Growth method of large-size zinc germanium phosphide crystal for increasing heat transfer

A germanium zinc phosphide and growth method technology, which is applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as easy cracking of germanium zinc phosphide crystals, crystal cracks, twin crystals, etc., to achieve slow heat dissipation, Effect of reducing thermal stress, suppressing eddy current and convection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: The growth method of increasing the heat transfer large-scale germanium phosphide zinc crystal of the present embodiment is carried out according to the following steps:

[0033] 1. Put the seed crystal 11 into the seed crystal well of the PBN crucible 9, and then add high-purity ZnGeP with a mass percent purity of 99.96%. 2 Polycrystalline raw material 12, then PBN crucible 9 is put into quartz ampoule 10, then quartz ampoule 10 is evacuated to 10 -4 Pa for vacuum packaging;

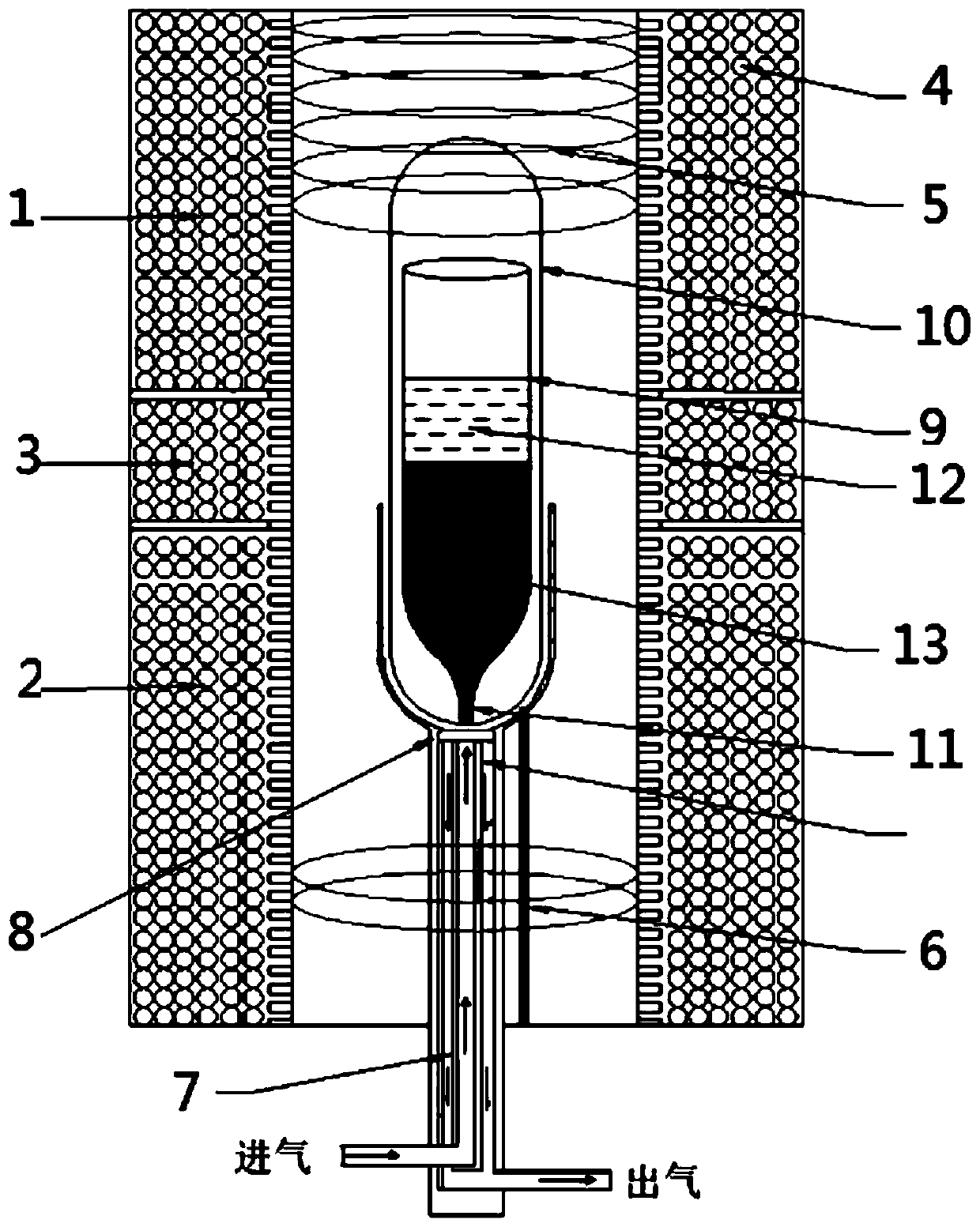

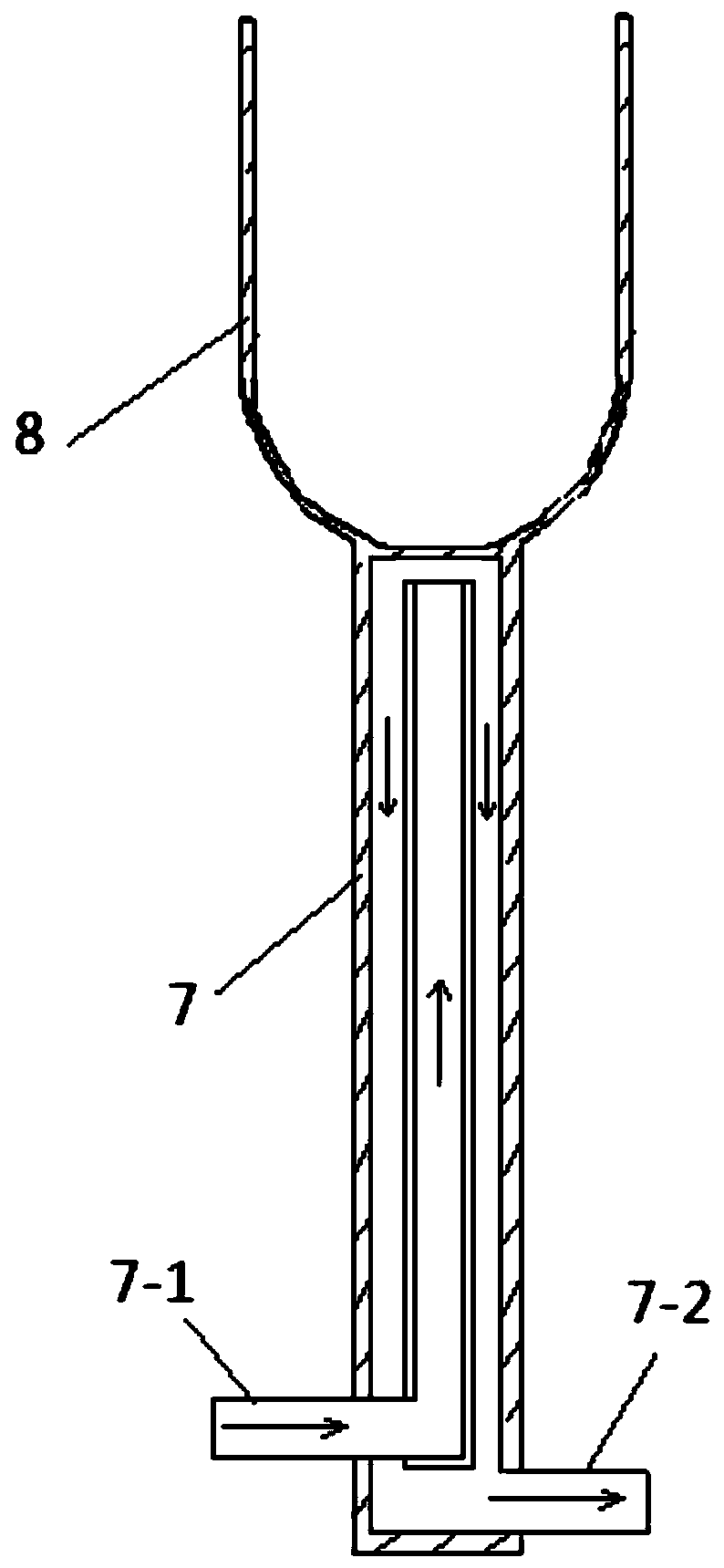

[0034] 2. Schematic diagram of the structure of the crystal growth furnace for growing crystals. figure 1 , 2 As shown, the upper part of the furnace body is a high-temperature zone 1, the lower part is a low-temperature zone 2, and the middle is a transition zone 3. The furnace is filled with alumina hollow balls 4 as insulation materials, and a resistance wire 5 is set in the cavity as a heating device, and a thermocouple 6 is set. As a temperature measuring device, the molybde...

Embodiment 2

[0042] Embodiment 2: The growth method of increasing heat transfer large-scale germanium phosphide zinc crystal of the present embodiment is carried out according to the following steps:

[0043] 1. Put the seed crystal 11 into the seed crystal well of the PBN crucible 9, and then add high-purity ZnGeP with a mass percent purity of 99.95% 2 Polycrystalline raw material 12, then PBN crucible 9 is put into quartz ampoule 10, then quartz ampoule 10 is evacuated to 10 -4 Pa for vacuum packaging;

[0044] Two, the structure of the crystal growth furnace of growing crystal is identical with the crystal growth furnace in embodiment 1; Quartz ampoule 10 is put on the crucible frame 8 in the crystal growth furnace, and the bottom of quartz ampoule 10 is positioned at low temperature zone 2, and quartz ampoule 10 The top of is located in high temperature zone 1; set the temperature in high temperature zone 1 to 1068°C, the temperature in low temperature zone 2 to 998°C, and the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com