guaranteed.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

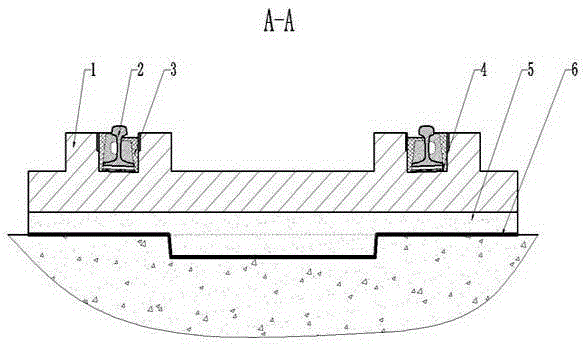

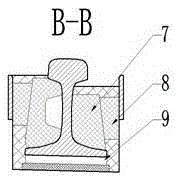

Embedded track system

InactiveCN105256668AShort construction periodReduce workloadBallastwayStructural engineeringEngineering

The invention discloses an embedded track system. The embedded track system comprises a base, a prefabricated track plate and steel rails, and two rail support grooves whose bottom portions have gradients are arranged in parallel corresponding to the width of a train wheel pair on the prefabricated track plate; in the rail support grooves, elastic cushion plates are firstly continuously laid, then height adjusting backing plates whose bottom portions also having the same gradients as the bottom portions of the rail support grooves are arranged in a discretely mode, and then the steel rails are arranged in the grooves; prefabricated sections are adhered to the two sides of each steel rail, and wedge blocks are arranged between the prefabricated sections and the walls of the rail support grooves for adjusting transverse positions of the steel rails; high-molecular castables are cast in the rail support grooves for filling residual space; and an adjustment layer is formed through cast-in-situ concrete for combining the prefabricated track plate with the base. The embedded track system has the following advantages: the construction cycle of a track line is shortened, and the construction quality is effectively guaranteed; vibration and noise are low; and the service life of the track line is longer.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

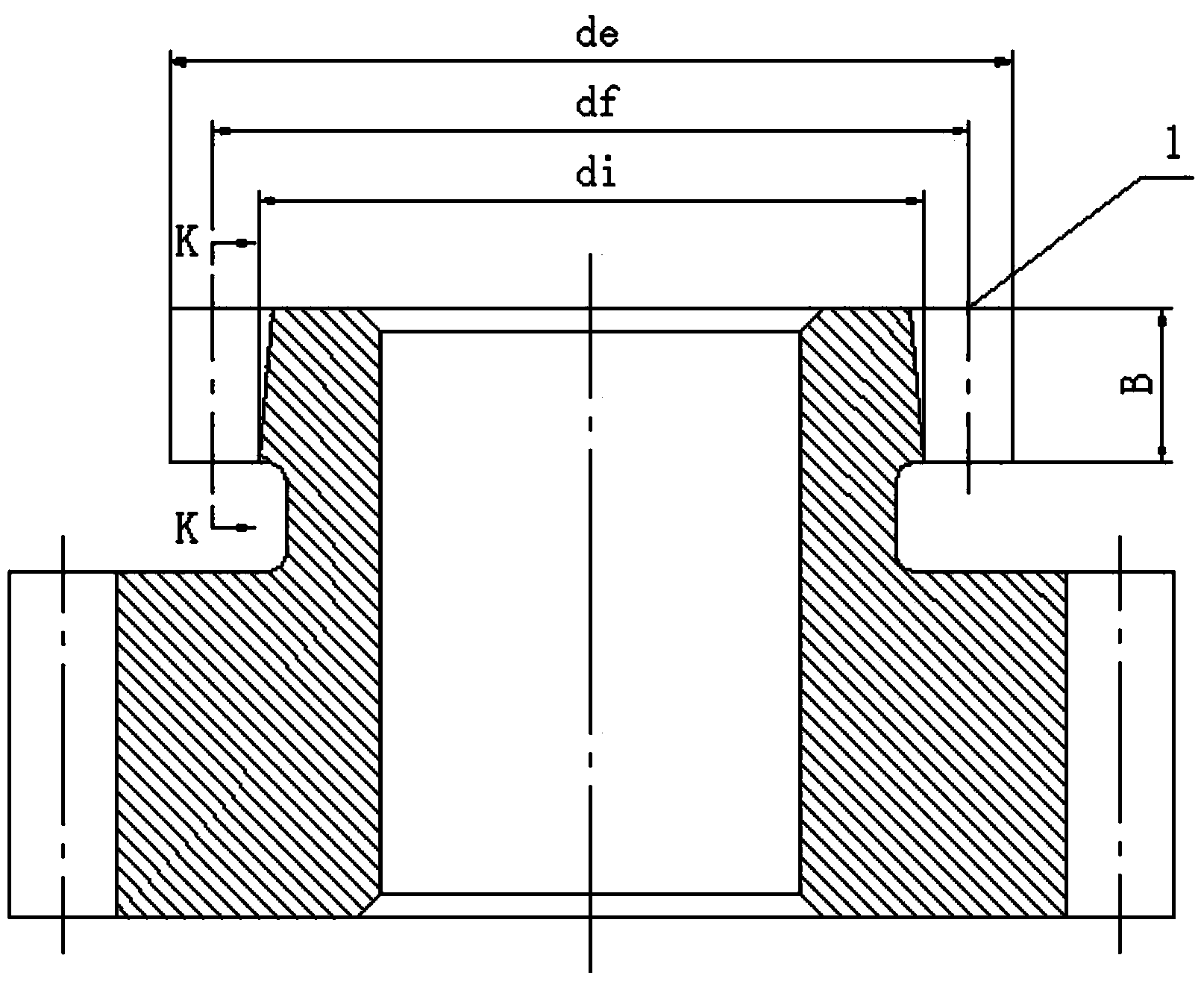

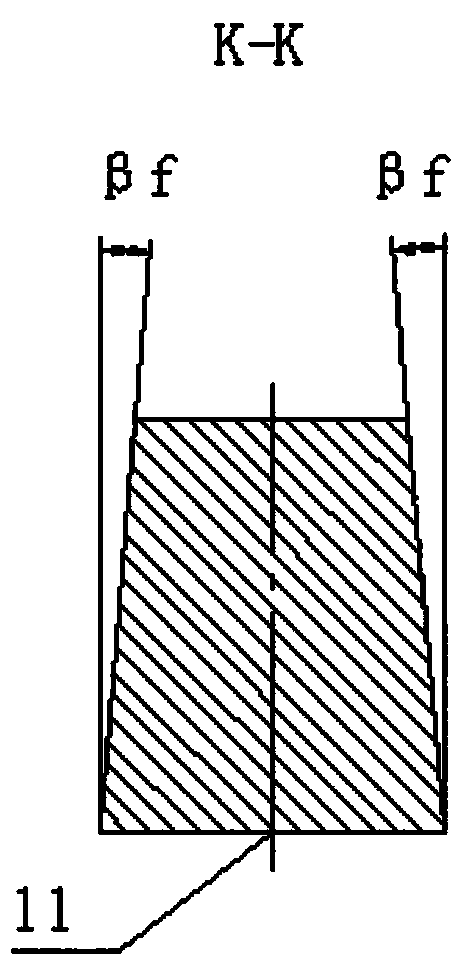

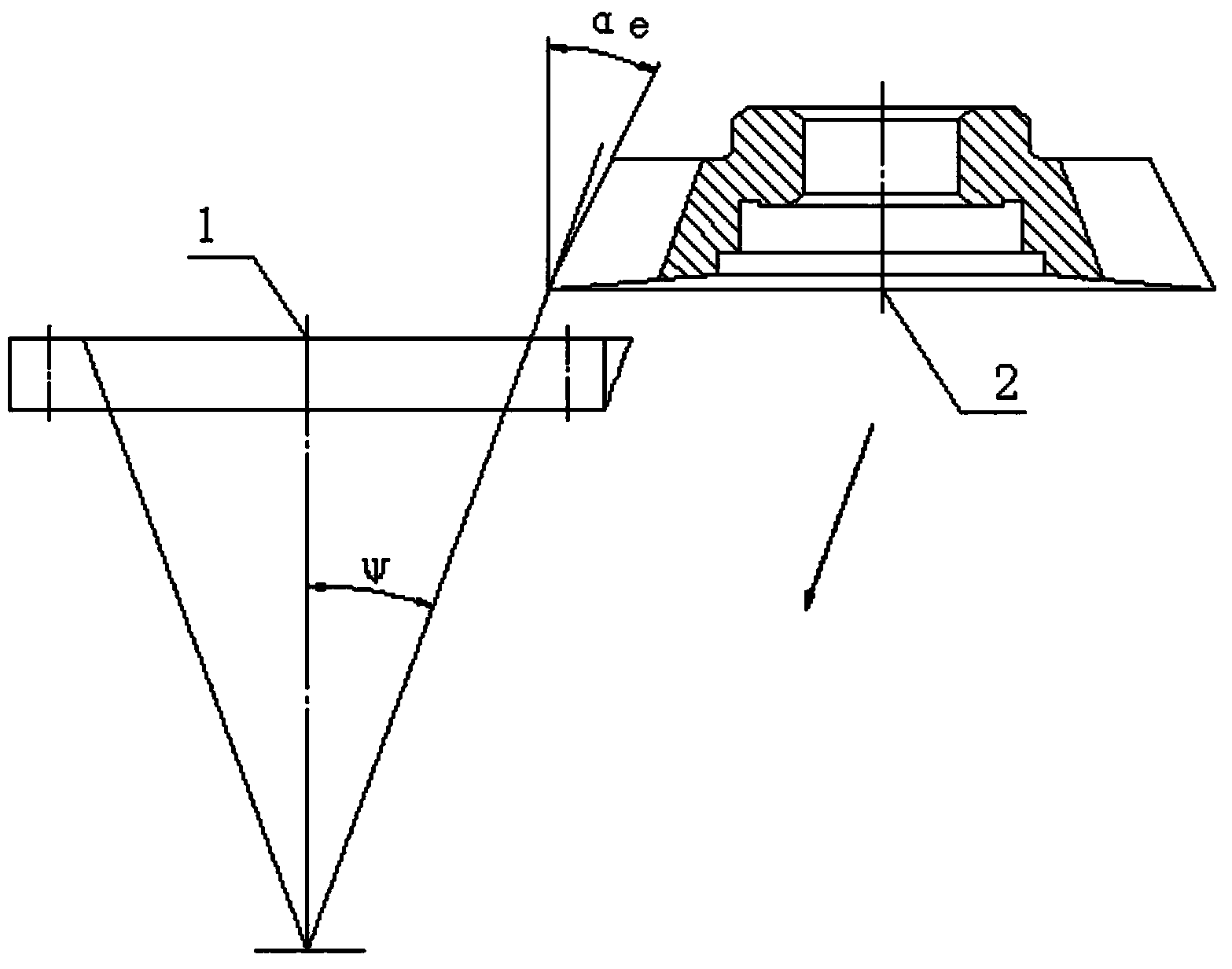

Slotting cutter of inverse-tapered spline straight gear and designing method of slotting cutter

InactiveCN103394768AHigh addendum strengthSolve the problem of low efficiency of separation processingGear teeth manufacturing toolsGear teethEngineeringTooth number

The invention discloses a slotting cutter of an inverse-tapered spline straight gear and a designing method of the slotting cutter. Basic parameters of the slotting cutter comprise a tooth number Zo, a front angle gamma, a tooth crest rear angle alpha e, a reference circle diameter dfo and a reference circle pressure angle alpha fo, wherein the reference circle diameter dfo is equal to Zom, and m represents the modulus of the inverse-tapered spline straight gear; and the reference circle pressure angle alpha fo meets the formula. According to the slotting cutter of the inverse-tapered spline straight gear, an adopted inclined surface, namely a V-V plane, of a larger end of the inverse-tapered spline straight gear is designed according to the principle of meshing the bevel gear and the slotting cutter, the slotting cutter has higher tooth crest intensity, the problem of low separation and processing efficiency of double gears in the prior art is thoroughly solved, and the geometric accuracy of an inserted tooth profile of the inverse-tapered spline straight gear is guaranteed. The invention further provides the designing method of the inverse-tapered spline straight gear. With the adoption of the designing method, the high-accuracy and high-strength slotting cutter of the inverse-tapered spline straight gear can be obtained, and the accuracy of the inserted tooth profile of the inverse-tapered spline straight gear is improved.

Owner:重庆工具厂有限责任公司

Formula of wax material for electroforming

InactiveCN1624206ASolve a series of problems that existLow shrinkageElectroforming processesWhite powderTitanium

A wax material used for electroforming is prepared from Sichuan wax, earth wax, rosin, beeswax and titanium white powder.

Owner:韩石楼

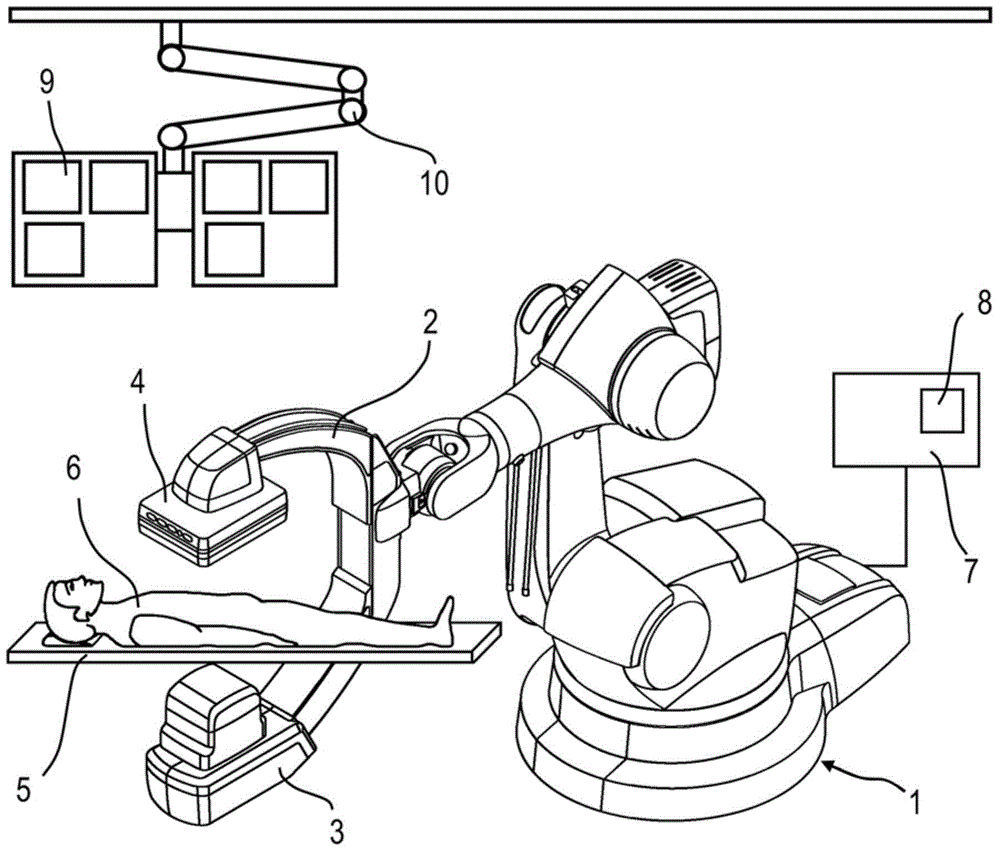

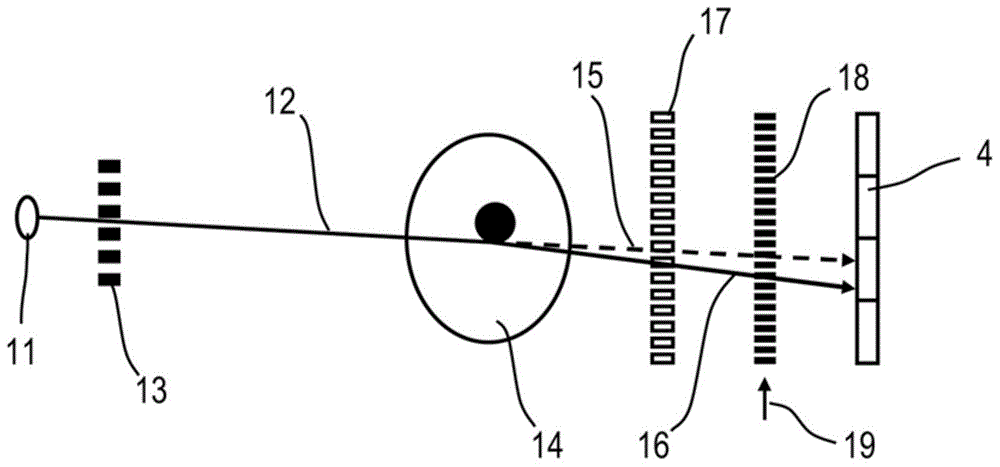

X-ray recording system for differential phase contrast imaging of an examination object by way of phase stepping

InactiveCN104042227AGuaranteed geometric accuracyReal-time phase contrast imagingComputerised tomographsTomographyPhase gratingX ray image

An x-ray recording system is for differential phase contrast imaging of an examination object (6) via phase stepping. In an embodiment, the x-ray recording system includes at least one x-ray emitter (3) for generating quasi coherent x-ray radiation; an x-ray image detector (4) with pixels arranged in a matrix; a defraction or phase grating (17) arranged between the examination object (6) and the x-ray image detector (4); and an analyzer grating (18) assigned to the phase grating (17), wherein the x-ray emitter (3) the x-ray image detector (4), the phase grating (17) and the analyzer grating (18) for the phase contrast imaging form components (32, K1 to Kn) in an arrangement. According to an embodiment, at least one measuring apparatus (34) for determining deviations in the geometric ratios of the components relative to one another from the geometry target, an analysis unit (35, 40) for evaluating the measured deviations, a computing unit (36, 41) for determining correction values and at least one correction device (37, 37, 42, 46) for setting the geometric ratios of the components (32, K1 to Kn) are included.

Owner:SIEMENS AG

Float-type hole grinding clamp

InactiveCN102699812AQuick loading and unloadingGuaranteed geometric accuracyWork carriersEngineeringBolt connection

The invention belongs to clamps, in particular to a float-type hole grinding clamp which is characterized by comprising a bottom plate, pillars, an annular plate, a press plate, a support screw and pin shafts, wherein the pillars are perpendicularly connected with the bottom plate through bolts to form a manger-shaped integral body; the annular plate is in pin connection with the pillars on two sides through the pin shafts; a circular plate for clamping a workpiece is arranged in the center of the circular ring of the annular plate; the adjustable support screw is in bolted connection with the bottom plate; and the circular plate is arranged above the end surface of the adjustable support screw, and is in movable clearance with the end surface of the adjustable support screw. The float-type hole grinding clamp has the benefits that the workpiece can be assembled and disassembled fast through the compressing inclined plane of the press plate; and both the annular plate and the circular plate can move freely, so as to realize the design purpose of 360-degree free floatation; and the hole is ground in a float-type manner, so as to ensure the geometric precision of the hole after processing.

Owner:天津市中马骏腾精密机械制造有限公司

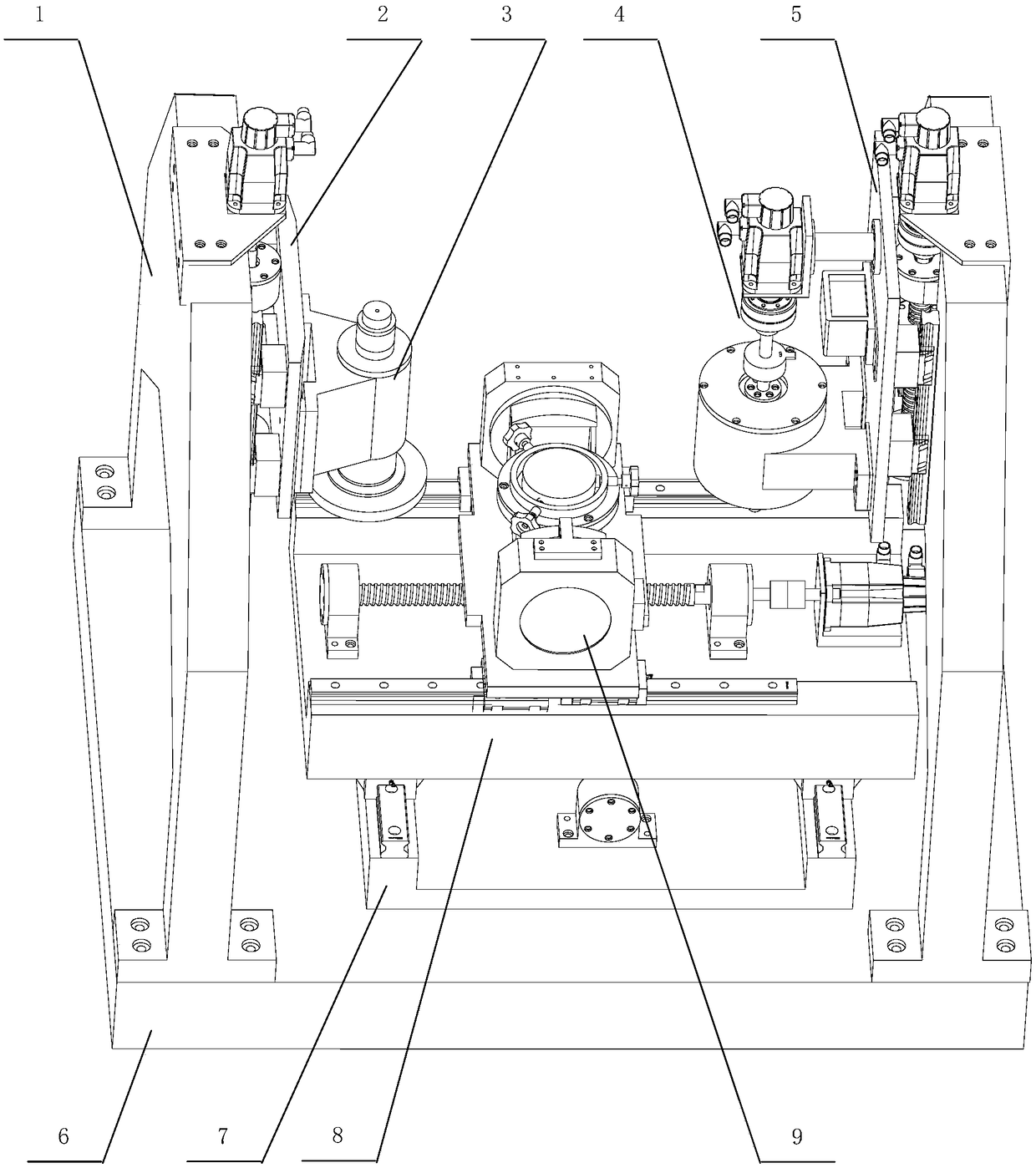

Rough processing and ultrasonic assisting fine processing type forming machine tool for composite grinding wheel and control method

ActiveCN109129038AGuaranteed dimensional accuracyGuaranteed geometric accuracyAutomatic grinding controlProcessing typeUltrasonic assisted

The invention relates to a rough processing and ultrasonic assisting fine processing type forming machine tool for a composite grinding wheel and a control method, and belongs to the field of accurateprocessing of hard and brittle materials. The rough processing and ultrasonic assisting fine processing type forming machine tool for the composite grinding wheel is characterized in that gantries are correspondingly fixedly connected to two sides of a base, wherein a Y-direction guide rail is lengthways fixedly connected to the middle position of the upper surface of the base; an X-direction guide rail is transversely fixedly connected to a sliding plate of the Y-direction guide rail; a rotating swinging double-shaft rotating platform is lengthways fixedly mounted on a sliding plate of the X-direction guide rail; a first Z-direction guide rail is fixedly connected to the middle position of the right side of the gantry at the left side; a grinding tool is fixedly connected to a sliding plate of the first Z-direction guide rail; a second Z-direction guide rail is fixedly connected to the middle position of the left side of the gantry at the right side; and an ultrasonic tool system isfixedly connected to a sliding plate of the second Z-direction guide rail. The rough processing and ultrasonic assisting fine processing type forming machine tool for the composite grinding wheel hasthe advantages that the grinding processing efficiency is improved while the abrasion of a cutting tool is reduced by rotating ultrasonic vibrating assisting grinding processing; the size accuracy andthe geometric accuracy are ensured; the efficiency is high; and the economic benefit is high.

Owner:JILIN UNIV

A composite repair method of modularized addition and subtraction materials in the defect area of the part surface

ActiveCN110640146BEasy to shapeConvenient path planningAdditive manufacturing apparatusIncreasing energy efficiencyPoint cloudStructural engineering

The invention relates to a composite repair method of modularized addition and subtraction materials for part surface defects, which relates to the technical field of mechanical processing. The main process includes three-dimensional scanning of the defect area on the surface of the part to obtain the point cloud data of the area to be repaired; calculating the characteristic parameters of the defect area according to the point cloud data; selecting the corresponding geometric module according to the characteristic parameters; and removing the defect area by modular milling Processing to obtain the regular area to be repaired; perform modular laser cladding repair on the area to be repaired; perform precision milling on the laser repaired surface to complete the repair. The present invention trims the complex and irregular defect shape into a regular geometric body by adding and subtracting materials, and on this basis, performs laser cladding repair on the modular geometric body to be repaired, and the path planning is convenient and fast, thereby improving the repair efficiency as a whole. In addition, the precision milling of the laser cladding area can maintain the repair accuracy of the shape and contour of the repaired surface, and at the same time improve the service performance of the repaired surface.

Owner:NANJING INST OF TECH

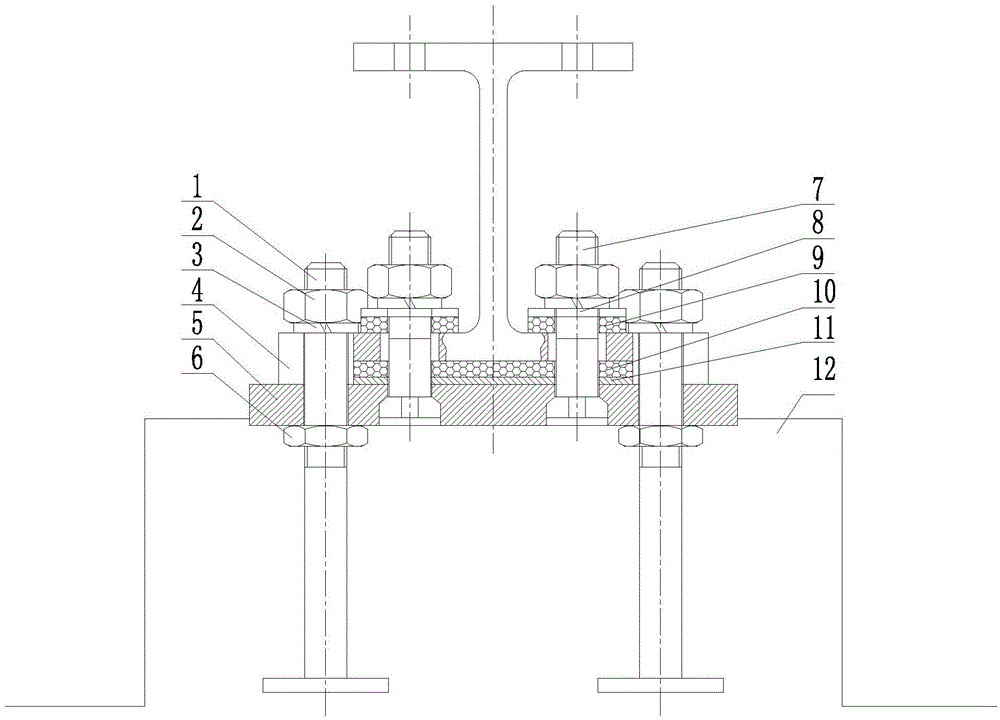

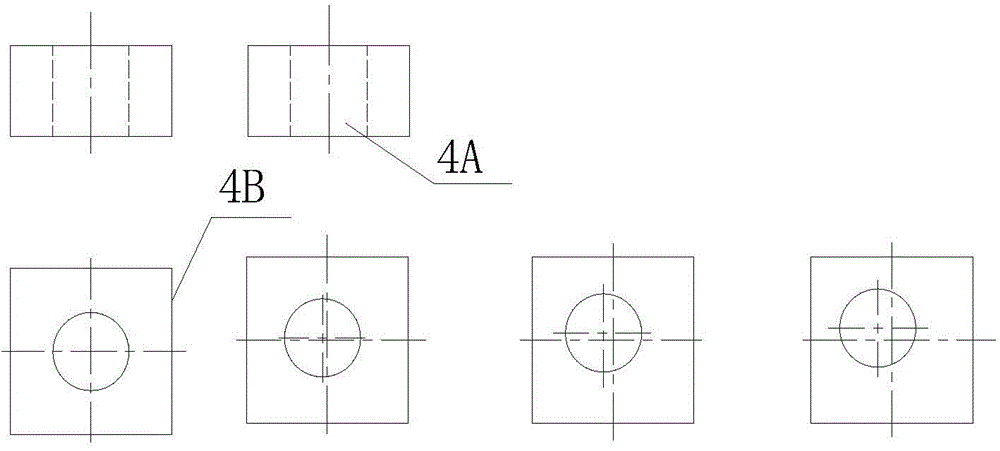

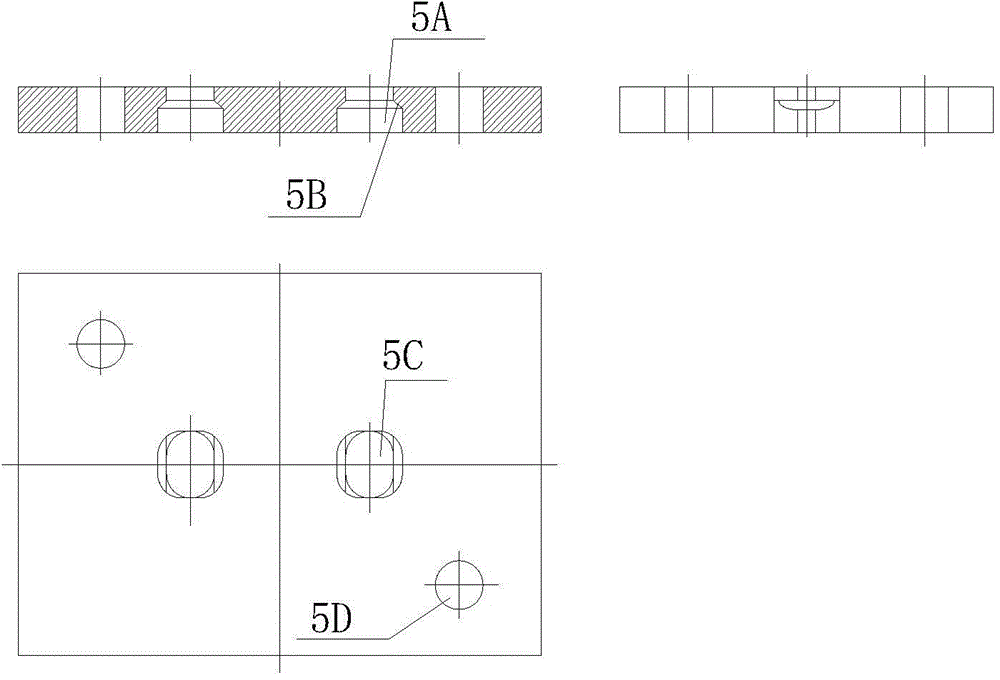

Low-maintenance low-and-middle-speed magnetic suspension three-dimensional adjustable fastener

The invention discloses a low-maintenance low-and-middle-speed magnetic suspension three-dimensional adjustable fastener. The low-maintenance low-and-middle-speed magnetic suspension three-dimensional adjustable fastener sequentially comprises an H-shaped sleeper, an iron cushion plate and a rail supporting table from top to bottom, wherein oblong holes are respectively formed in bottom plates of two sides of the H-shaped sleeper; the iron cushion plate is provided with a first bolt connecting hole and a second bolt connecting hole; the H-shaped sleeper is screwed in the oblong holes and the first bolt connecting hole through T-shaped bolts and is connected with the iron cushion plate; the iron cushion plate is screwed in the second bolt connecting hole through an anchoring bolt and is connected with the rail supporting table; the first bolt connecting hole comprises a T-shaped bolt screwing-in hole and a T-shaped bolt locking hole; and the T-shaped bolt screwing-in hole is positioned above the T-shaped bolt locking hole. The oblong holes are formed in the H-shaped sleeper, so that lines along a rail row can be adjusted in the longitudinal direction, notches are formed in the iron cushion plate and the H-shaped sleeper, the rail row can be adjusted and limited in the transverse direction, and vertical large-range heightening can be implemented through a combination of different heightening cushion plates.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Double-curve bent component machining process

The invention belongs to the technical field of steel structural components, and in particular, discloses a double-curve bent component machining process. The double-curve bent component machining process comprises the following steps: (1) bent part blanking: steel plates and profiles are manufactured as single part plates for manufacturing double-curve bent components; (2) grooves are machined; (3) no-mold formation: wing webs are warped before box assembly through the following steps: (A) the part plates are bent by adopting a three-center circle bending machine according to drawing requirements; (B) the qualified bent part plates are warped by using a hydropress according to drawing warping requirements; and (C) self-inspection is performed on machined parts; and the inspection mode isto use foetal membranes or sample plates for warping amplitude detection; (4) sample mold frames of components are warped; and the mold frames are manufactured; (5) assembly of warped components: webs, baseplates and side plates are assembled by using the mold frames; and (6) the warped components are welded. The process can effectively solve the problems of high machining difficulty and low machining size precision of the double-curve bent components.

Owner:珠海十字门中央商务区建设控股有限公司

Large-area complex-terrain-region unmanned plane sequence image rapid seamless splicing method

InactiveCN104156968BAvoid blind matchingNarrow searchImage analysisLevenberg–Marquardt algorithmTerrain

Provided is a large-area complex-terrain-region unmanned plane sequence image rapid seamless splicing method which comprises the following steps: to begin with, with air strip arrangement features of unmanned plane image sequence being prior knowledge, carrying out inter-image multiple-overlap SIFT feature point extraction and matching; then, carrying out matching point gross error removing and purifying based on random sample consensus algorithm, and solving transformation parameters of each image in spliced regions in an adjustment manner through an Levenberg-Marquardt algorithm; next, carrying out overlapped region image optimized selection according to the relative position relationship between central projection image point displacement rules and the images, and determining splicing lines; and finally, carrying out image uniform-coloring and fusion at the edge-connection places, and outputting spliced images, thereby realizing mass unmanned plane image seamless splicing. The seamless splicing method helps to improve the extraction efficiency of the SIFT feature points, guarantee the geometric accuracy of the spliced images, and eliminate the tiny color difference at the two sides of the image splicing line, and thus the spliced images with natural color transition and good natural object and landform continuity are obtained.

Owner:SHANDONG LINYI TOBACCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com