Float-type hole grinding clamp

A floating and drilled technology, applied in the direction of the work carrier, can solve the problems of low work efficiency, prone to accidents, and high labor intensity of workers, so as to reduce labor intensity, ensure geometric accuracy, and improve labor productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

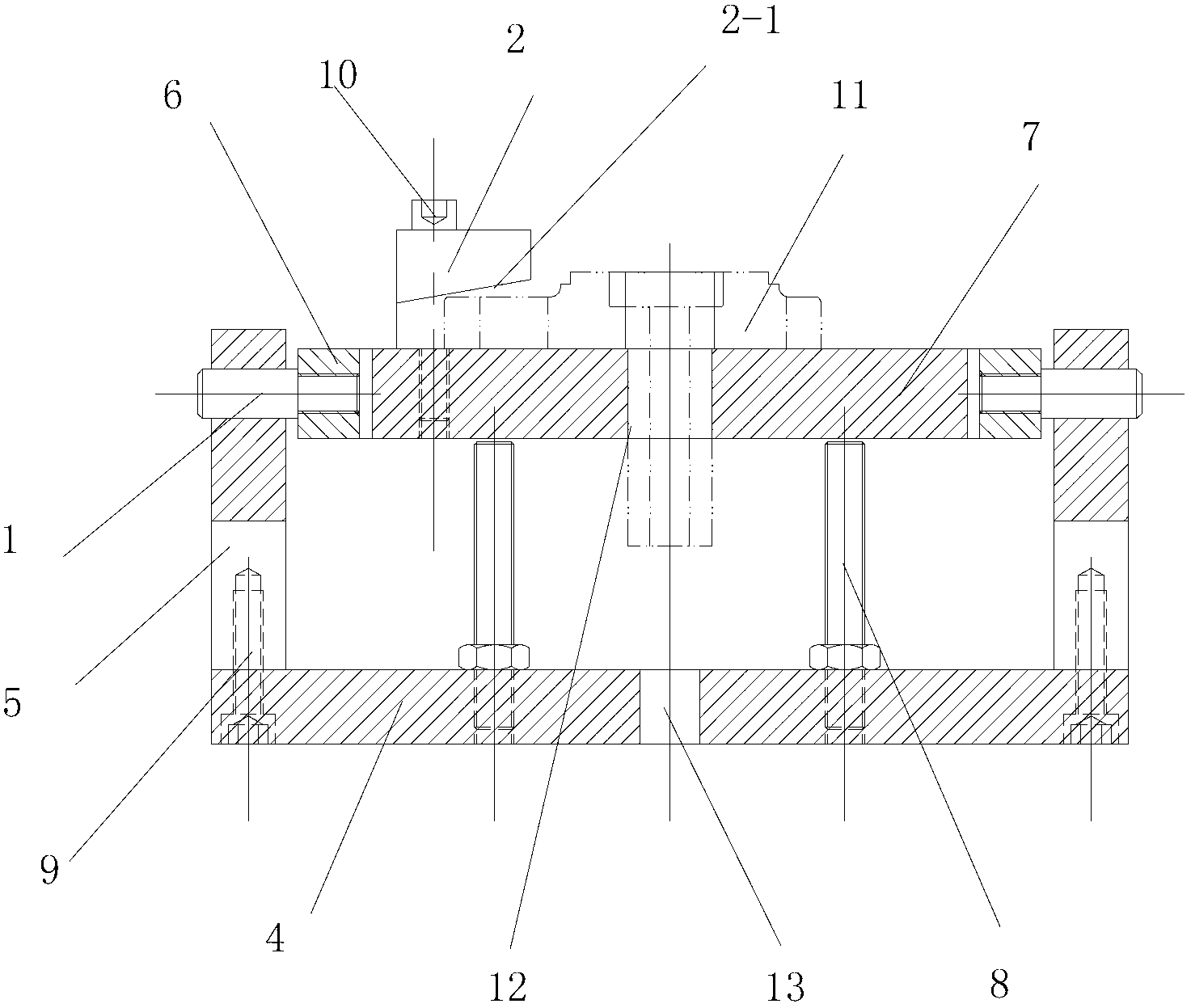

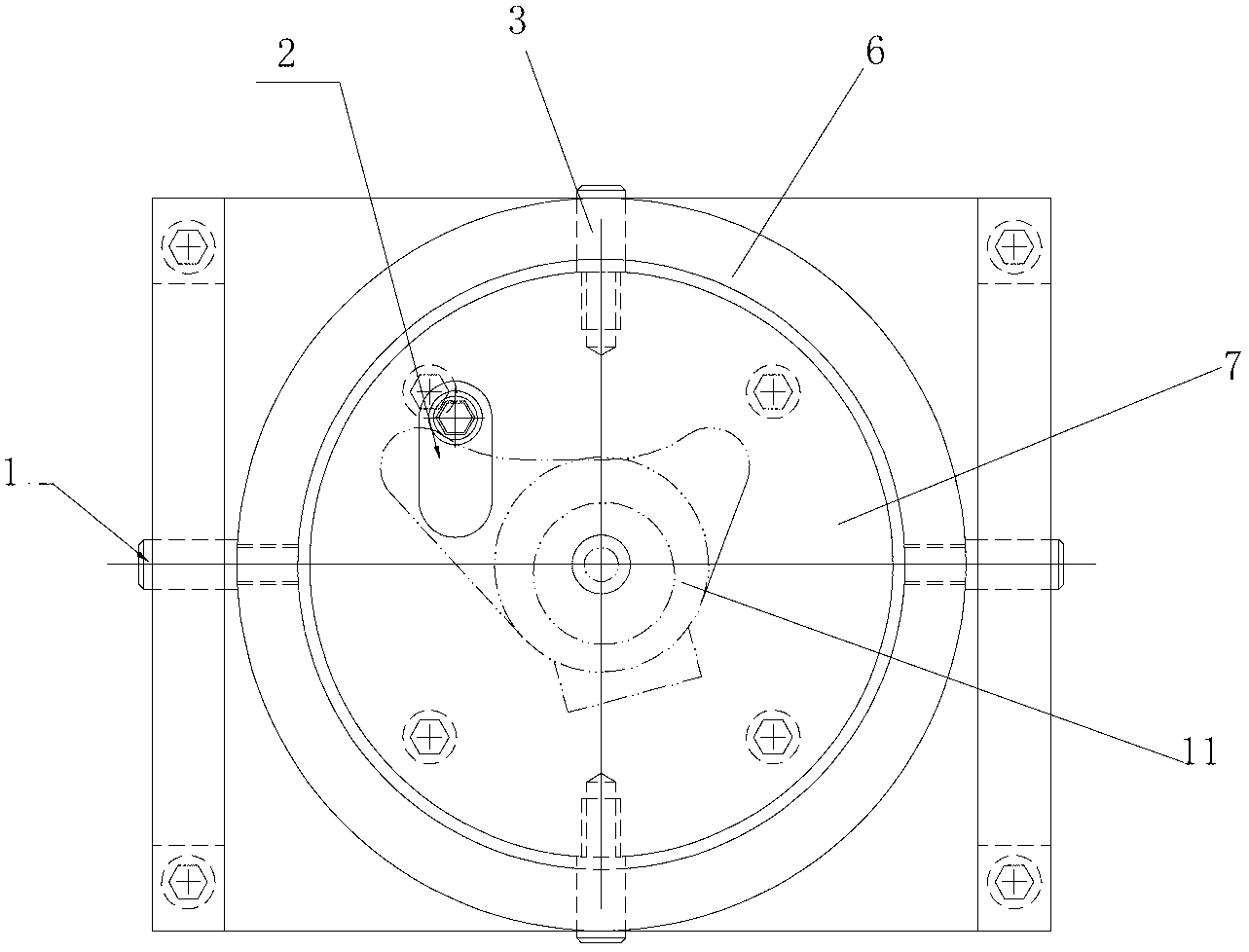

[0015] Below in conjunction with the preferred embodiments, the specific implementation methods provided according to the present invention are described in detail as follows: See the accompanying drawings for details, a floating drilling fixture, including a bottom plate 4, a pillar 5, an annular plate 6, a pressure plate, a supporting screw and pins shaft, the pillar is vertically connected to the bottom plate by screws 9 to form a manger-shaped whole, the annular plate is pinned to the pillars on both sides through the pin shaft 1, and a circular plate for clamping the workpiece is placed in the center of the ring of the annular plate 7. Adjusting support screws 8 are screwed on the bottom plate, the number of the adjustment support screws is four, and they are screwed on the bottom plate in a square position. The circular plate is placed above the end surface of the adjusting support screw, and a movable gap is provided between the circular plate for clamping the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com