Automatic throttle valve production line

An automatic production line and throttle valve technology, applied in the direction of feeding devices, manufacturing tools, positioning devices, etc., can solve the problems of not being able to adapt to the large environment, and achieve the effects of saving manpower, low automation, and strong replaceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to better illustrate and describe the content of the present invention, the following description will be carried out in conjunction with the accompanying drawings and implementation examples:

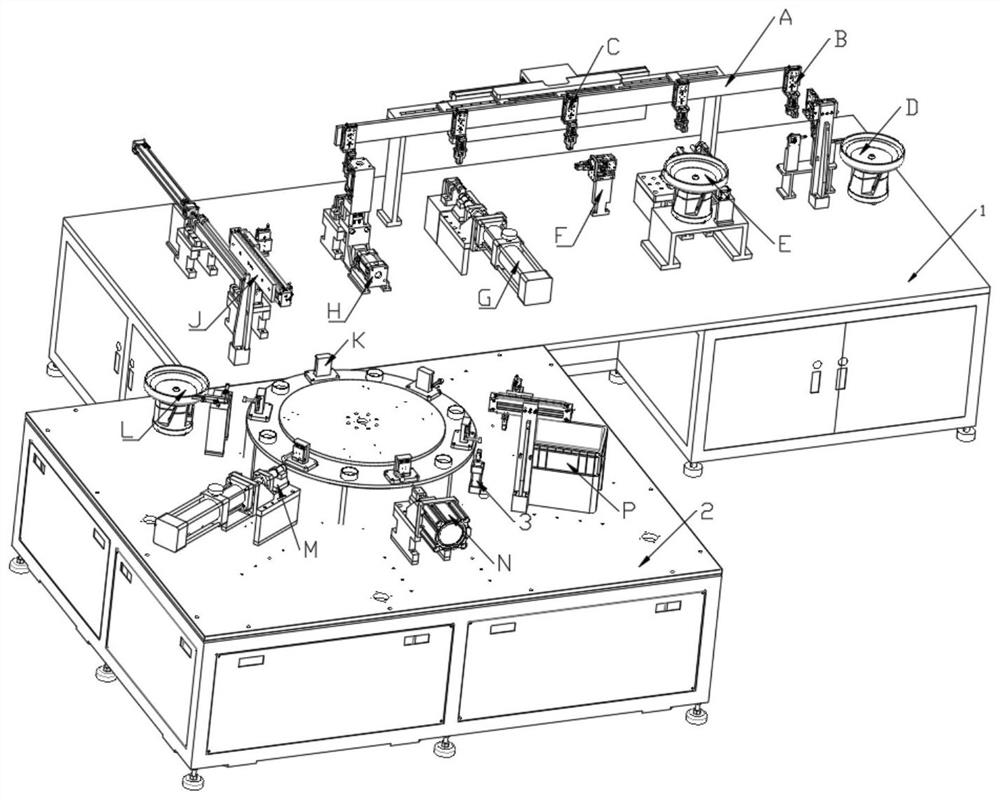

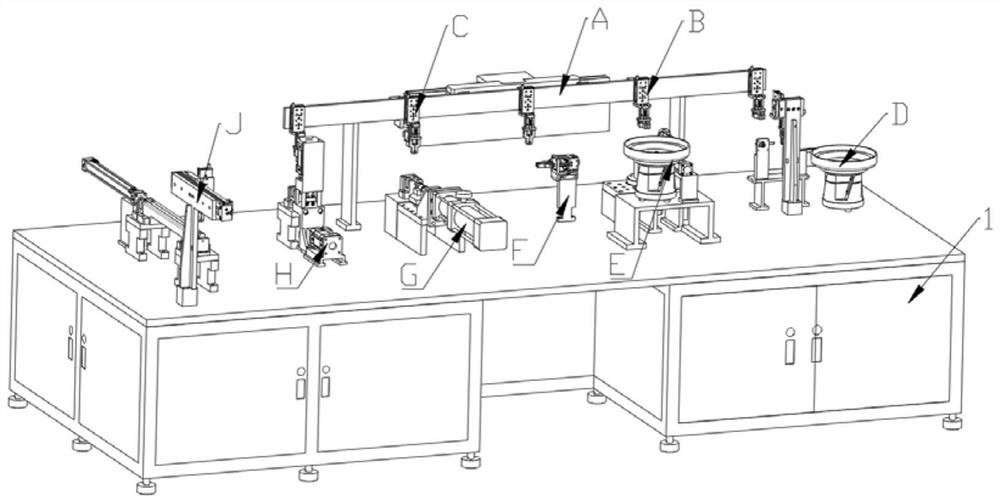

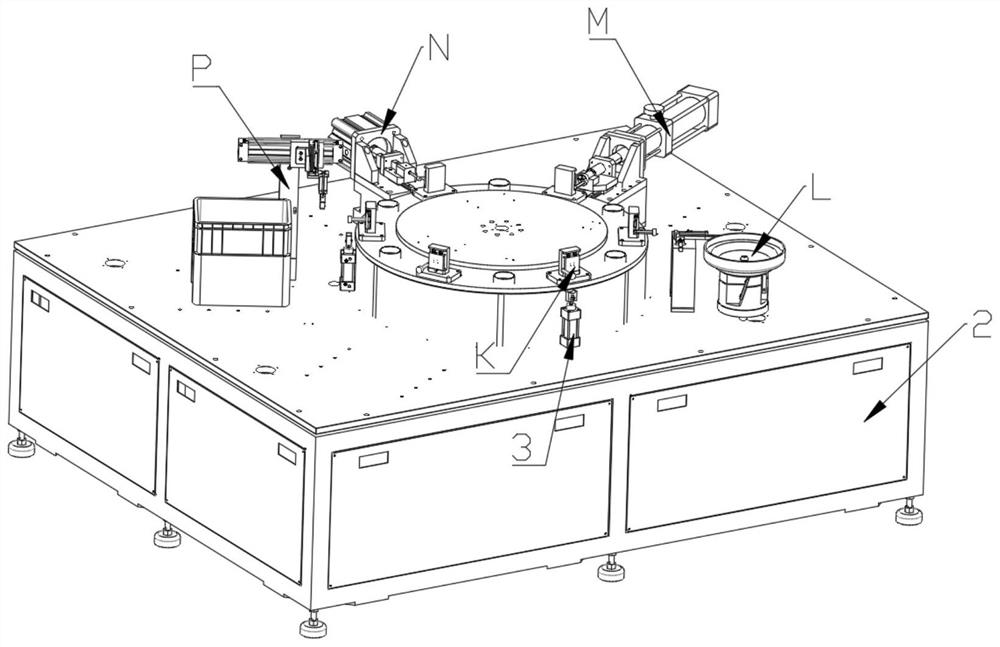

[0051] Have Figure 1-Figure 24 As shown, the present invention discloses an automatic production line for a throttle valve, including an electrical cabinet 1, and the electrical cabinet 1 is provided with a transfer device A, a valve body cutting device D, a valve core seat clamping device E, a ninety The degree rotating device F, the first necking device G, the dotting device H, the pushing device J, the front side of the electrical cabinet 1 is also provided with an indexing plate 2, and the indexing plate 2 is provided with several circular arrays. A valve body carrier K, the valve body carrier K can rotate around the center of the annular array, and a filter screen device L, a second necking device M, a flaring device are sequentially installed on the valve body ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com