Automatic gravity gripper

A gripper, automatic technology, applied in the direction of external frame, transportation and packaging, packaging, etc., can solve the problems of unsafe, no gripping function, single, etc., to achieve the effect of strong interchangeability and fast loading and unloading of objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

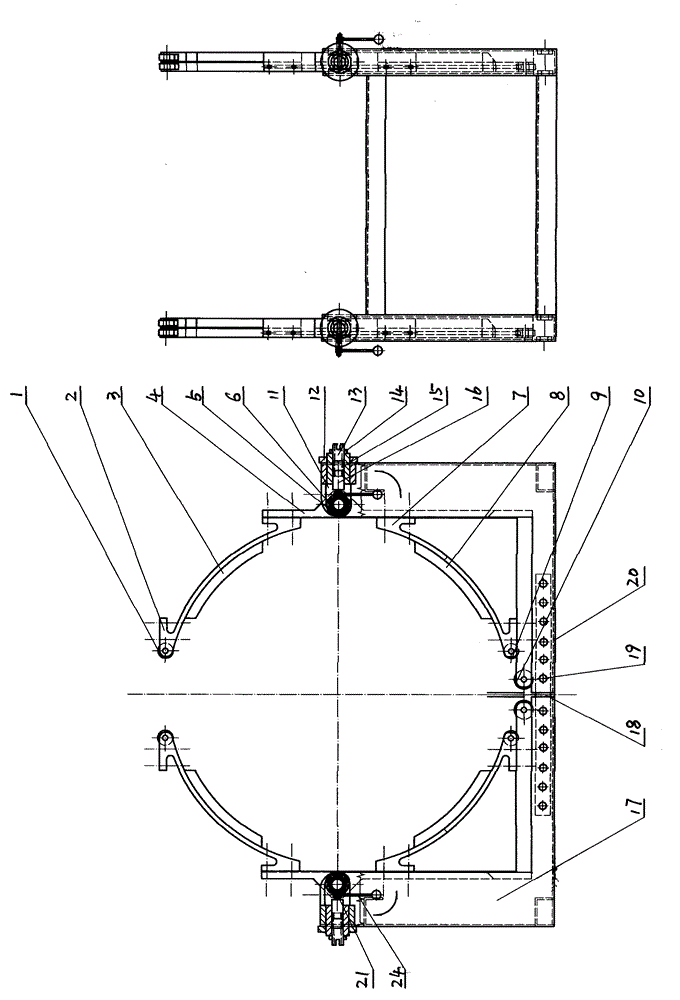

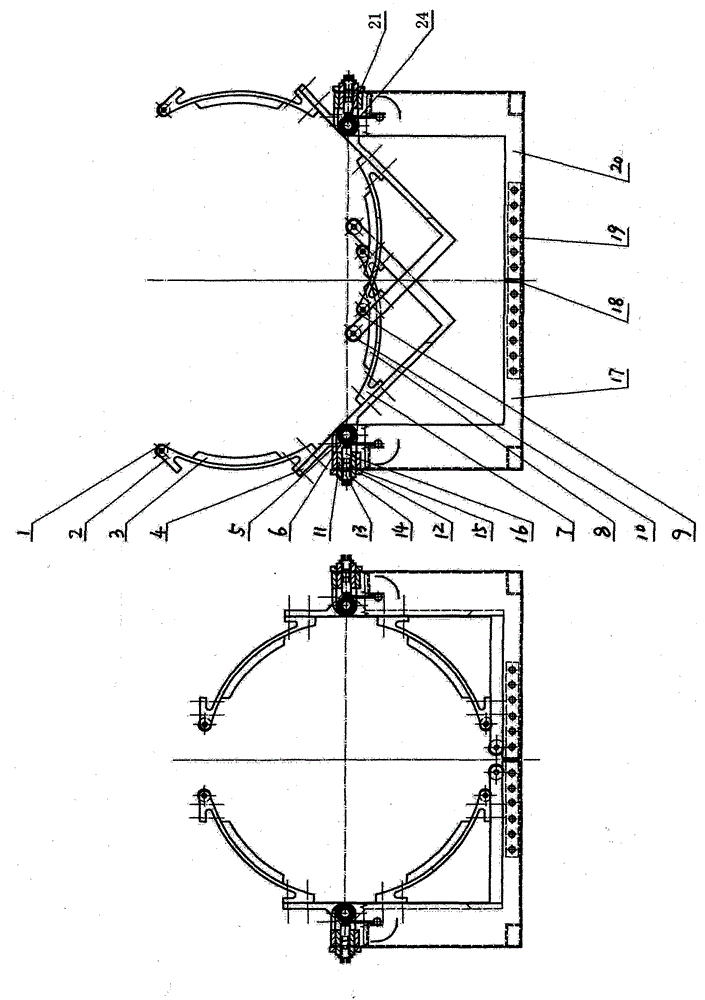

[0022] The invention is composed of a holder seat assembly, a square shaft assembly, a groove-shaped movable clamping head assembly, and a ratchet lock assembly.

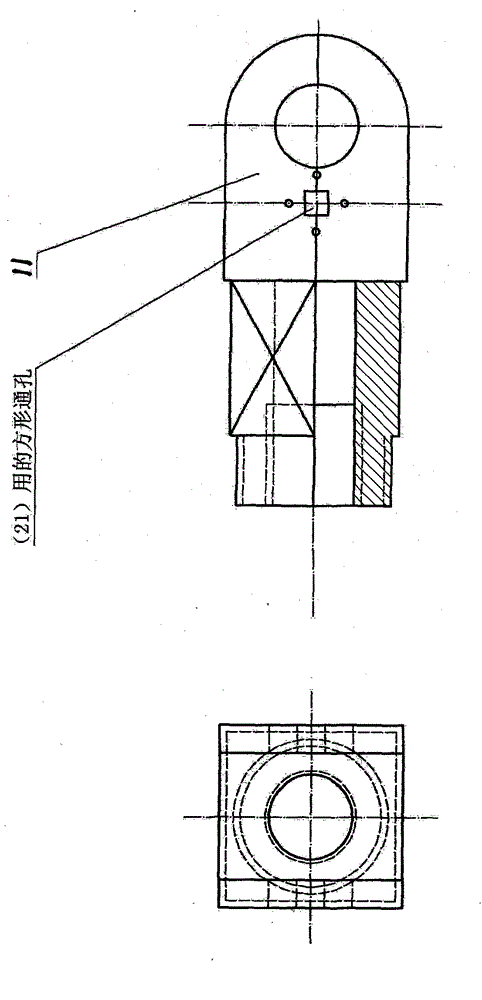

[0023] see figure 1 , figure 2 , image 3 The left side of the gripper seat assembly is made up of the left adjustable gripper seat (17), the adjusting plate (18), the screw (19), and the right adjustable gripper seat (20) the same as the inside and outside shape of the right side. The front view sees that the shape is like a half-side separable and adjustable square, or it can be a rectangle or a polygon. There is a square through hole for the square shaft (11) on the left side and the right side, or it can be a rectangular through hole, Polygonal vias, circular vias, oval vias. A through hole for the use of a circular ratchet lock seat (26) is respectively arranged on the left side and the right side of the front. From the left view, it can be a single rack or multiple racks. The left and right adjustable ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com