Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85 results about "Quartz ampoule" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing Te-Zn-Cd monocrystal in large volume

ActiveCN101092748ASmall sizeIncrease the single crystal ratePolycrystalline material growthFrom frozen solutionsCarbon filmRoom temperature

This invention discloses a method for preparing large-volume cadmium zinc telluride (CZT) single crystal. The method comprises: (1) selecting high-melting-point CZT single crystal as the seed crystal; (2) coating a carbon film on the inner side of a quartz ampoule, placing CZT seed crystal in the seed crystal bag at the bottom of the ampoule so that the seeding growth surface of CZT seed crystal is upward, then adding low-melting-point CZT polycrystal, vacuumizing the quartz ampoule, and sealing by welding; (3) placing the quartz ampoule into an ACRT-B type crystal growth apparatus, heating the temperatures of the high-temperature zone and the low-temperature zone to 1135-1145 deg.C and 1030-1040 deg.C within 18-20 h, overheating for 12-16h, and descending the supporting bar at a speed of 0.8 mm / h for 200-240 h; (4) cooling the high-temperature zone and the low-temperature zone to 870-890 deg. within 5-6 h, annealing the crystal ingot in situ for 144-168 h, then slowly cooling to 550-560 deg.C at a rate of 5 deg.C / h, shutting off the power source, and cooling to room temperature. The method can obtain large-volume CZT single crystal, and increase the single crystal ratio in the crystal ingot.

Owner:IMDETEK

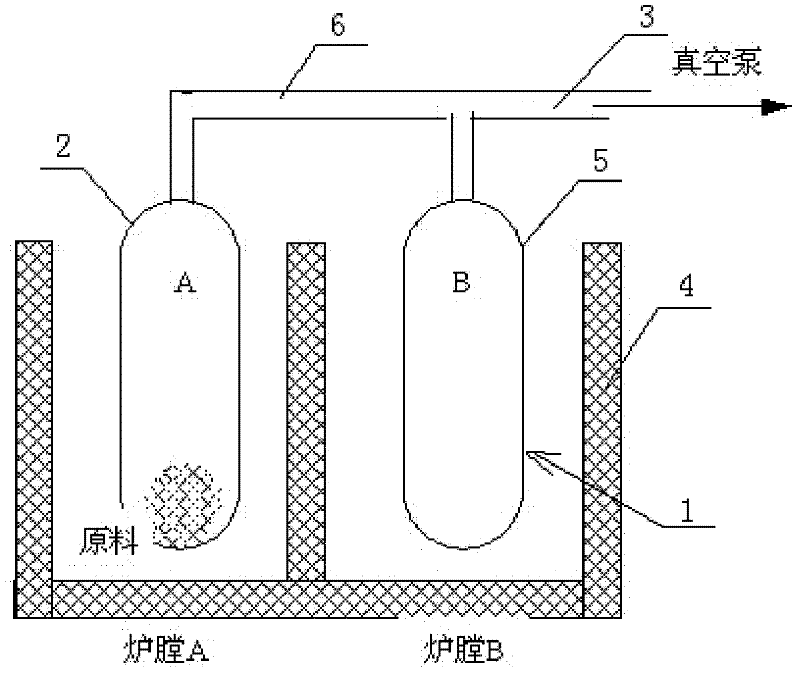

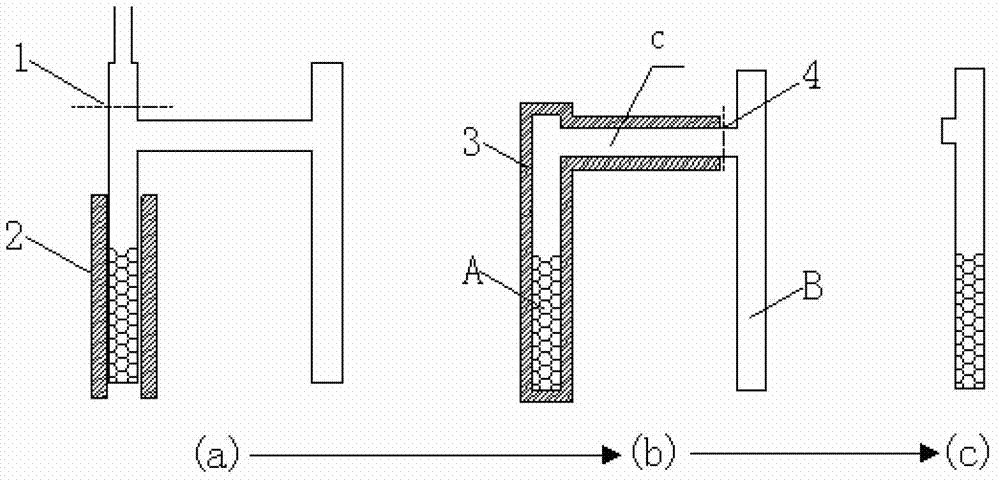

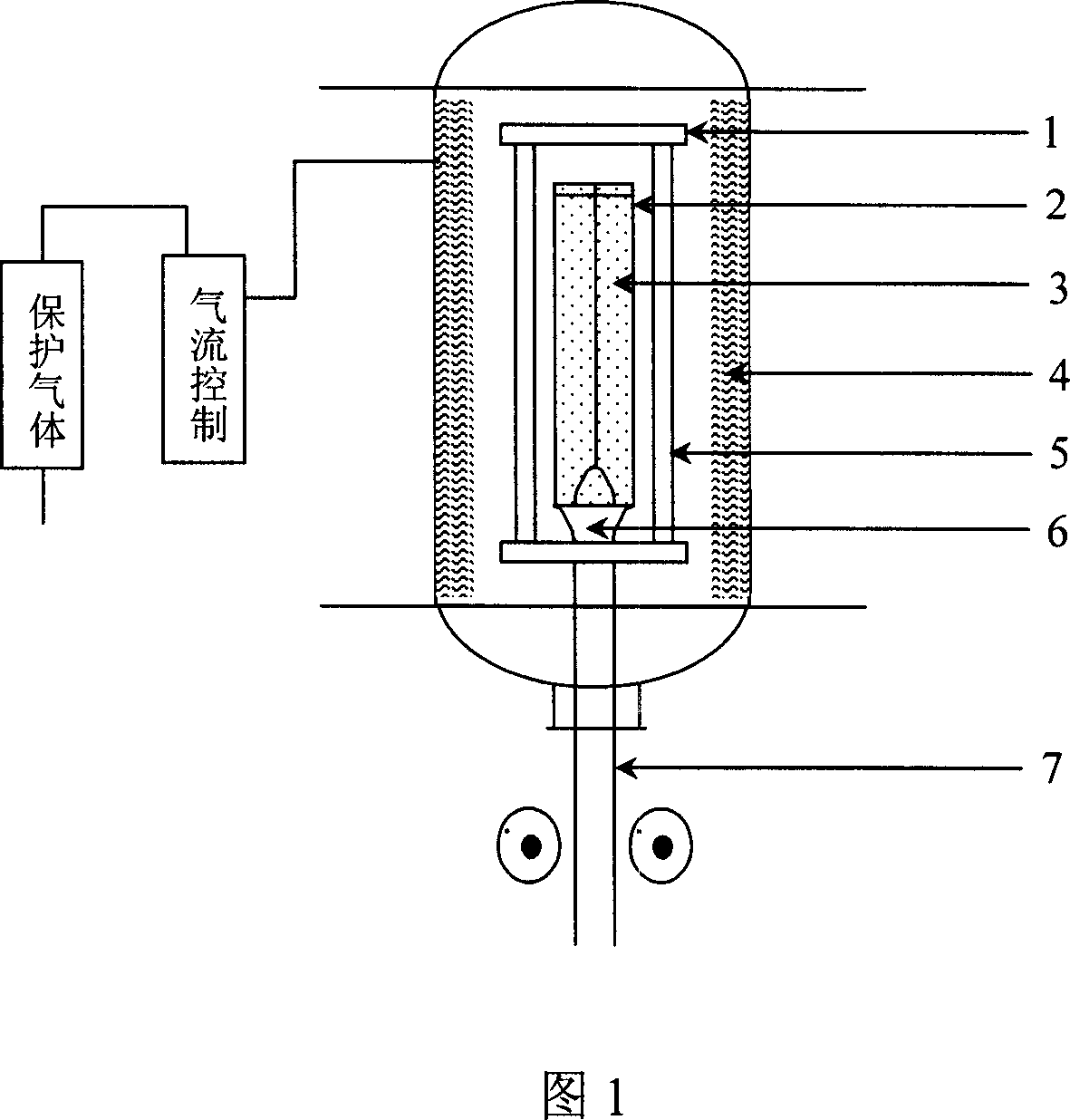

Apparatus and method for producing high-purity sulphur glass

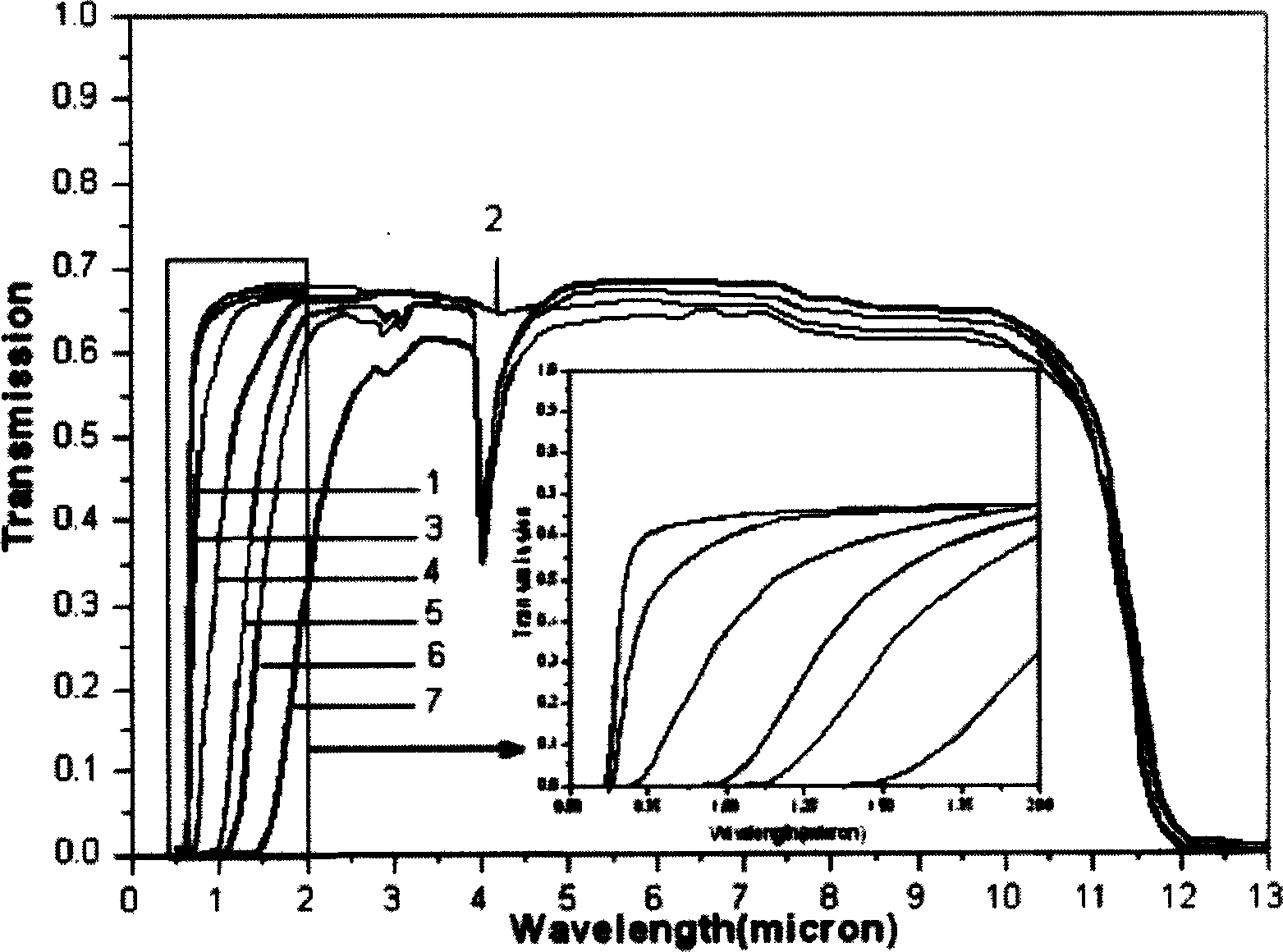

ActiveCN101492235AUniform optical qualityGood infrared transmittancePot furnacesGlass furnace apparatusTemperature controlChalcogenide glass

The invention discloses a device for preparing high-purity chalcogenide glass, which is characterized by comprising a swaying furnace body with the function of swaying backwards and forwards and a quartz ampoule, wherein the swaying furnace body is provided with a first hearth and a second hearth which are provided with an independent temperature control and heating system respectively and are communicated with each other through a transition area; the quartz ampoule comprises a glass raw material tube and a purification glass tube which are communicated with each other through a connecting tube; the glass raw material tube is arranged in the first hearth; the purification glass tube is arranged in the second hearth; and the connecting tube is positioned in the transition area. The device has the advantages that one quartz ampoule provided with the glass raw material tube and the purification glass tube is arranged on the device, the glass raw material tube and the purification glass tube are placed in two hearths with different temperatures respectively, the temperature difference between the two hearths is controlled to realize the purification of glass so that the high-purity chalcogenide glass with even optical quality and good infrared light transmittance can be obtained.

Owner:NINGBO UNIV +1

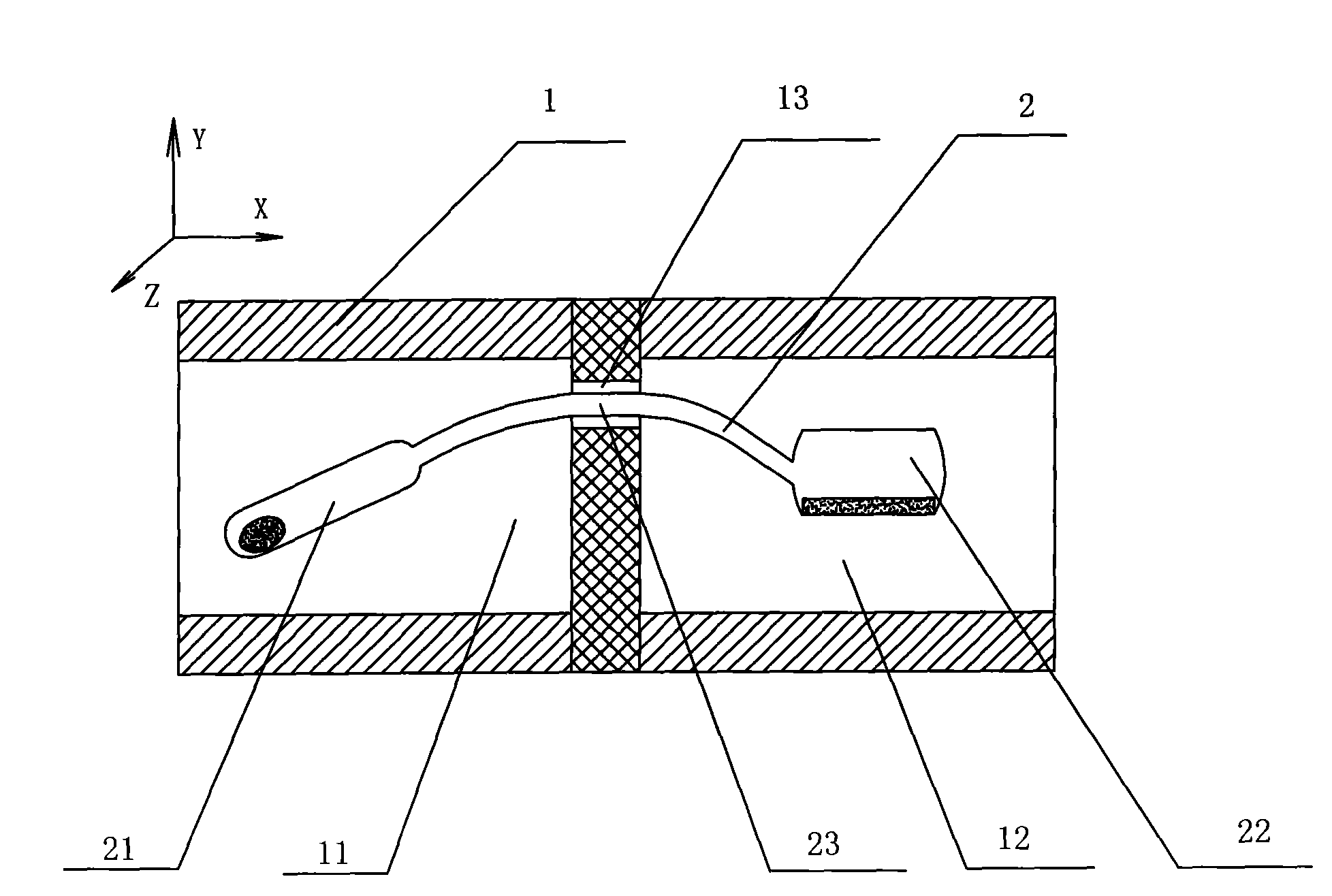

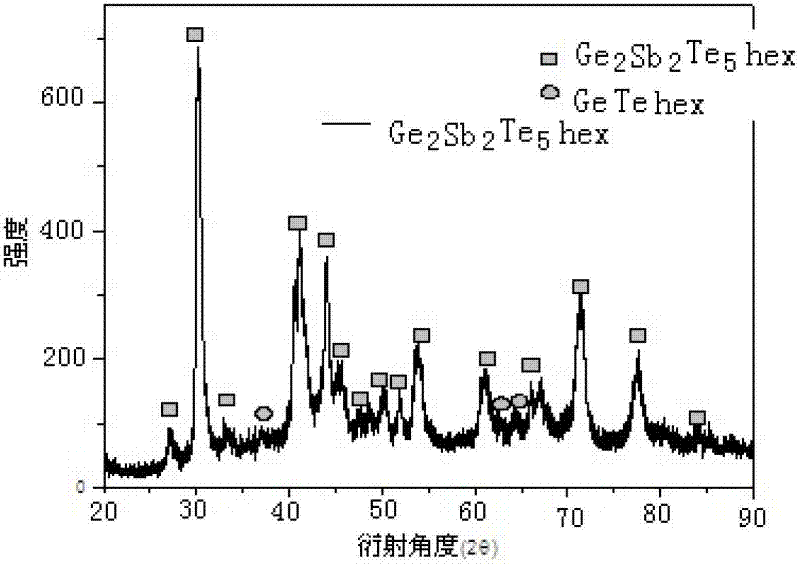

High-purity chalcogenide phase change alloy target and preparation method for same

The invention discloses a high-purity chalcogenide phase change alloy target and a preparation method for the same. The high-purity chalcogenide phase change alloy target is characterized by mainly comprising, by weight, 0-20% of germanium, 20-40% of antimony and 50-70% of tellurium, the weight number sum of a mixture consisting of various raw materials is 100%, and 0.1wt% of magnesium rods and 300ppm of TeCl4 are added into the mixture. The preparation method includes: proportionally mixing the raw materials for the target respectively with the purity of 99.99%, and adding the magnesium rods and the TeCl4; filling the mixture into an H-shaped double-barreled quartz ampoule, and sealing after vacuum is controlled; placing the double-barreled quartz ampoule into a double-barreled distilling furnace for distillation and purification; and finally, placing a quartz tube containing purified simple substance germanium, simple substance antimony and simple substance tellurium into a rocking furnace, and founding and annealing so as to obtain the product. The high-purity chalcogenide phase change alloy target is even in components and high in purity, and the method is simple in operation process, non-corrosive, short in processing cycle and high in efficiency.

Owner:NINGBO UNIV

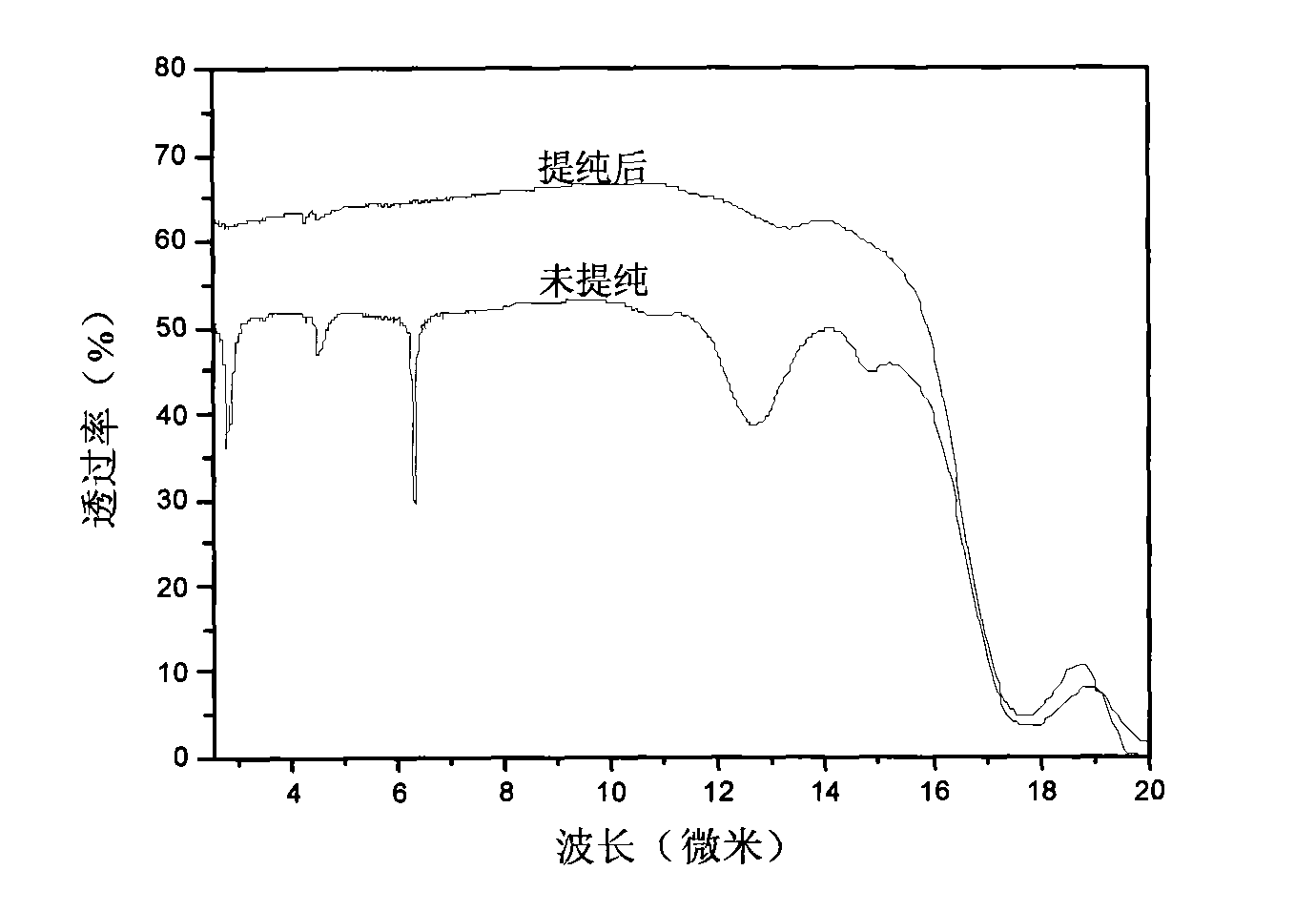

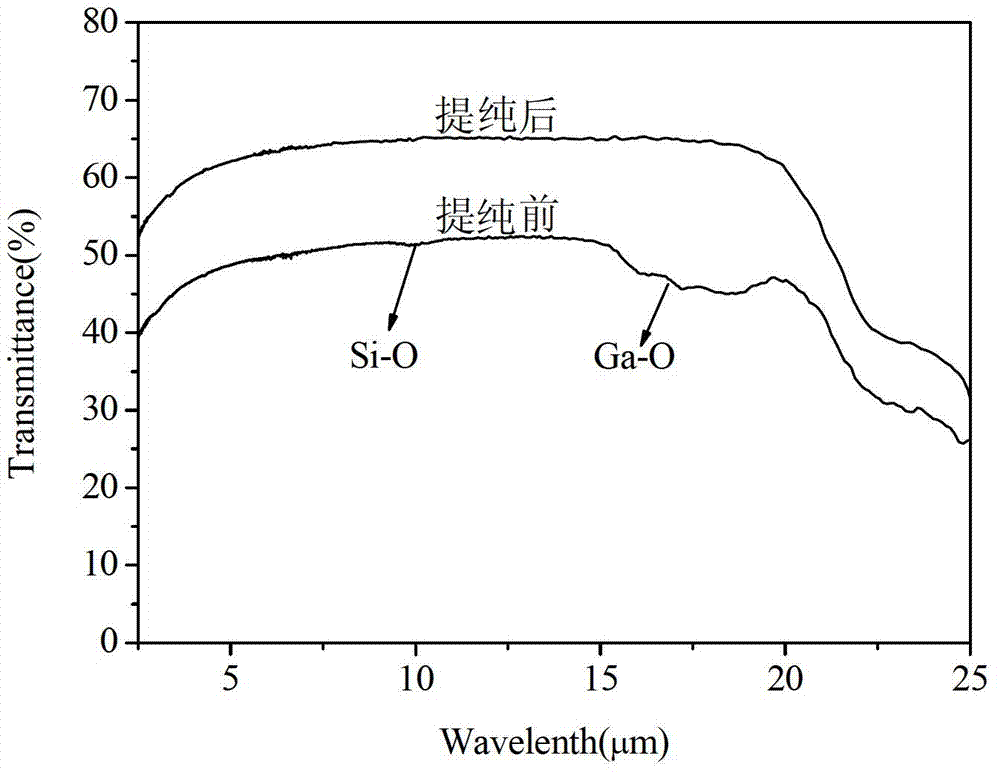

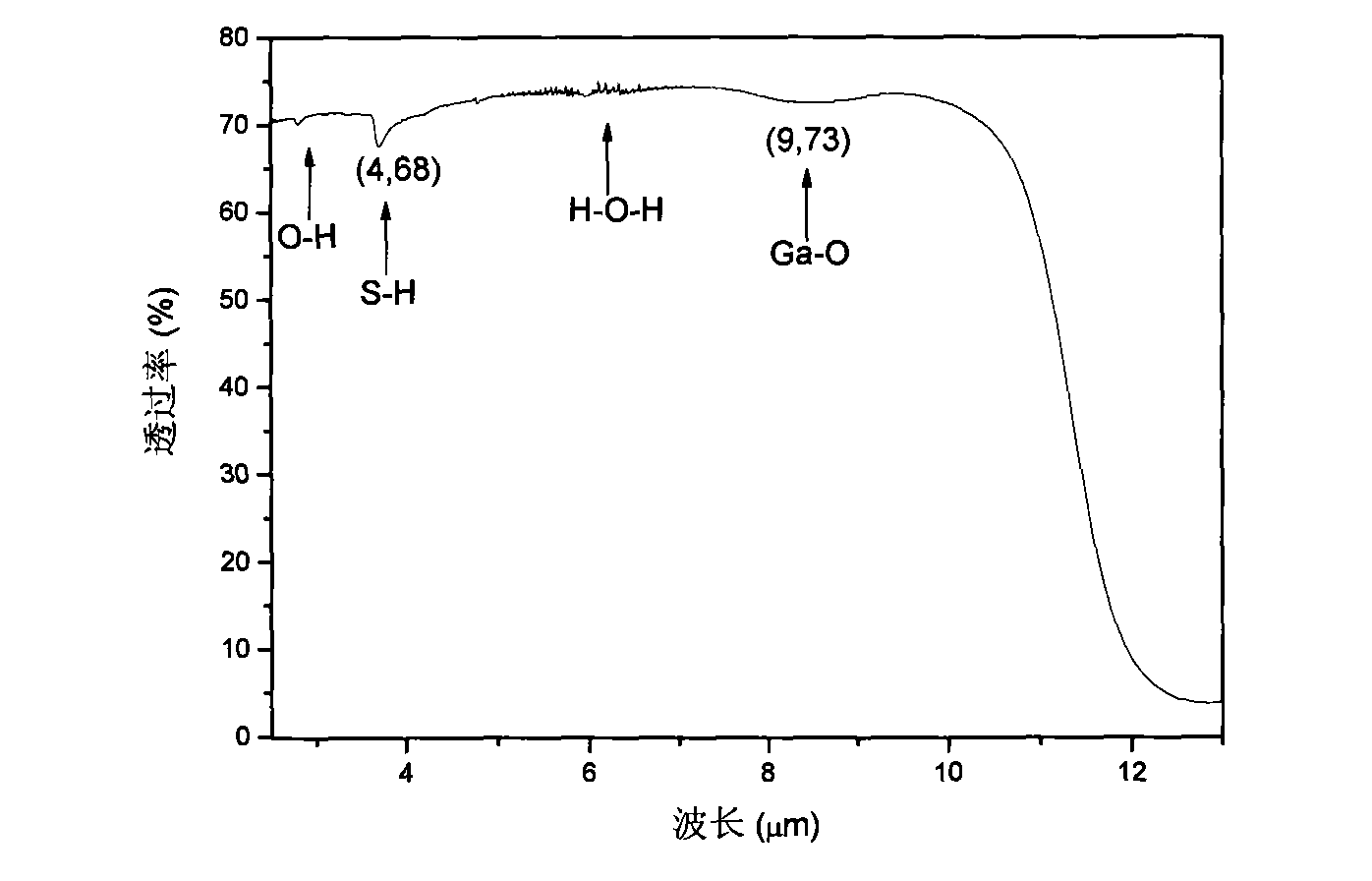

Preparation method of high-purity and low-loss chalcogenide glass

InactiveCN103332851AImprove uniformityHigh purityGlass furnace apparatusChalcogenide glassPhotochemistry

The invention provides a preparation method of high-purity and low-loss chalcogenide glass, belonging to a preparation method of the chalcogenide glass. The preparation method comprises the following steps of: removing hydrocarbon impurity in the glass by taking ultra-dry gallium chloride as a purifying agent, and distilling and purifying the glass in combination with the conventional deoxidant, aluminum, magnesium or zirconium metal; placing glass mixture into a quartz ampoule to be sealed in by means of vacuum supply, founding the glass mixture in a vacuum ampoule, dynamically distilling the glass, and remelting the mixture after distilling; and effectively removing the hydrocarbon impurity in the glass by taking the ultra-dry gallium chloride as the purifying agent, so that the Mie scattering imperfection is hardly formed in the finally-obtained high-purity chalcogenide glass, and the low-loss homogeneous glass can be obtained. According to the high-purity chalcogenide glass synthesized by the preparation method provided by the invention, the minimum loss under the infrared transmission waveband is less than 0.3dB / m, and the corresponding loss of the absorption peak of the residual impurity is less than 8dB / m, so that the preparation method can be used in the field of an infrared glass optical element and an infrared optical fiber. The ultra-dry gallium chloride purifying agent can be easily obtained, and is lower in price; the carbon, hydrogen and oxygen impurities can be removed from the chalcogenide glass at high efficiency; the prepared chalcogenide glass is better in uniformity and less in light scattering.

Owner:XUZHOU NORMAL UNIVERSITY

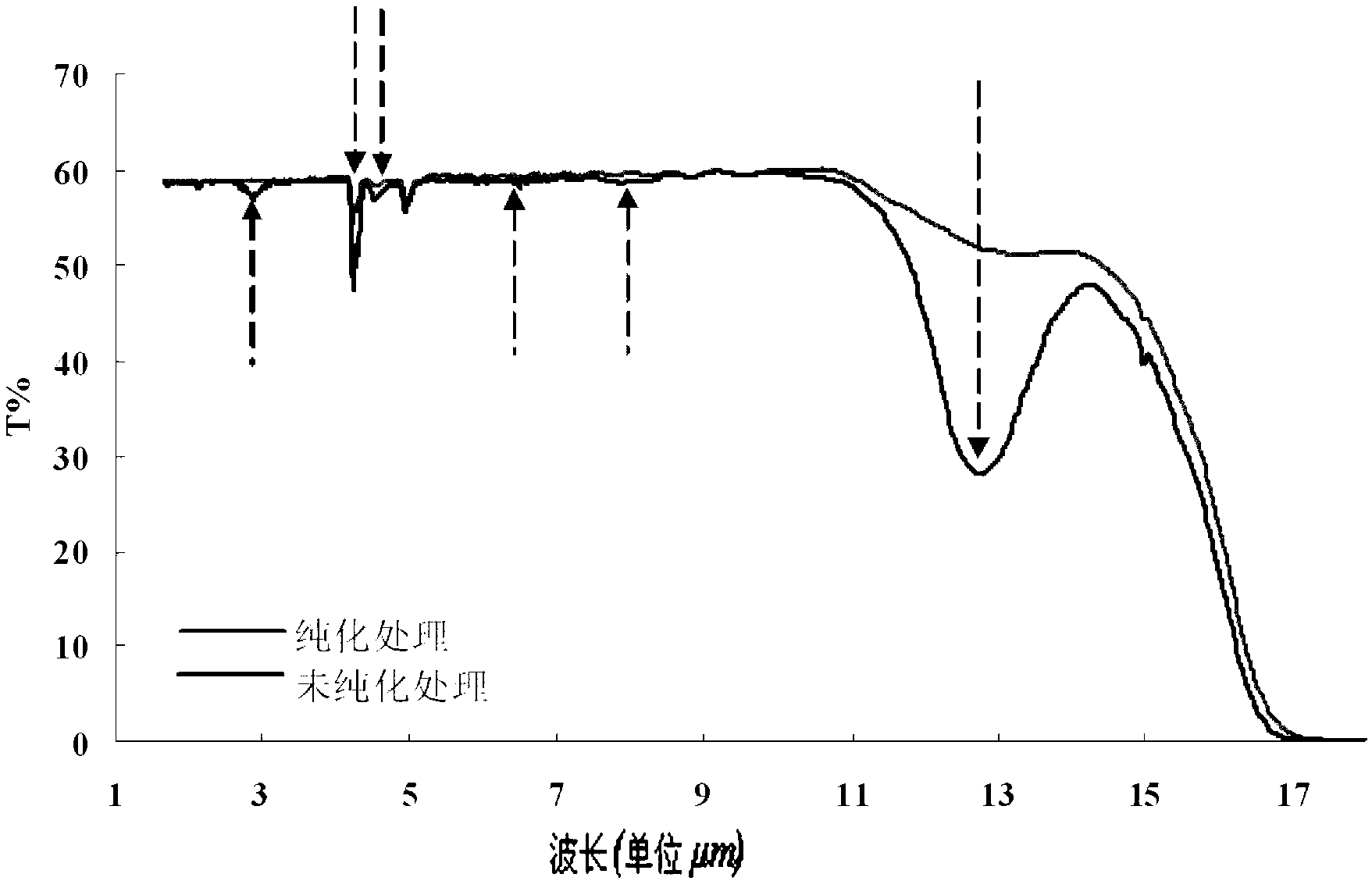

Purification method for preparing high-purity infrared chalcogenide glass, and apparatus thereof

The invention discloses a purification method for preparing high-purity infrared chalcogenide glass, and an apparatus thereof. The purification method comprises the following steps: 1, fully mixing a chalcogenide glass raw material and a deoxidant to obtain a mixture, placing the mixture in a quartz ampoule, and pre-evacuating the quartz ampoule until the vacuum degree is less than or equal to 5*10<-4>Pa; 2, placing the evacuated quartz ampoule in a purifying furnace, carrying out raw material entirety purification at 200-400DEG C for 1-6h, and cooling the portions of the quartz ampoule outside the purifying furnace for solidifying volatile components; and 3, cooling the quartz ampoule to room temperature after the purification is completed, carrying out 900-950DEG C high-temperature melting of the quartz ampoule melt-sealed by the oxyhydrogen flame in a rocking furnace, carrying out heat insulation for 6-20h, cooling to 500-650DEG C, and quenching to obtain a chalcogenide glass blank. The method can effectively eliminate impurity peaks in a 1-13mum infrared area range of the chalcogenide glass.

Owner:CHINA BUILDING MATERIALS ACAD

Preparation method of zinc selenide polycrystalline material for single crystal growth

InactiveCN101665245AShort holding timeHigh yieldPolycrystalline material growthZinc compoundsZinc selenideSingle crystal

The invention discloses a preparation method of a zinc selenide polycrystalline material for single crystal growth. The zinc selenide polycrystalline material is prepared from blocky zinc and blocky selenium of which the purities are over 99.999 percent as raw materials in an electronic-grade quartz ampoule. The preparation method comprises the following steps: removing impurities on the inner wall of the ampoule; feeding the zinc and the selenium in a molar ratio of (1.0-1.05):1.0 into the ampoule; feeding a reaction promoter of which the volume concentration is 3-12mg.cm<-3> into the ampoule; evacuating the ampoule, sealing the ampoule, horizontally standing the ampoule in a tube furnace, and quickly raising the temperature to between 94 and 1,000 DEG C; and after maintaining the temperature, cooling the ampoule to a room temperature to generate a large amount of high-purity zinc selenide polycrystalline powder. The zinc selenide polycrystalline powdery material prepared by the invention has the components of Zn and Se, with high purity of over 99.999 percent, in a ratio of 1.0:(1.0-1.03), and can be directly used as a growing raw material of a zinc selenide single crystal. The preparation method has the advantages of simple process, low cost and wide application range.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

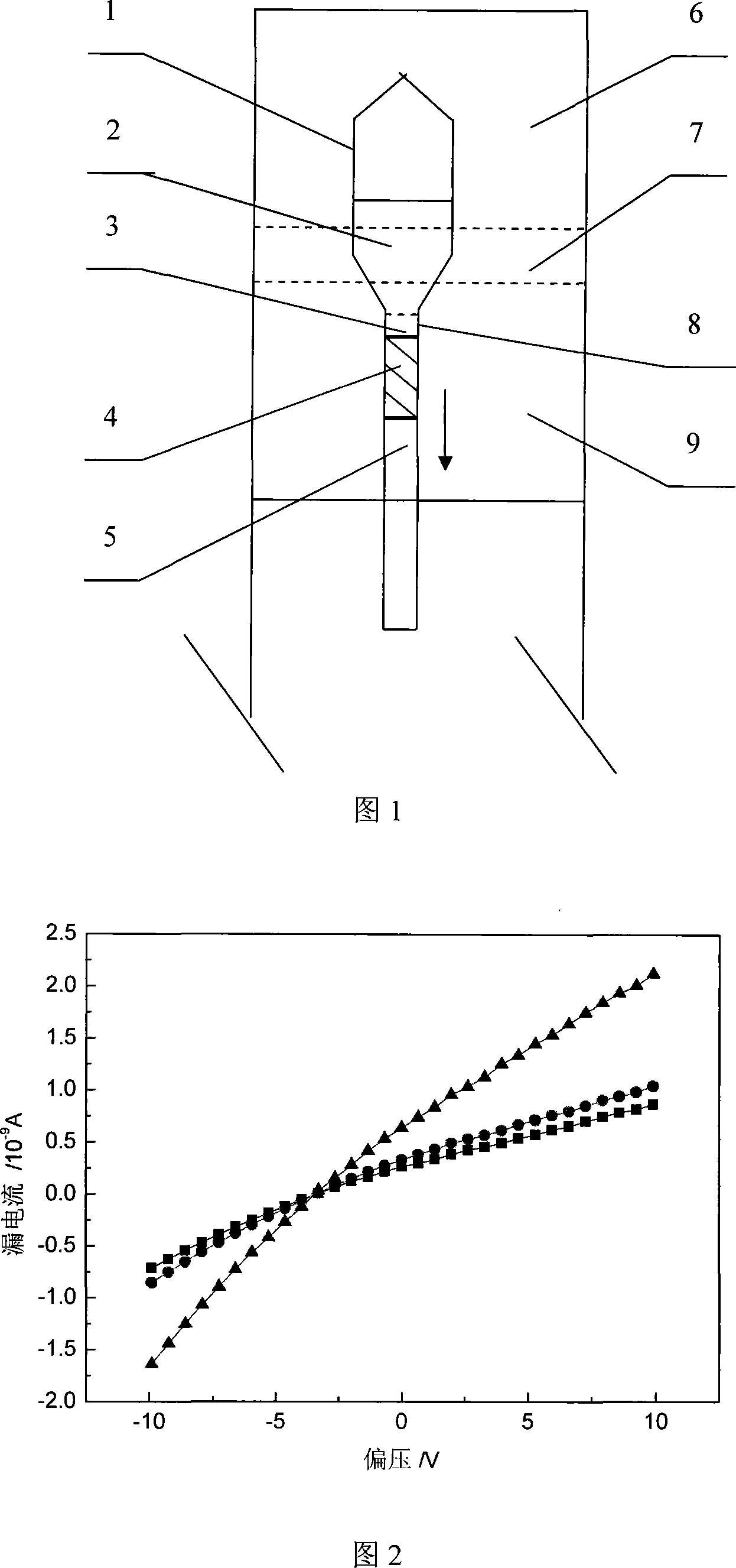

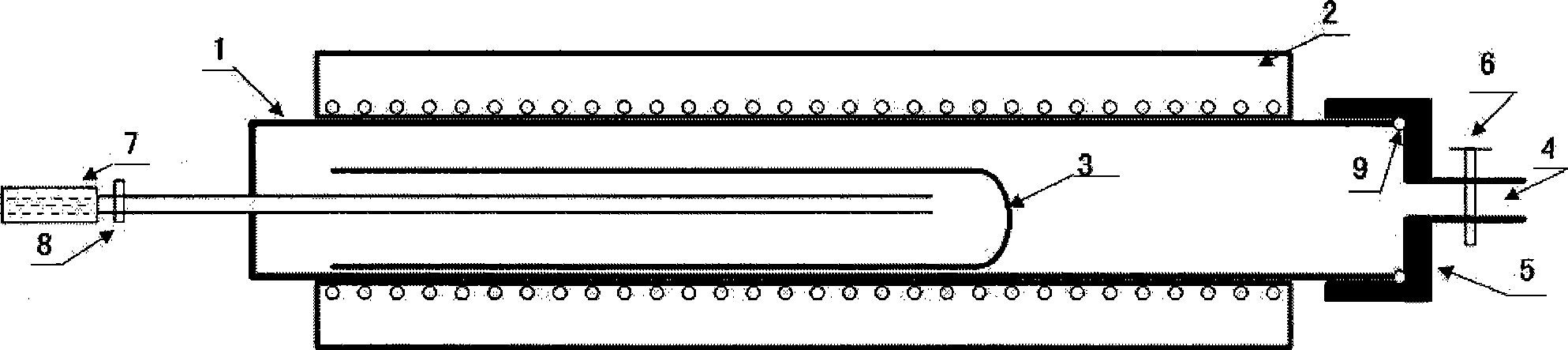

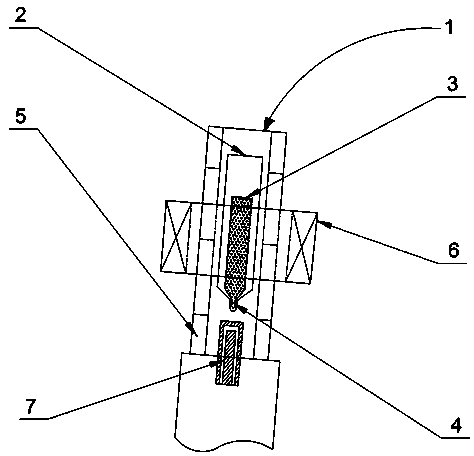

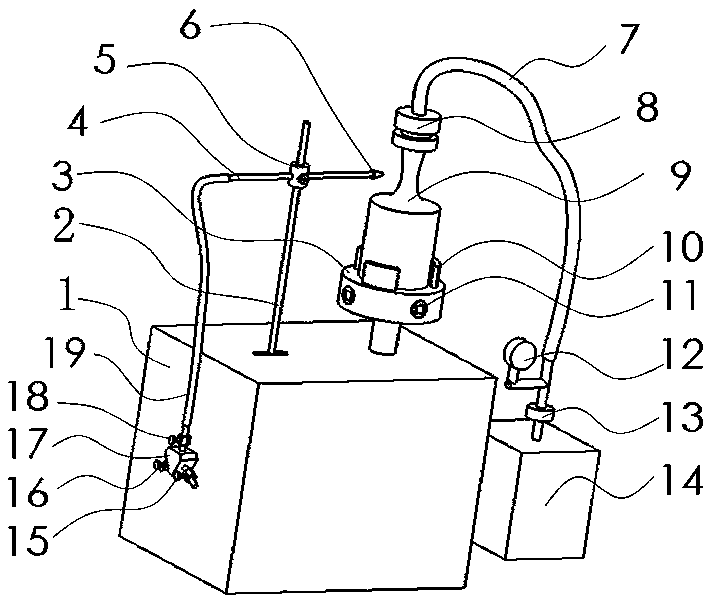

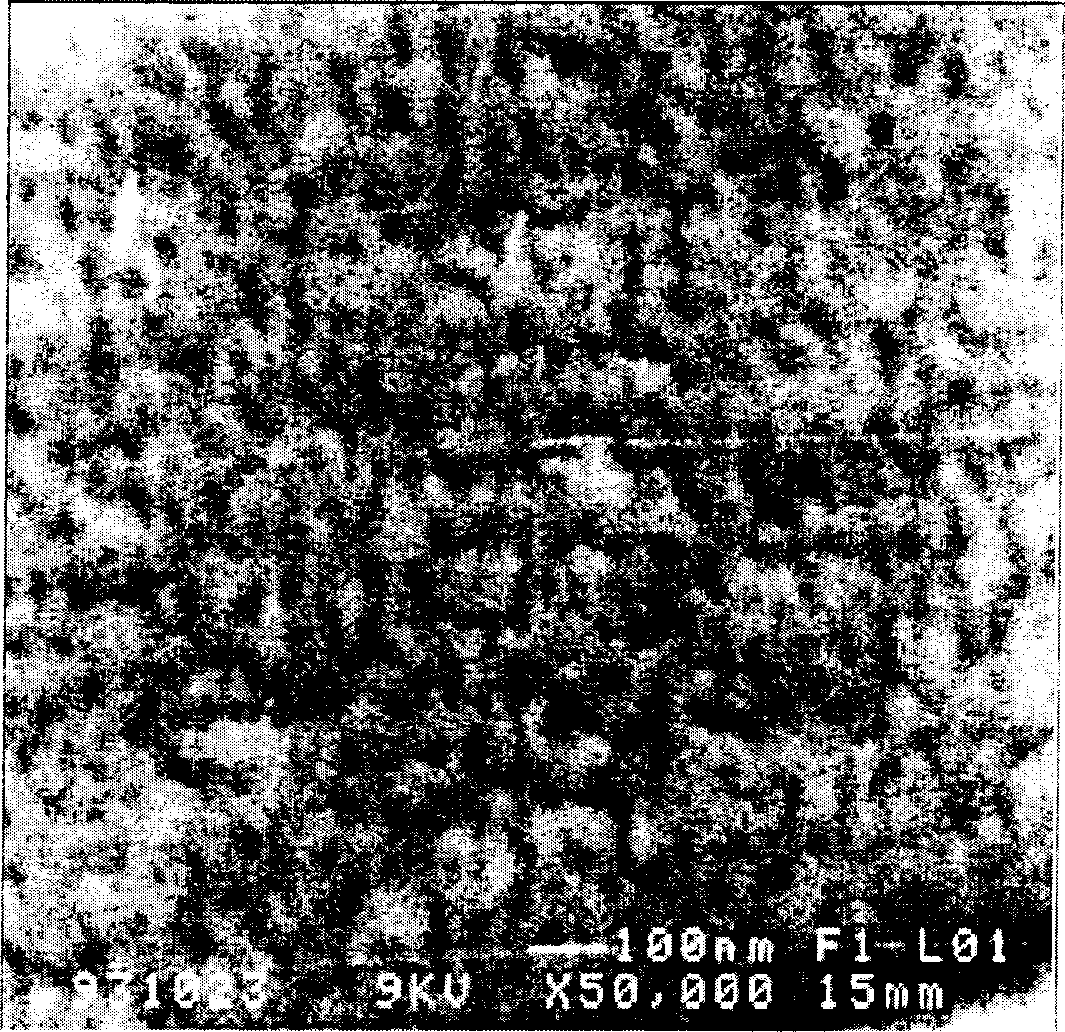

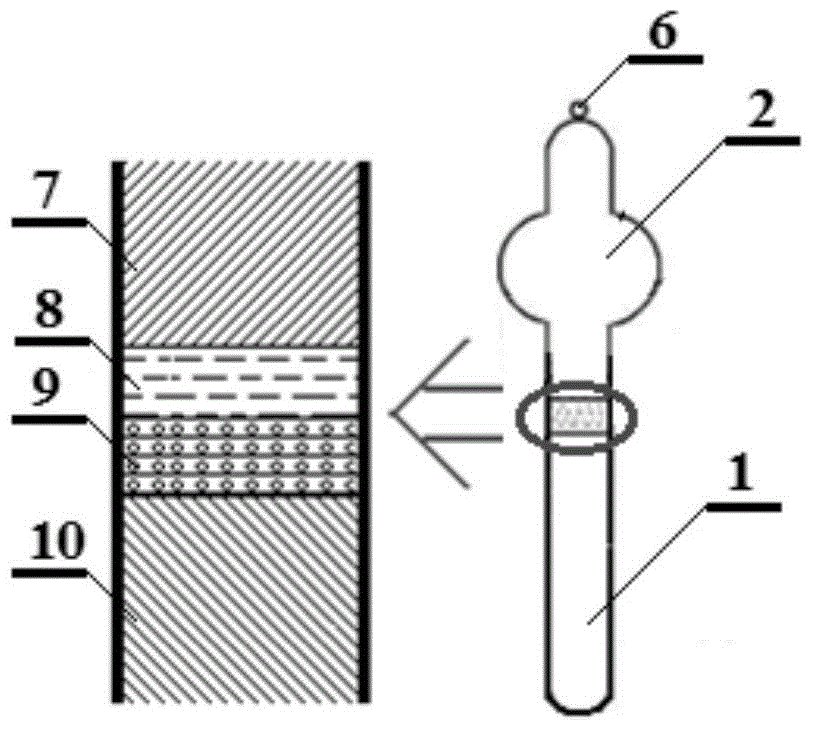

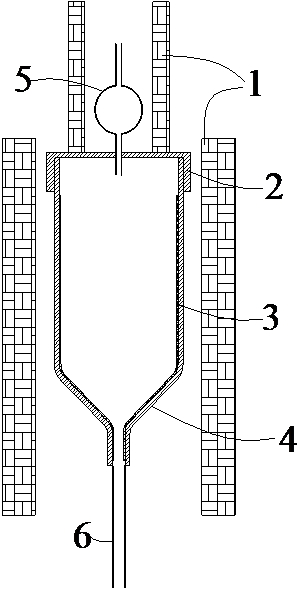

Method for plating carbon film on ampoule internal wall for CdZnTe crystal growth and apparatus thereof

The invention relates to a method for coating a carbon film on the inner wall of a quartz ampoule applied to CdZnTe crystal growth, and equipment thereof, pertaining to the technical field of the coating technique of a vessel used for special crystal growth. The invention adopts a vacuum thermal decomposition coating technique; the quartz ampoule to be coated with carbon is put into a quartz furnace tube of a heating furnace; the vacuum degree thereof is maintained between 10<-1>Pa and 10<-3>Pa by virtue of a vacuum pumping system; at the same time, absolute ethyl alcohol which acts as a carbon source is pumped in, with the flow controlled between 0.5ml / min and 5ml / min; the quartz ampoule is heated in the vacuum until the temperature reaches the thermal decomposition coating temperature which is between 950 DEG C and 1100 DEG C; the heating is maintained for 10min and 60min at the temperature to guarantee the full deposition of the carbon; and the quartz ampoule coated with the carbon film is obtained after the temperature is reduced to room temperature. The method can produce the quartz ampoule coated with the carbon film, with high adhesion and compactness, and the carbon film is not easy to fall off, thereby being conducive to the synthetic growth of CdZnTe crystal.

Owner:SHANGHAI UNIV

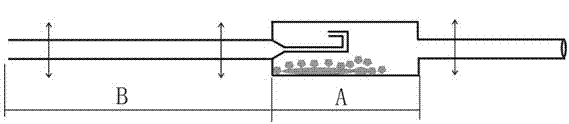

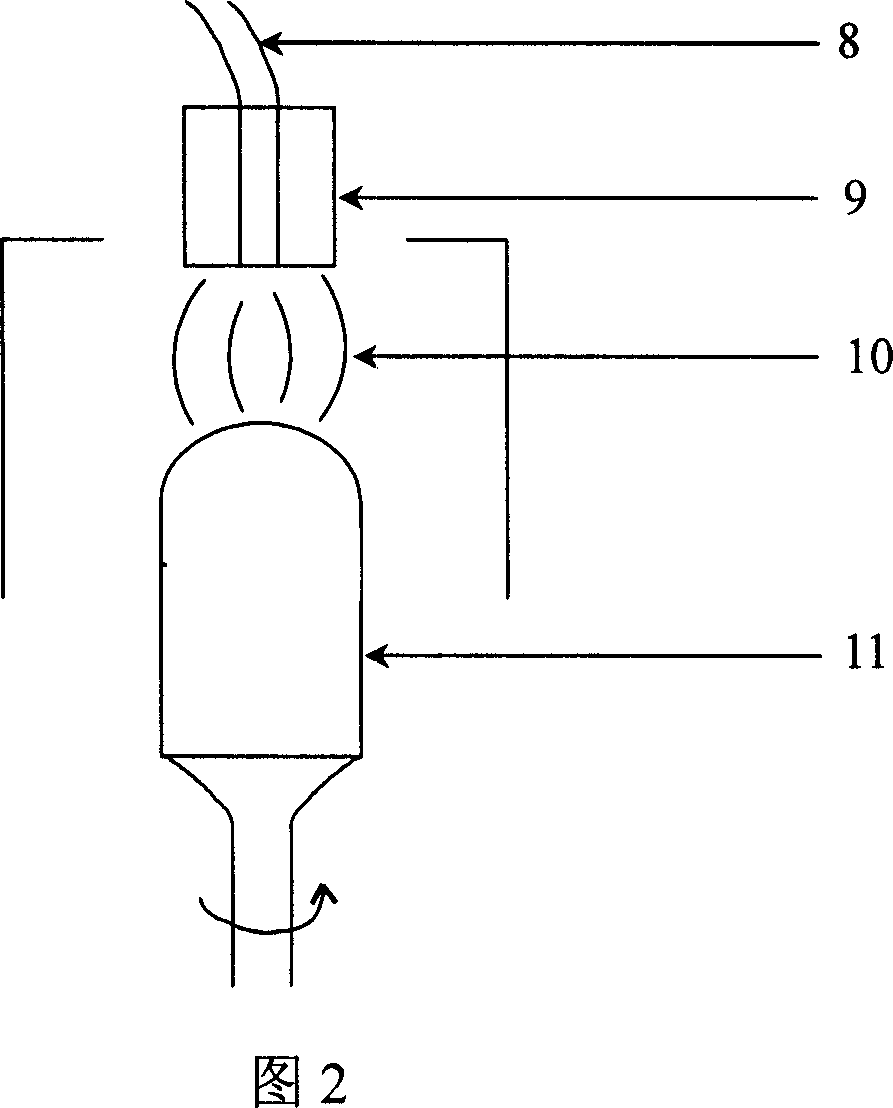

Preparation device of gallium-containing chalcogenide glass having high melting point and high boiling point, and preparation method thereof

The invention discloses a preparation device of gallium-containing chalcogenide glass having a high melting point and a high boiling point, and a preparation method thereof. The preparation device comprises a resistive heating system, an instant heating furnace, and an H-shaped quartz ampoule, wherein the resistive heating system has a temperature controller; the instant heating furnace can rapidly heat a glass raw material tube and a connection tube; the H-shaped quartz ampoule comprises the glass raw material tube and a purification glass tube; the glass raw material tube is communicated with the purification glass tube through the connection tube; and the upper end opening of the glass raw material tube is connected with a vacuum pump. The preparation device has the following advantage: the heating system can instantly heat the glass raw material tube and the connection tube to 1400DEG C to rapidly gasify a glass raw material in the glass raw material tube, the gasified glass raw material is distilled to the purification glass tube by going through the connection tube, and impurities are residual in the glass raw material tube because of high melting points, so the gallium-containing chalcogenide glass with low impurity contents is obtained.

Owner:NINGBO UNIV

Method and device for growing germanium crystal

ActiveCN101736401APolycrystalline material growthFrom frozen solutionsCrucibleCrystallization temperature

The invention discloses a method and a device for growing a germanium crystal. The method comprises the following steps of: loading a first Ge raw material into a crucible which is provided with a crystal seed mixer with crystal seeds placed therein; loading a second Ge raw material into a loading container which is to be arranged in a quartz ampoule and is used for replenishing the Ge material; sealing the crucible and the loading container in the quartz ampoule; putting the quartz ampoule sealed with the crucible and the loading container into a crystal growing melting furnace provided with a movable ampoule supporting seat which supports the quartz ampoule; melting the first Ge raw material in the crucible to generate a molten mass; melting the second Ge raw material in the container and adding the second Ge raw material into the molten mass; controlling the crystallization temperature gradient of the molten mass so that the molten mass is crystallized when contacting the crystal seeds to form a monocrystalline germanium crystal bar; and cooling the monocrystalline germanium crystal bar. The invention also provides the device which can be used for implementing the method and comprises the loading container, wherein a process for forming the monocrystalline germanium crystal bar includes bluidling 0.3-2.5DEG / cm of temperature gradient in a crystal bar growing zone.

Owner:AXT INC +1

Broadband-spectrum optical glass and method of producing the same

ActiveCN101492249ALight transmission is easyEasy to manufactureGlass furnace apparatusDouble tubeMetallurgy

The invention relates to broad-spectrum optical glass and a preparation method thereof, which is characterized in that: (1) the glass comprises the following components in percentage by mol: 20 to 33 percent of Ga2S3, 5 to 40 percent of GeS, 38 to 67 percent of CsX, and 2 to 5 percent of YS2; the preparation method comprises the following steps: mixing elementary substances such as Ga, Ge and S and compounds such as CsX and YS2 to obtain a mixture, and putting 0.01 weight percent of magnesium ribbon as deoxidizer into the mixture, wherein X is Cl or I or Br; and Y is Ti or Zr or Hf; (2) filling the mixture into one quartz tube in an H-shaped double-tube quartz ampoule subjected to dehydroxylation pretreatment, vacuumizing the quartz tube, and sealing the quartz ampoule by hydrogen flame when the pressure is less than or equal to 1*10Pa; (3) putting the sealed quartz ampoule filled with the mixture into a double-tube distilling furnace, distilling and purifying the mixture to obtain extract of Ge, Ga and S in the other quartz tube of the H-shaped double-tube quartz ampoule; and (4) putting the purified quartz ampoule into a rocking furnace, slowly heating the quartz ampoule to between 800 and 950 DEG C, smelting the mixture for 8 to 12 hours by rocking, then taking out and cooling the mixture, preserving heat at a temperature of between 150 and 330 DEG C, and then carrying out related annealing treatment to obtain a broad-spectrum optical glass product.

Owner:宁波阳光和谱光电科技有限公司

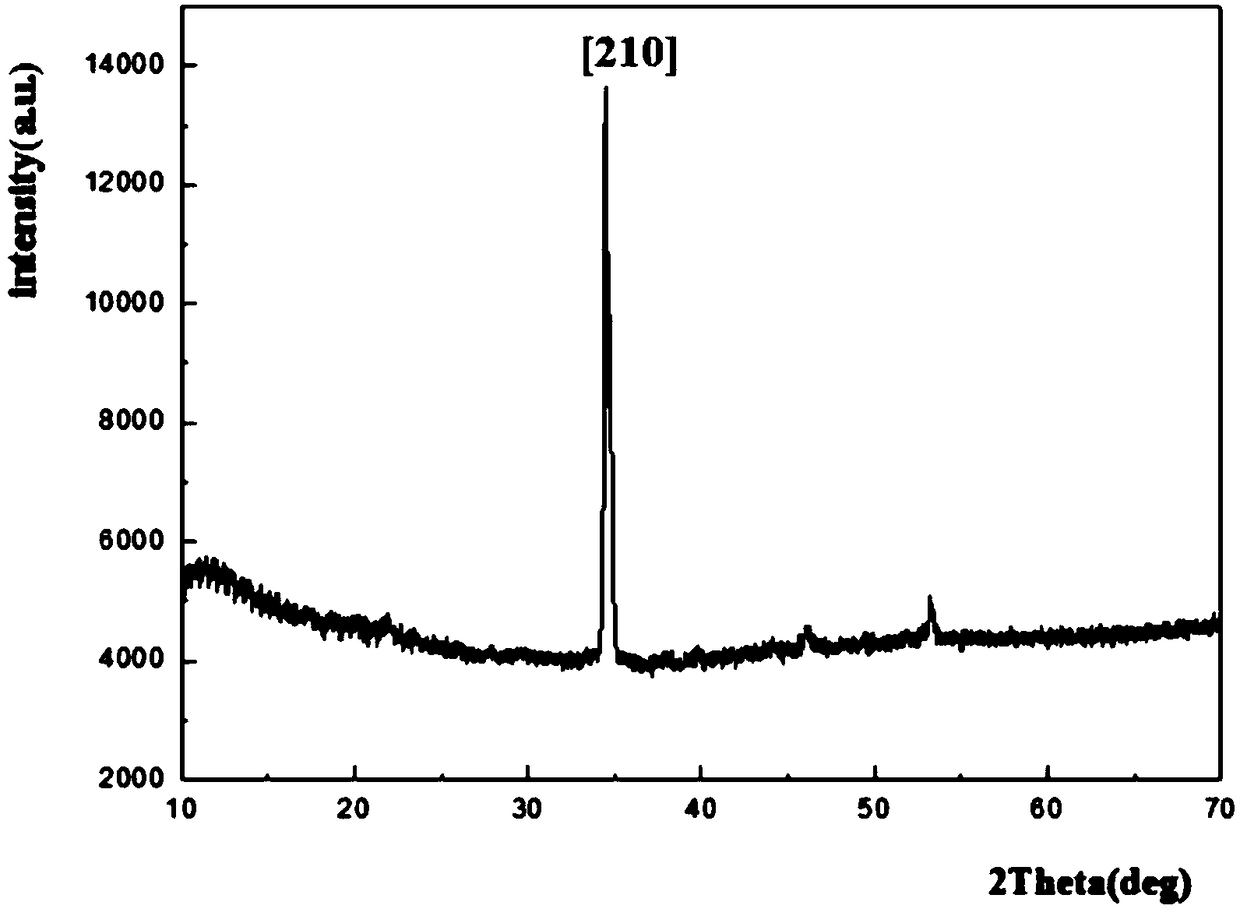

Prepn process of Ce-doped lanthanum oxide scintillation crystal

The present invention is preparation process of Ce-doped lanthanum chloride scintillation crystal. The scintillation crystal has the chemical composition of La(1-x)CexCl3, where x is 0.01-0.2, and features that La2O3, anhydrous NH4Cl, CeCl3 .7H2O and other facile chemical materials are pretreated, converted and molten to form ingot and the ingot is set quartz ampoule bottle for growing Ce-doped lanthanum chloride scintillation crystal through a falling crucible process. The present invention has common industrial material adopted and simple production process, and the prepared crystal has relatively low oxygen impurity and relatively high optical quality.

Owner:北京工物科技有限责任公司

Growing method of gallium arsenide monocrystalline

ActiveCN106319630ASolving the problem of not wetting with quartz cruciblesSolve the problem of low crystal growth ratePolycrystalline material growthFrom frozen solutionsGallium arsenateSeed crystal

The invention provides a growing method of gallium arsenide monocrystalline. The method comprises the following components: (1) a quartz crucible is cleaned; (2) the quartz crucible is placed in a quartz tube which contains gallium of high purity, vacuum-pumping and inflation operation are repeatedly carried out for the quartz tube, and finally inert gas or nitrogen is filled; (3) the quartz tube is heated till the temperature in the quartz tube reaches to 1240 DEG C or above and insulation is carried out, and the quartz tube is cooled to room temperature; (4) the quartz crucible is taken out from the quartz tube and is immersed in acid, deionized water is used for washing, absolute ethyl alcohol is used for carrying out dehydration treatment, and the quartz crucible is placed in a drying box for standby; (5) seed crystal, polycrystalline materials, and the balance being arsenic are placed in the quartz crucible in order according to charging requirements, the quartz crucible is placed in a quartz ampoule, and vacuum-pumping, baking and soldering and sealing treatment are carried out; (6) a traditional VGF method is used for accomplishing the growth of gallium arsenide monocrystalline. PBN crucibles are not used, a liquid sealing agent B2O3 is not used, and GaAs monocrystalline is not polluted by extra introduction of B element from the source.

Owner:广东先导微电子科技有限公司

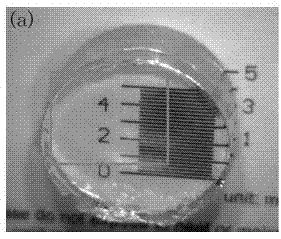

Method for coating carbon on quartz ampoule for growing crystals

The invention discloses a method for coating carbon on a quartz ampoule for growing crystals. The method comprises the following steps: putting a to-be-coated quartz ampoule by carbon into a tube furnace, increasing the temperature of the tube furnace to the temperature for coating carbon, and exhausting air in the tube furnace; then introducing acetylene which serves as a carbon source into the tube furnace, pyrolyzing the acetylene at a high temperature, and depositing a layer of carbon film on the inner wall of the quartz ampoule; and finally post-processsing the carbon film. By adopting the method disclosed by the invention, a gas way device can be simplified, no vacuum device and exhaust pipe needs to be installed, and the efficiency of coating carbon can be improved significantly. In addition, the method can meet the carbon coating requirements of quartz ampoules of various sizes and shapes.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

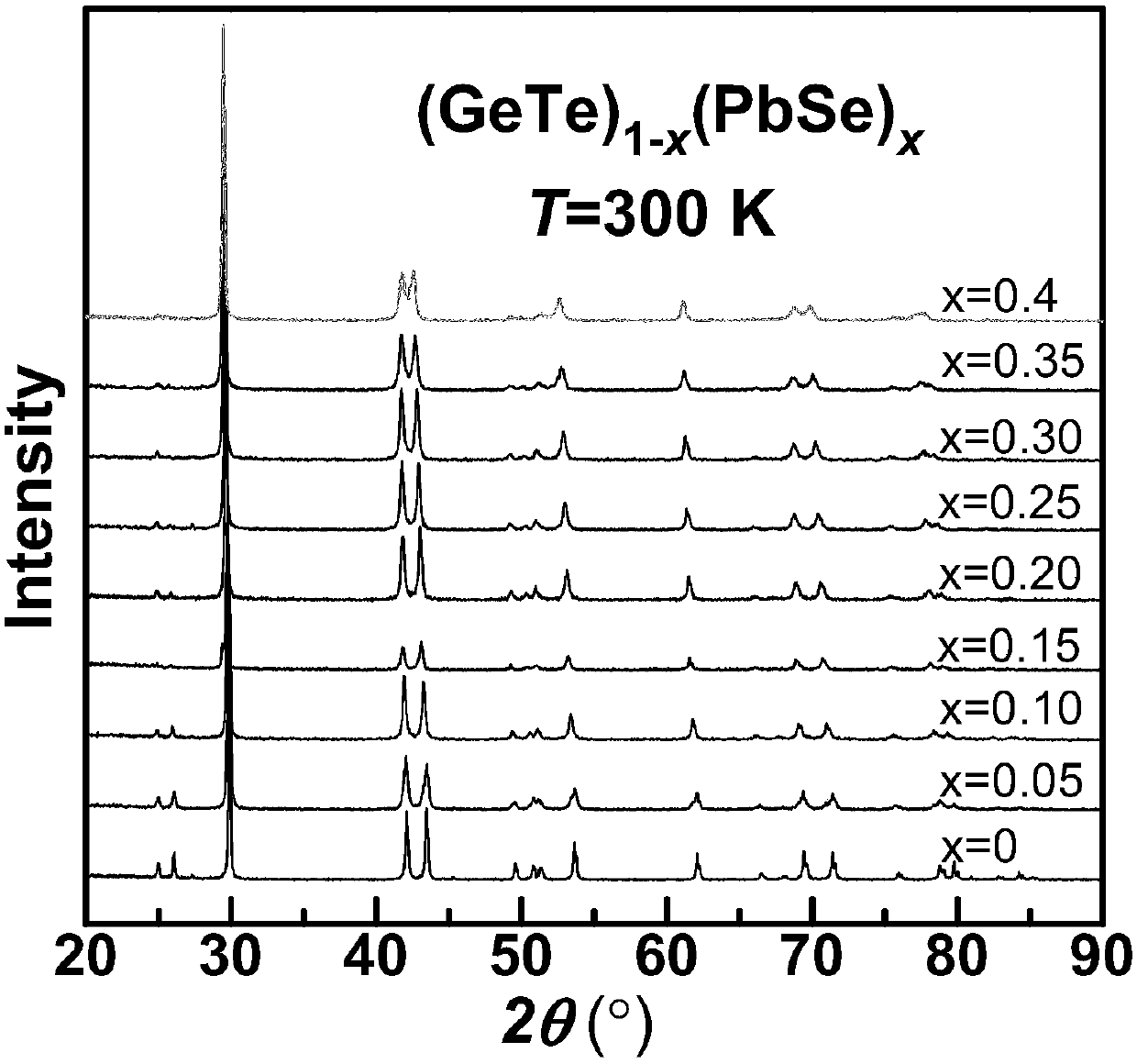

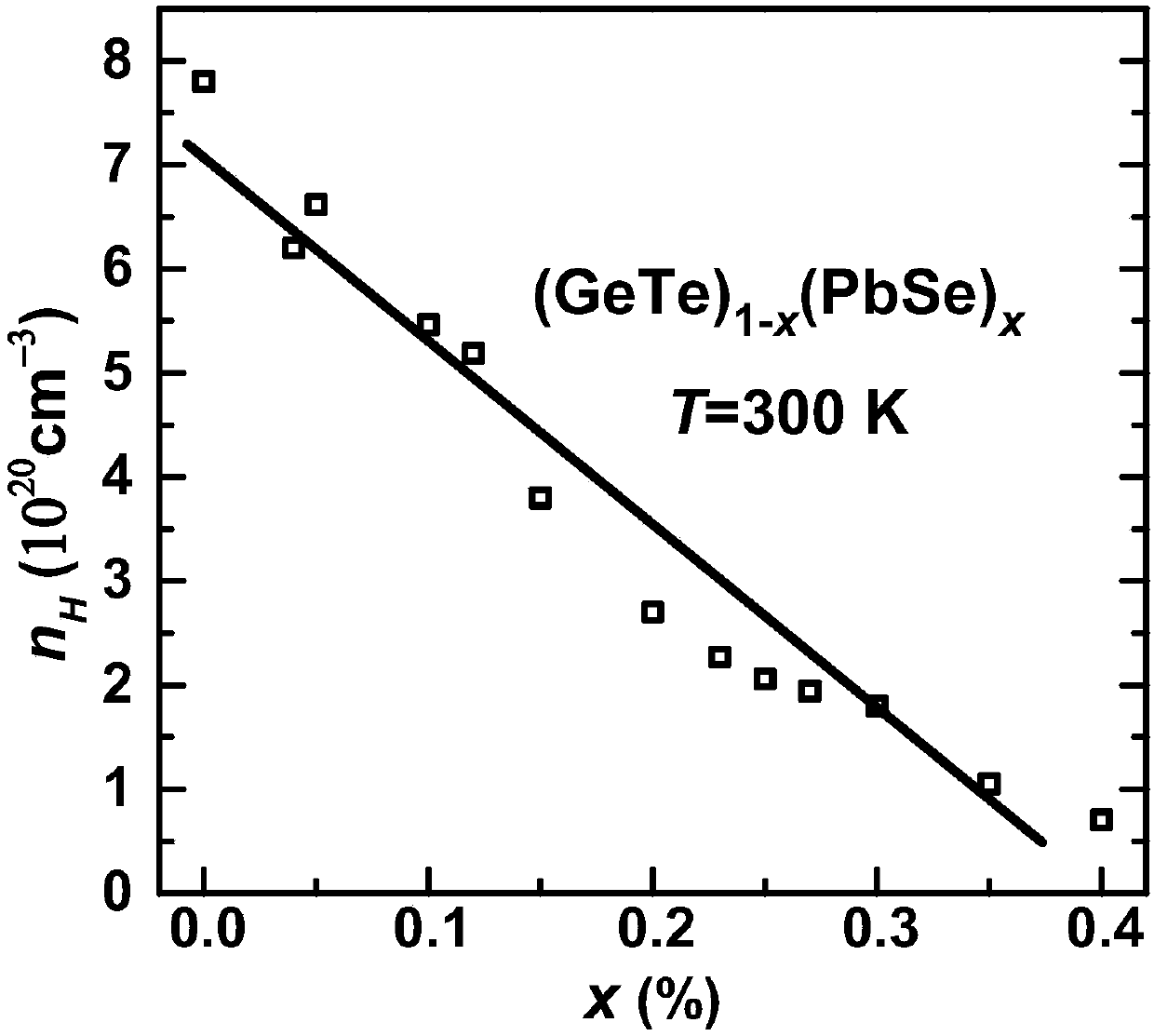

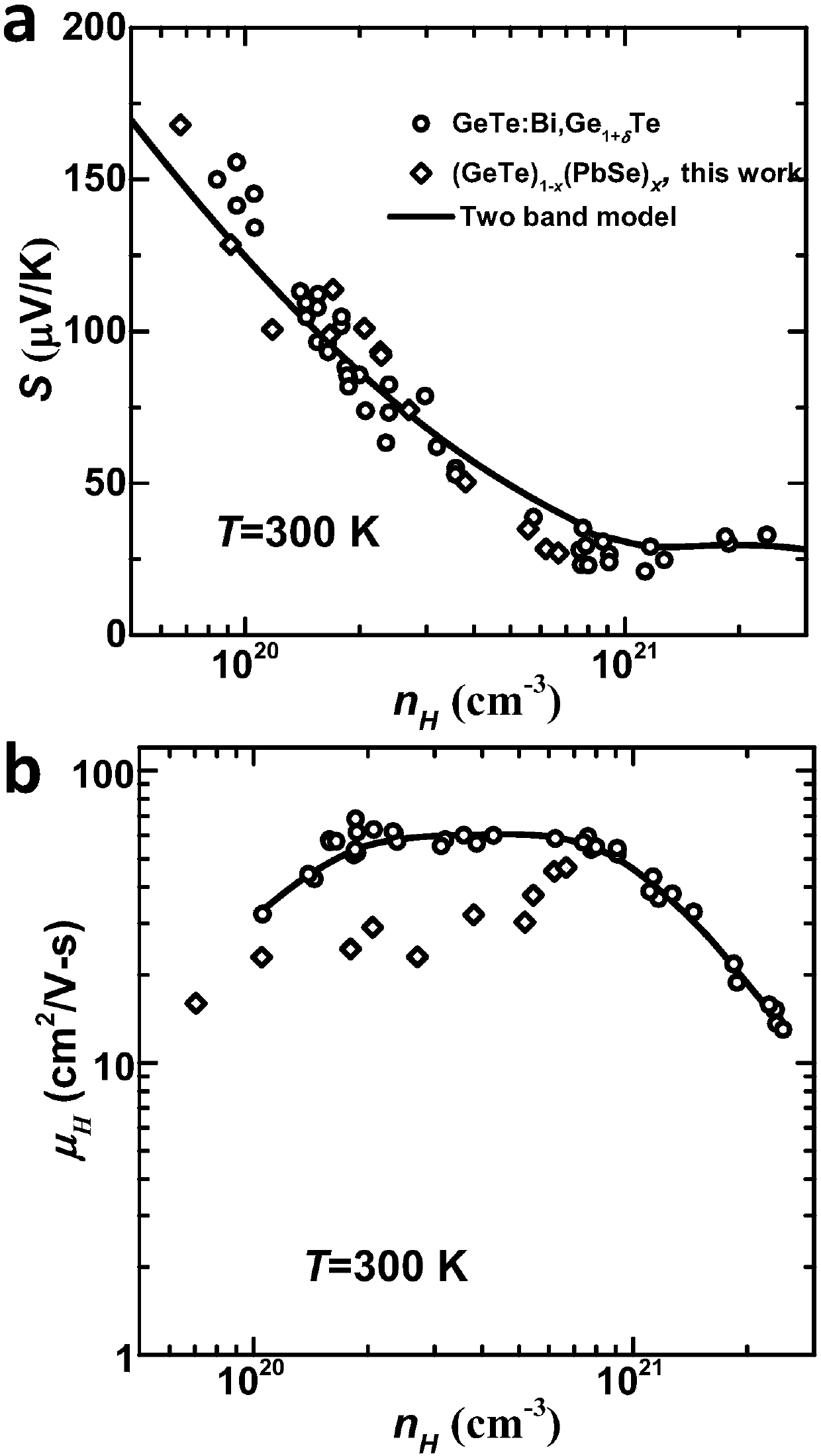

Alloy thermoelectric semiconductor material and fabrication method thereof

ActiveCN107799646ALower lattice thermal conductivityImprove thermoelectric performanceThermoelectric device manufacture/treatmentThermoelectric device junction materialsSemiconductor materialsAlloy

The invention relates to an alloy thermoelectric semiconductor material and a fabrication method thereof. The chemical formula of the alloy thermoelectric semiconductor material is (GeTe)<1-x>(PbSe)<x>, and x is more than 0 but less than0.4. During fabrication, simple elements Ge, Te, Pb and Se are sequentially loaded in a quartz ampoule from small to large and are packaged after vacuumizing, andthe steps of melting quenching, annealing quenching and hot-press sintering are sequentially performed to finally fabricate the alloy thermoelectric semiconductor material. Compared with the prior art, substitution of the elements (Ge / Pb and Te / Se) in the main group are performed on positions of a negative ion and a positive ion in a GeTe material, the large-range control of carrier concentrationis achieved, the carrier concentration level of the GeTe material is optimized, meanwhile, the thermoelectric merit figure of the material is also increased by point defect introduced by element substitution, the lattice thermal conduction of the material is substantially reduced as well as the carrier concentration is regulated, and a new idea is provided for improvement of thermoelectric performance of a GeTe-based thermoelectric material and same-type material.

Owner:TONGJI UNIV

Chalcohalide glass and preparation method thereof

Owner:NANJING WAVELENGTH OPTO ELECTRONICS SCI & TECH CO LTD

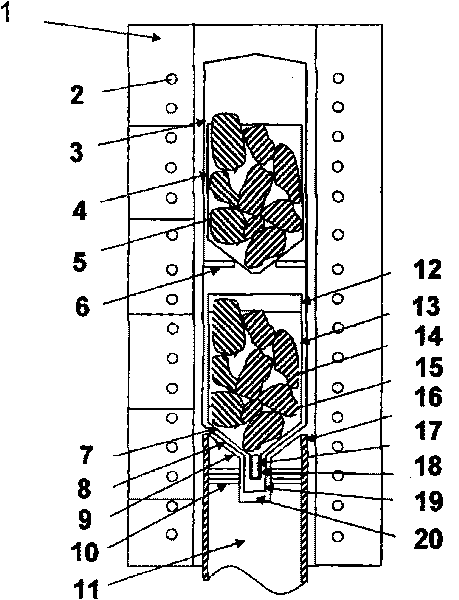

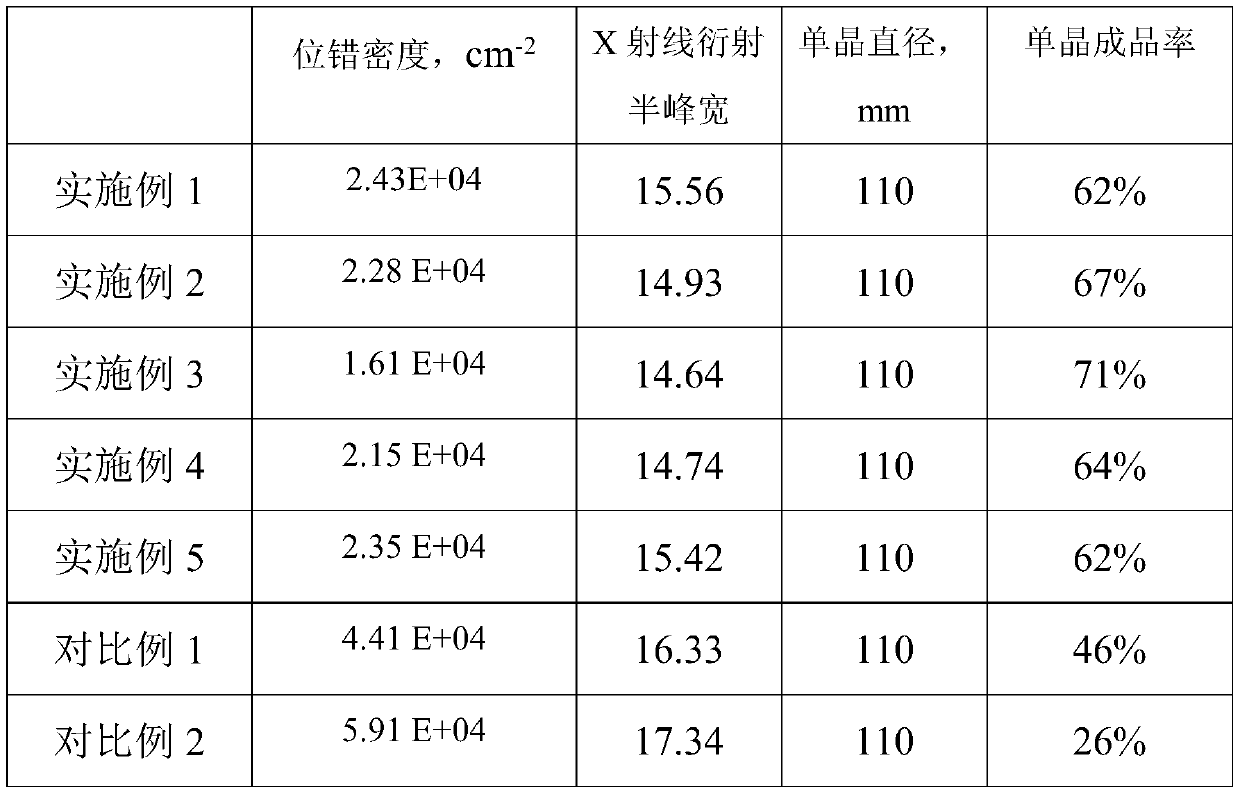

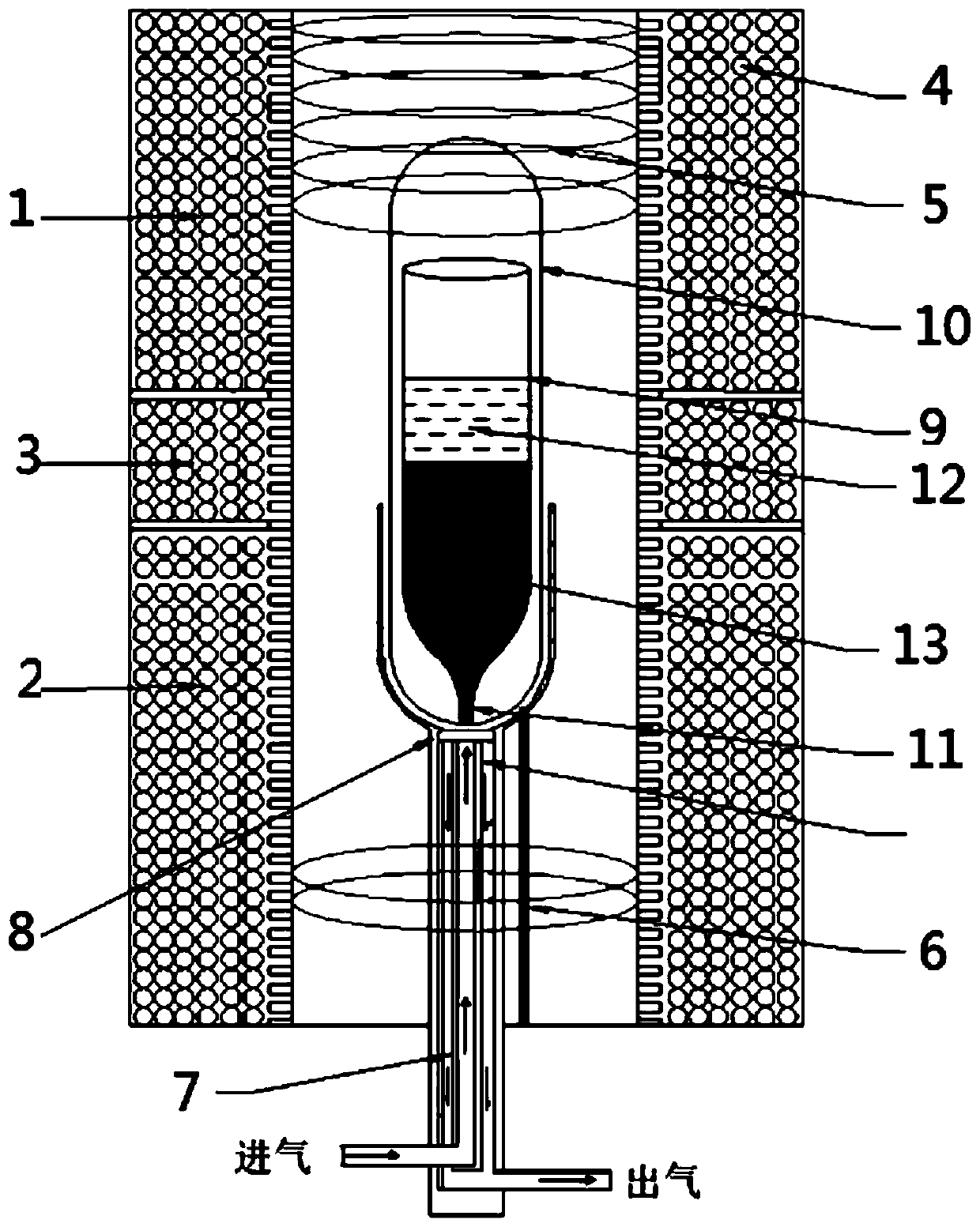

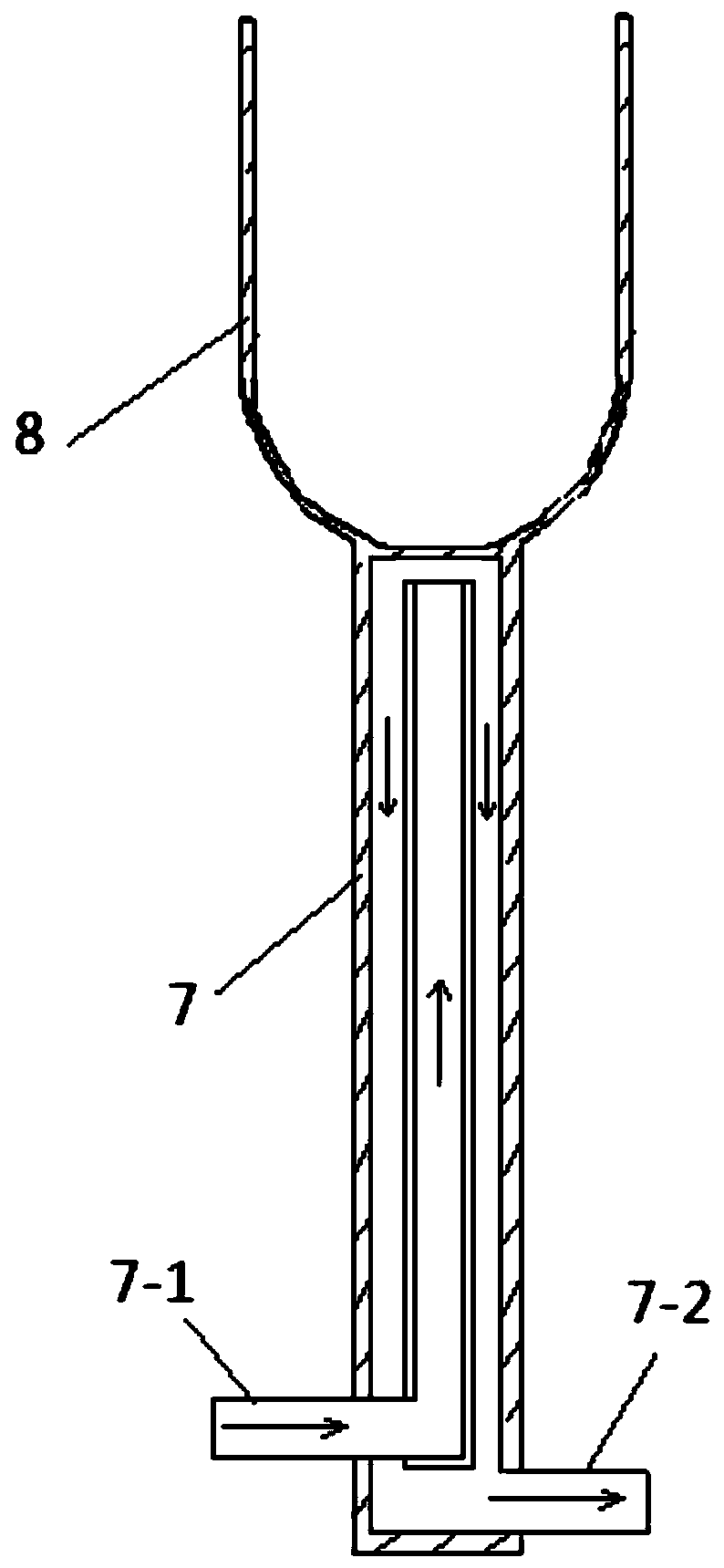

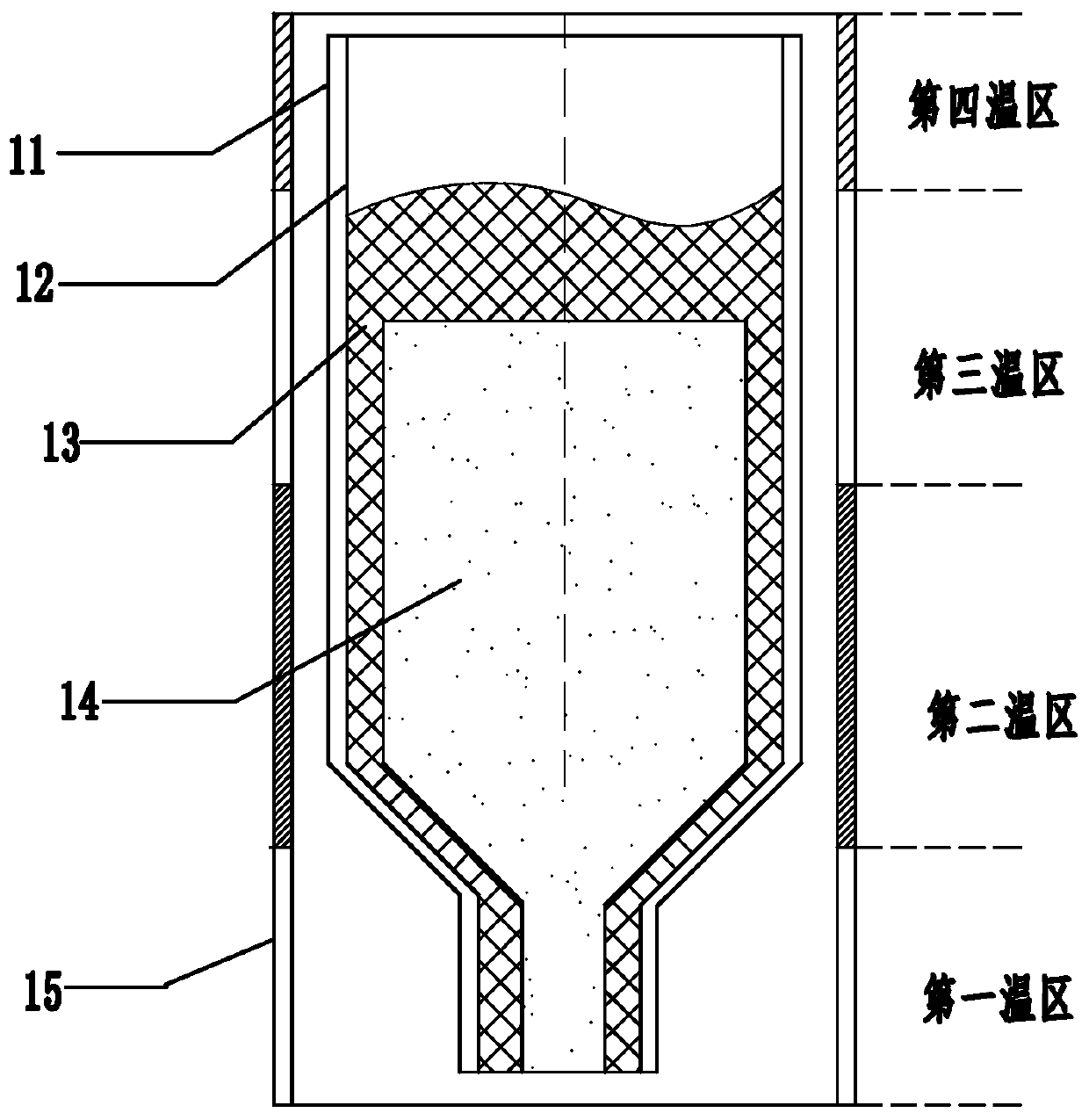

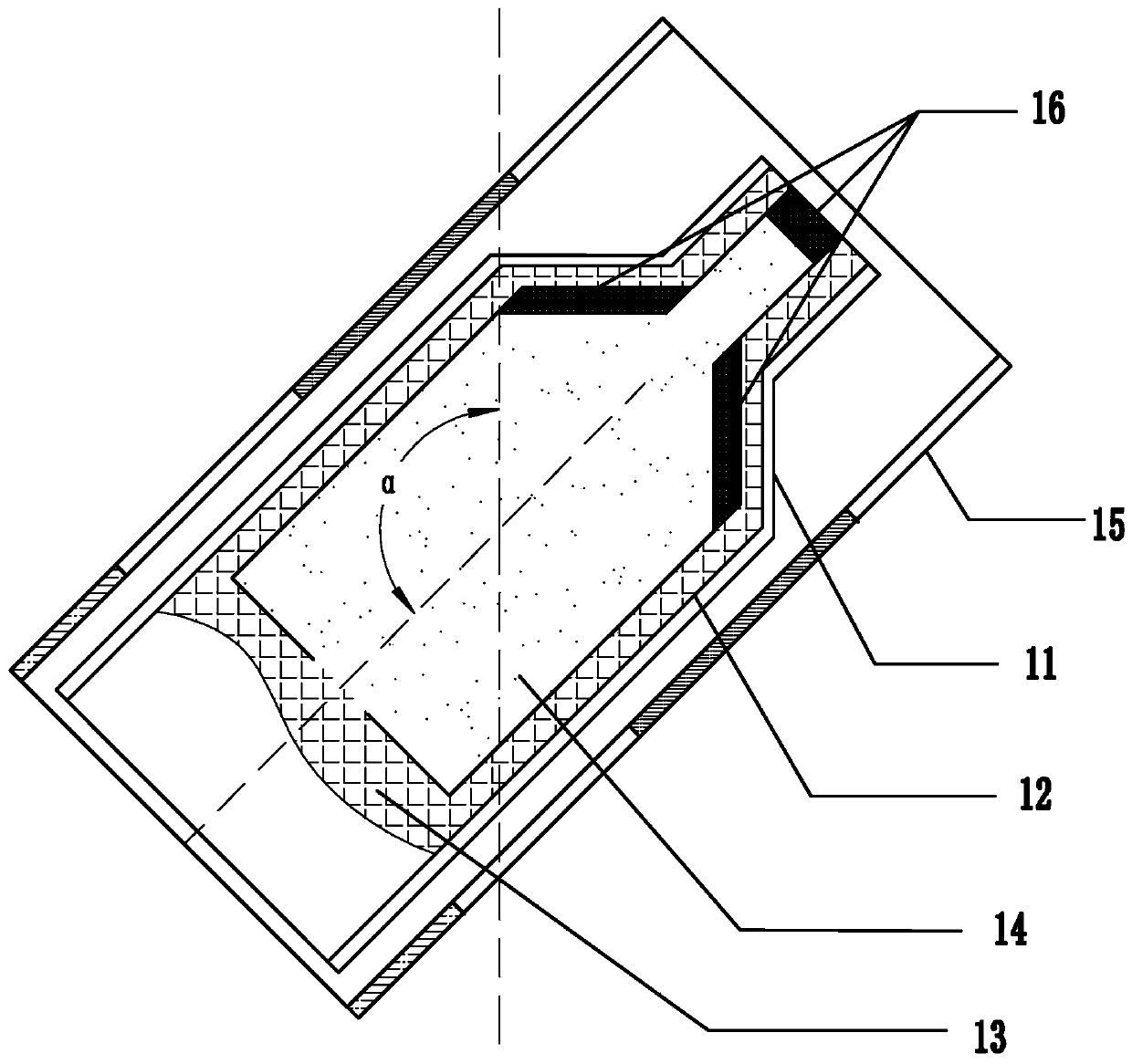

Cadmium zinc telluride single crystal furnace and growth process of cadmium zinc telluride single crystals

ActiveCN110106555APromote growthImprove performancePolycrystalline material growthFrom frozen solutionsEconomic benefitsNitrogen

A cadmium zinc telluride single crystal furnace comprises a furnace body, a quartz ampoule is arranged in the furnace body, a boron nitride crucible is arranged in the quartz ampoule, an excitation coil is arranged outside the furnace body, a heat conduction device is arranged below the quartz ampoule, and the furnace body is inclined by 3-15 degrees relative to the vertical direction. A growth process of cadmium zinc telluride single crystals includes the steps that Cd1-xZnxTe seed crystals are selected, and the Cd1-xZnxTe seed crystals are ground and then soaked in a bromine-methanol solution, wherein x is selected within the range of 0.04-0.2; Cd1-xZnxTe polycrystals are selected, and the quartz ampoule is vacuumized and then sealed, wherein x is 0.04; the furnace is inclined by 3-15 degrees relative to the vertical direction, wherein the spiral nitrogen pipeline is arranged below the quartz ampoule, and the excitation coil is installed outside the furnace; crystal seeding is carried out; crystal growth is carried out, wherein the furnace body is placed in a cusp magnetic field, the initial flow rate of nitrogen is 50 mL / min, and the flow rate is increased at the speed of 0.1 mL / min; in-situ annealing and cooling are carried out. The cadmium zinc telluride single crystals obtained by the growth process have good lattice structure integrity and large diameter, the single crystal yield is high, the quality of the obtained single crystals is improved, and the economic benefit is good.

Owner:湖南大合新材料有限公司

Preparation method of bromine-lead-cesium monocrystal by horizontal moving zone melting

ActiveCN108193271AReduce crackingHigh purityPolycrystalline material growthBy zone-melting liquidsCarbon filmZone melting

The invention discloses a preparation method of a bromine-lead-cesium monocrystal by horizontal moving zone melting. The preparation method specifically comprises the following steps: (1) placing a quartz ampoule in a reaction furnace chamber, and introducing methane to carry out carbon film plating treatment to obtain a carbon-plated ampoule; (2) loading bromine-lead-cesium powder into the carbon-plated ampoule, carrying out vacuumizing and sealing, and placing the ampoule in a heat treatment furnace to melt the bromine-lead-cesium powder first, and then cooling and solidifying the product toform a polycrystalline material rod; and (3) placing the sealed ampoule containing the polycrystalline material rod in a horizontal moving zone melting furnace, heating a heater to 620-650 DEG C, andmoving the heater from the tip of the sealed ampoule to the tail end of the sealed ampoule, thereby completing the growth of a bromine-lead-cesium crystal and obtaining the bromine-lead-cesium crystal. The preparation method provided by the invention can effectively solve the problems of large mechanical vibration, high thermal stress in the crystal, difficulty in growing a large-size bromine-lead-cesium monocrystal and the like in a crystal growth process compared with the prior art by improving the key integral flow process design, and reaction conditions and parameters of each step.

Owner:HUAZHONG UNIV OF SCI & TECH

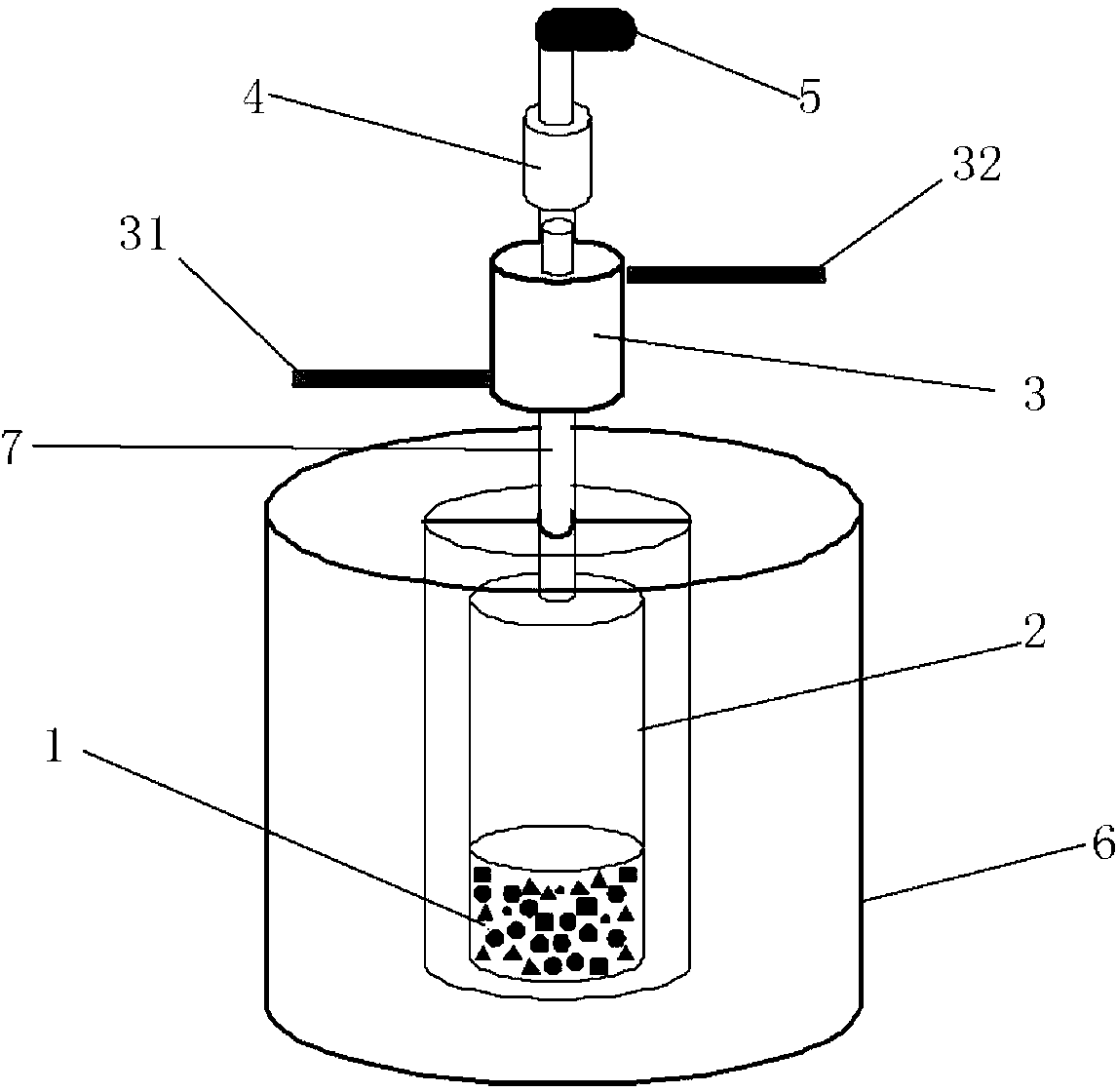

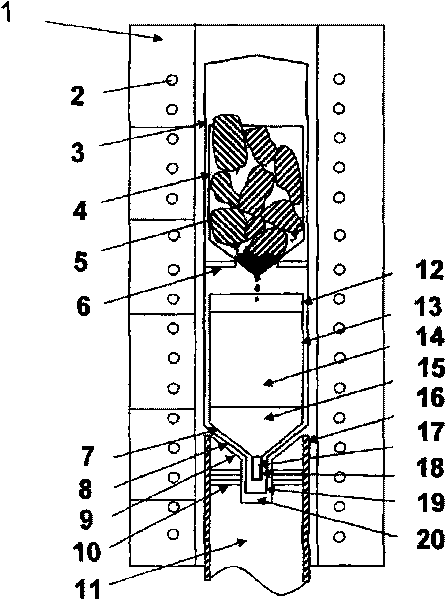

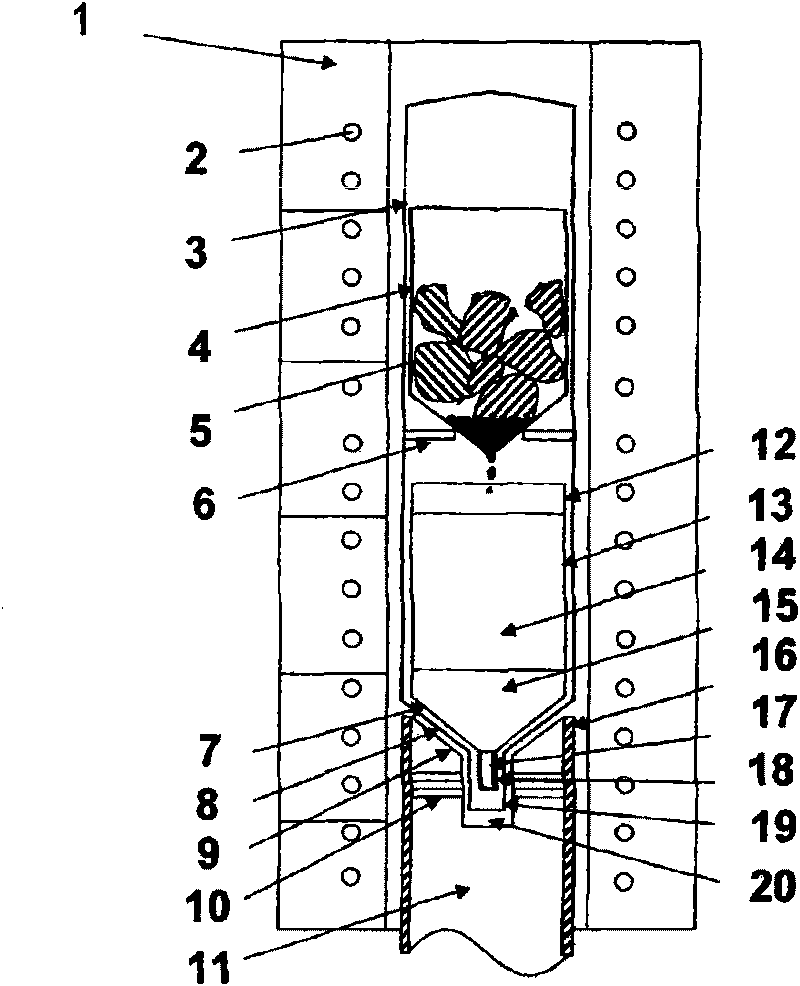

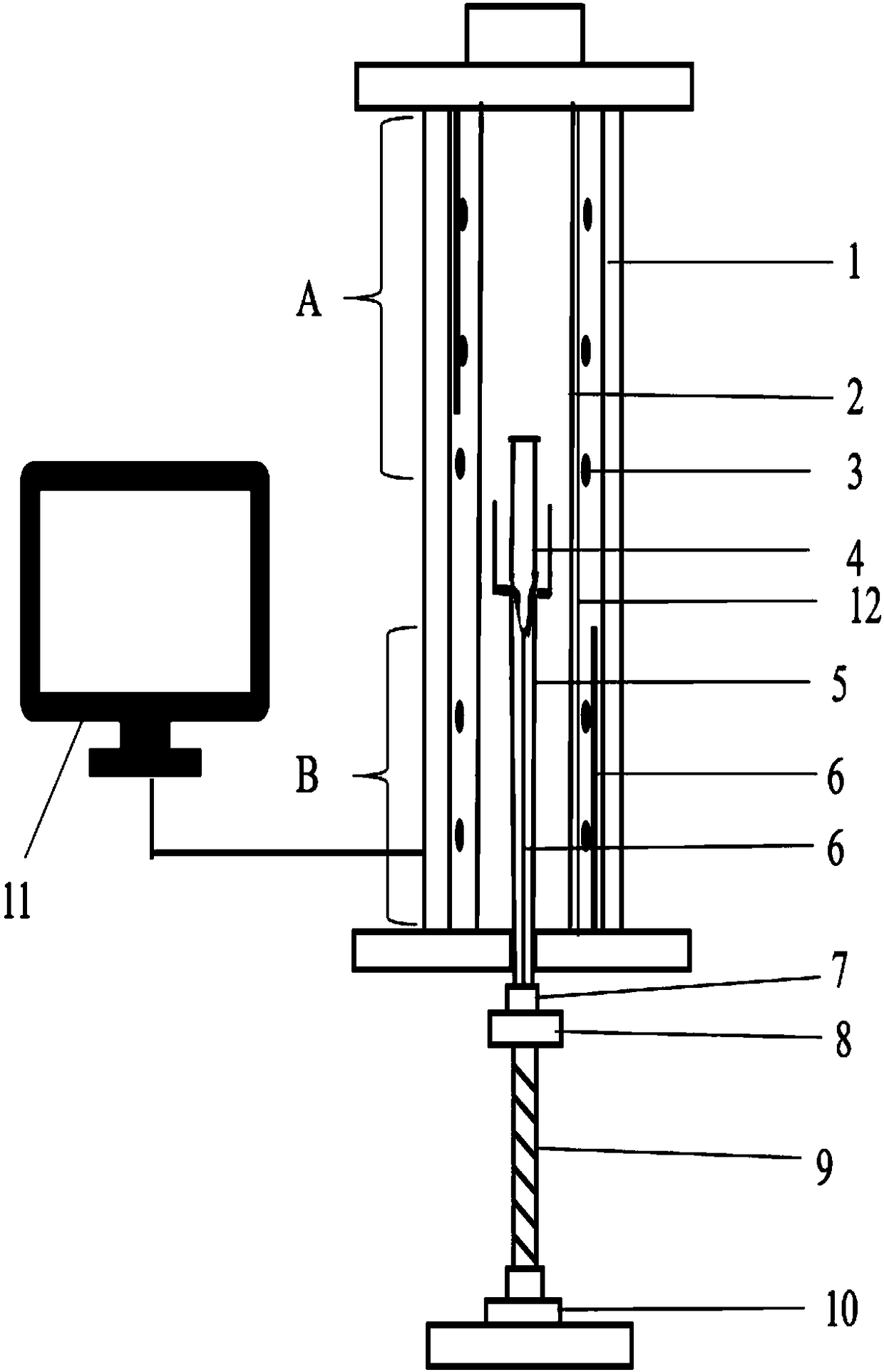

Apparatus for vertical pulling growth of CdZnTe monocrystals, and method thereof

ActiveCN103088409AImprove component uniformityThe synthesis process is simplePolycrystalline material growthBy pulling from meltSingle crystalIngot

The invention discloses an apparatus for the vertical pulling growth of CdZnTe monocrystals, and a method thereof. The apparatus comprises a tubular furnace body, a quartz ampoule and a graphite boat, the furnace body comprises synthetic furnaces, buffer furnaces, inclined plane furnaces and Cd source furnaces, the quartz ampoule is arranged in the furnace body, the graphite boat is arranged in the quartz ampoule. The method for the vertical pulling growth of CdZnTe monocrystals through adopting the apparatus generally comprises the following steps: uniformly putting a high-purity Te raw material, a high-purity Zn raw material and a high-purity Cd raw material in the graphite boat according to synthetic proportions, putting a small amount of Cd at the bottom of the quartz ampoule, slowly putting the graphite boat on the baffle board of the quartz ampoule, carrying out vacuumizing tube sealing, putting the quartz ampoule in the tubular furnace body to make the graphite boat in the middle of the synthetic furnaces, controlling conditions for synthesizing polycrystals, controlling the temperature distribution of the furnace body, slowly upward moving the furnace body until crystallization finishing, and carrying out vertical pulling growth to obtain the CdZnTe monocrystals. According to the invention, CdZnTe polycrystals are synthesized without using other rocking furnaces; and the obtained CdZnTe monocrystals have the advantages of uniform crystal ingot component, less twin crystals, and less Te precipitation or inclusions.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

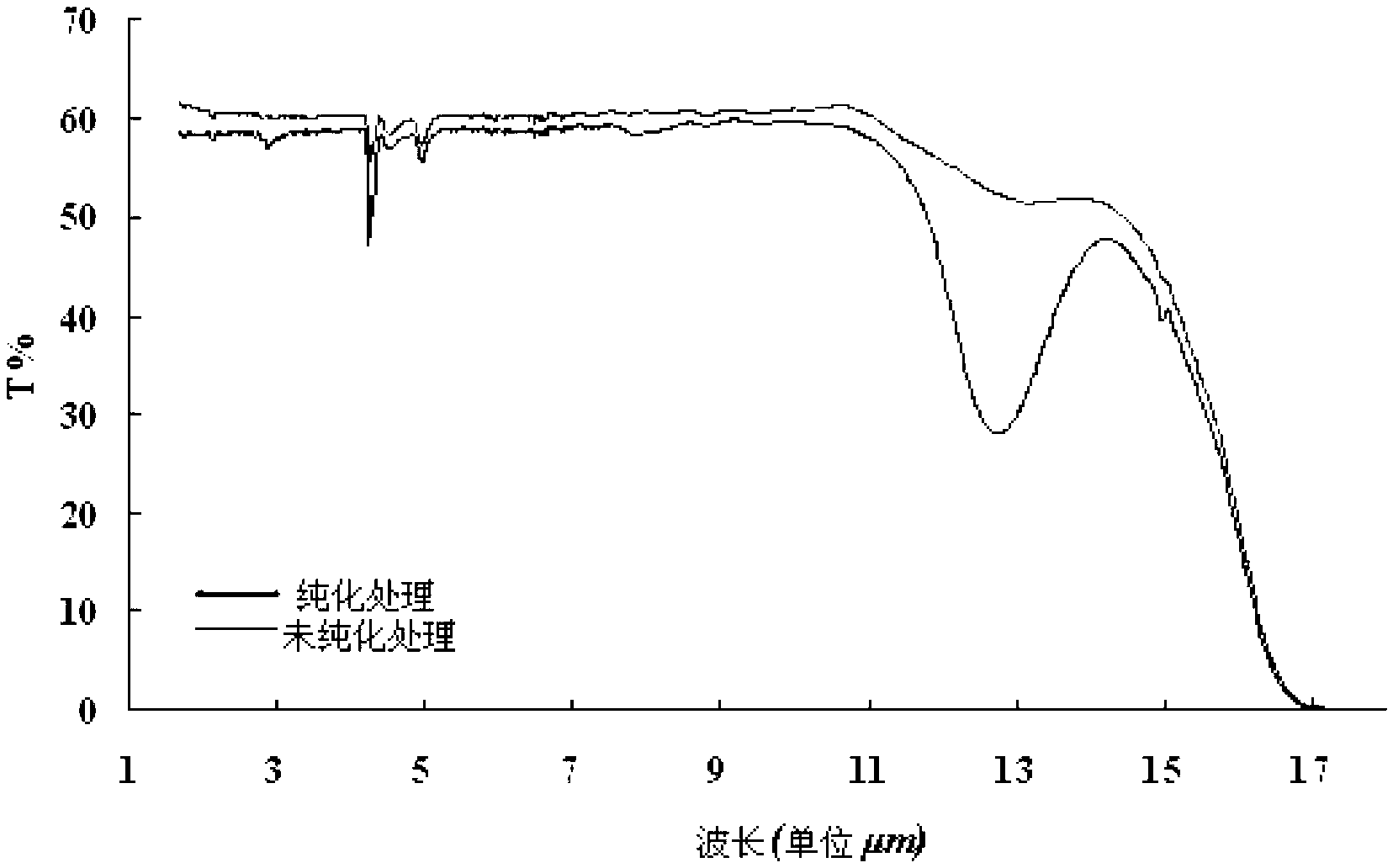

Preparation method of high-purity and low-loss chalcogenide glass

InactiveCN103332851BImprove uniformityHigh purityGlass furnace apparatusChalcogenide glassPhotochemistry

The invention provides a preparation method of high-purity and low-loss chalcogenide glass, belonging to a preparation method of the chalcogenide glass. The preparation method comprises the following steps of: removing hydrocarbon impurity in the glass by taking ultra-dry gallium chloride as a purifying agent, and distilling and purifying the glass in combination with the conventional deoxidant, aluminum, magnesium or zirconium metal; placing glass mixture into a quartz ampoule to be sealed in by means of vacuum supply, founding the glass mixture in a vacuum ampoule, dynamically distilling the glass, and remelting the mixture after distilling; and effectively removing the hydrocarbon impurity in the glass by taking the ultra-dry gallium chloride as the purifying agent, so that the Mie scattering imperfection is hardly formed in the finally-obtained high-purity chalcogenide glass, and the low-loss homogeneous glass can be obtained. According to the high-purity chalcogenide glass synthesized by the preparation method provided by the invention, the minimum loss under the infrared transmission waveband is less than 0.3dB / m, and the corresponding loss of the absorption peak of the residual impurity is less than 8dB / m, so that the preparation method can be used in the field of an infrared glass optical element and an infrared optical fiber. The ultra-dry gallium chloride purifying agent can be easily obtained, and is lower in price; the carbon, hydrogen and oxygen impurities can be removed from the chalcogenide glass at high efficiency; the prepared chalcogenide glass is better in uniformity and less in light scattering.

Owner:XUZHOU NORMAL UNIVERSITY

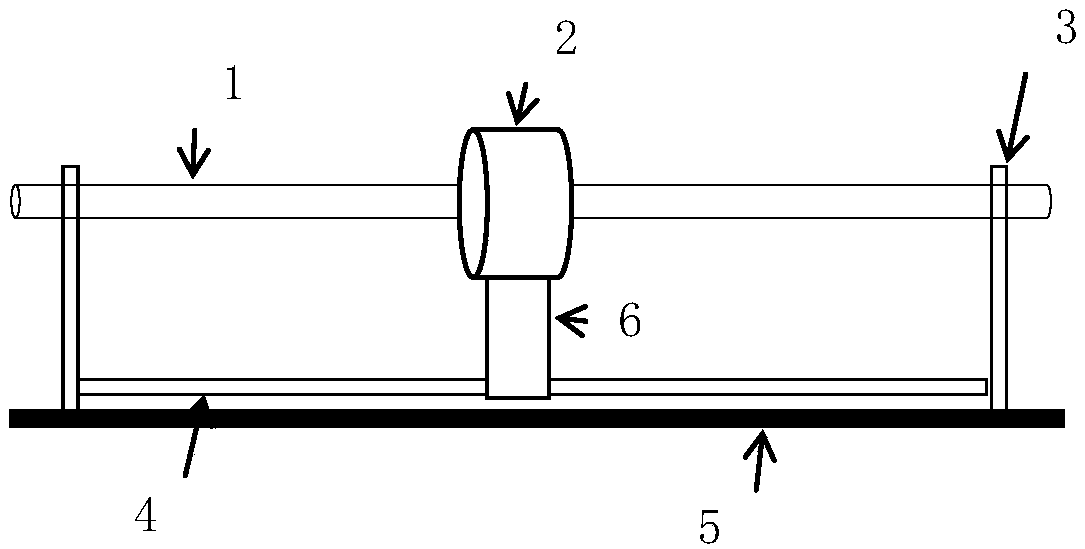

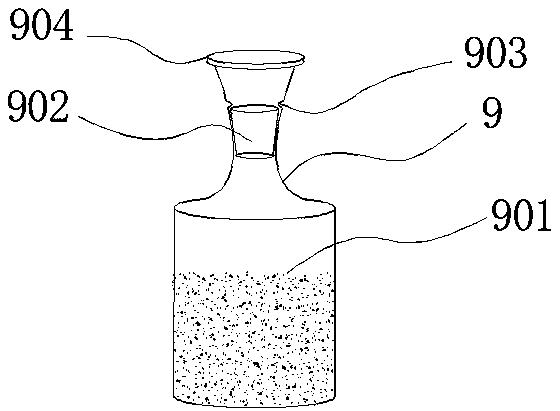

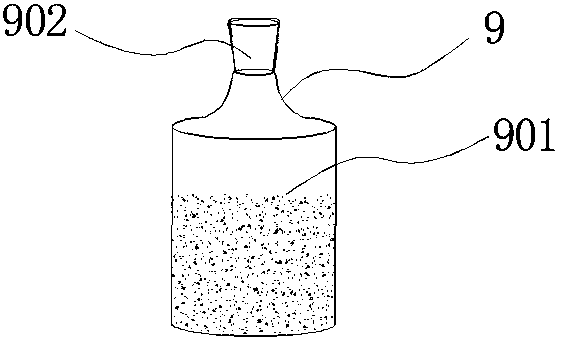

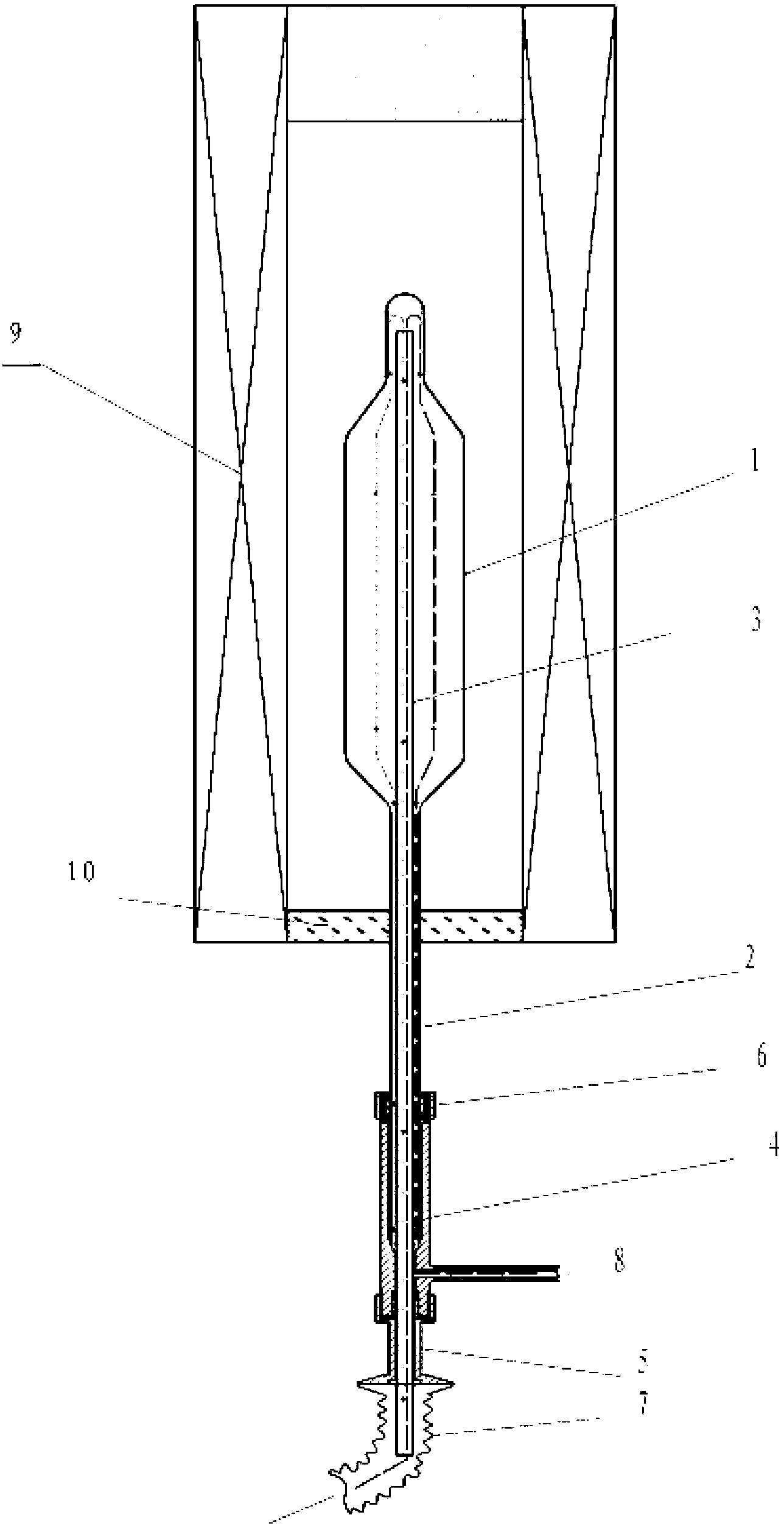

Quartz ampoule bottle sealing device and method

ActiveCN109354394AFirmly connectedEasy to removeGlass furnace apparatusGlass reforming apparatusCombustionChalcogenide glass

The invention belongs to the technical field of chalcogenide glass production, discloses a quartz ampoule bottle sealing device and method and mainly solves problems of low sealing quality, high laborintensity and low efficiency in manual sealing. The quartz ampoule bottle sealing device comprises a body, a combustion unit, a clamping unit, a vacuum unit and a control unit. The combustion unit mainly comprises a translation mechanism and a burning gun; the clamping unit comprises a tray, a rotating shaft, arc clamping plates, a clamping plate radial adjustment mechanism and a rotating and lifting mechanism, and tray is capable of clamping a quartz ampoule bottle to rotate and move up and down; the vacuum unit mainly comprises a vacuum molecular pump, a vacuum gauge and a vacuum rotating joint. In an ampoule bottle sealing process, the control unit performs burning gun translation and tray lifting interpolation control according to inputted bottle plug size data, and sealing is realized by flame core in spiral ascending relative to a bottleneck; after sealing is finished, bottleneck closing treatment is performed, and excessive parts are removed, so that subsequent space occupationof melting equipment is reduced.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

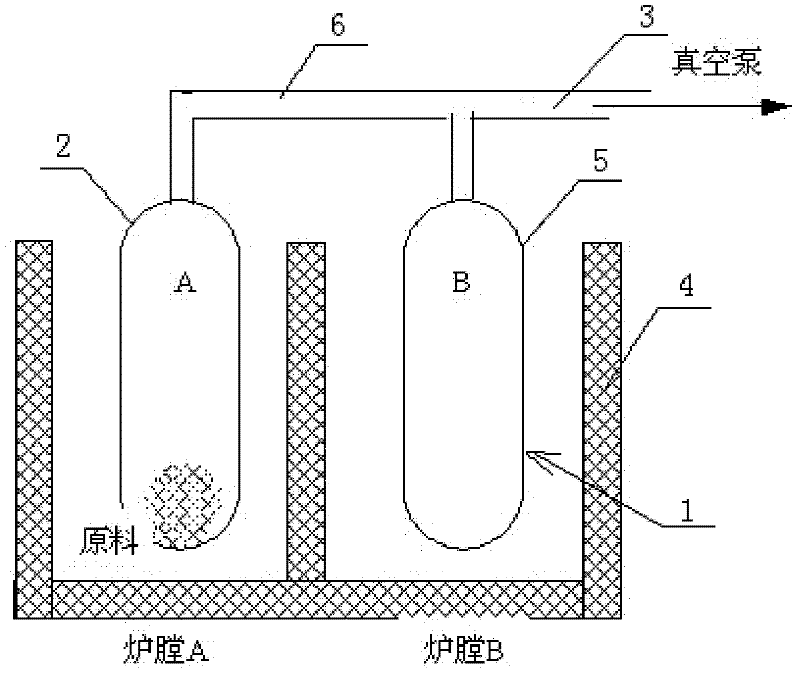

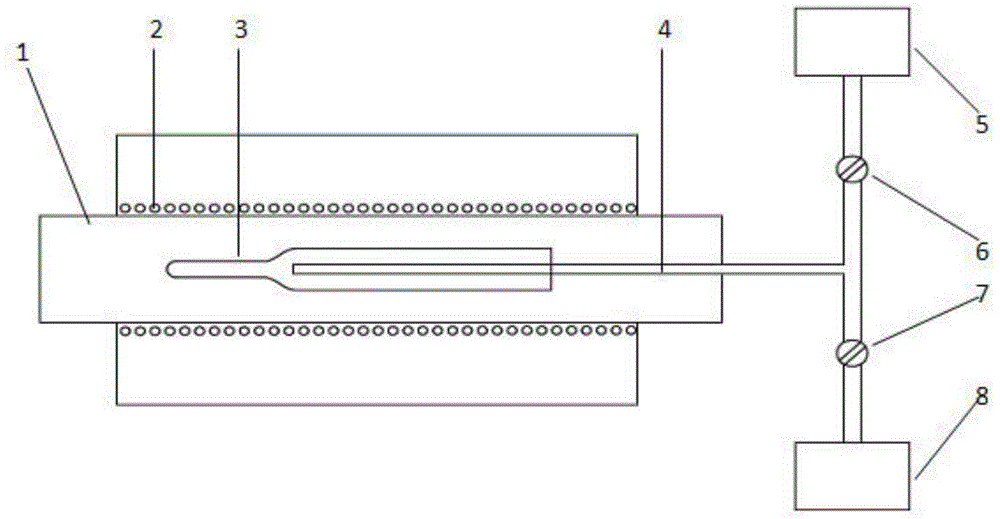

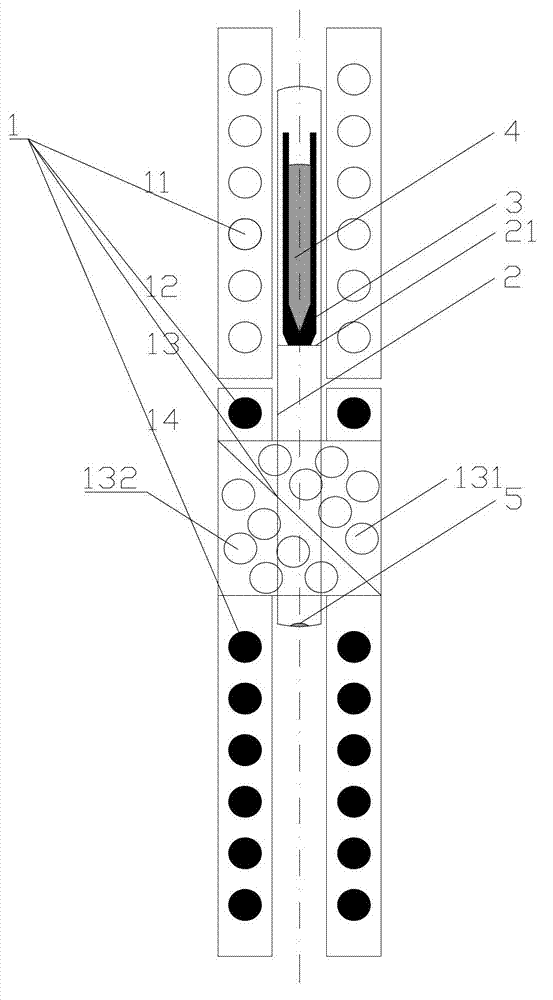

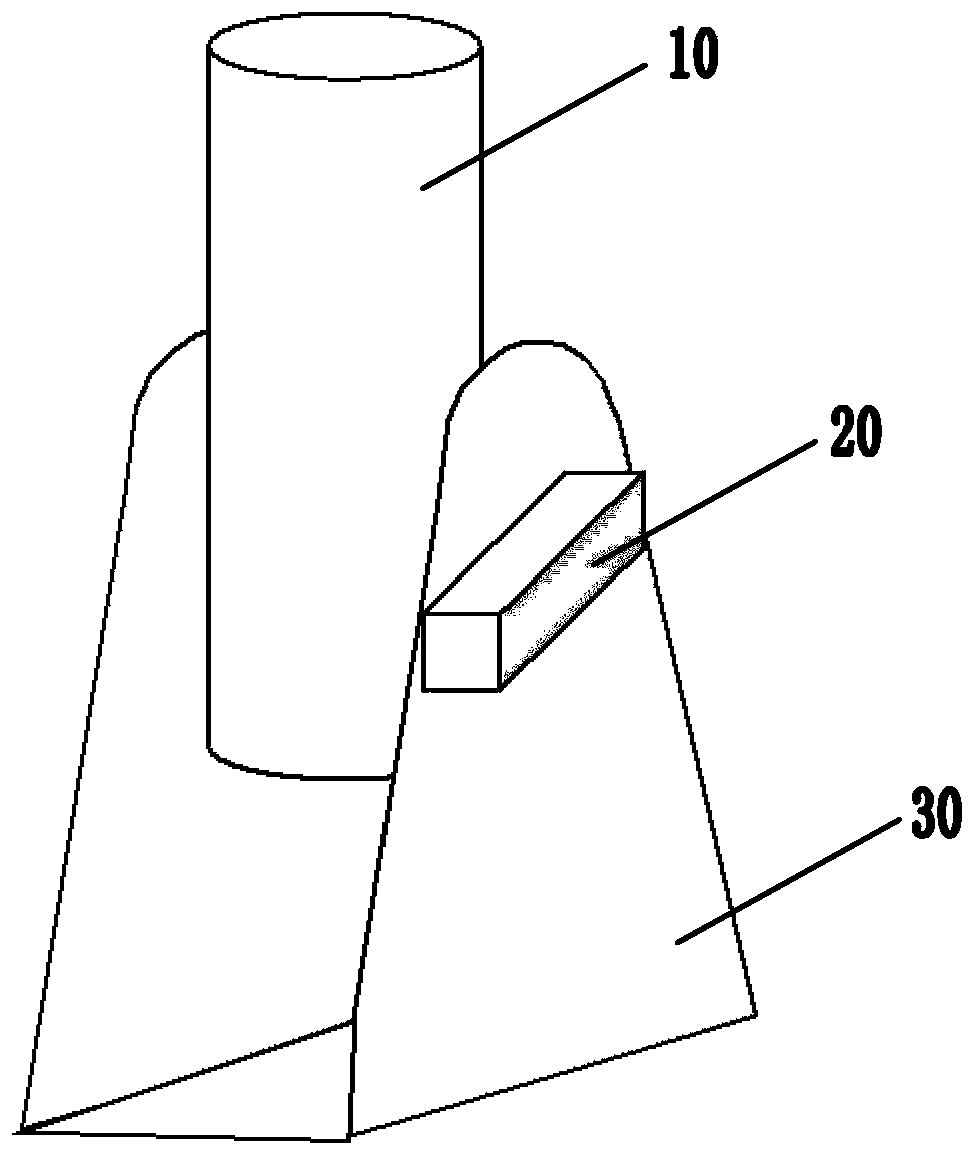

Device for preparing carbon film on inner wall of quartz ampoule used for monocrystal growth

The invention discloses a device for preparing a carbon film on the inner wall of a quartz ampoule used for monocrystal growth. The device is characterized in that an ampoule bracket is arranged at the neck of the quartz ampoule; a channel is arranged in the ampoule bracket; a flow guide tube is arranged in the channel; one end of the flow guide tube is inserted in the bottom of the quartz ampoule; the other end of the flow guide tube penetrates out of the ampoule bracket to be connected with an exhaust pipe; one end of the exhaust pipe is connected with a vacuum pump; an air inlet pipe is arranged on the ampoule bracket; carbon film splitting gas enters the quartz ampoule through a gap between the flow guide tube and the neck; and a flowmeter is arranged on each of the air inlet pipe and the exhaust pipe. The ampoule bracket is arranged at the neck of the quartz ampoule, and dynamic equilibrium of splitting gas in the quartz ampoule is realized through the flowmeters arranged on the air inlet pipe and the exhaust pipe, so that an even carbon film can be obtained in the quartz ampoule.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

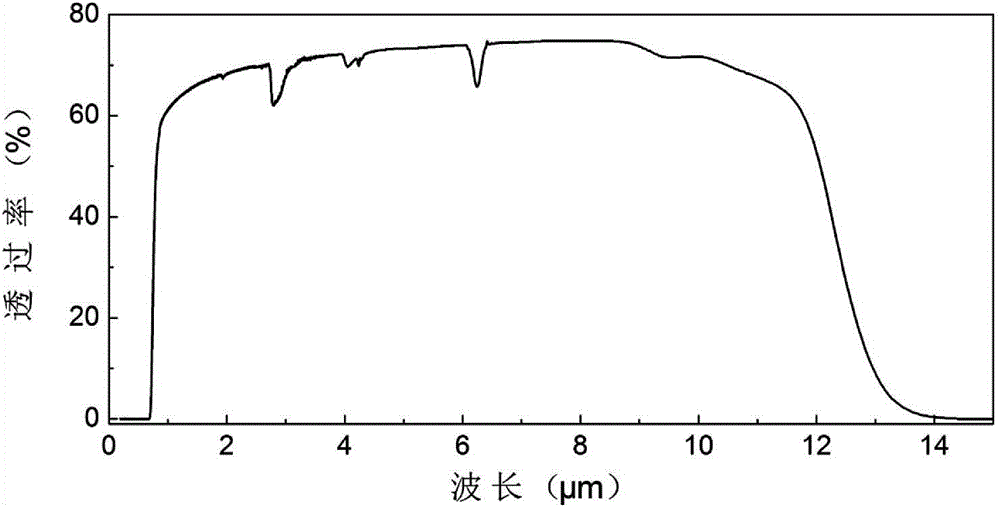

Method for preparing high-purity chalcogenide glass for optical fiber

ActiveCN106927673AHigh purityGuaranteed purityGlass furnace apparatusGlass shaping apparatusDistillationDehydrogenation

The invention relates to a method for preparing high-purity chalcogenide glass for optical fiber. According to the method, single raw materials for preparing a chalcogenide glass product are subjected to three times of dynamic full distillation, a deoxidant and a dehydrogenation agent are uniformly doped, then impurities such as moisture and oxides in different single raw materials can be removed at an early stage of melting, high purity of the single raw materials for melting can be ensured, and furthermore the purity of a chalcogenide glass product obtained later can be ensured; after the chalcogenide glass product is prepared preliminarily, two times of dynamic full distillation and one time of sealed distillation purification are implemented on the preliminarily prepared chalcogenide glass product in quartz ampoule bottles, then influence of impurities upon the purity of the obtained chalcogenide glass product is further eliminated, finally the purified chalcogenide glass is molten, and thus a high-purity chalcogenide glass rod product can be prepared.

Owner:NINGBO UNIV

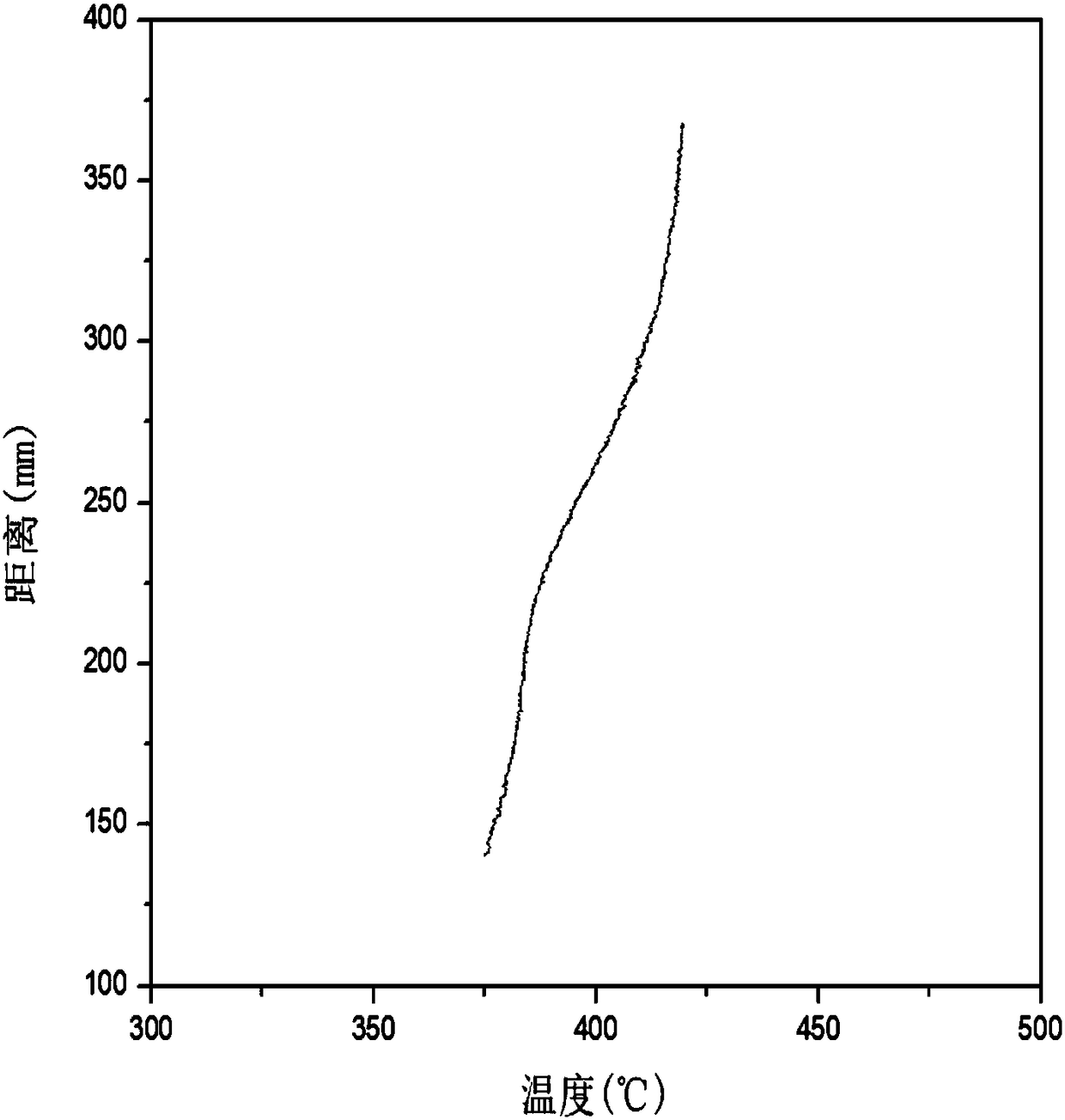

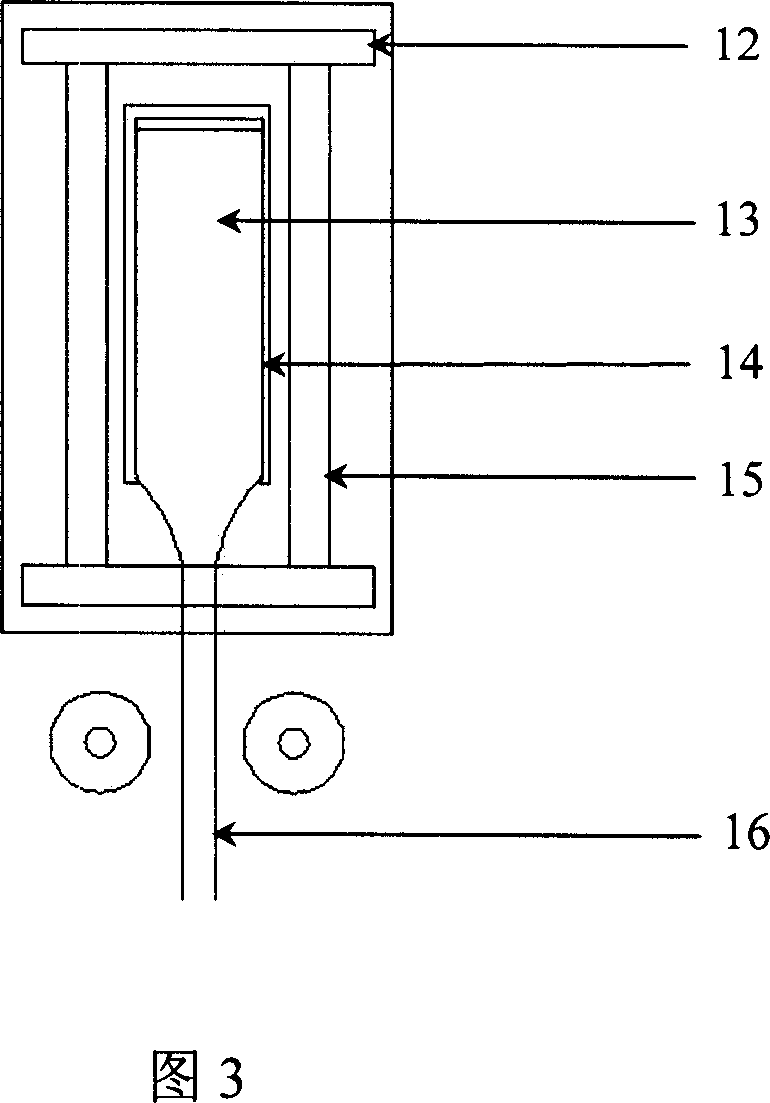

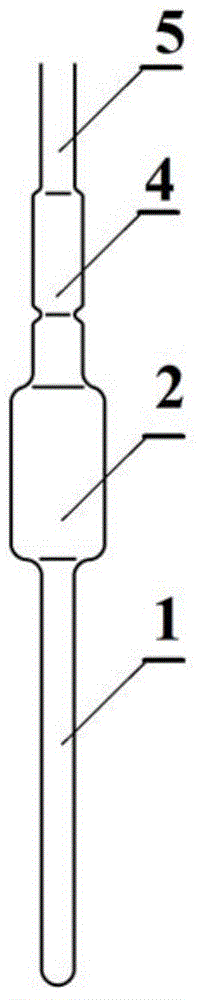

Mercurous chloride single crystal growing device and method

ActiveCN108411366APrecise control of temperature distributionSuitable for growthPolycrystalline material growthFrom frozen solutionsGas phaseSingle crystal

The invention relates to a mercurous chloride single crystal growing device and method. The device comprises a furnace body, and a rack and a supporting mechanism which are connected with the furnacebody and used for supporting the furnace body; the furnace body comprises a furnace tube and a heat preservation sleeve coating the outer surface of the furnace tube, and a heating furnace wire is arranged between the furnace tube and the heat preservation sleeve; the supporting mechanism is connected with a long crystalline style through a rotating device for controlling the rotation of the longcrystalline style, the long crystalline style is inserted in the furnace tube, the end portion, located in the furnace tube, of the long crystalline style is provided with a growing quartz ampoule; the supporting mechanism is also used for controlling the lifting of the long crystalline style through a lifting rod and a lifting bracket. The mercurous chloride single crystal growing device and method have the advantages that not only can the temperature of the crystal growing be accurately controlled, but also the situations of the crystal growing can be monitored at any time, and large-size and high-quality crystal can be easily obtained through physical vapor transport.

Owner:SHANDONG UNIV

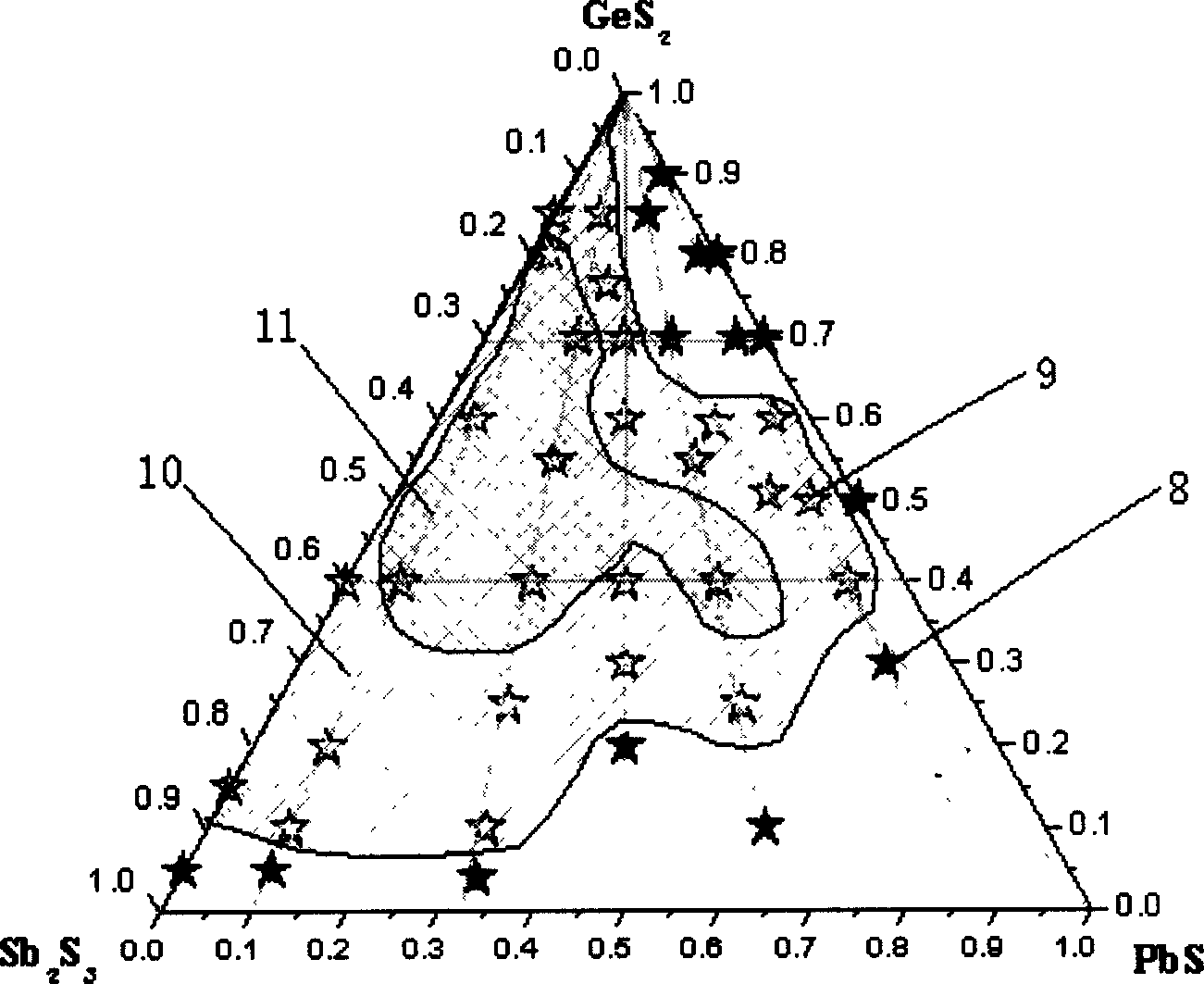

Lad containing sulfide glass and its preparationm method

InactiveCN1736917AImprove mechanical propertiesImprove efficiencyGlass furnace apparatusNonlinear opticsSulfur

The invention discloses the composition, preparation method and micro crystallization method for lead-containing sulfide glass used in infrared optics, nonlinear optics and optoelectronics. Wherein, the main composition is sulfur, germanium, stibium and lead that also serves as crystal nucleus agent. The preparation method comprises: (a) pretreating the quartz ampoule; (b) preparing glass batch; (c) sealing in vacuum; (d) melting glass; (e) micro crystallizing the glass. The result shows that the product has well performance particular to special permeance ability on infrared zone of 1-12um.

Owner:EAST CHINA UNIV OF SCI & TECH

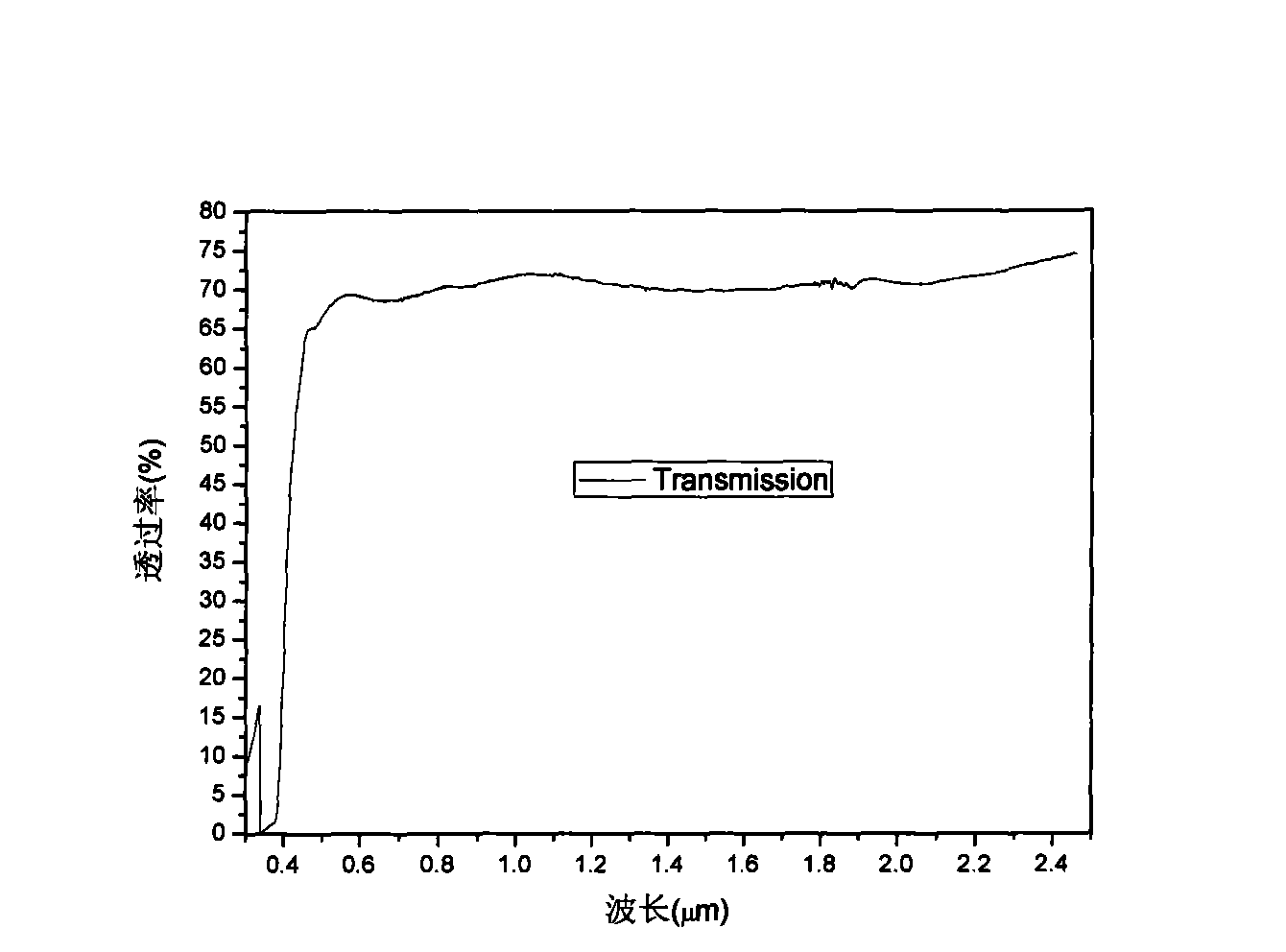

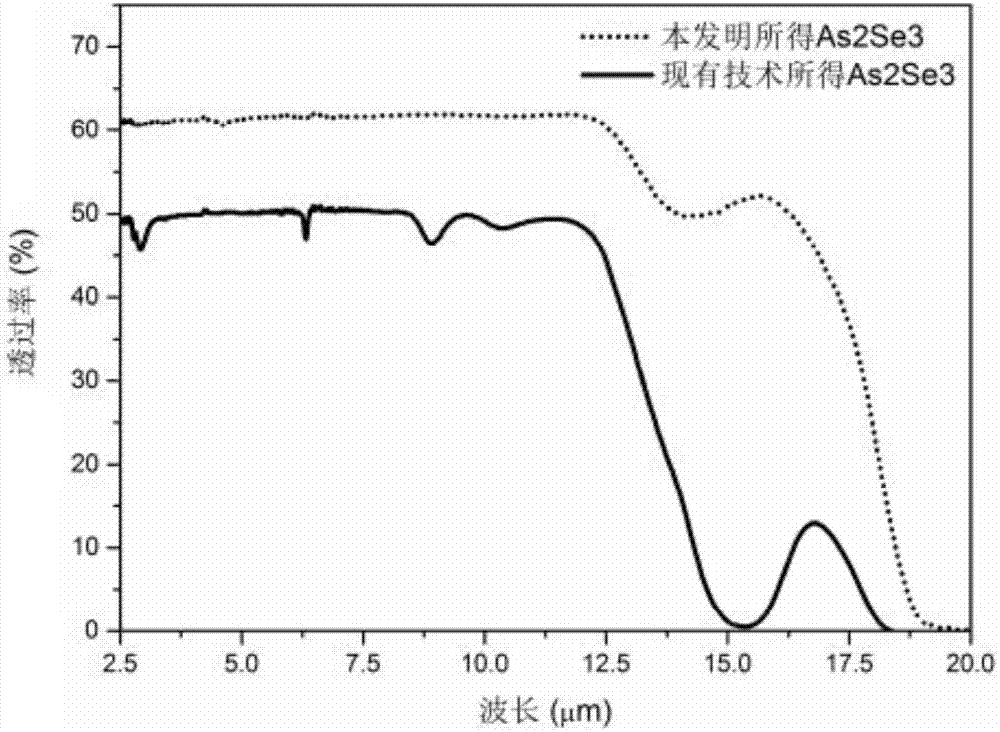

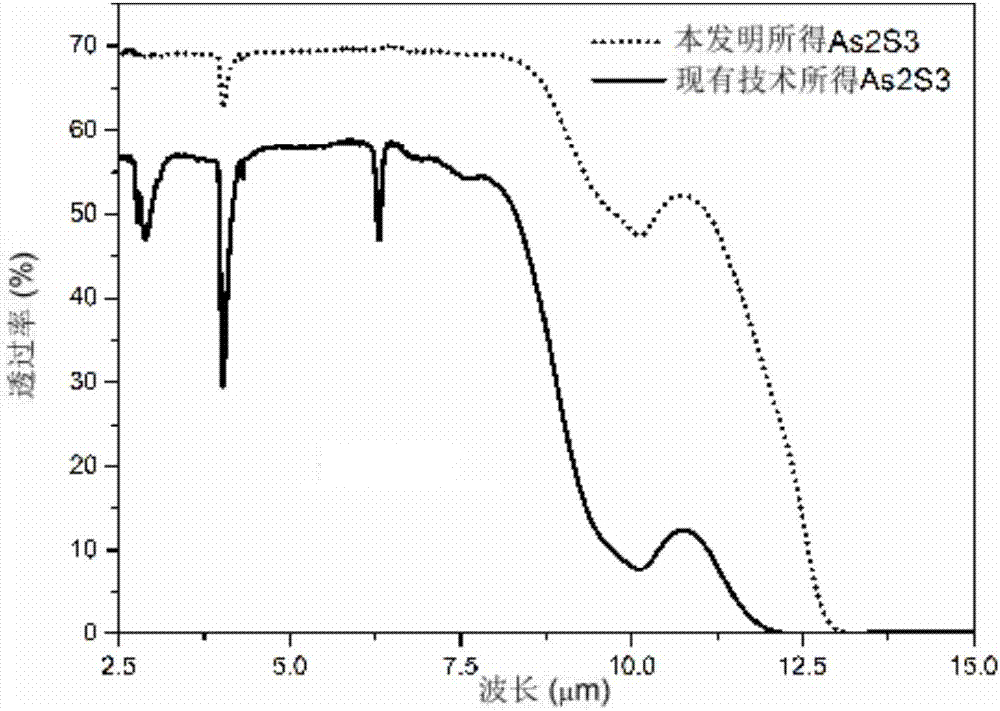

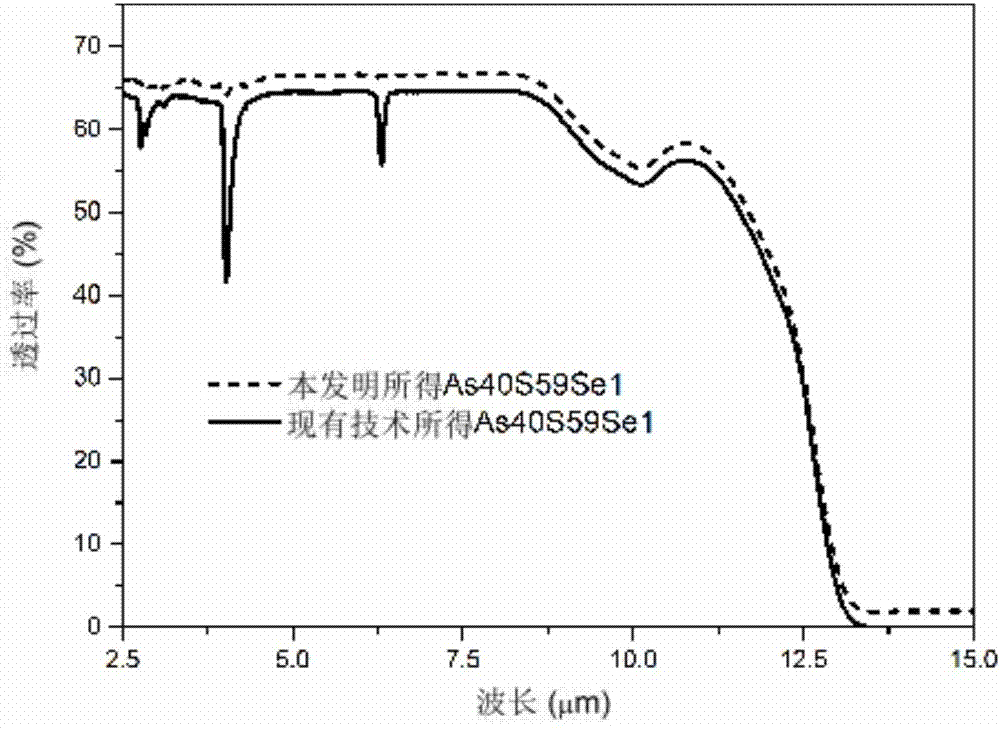

Preparation method of high-purity chalcogenide infrared glass

The invention discloses a preparation method of high-purity chalcogenide infrared glass which is a distillation-co-condensation method, and belongs to a preparation method of chalcogenide glass. The method comprises: using high-purity argon as power to drive different activated materials to mix in a molecular form in a quartz spiral tube, and condensing in a quartz ampoule; evacuating and sealing the quartz ampoule and then placing in a rocking furnace for rocking, and cooling and annealing to obtain the high-purity chalcogenide infrared glass. The infrared glass prepared by the invention is free of composition stripes due to non-uniform mixing in a mixing process, average transmittance (@2-6 Mum) of the infrared glass is greater than 70 %, and the prepared high-purity chalcogenide glass is 0.25 dB / m in lowest loss.

Owner:北京玻璃研究院有限公司

Quartz rod production method

ActiveCN1966437AHigh purityLow hydroxyl contentGlass drawing apparatusGlass forming apparatusIntermediate frequencyThick wall

There's provided a way to produce quartz sticks: smelting the quartz sand to prepare hollow quartz columns by plasms body flame; by mechanical cold work to prepare quartz ampoule with thick walls; producing the quartz sticks by intermediate frequency heating quadric-forming technology absence of contact. The quartz ampoule with thick walls is hanged in the intermediate frequency stove so as to cause underpressure in the quartz ampoule then the producers can melt and shrink the ampoule as well as producing the quartz sticks at the same time. The quartz sticks in the invention has high purity, low hydroxyl radical content, high measurement precision, high appearance quality without flaws which can be used in high technology domain.

Owner:久智光电子材料科技有限公司 +1

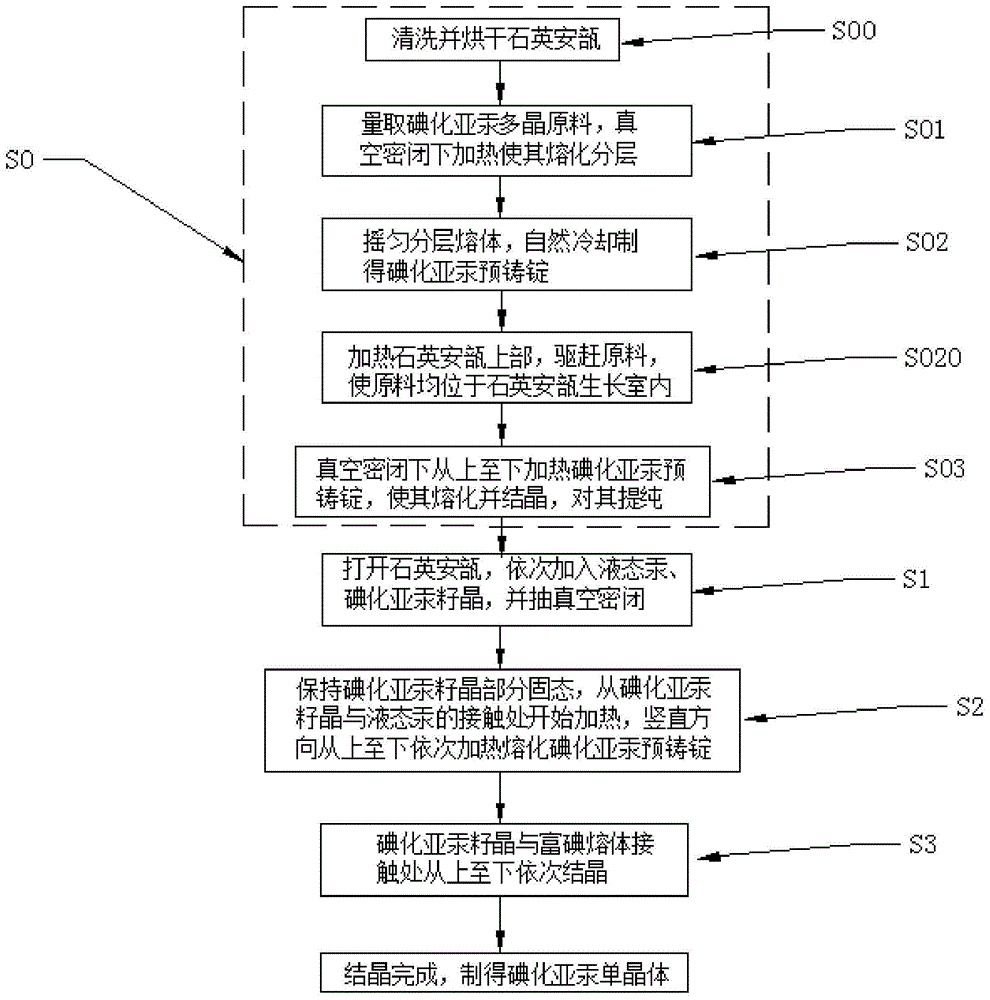

Method and device for growth of mercurous iodide single crystal

InactiveCN105063752AQuality improvementHigh quality high qualityPolycrystalline material growthBy zone-melting liquidsLiquid stateIngot

The invention discloses a method for growth of a mercurous iodide single crystal. The method includes placement of mercurous iodide seed crystals and liquid state mercury, and melting and crystallization of a mercurous iodide precast ingot, and further includes heating and melting of mercurous iodide polycrystalline raw materials and natural cooling to prepare the mercurous iodide precast ingot. The invention further discloses a device employed by the method for growth of the mercurous iodide single crystal. The device consists of a quartz ampoule and a heater. The method and device for growth of mercurous iodide single crystal provided by the invention can prepare high quality and large size mercurous iodide single crystal, which is close to an ideal stoichiometric proportion, and the remaining mercury can be recycled. At the same time, the mercurous iodide precast ingot and the mercurous iodide single crystal can be purified repeatedly so as to obtain mercurous iodide single crystal with higher purity.

Owner:XIHUA UNIV

Growth method of large-size zinc germanium phosphide crystal for increasing heat transfer

ActiveCN110042461AEvenly heatedQuality improvementPolycrystalline material growthFrom frozen solutionsBridgman methodHigh energy laser

The invention provides a growth method of a large-size zinc germanium phosphide crystal for increasing heat transfer, relates to a growth method of a zinc germanium phosphide crystal, and aims to solve the technical problems that an existing zinc germanium phosphide crystal grown by adopting a vertical Bridgman method is liable to crack and cracks and twinned defects are formed in the crystal. Themethod comprises the following steps: 1, putting a seed crystal and a ZnGeP2 polycrystalline material into a PBN crucible, filling a quartz ampoule and packaging in vacuum; 2, putting the quartz ampoule into a crystal growth furnace and raising the temperature; 3, heating to partially melt the ZnGeP2 polycrystalline material and the seed crystal; 3, carrying out seed crystal regrowth; 4, carryingout crystal growth; 5, cooling to obtain the zinc germanium phosphide crystal. In a preparation process, the growth rate of the crystal and the dissipation rate of heat in the crystal are adjusted through adjusting the flow and temperature of inert gas. The inner part of the zinc germanium phosphide crystal has no cracks and twinned defects; the 2 mum absorption coefficient of a crystal element is reduced to 0.02 cm<-1> and the zinc germanium phosphide crystal can be used for high-energy laser output devices.

Owner:HARBIN INST OF TECH

Annealing and crucible releasing method after crystal growth and crystal preparation method

InactiveCN110725008ASimplify procedure stepsAvoid damagePolycrystalline material growthAfter-treatment detailsCruciblePhysical chemistry

The invention discloses an annealing and crucible releasing method after crystal growth and a crystal preparation method. The annealing and crucible releasing method comprises an annealing step and acrucible releasing step after the annealing step; specifically, the annealing step comprises the following stages: a first stage which is a temperature rise stage: wherein raising the temperature to be higher than the melting point of a covering agent and lower than the dissociation temperature of a crystal surface; a second stage which is a constant temperature stage: wherein maintaining the temperature to be constant for 3 to 7h; a third stage, wherein regulating the inclination angle of a crystal growth furnace, and keeping the longitudinal rotation angle of the crystal growth furnace to be95 to 150 degrees, and maintaining the temperature to be constant for 1-4 hours; a fourth stage which is a cooling stage: wherein reducing the temperature gradually to room temperature; and the crucible releasing step specifically comprises the following steps: taking out a crucible from a quartz ampoule bottle, and carrying out ultrasonic water bath at 40-80 DEG C for 1-4 hours. According to theinvention, crystal preparation procedures can be reduced, damage to the crucible in the crucible releasing process is reduced, the quality of the single crystal is ensured, and the cost is saved.

Owner:珠海鼎泰芯源晶体有限公司

PBN crucible oxidation pretreatment device and method and application thereof

PendingCN113213971AAvoid damageSimple structurePolycrystalline material growthFrom frozen solutionsSemiconductor materialsMetallurgy

The invention belongs to the technical field of semiconductor material preparation, and particularly discloses a PBN crucible oxidation pretreatment device and method and application thereof. The pretreatment device comprises a quartz ampoule containing a PBN crucible, wherein an opening is formed in the top of the quartz ampoule, a matched sealing cover is arranged at the top opening, an air inlet is formed in the sealing cover, an air outlet is formed in the quartz ampoule, and the air inlet and the air outlet are respectively communicated with an air inlet pipe and an air outlet pipe; a vacuumizing device, which is connected with the quartz ampoule; a heating device, which is arranged to be used for heating the quartz ampoule and the air inlet pipe; and an air supply device, which is connected with the air inlet pipe. In the growth process of the gallium arsenide single crystal, the oxidation layer is only formed on the inner wall of the PBN crucible treated by the method disclosed by the invention, the moisture in the air absorbed by the oxidation layer in the contact process with the air can be effectively reduced in the charging process, and the damage of a heating device and the PBN crucible in the crystal growth stage caused by the expansion of the quartz ampoule in the crystal growth process is effectively prevented.

Owner:广东先导微电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com