Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Suppress eddy current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

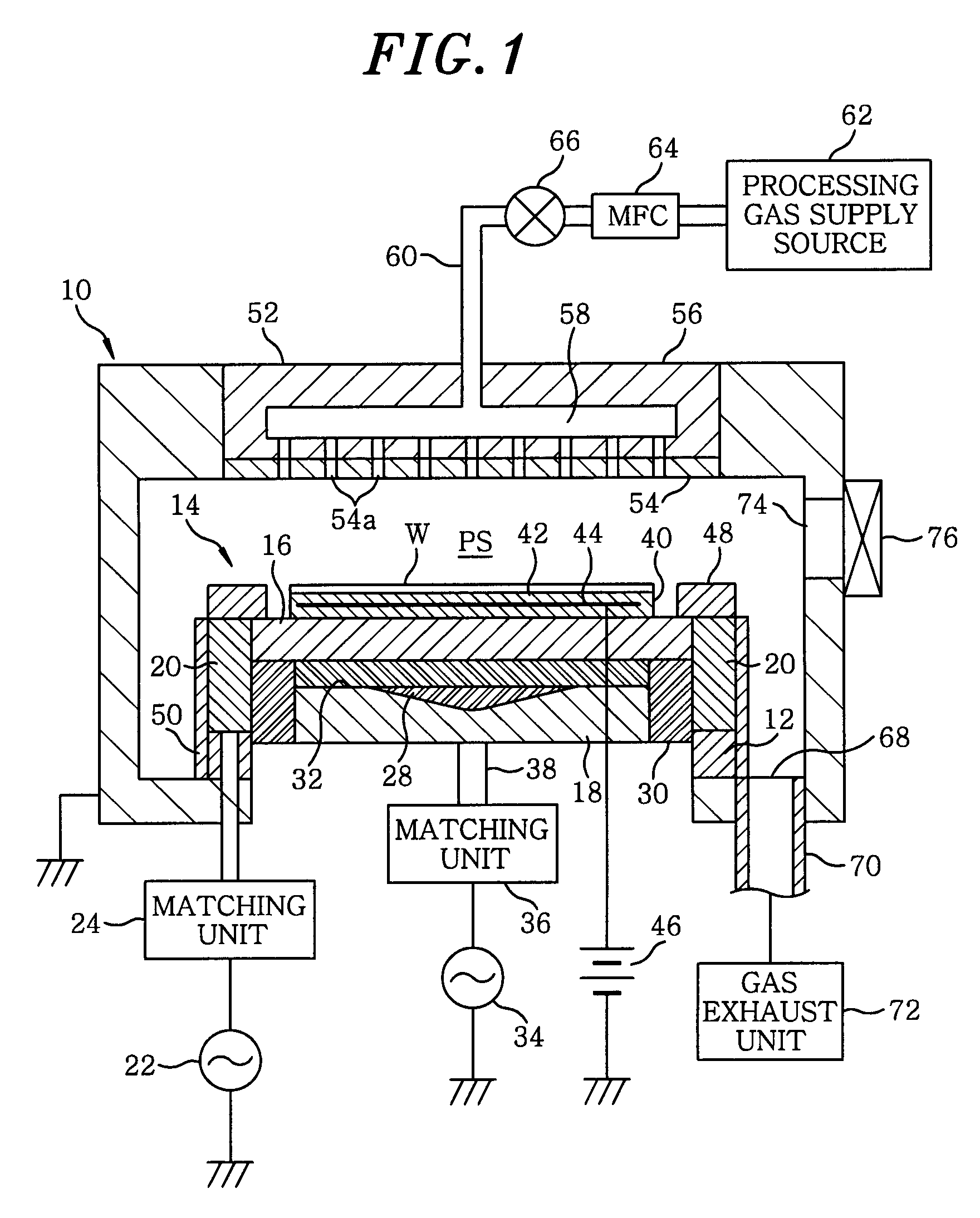

Plasma processing apparatus

ActiveUS20070227662A1Improve efficiencyImprove accuracyElectric discharge tubesSemiconductor/solid-state device manufacturingHigh frequency powerGas supply

In a plasma processing apparatus including a vacuum-evacuable processing chamber, a first lower electrode for supporting a substrate to be processed thereon is disposed in the processing chamber and an upper electrode is disposed above the first lower electrode to face the first lower electrode. Further, a second lower electrode is disposed under the first lower electrode while being electrically isolated from the first lower electrode. A processing gas supply unit supplies a processing gas into a space between the upper electrode and the first lower electrode. A first high frequency power supply unit applies a first high frequency power of a first frequency to the first lower electrode, and a second high frequency power supply unit applies a second high frequency power of a second frequency higher than the first frequency to the second lower electrode.

Owner:TOKYO ELECTRON LTD

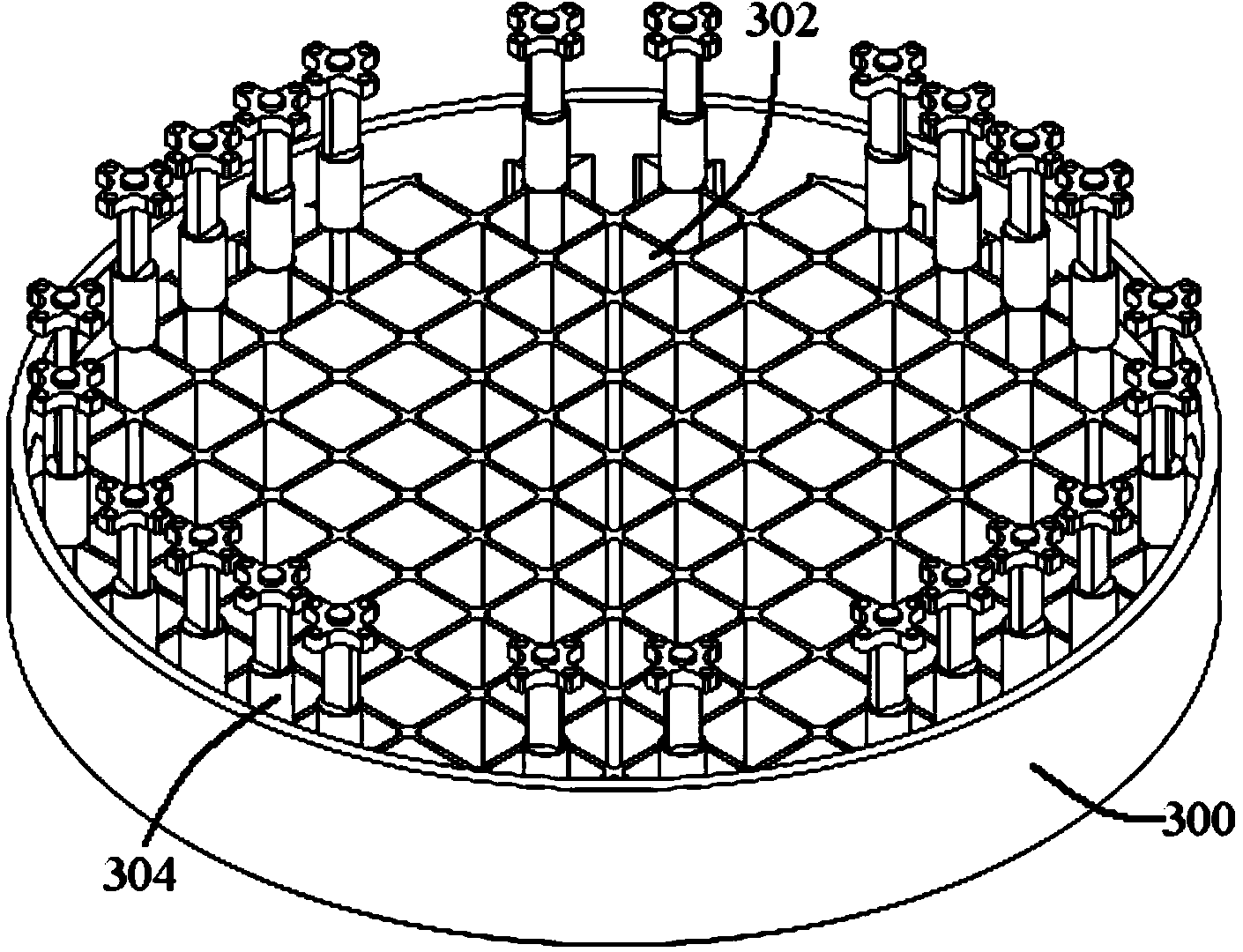

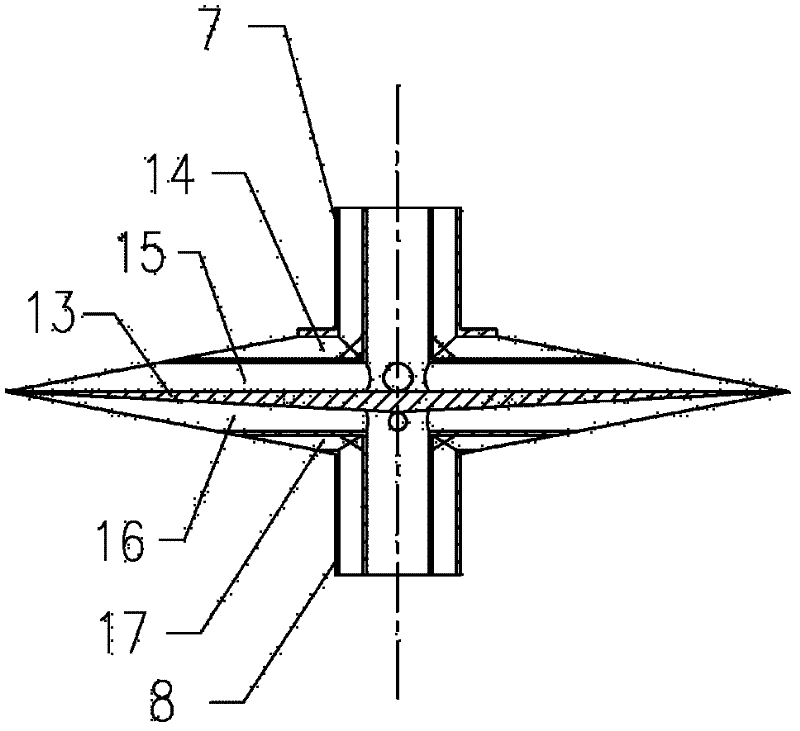

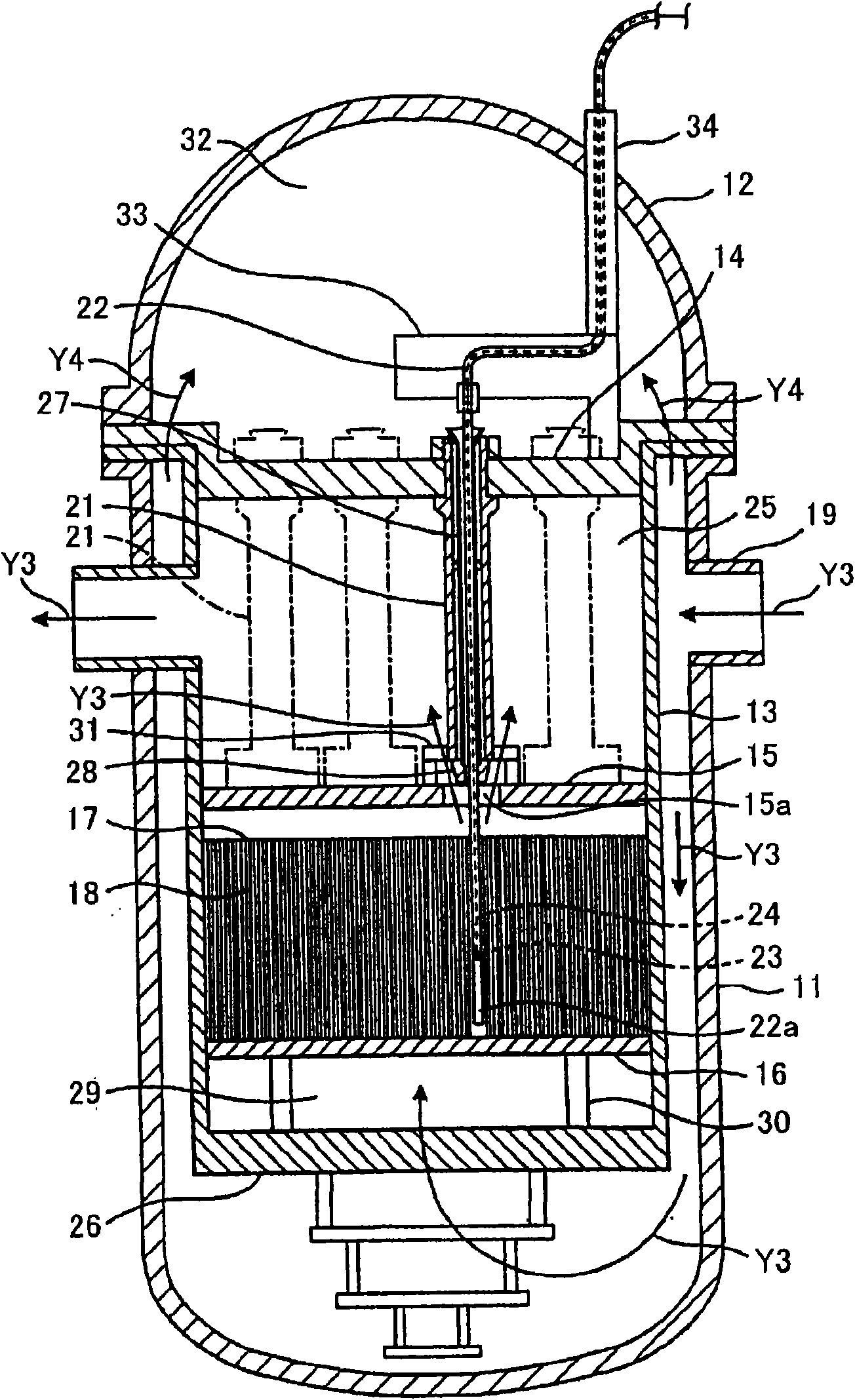

In-pile flow distribution device of reactor of nuclear power station

InactiveCN103971763ASimple structureImprove distribution uniformityNuclear energy generationShieldingNuclear powerNuclear engineering

The invention discloses an in-pile flow distribution device of a reactor of a nuclear power station. The device is used for distributing flow of a reactor core coolant; the flow distribution device comprises a lower reactor core support plate, a surrounding basket-shaped structure and vertical columns, wherein the surrounding basket-shaped structure is fixed below the lower reactor core support plate and comprises a porous surrounding basket and an eddy-current confinement plate positioned at the bottom of the porous surrounding basket; a plurality of flowing holes are respectively formed in the porous surrounding basket and the eddy-current confinement plate; the vertical plates are vertically arranged between the eddy-current confinement plate and the lower reactor core support plate. The in-pile flow distribution device of the reactor of the nuclear power station is relatively simple in structure, and by stirring and mixing the coolant through the eddy-current confinement plate and the vertical columns, eddy-current of a lower chamber is effectively inhibited, and the structure of the lower chamber is prevented from vortex shedding. The coolant is subjected to twice flow distribution through the surrounding basket-shaped structure and the lower reactor core support plate, so that the distribution effect is better, and the flow distribution uniformity in a reactor core fuel component is better.

Owner:中广核工程有限公司 +1

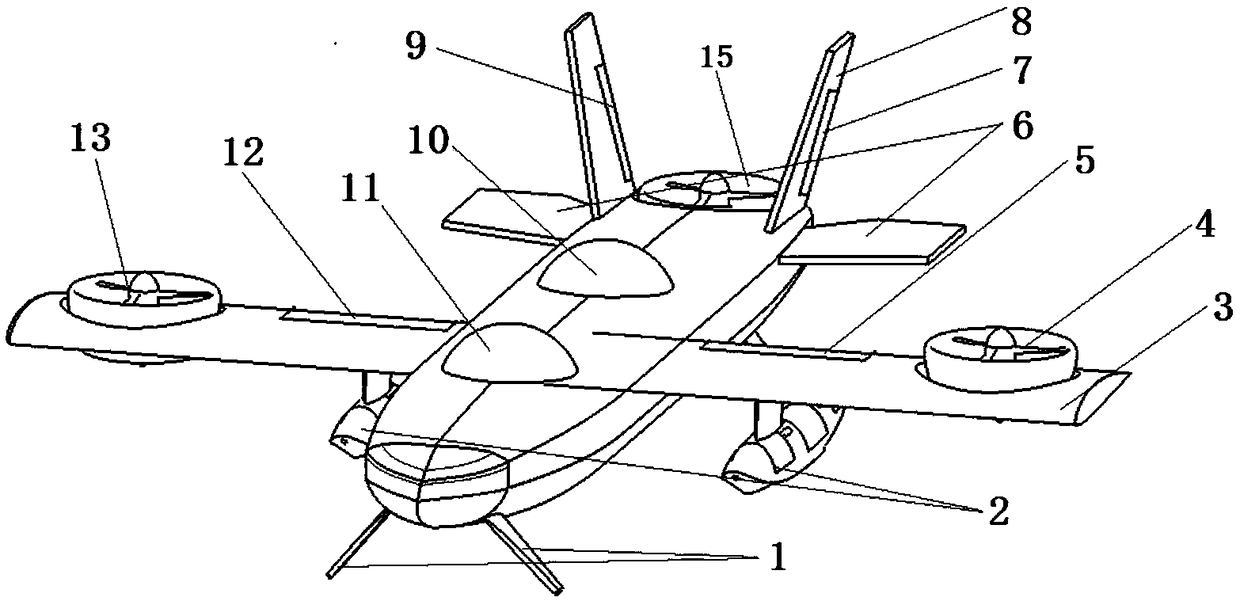

Polyxeny aircraft additionally provided with hydrofoil

PendingCN109353500AImprove performanceImprove protectionConvertible vehiclesSeaplanesDucted propellerVertical take off and landing

The invention discloses a polyxeny aircraft additionally provided with a hydrofoil, and belongs to the field of aslant-rotation aircrafts, hydrofoils and ducted propellers. A hydrofoil device is installed at the belly part of the lower end of an aircraft body, and a tail part ducted propeller is installed at the tail part of the upper end of the aircraft body; a set of V-shaped empennages are installed at the two sides of the tail part ducted propeller; a left ducted propeller and a right ducted propeller are installed at the upper ends of the ends of left and right aerofoils respectively; floats are symmetrically installed at the lower ends of the aerofoils. According to the polyxeny aircraft, the ducted propellers are utilized for replacing propellers, the performance of the aircraft canbe improved, the left ducted propeller, the right ducted propeller and the tail part ducted propeller can aslant rotate, and vertical take-off and landing of the aircraft on the water surface and theground can be achieved; meanwhile, the hydrofoil device is adopted, so that the aircraft has the quick and flexible water surface movement capability, and has the features of aslant-rotation aircrafts and foilcrafts.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Flat surface active shielded gradient coil preparation method

ActiveCN101191829AUniform linearityMagnetic field switching speed is fastMagnetic measurementsEngineeringSoftware

The invention discloses a method for making flat active shielding gradient coil, relating to the technique of flat active shielding gradient coil used in the MRI system. The method comprises the following steps of: making initial proposal according to the design index; using gradient magnetic field inversion calculation software to perform analog calculation to obtain the original design proposal; using large commercial magnetic field simulation calculation software to perform forward verification calculation to the original design proposal; amending repeatedly the design proposal by means of inversion calculation and forward calculation to obtain the primary proposal of the gradient coil; carrying out trail production of the gradient coil according to the primary proposal; testing the related technical data and enhancing the design proposal according to the result of the test to obtain high-performance flat active shielding gradient coil. The gradient coil made by the method of the invention can generate strong gradient magnetic field with uniform linearity and fast switching and can effectively avoid eddy current.

Owner:BEIJING WANDONG MEDICAL TECH CO LTD +1

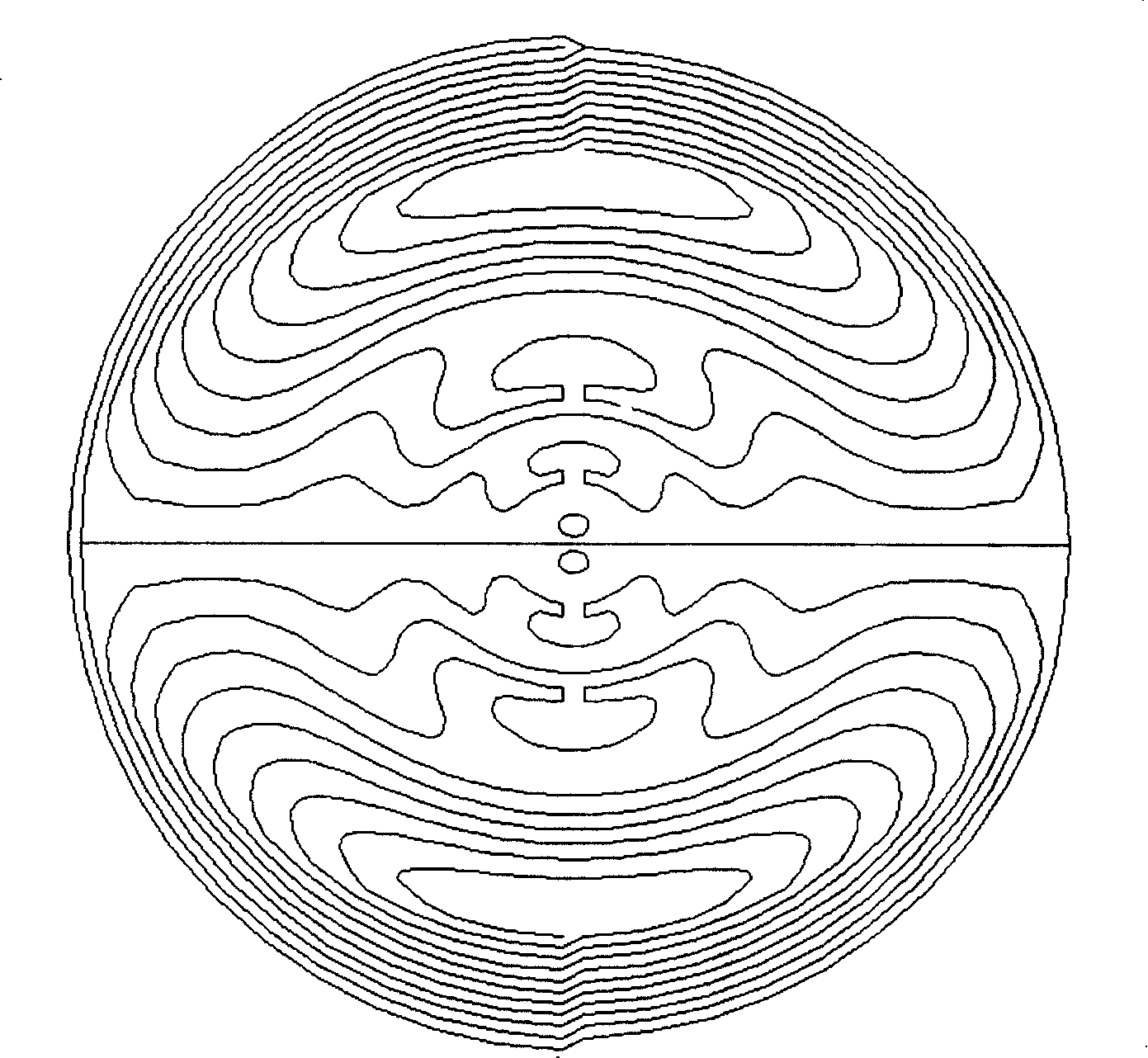

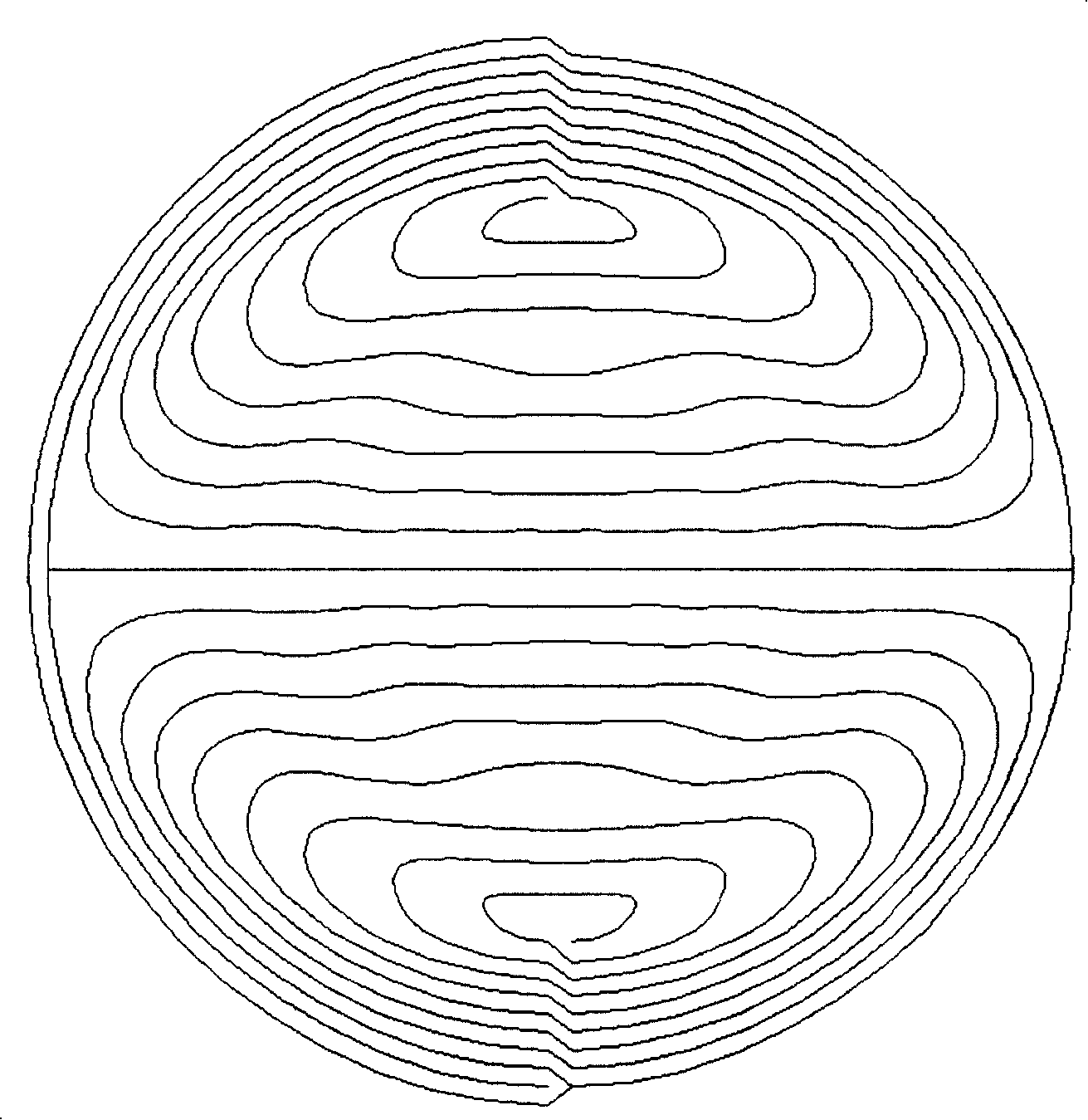

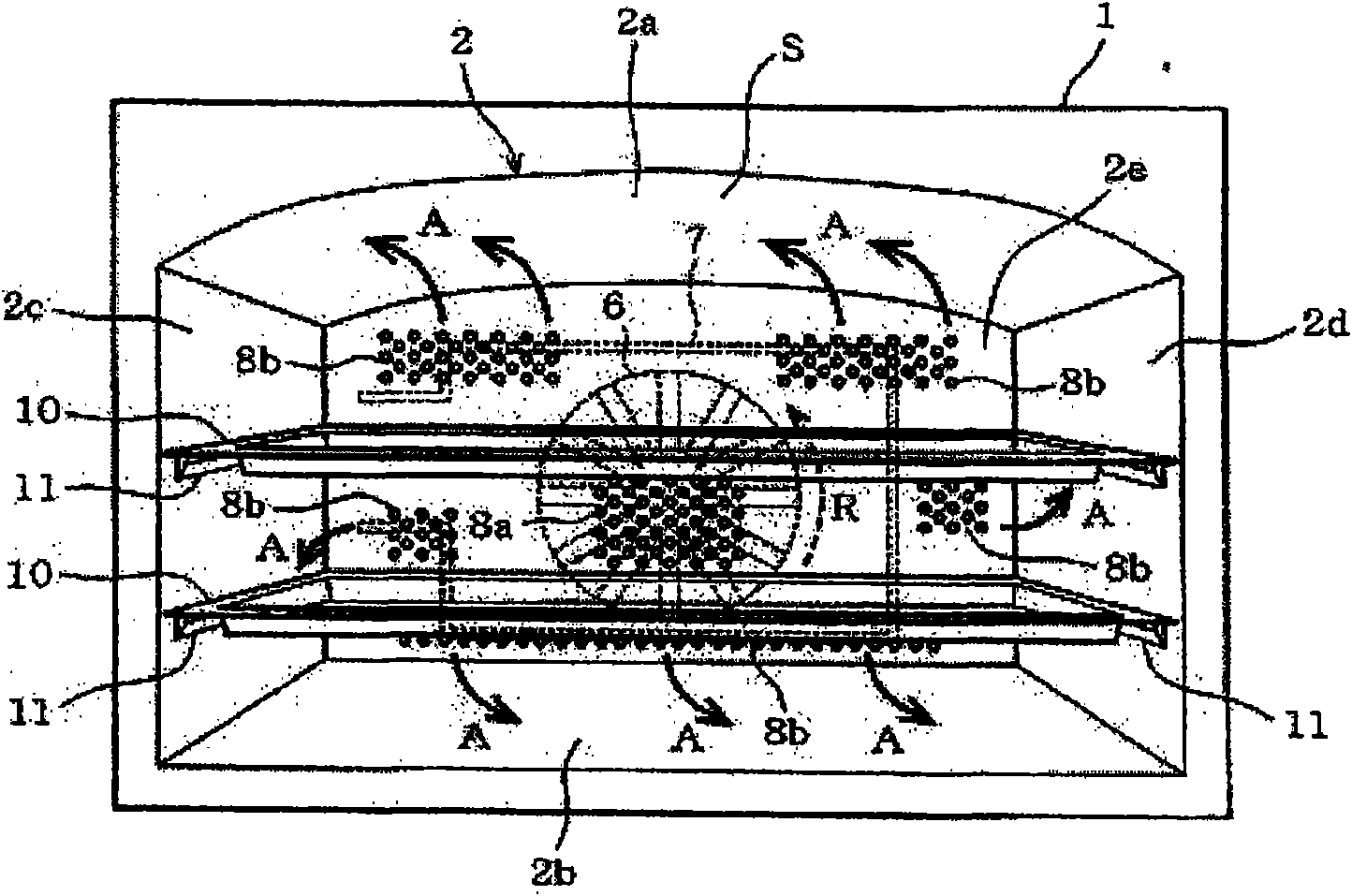

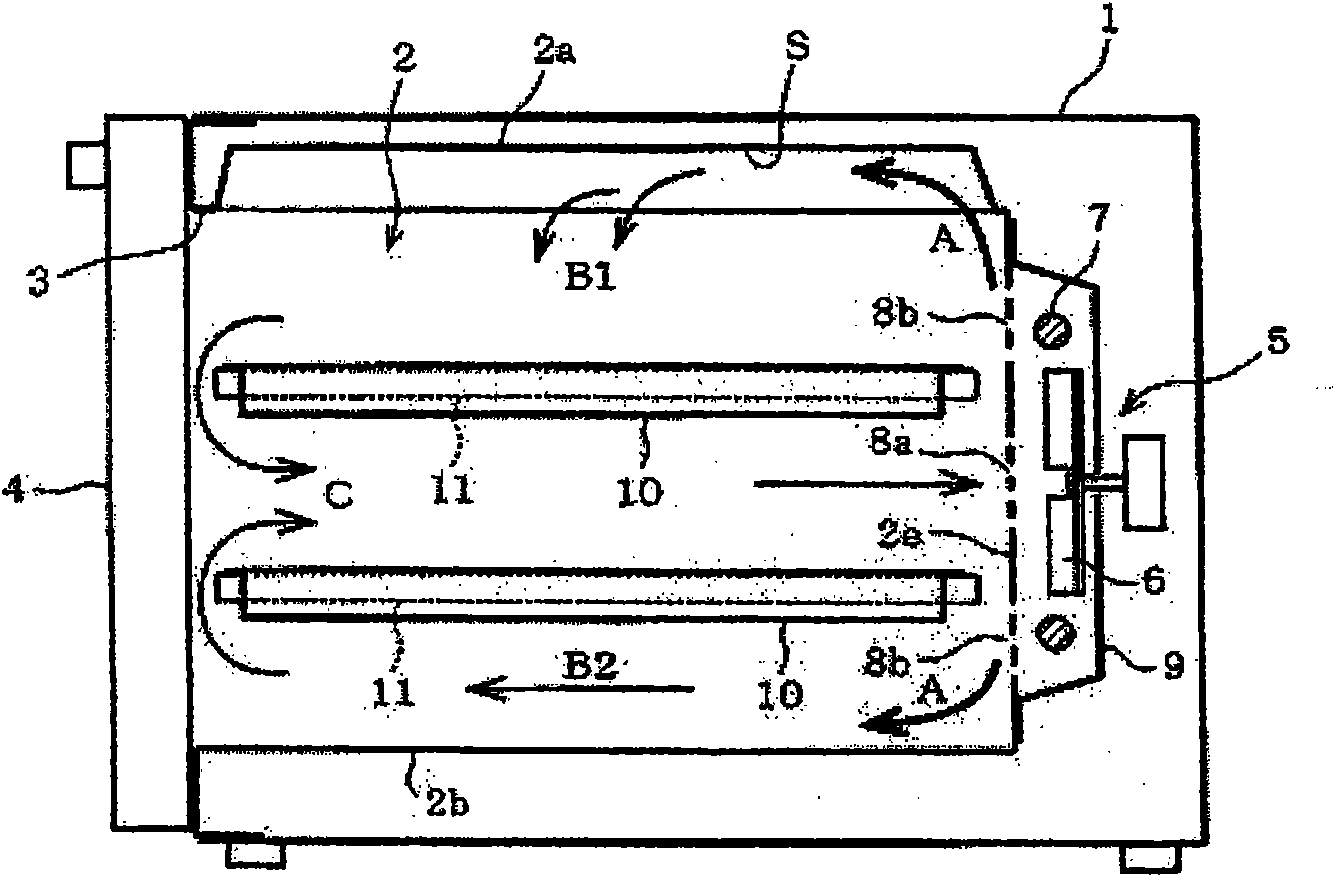

Heating cooking device

ActiveCN101660777ASuppress eddy currentPromote homogenizationDomestic stoves or rangesLighting and heating apparatusHot air ovenCurve shape

The present invention provides a heating cooking device, the hot air blown from a hot air circling unit can be evenly circled in a oven body and seek to equalization heating distribution. In order toheat the food contained in the oven body (2) by the hot air oven, the heating cooking device has a hot air circling unit comprising a hot air heater (7) and a hot air fan (6), wherein a curve shape portion (S) having a depressed inner side is arranged at least one of peripheral surface of the peripheral surfaces of the oven body (2) blowing hot air from the hot air circling unit.

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

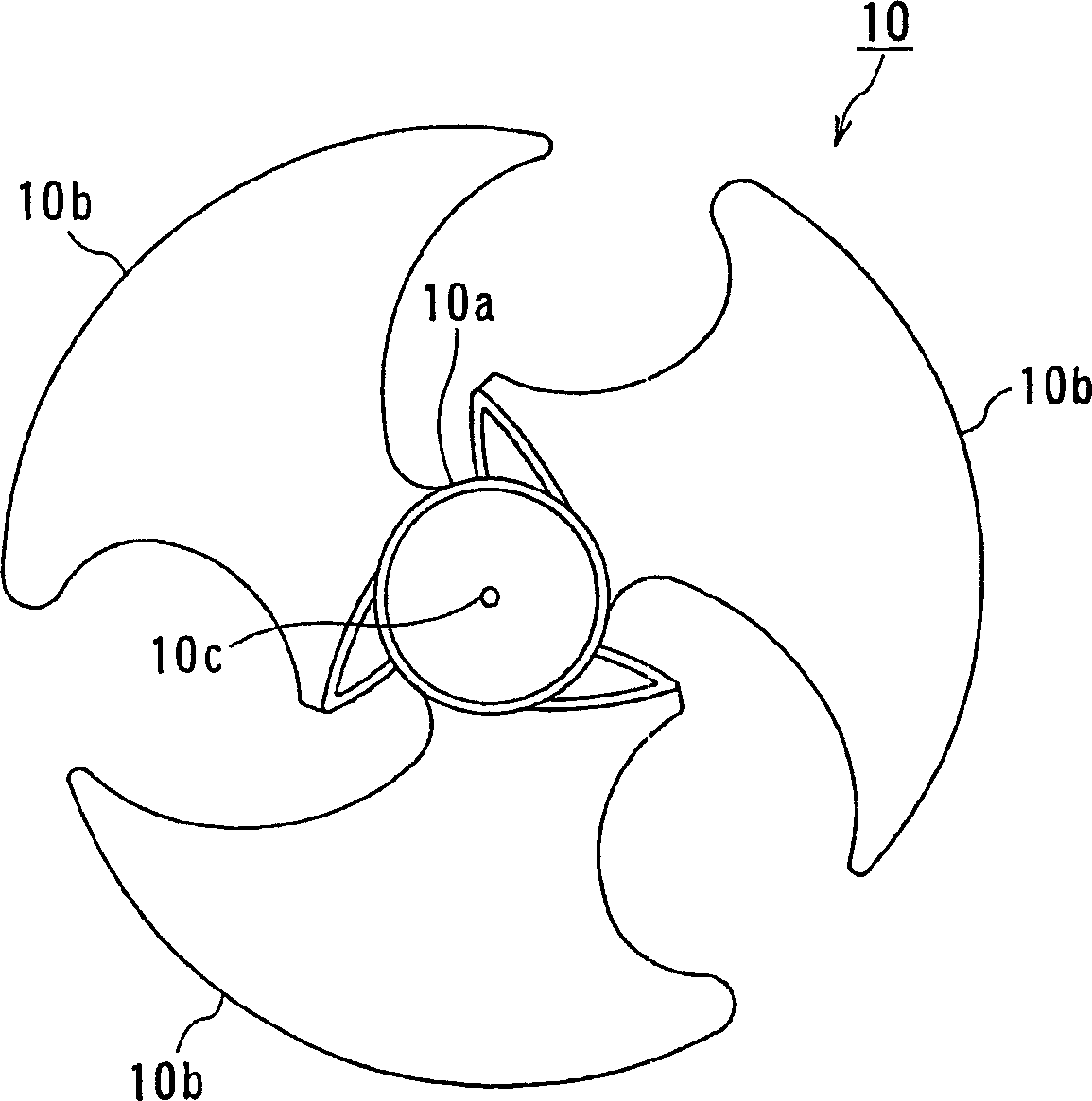

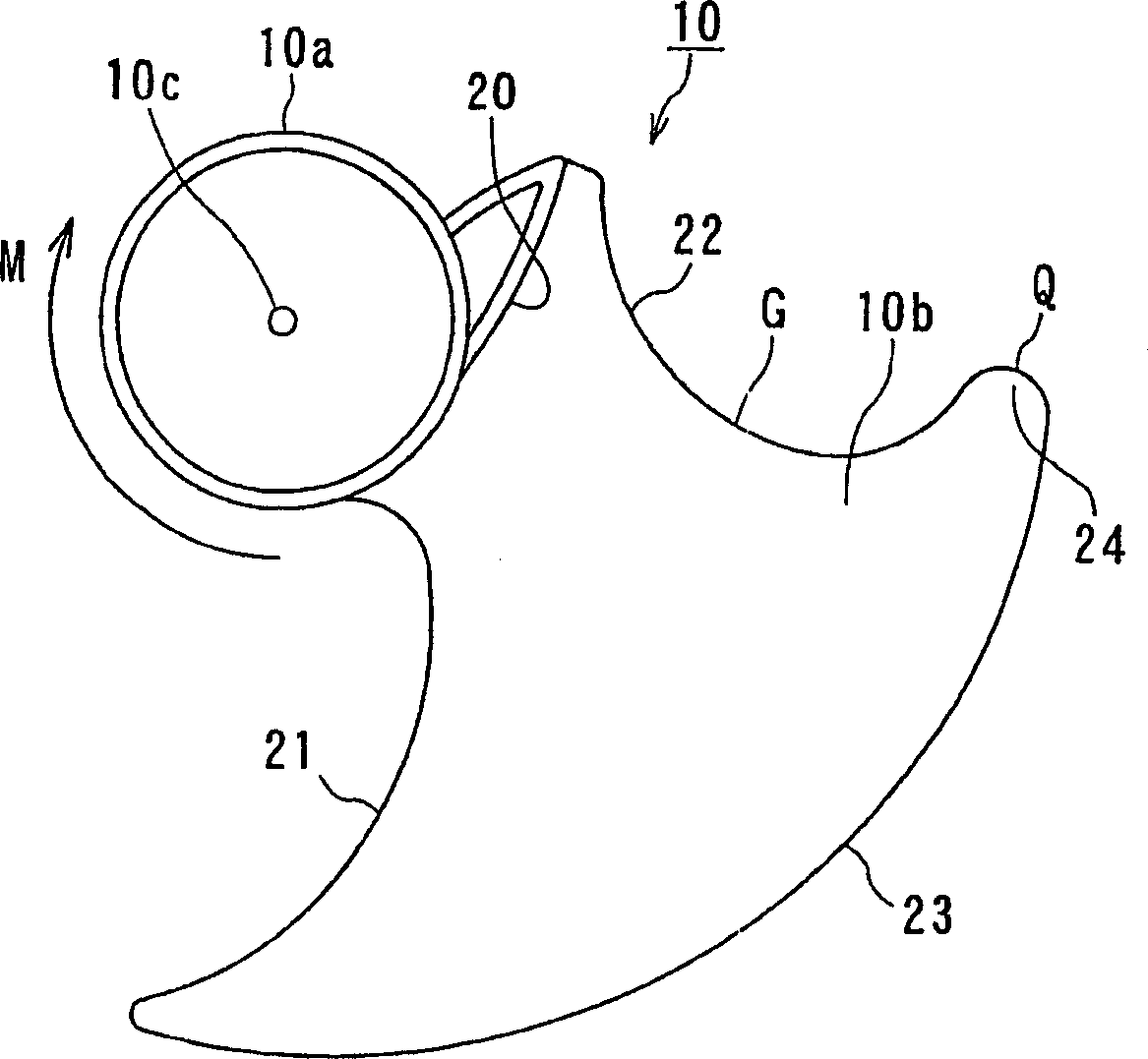

Propeller Fan

ActiveCN102341603ASuppress eddy currentImproved air supply-noise characteristicsPump componentsAxial flow pumpsRadial positionPropeller

Provided is a propeller fan comprising a hub fitted on a spindle, and a plurality of wings mounted radially on the hub for blowing a wind in the spindle direction. In a first region of the wing from the spindle to a predetermined radius, the edge line of the maximum camber in the cylindrical section of the wing, which is cut from the spindle along an arbitrary radius, is within 50 % of a wing chord length from a wing front edge. In a second region of the wing from the predetermined radius to a wing outer-edge, the edge line of the maximum camber in the cylindrical section of the wing, which is cut from the spindle along the arbitrary radius, is connected at the predetermined radial position to the edge line of the maximum camber of the first region, and is positioned, as radially enlarged, on the side of a wing trailing-edge, so that the edge line is within 50 % of the wing chord length from a wing front edge at the wing outer-edge.

Owner:MITSUBISHI ELECTRIC CORP

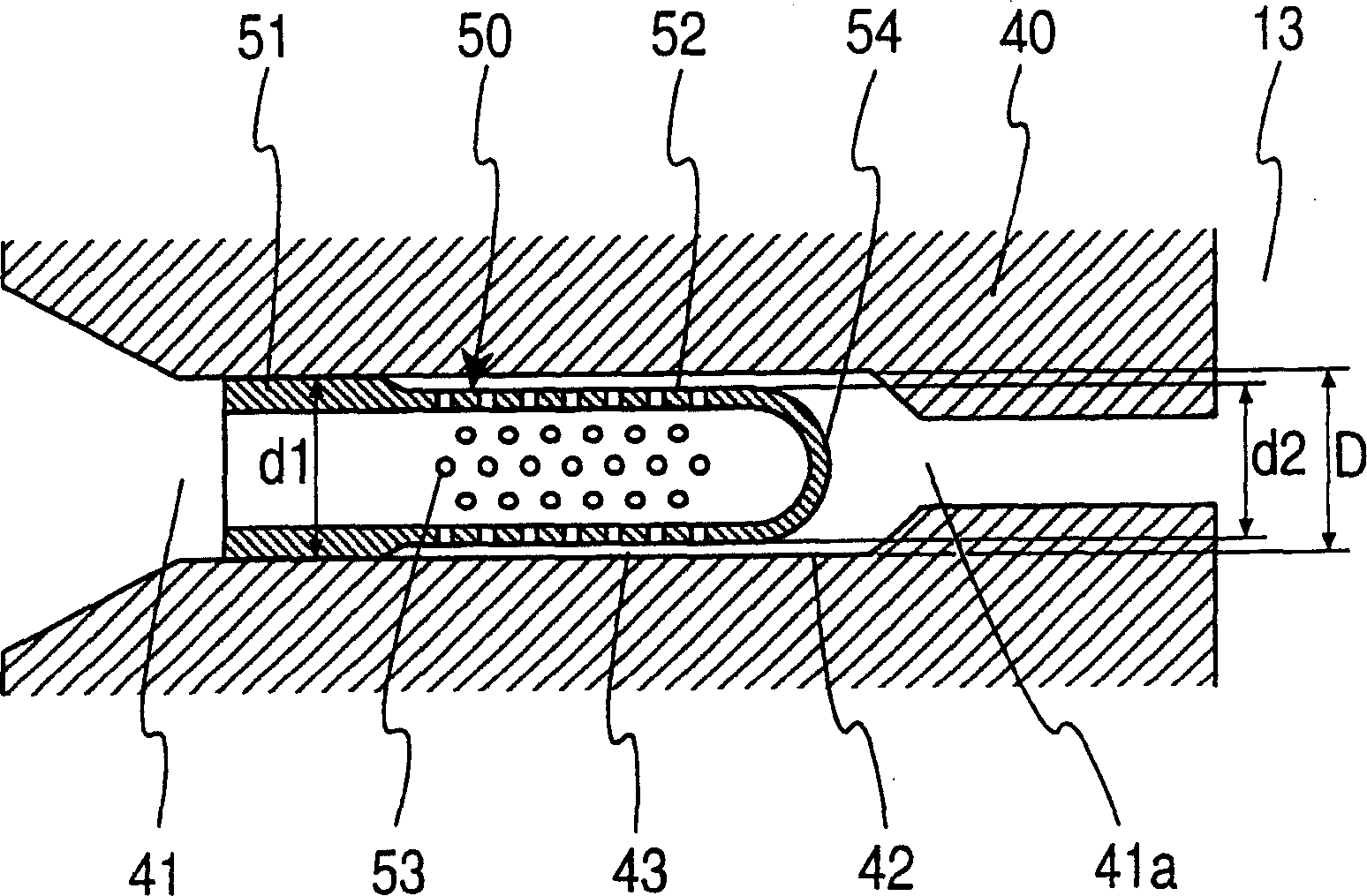

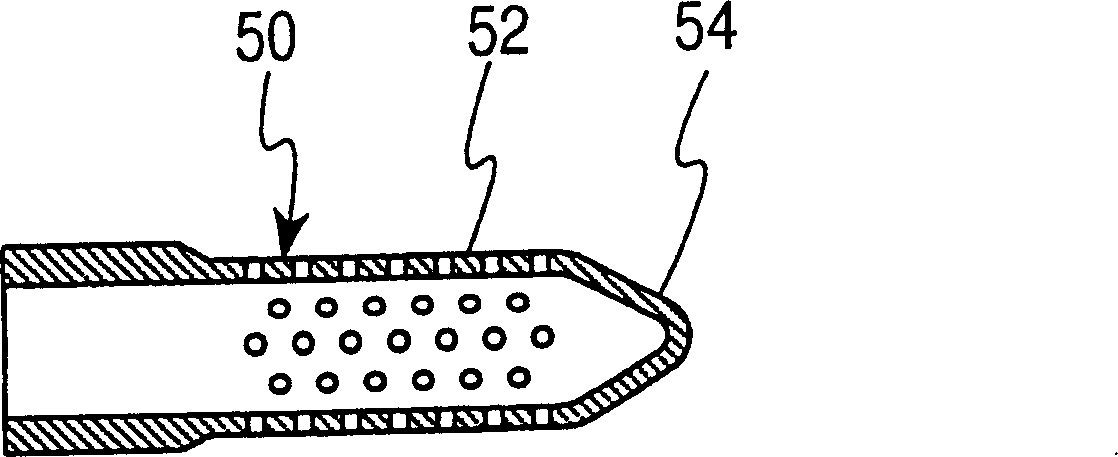

Filter with hole in its filtering part

ActiveCN1480639ASuppress eddy currentSmall pressure lossMachines/enginesMembrane filtersEngineeringInjector

A filter is press-inserted into a mounting bore of an injector. The filter has an inlet section at an opening-end fuel inlet side and a filter section which has a number of holes. The bottom of the filter section is hemispherically-shaped so that a flow area formed between the outer surface of the hemispherical bottom portion and the inner round surface of the mounting inlet bore widens gradually to reduce pressure loss effectively.

Owner:DENSO CORP

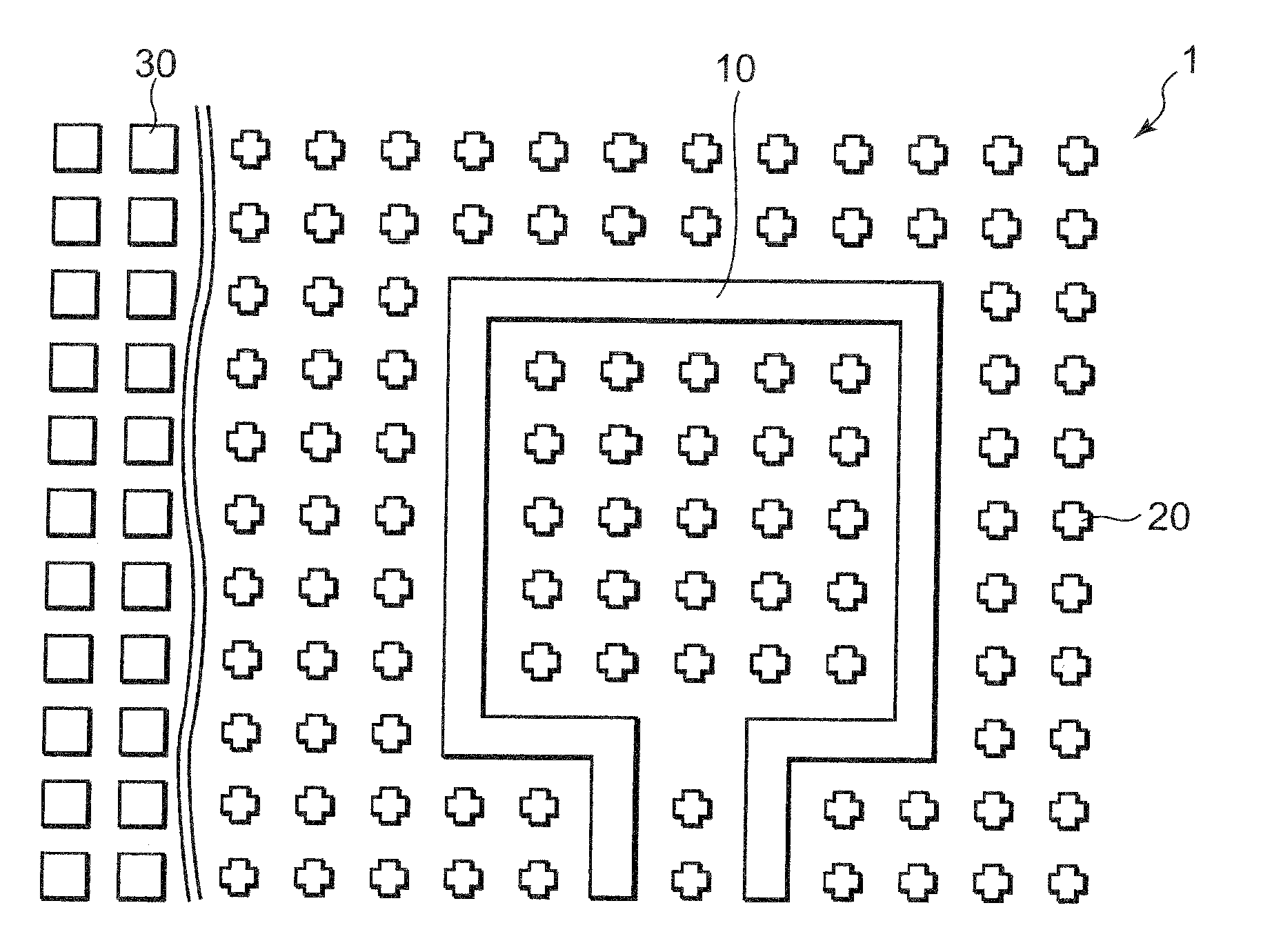

Semiconductor device

ActiveUS20080179719A1Increased complexityAvoid flowSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

A semiconductor device (1) includes a wiring (10) and dummy conductor patterns (20). The wiring (10) is a wiring through which a current with a frequency of 5 GHz or higher flows. Near the wiring (10), the dummy conductor patterns (20) are formed. A planar shape of each of the dummy conductor patterns (20) is equivalent to a shape with an internal angle larger than 180°.

Owner:RENESAS ELECTRONICS CORP

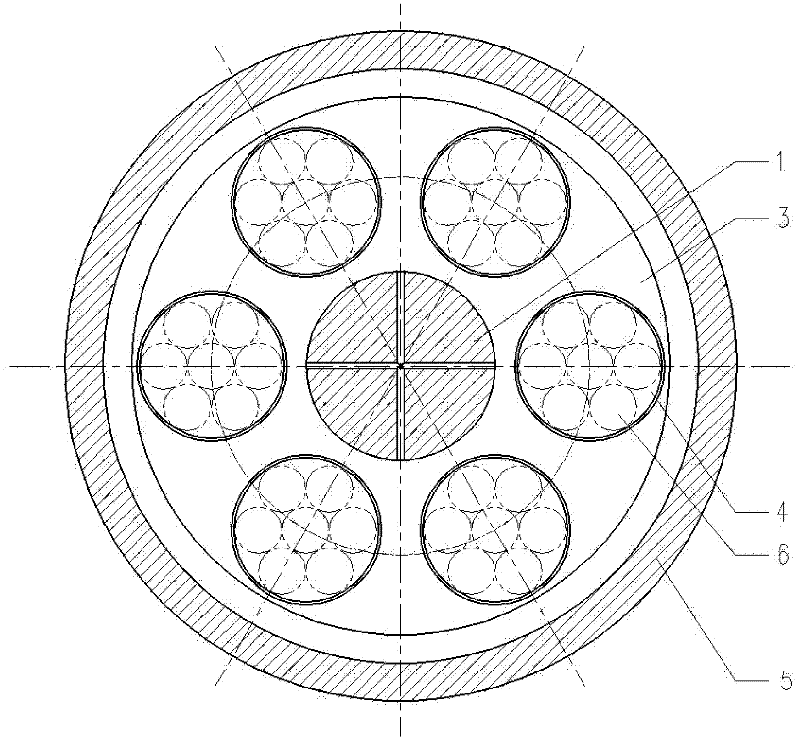

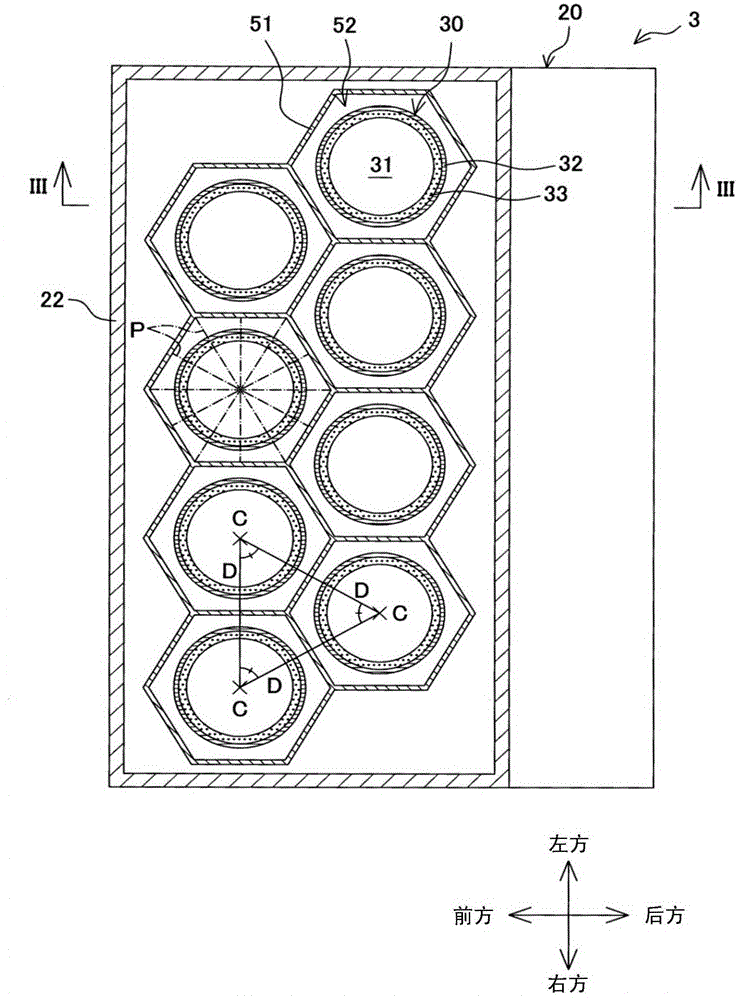

Suspended spraying type metal organic chemical vapor deposition (MOCVD) reactor

ActiveCN102234792ASmall sizeImprove uniformityFrom chemically reactive gasesChemical vapor deposition coatingSource materialGraphite

The invention relates to a suspended spraying type metal organic chemical vapor deposition (MOCVD) reactor, which can be used for the epitaxial growth of light emitting diodes (LEDs) on a large scale. The suspended spraying type MOCVD reactor comprises a nozzle, a base, a cover plate, flow diversion holes and a reaction zone, wherein the nozzle is arranged in the center of the base and comprises an upper nozzle and a lower nozzle; the lower nozzle is positioned on the lower part of the upper nozzle; the upper nozzle and the lower nozzle are provided with two radial channels respectively; the base comprise a large graphite disk; small graphite disks are arranged in the large graphite disk along the circumferential direction; wafer substrates are arranged in each small graphite disk along the circumferential direction; the bottom of the large graphite disk is provided with a revolution driving mechanism; the bottom of each small graphite disk is provided with an autorotation drive mechanism; and the flow diversion holes are formed on the inner wall of the cavity of the reaction zone along the circumferential direction. The suspended spraying type MOCVD reactor can improve the deposition uniformity of thin films and the utilization rate of source materials, prolong the service life of the graphite disks of the base, improve the introduction of source gas and the distribution of carrier gas, optimize the designs of the size of the reactor and the curve surface of the cover plate and prevent the generation of eddy current.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

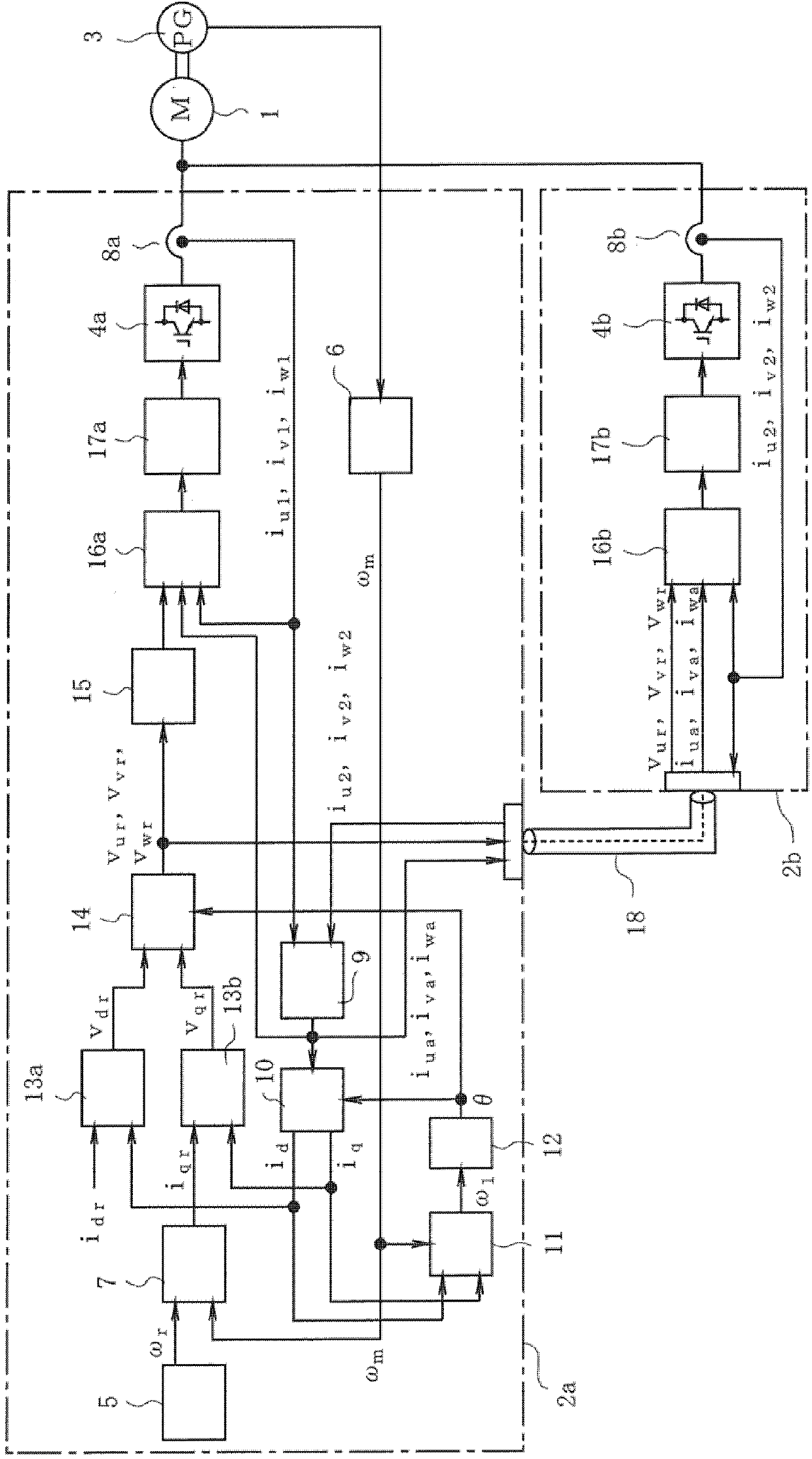

Parallel inverter device

Inverters connected in parallel each include a power converter that carries out a direct current to alternating current conversion and supplies voltage to a motor, and a control unit, where one of the inverters is a master inverter and the control unit computes a voltage command value for the power converter in the one inverter, while the other inverter is a slave inverter and the power converter in the slave inverter is driven by the voltage command value, a transmission means transmits the voltage command value, and the control unit of the master inverter includes a delay device that delays the voltage command value by a transmission time needed when transmitting a computed voltage command value to the slave inverter, and provides the voltage command value delayed by the delay device to the power converter of the master inverter.

Owner:FUJI ELECTRIC CO LTD

Novel bridge vortex-induced vibration suppression device replacing protective guard

PendingCN111910504AAvoid wind loadsWind loadBridge structural detailsBridge deckStructural engineering

The novel bridge vortex-induced vibration suppression device is characterized in that the novel bridge vortex-induced vibration suppression device comprises a plurality of suppression assemblies composed of protective railings and grids, the protective railings are longitudinally arranged on a bridge floor main beam, heightening grids are transversely arranged at the bottoms of the protective railings, and the grids are transversely arranged at the upper portions of the protective railings; the centers of the two ends of the grid and the heightening grid are movably connected with the protective barrier and can be turned over and opened around the joint. According to the utility model, the formation of vortex vibration is inhibited from the source, the grid can be completely opened at a dangerous wind speed, the wind drag coefficient is reduced, the main beam is prevented from being subjected to an overlarge wind drag load, and the opening height of the grid can be adjusted in a targeted manner by the intelligent grid according to the condition of the wind speed, so that the generation of eddy current of the whole bridge is better inhibited. The system is an important component ofan intelligent control system.

Owner:CHINA MERCHANTS MARINE & OFFSHORE RES INST CO LTD +1

Thrust generating apparatus

InactiveCN101602401AGood steeringSimple structureSteering by propulsive elementsPropulsive elementsEngineeringNozzle

A thrust generating apparatus is provided that can transform a spouting water flow having a small diameter into a water flow having a large diameter, and that can be provided at the bow or the stern end. A bell-shaped nozzle is coupled to an ejection port of a pump water flow, a ring having a blade-shaped cross section is disposed inside the nozzle, and a shell-shaped cone is disposed inside the ring on the center line of a water flow. Thereby, an ejection flow is straightened, and a thrust is generated. In addition, the bottom of the cone is open, a slit is further provided at a shoulder portion of the cone forward of the ring, and the water flow inside the cone is in communication with a water flow outside the cone. Furthermore, a rotating door is provided that enables the nozzle to pivot toward a shell plating opening on a port side or a starboard side, and that closes or opens the shell plating opening in accordance with the position of the nozzle.

Owner:长山明

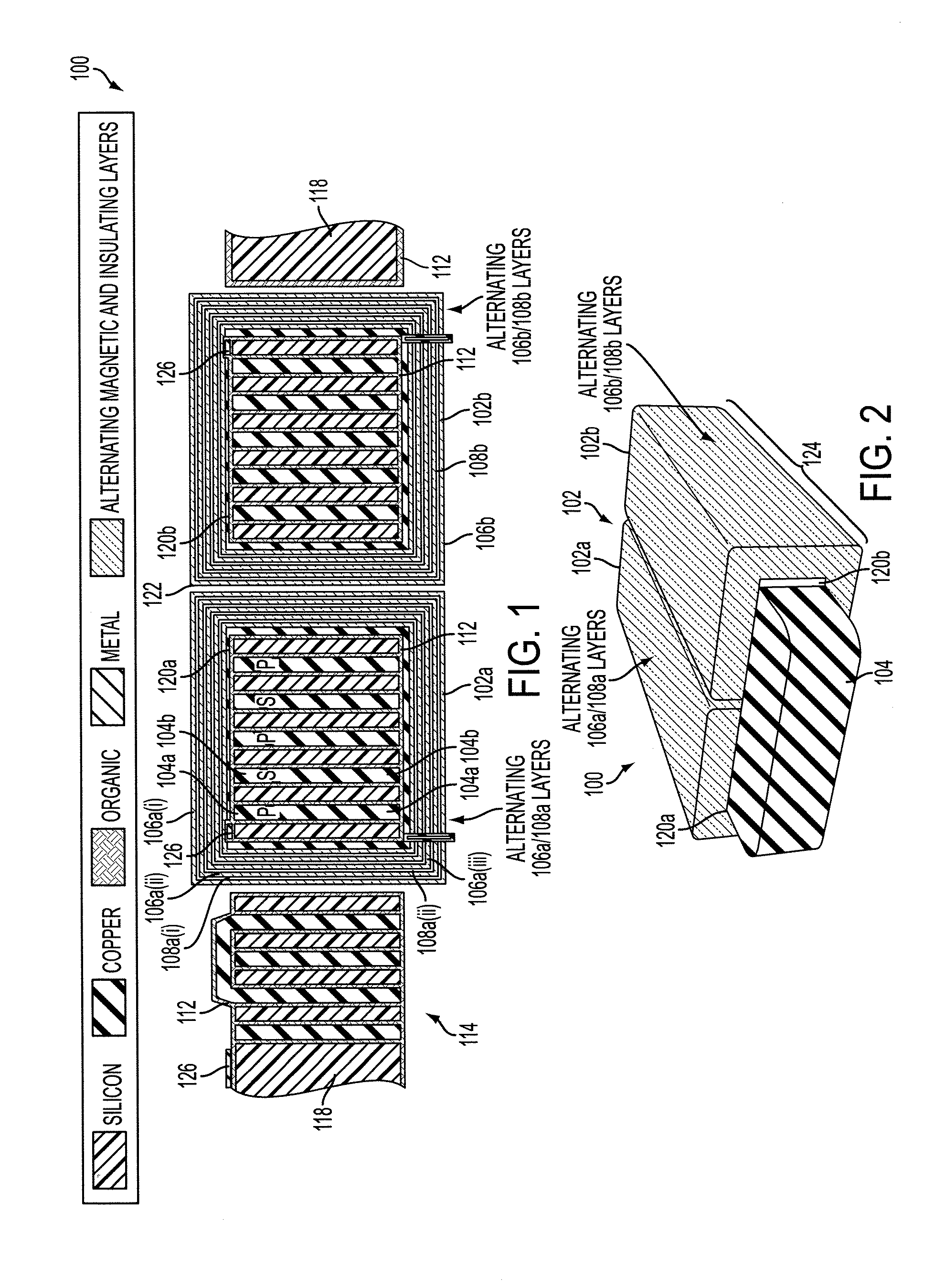

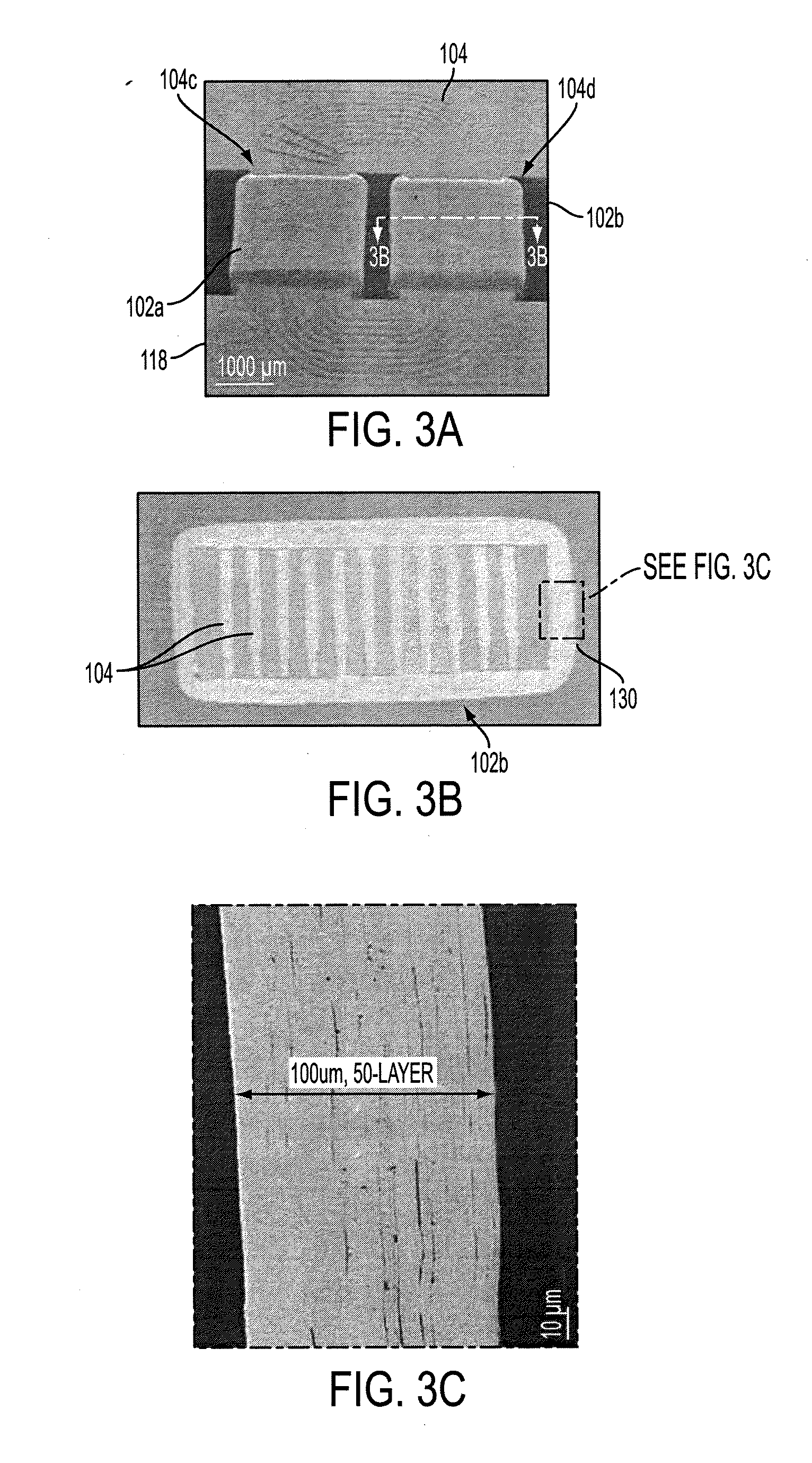

Micro-fabricated integrated coil and magnetic circuit and method of manufacturing thereof

ActiveUS20160064470A1Improve power densityImprove transient responseSemiconductor/solid-state device detailsSolid-state devicesEngineeringConductor Coil

A micro-fabricated electromagnetic device is provided for on-circuit integration. The electromagnetic device includes a core. The core has a plurality of electrically insulating layers positioned alternatingly between a plurality of magnetic layers to collectively form a continuous laminate having alternating magnetic and electrically insulating layers. The electromagnetic device includes a coil embedded in openings of the semiconductor substrate. An insulating material is positioned in the cavity and between the coil and an inner surface of the core. A method of manufacturing the electromagnetic device includes providing a semiconductor substrate having openings formed therein. Windings of a coil are electroplated and embedded in the openings. The insulating material is coated on or around an exposed surface of the coil. Alternating magnetic layers and electrically insulating layers may be micro-fabricated and electroplated as a single and substantially continuous segment on or around the insulating material.

Owner:TELEDYNE SCI & IMAGING

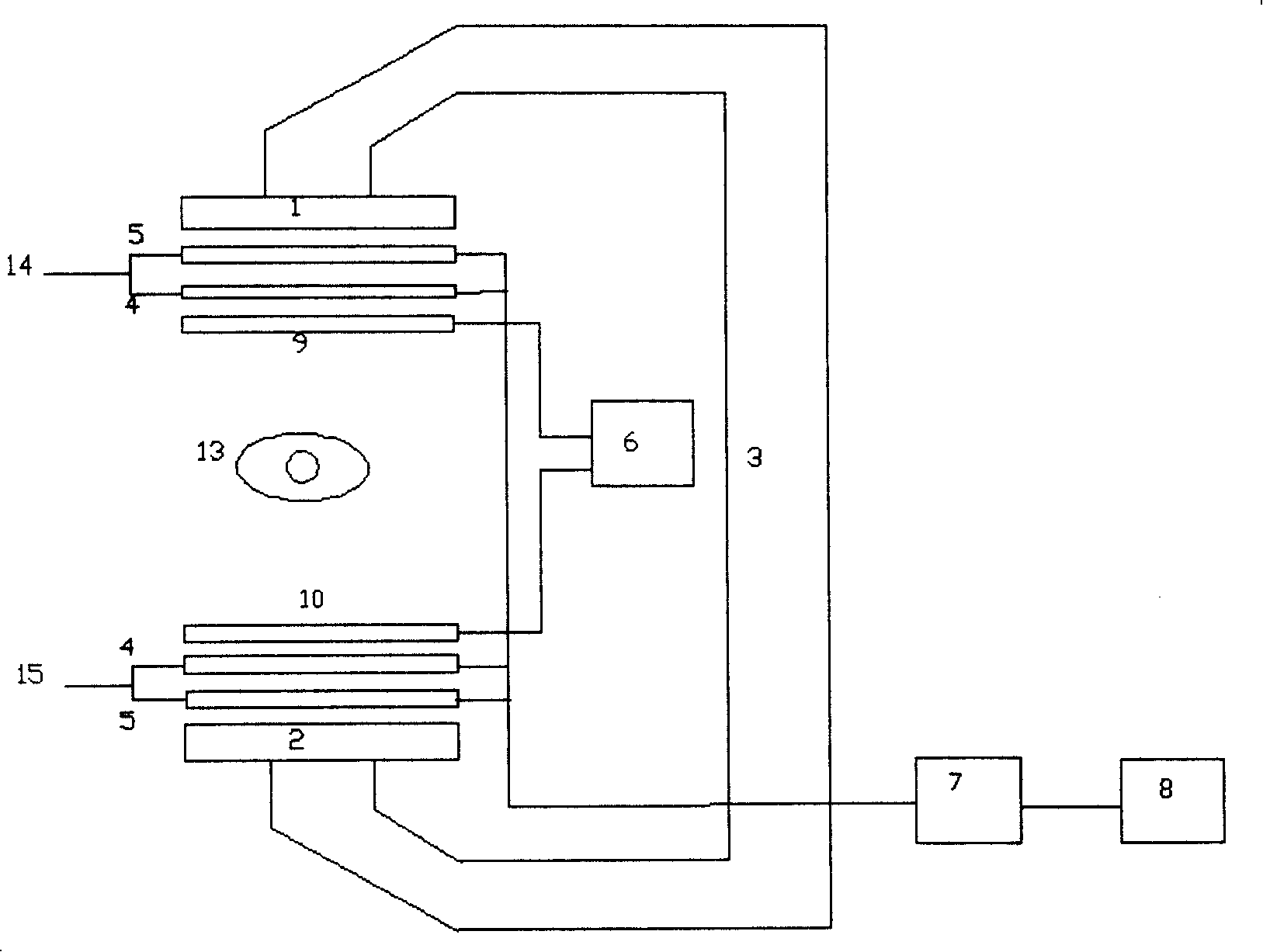

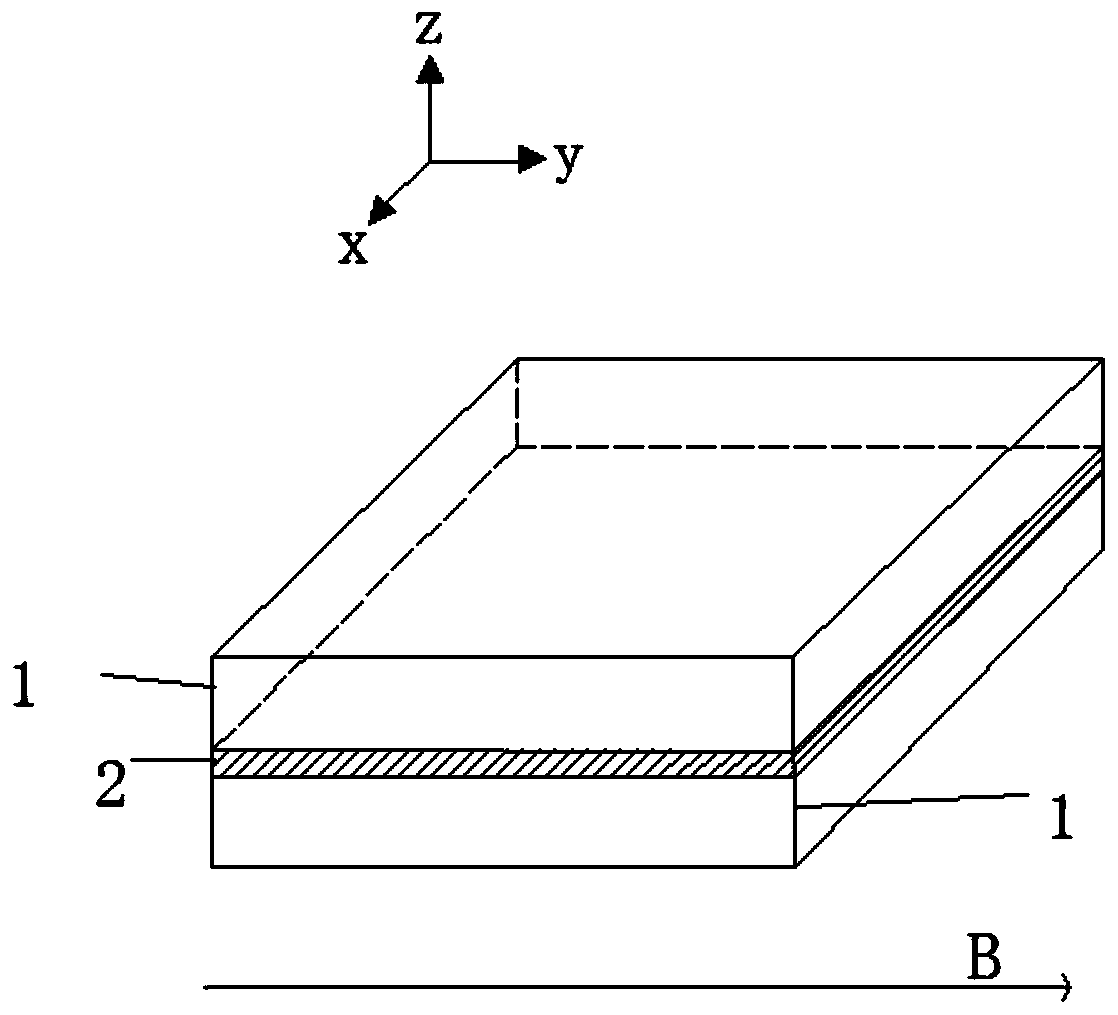

Treatment of eddy current on polar plate in permanent magnet device of magnetic resonance imaging system

InactiveCN1399940AImprove image qualitySuppress eddy currentDiagnostic recording/measuringSensorsElectrical resistance and conductanceNMR - Nuclear magnetic resonance

The method of treating eddy current on the polar plate in permanent magnet device of nuclear magnetic resonance imaging system is characterized by that the polar plate (component) of its permanent magnet is formed from polar plate body, filtering layer, isolating layer for separating polar plate body and filtering layer, protecting layer for protecting filtering layer and uniform filed ring. It can make the eddy current be filtered off in the filtering layer, and make it do not infiltrate into the polar plate, and between filtering layer and polar plate body there are higher electric resistance and magnetic resistance, and the filtering layer material and insulating material mixed and overlapped direction is perpendicular to the direction of magnet working space magnetic field. Said invention can effectively inhibit eddy current so as to greatly can raise imaging quality.

Owner:WUHAN HONGJIAN ELECTRIC TECH

Gas spraying head and deposition device

ActiveCN105779970AUniform flowWell mixedChemical vapor deposition coatingEngineeringMechanical engineering

The invention discloses a gas spraying head and a deposition device. The gas spraying head comprises a cooling plate with an upper surface and a lower surface opposite to each other; the cooling plate includes a center area and a peripheral area; the peripheral area includes multiple cooling pipe areas; each cooling pipe area has a set of cooling pipes; one set of cooling pipes includes multiple arc pipe sections arranged from the center to the edge of the cooling plate in parallel; all the arc pipe sections are positioned on concentric circles with different radius; multiple connecting parts are arranged between the multiple arc pipe sections and the adjacent arc pipe sections; multiple ventilation grooves are formed among the connecting parts; the ventilation grooves penetrate through the cooling plate along the side walls of the adjacent arc pipe sections, and are positioned on the concentric circles with different radius; in one cooling pipe area, one set of ventilation grooves formed by the multiple ventilation grooves on the concentric circles with the same radius are communicated to a first gas output port and a second gas output port along with radius increment; and the center area includes multiple intake ports penetrating through the cooling plate. The gas spraying head can improve the film forming quality.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

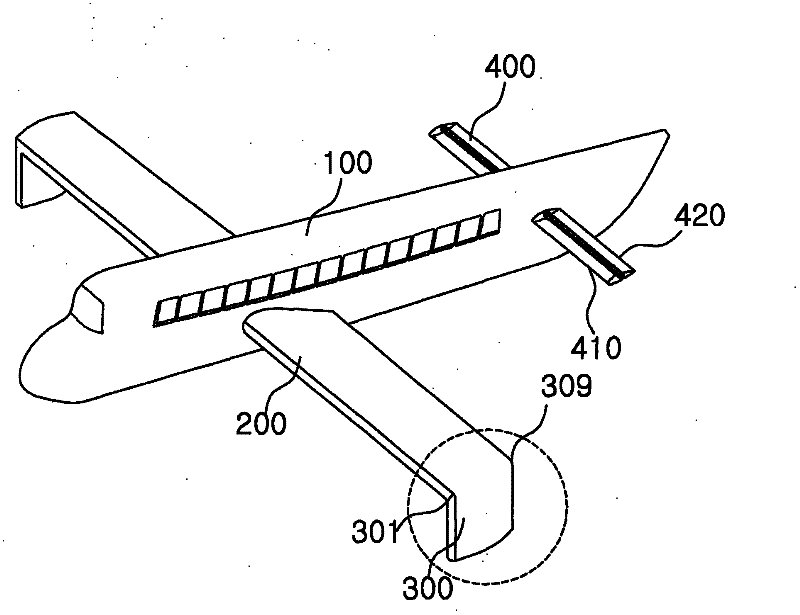

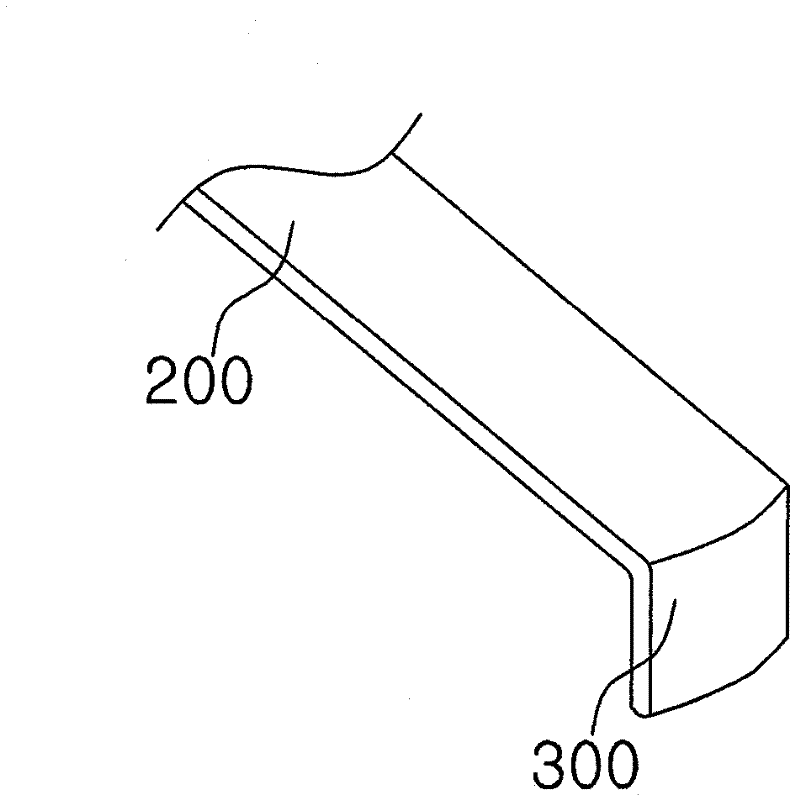

Wing structure for wig vehicle

InactiveCN102131695ASuppress eddy currentLarge thrustAircraft stabilisationDrag reductionRudderFuselage

The present invention relates to a wing structure for a WIG vehicle. More specifically, the wing structure of a WIG vehicle comprises left and right side main wings, left and right downward wings, and a rudder unit. The left and right main wings protrude out from the central portions of left and right sides of the WIG vehicle. The panel of the main wing is flat and tapers successively toward the lateral edge, whereof the cross-section is airfoil-shaped and has the shape of a tadpole. The panel shaped left and right downward wings are connected with both ends of the left and right main wings without a joint and are formed heading downward to suppress vortex and guidance drag generated in both ends of the main wings. The rudder units are mounted on the rear surface of the left and right downward panels with a slight gap in order to compensate asymmetry between left and right lateral ends caused by movement under control of the fuselage driving unit of the WIG vehicle and to turn the fuselage left or right. Therefore, the wing structure of the WIG vehicle is capable of minimizing vortex and guidance drag generated in both ends of the left and right main wings by maximizing ground effect. Additionally, the wing structure has advantages for absorbing impact from the fuselage when taking off and landing and stabilizing horizontal disturbance of the fuselage because the left and right downward wings occupy much more volume than a winglet.

Owner:WING SHIP TECH CO LTD

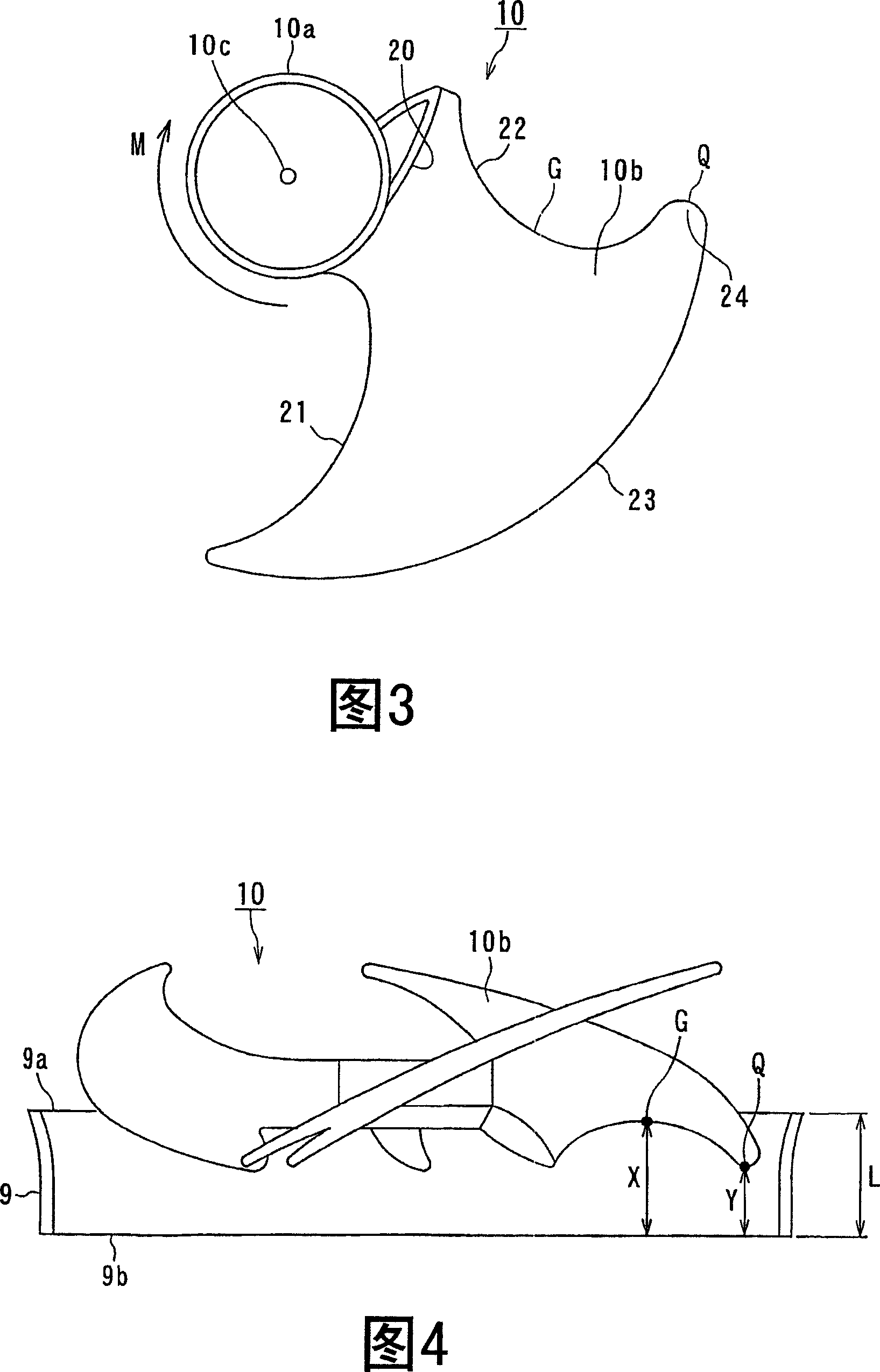

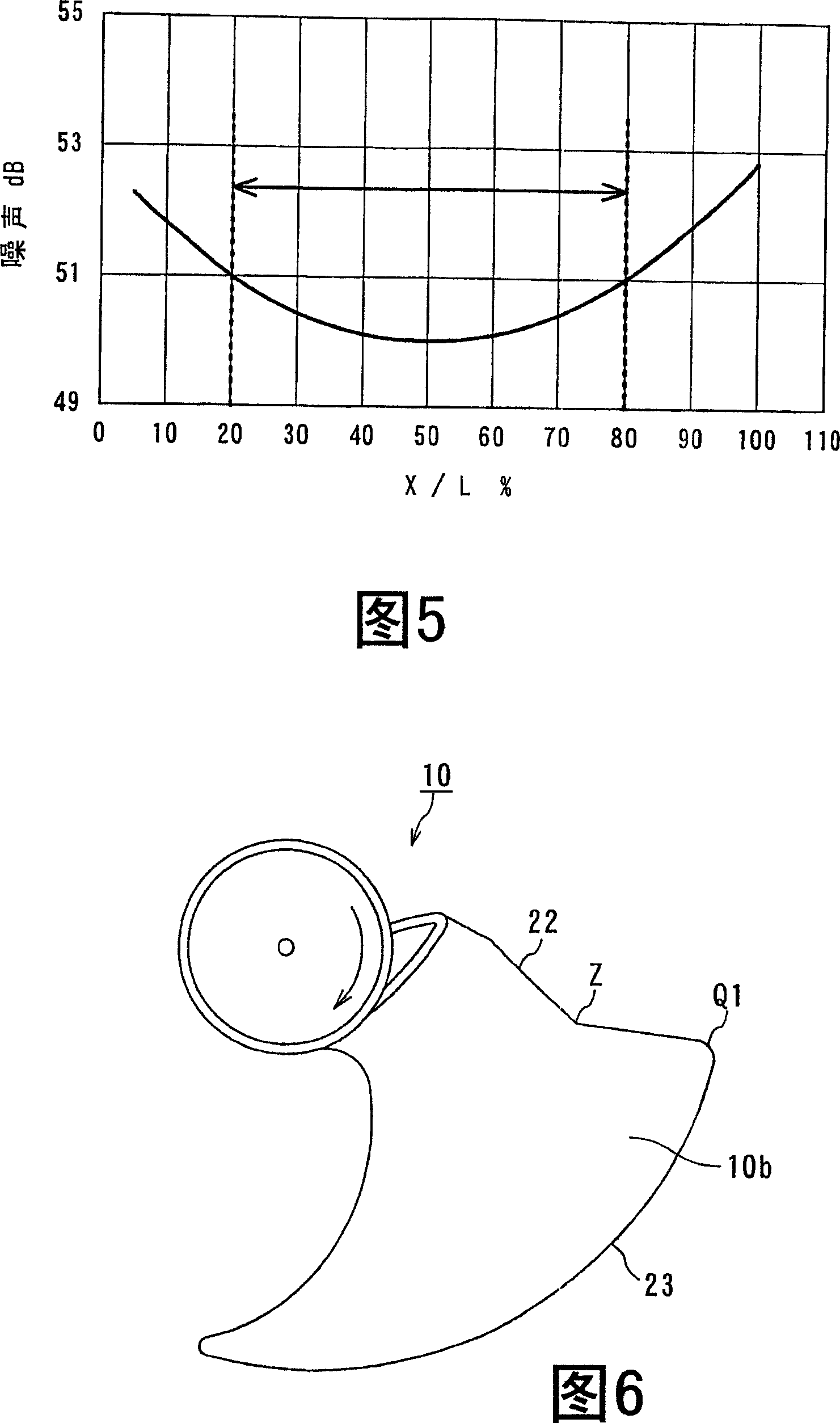

Outdoor unit for air conditioner

ActiveCN101025281AReduce noiseReduce loadPump componentsLighting and heating apparatusFront edgeAxial length

An outdoor unit for an air conditioner has an axial-flow fan and a bell mouth. The axial-flow fan is constructed by arranging blades at predetermined intervals along the outer periphery of a hub, each of the blades being formed such that the outline of its rear edge relative to the rotational direction is recessed toward its front edge. The bell mouth is provided on the side of air blow by the axial-flow fan. An axial-flow blower is provided in the outdoor unit. The bell mouth and the axial-flow fan are arranged in the axial-flow blower such that a ratio X / L is in the range of 0.2-0.8 with X being the distance between that portion of the blade's rear edge outline that is most deeply inwardly recessed in the rotating direction and an air outflow surface of the bell mouth, L being the axial length of bell mouth.

Owner:TOSHIBA CARRIER CORP

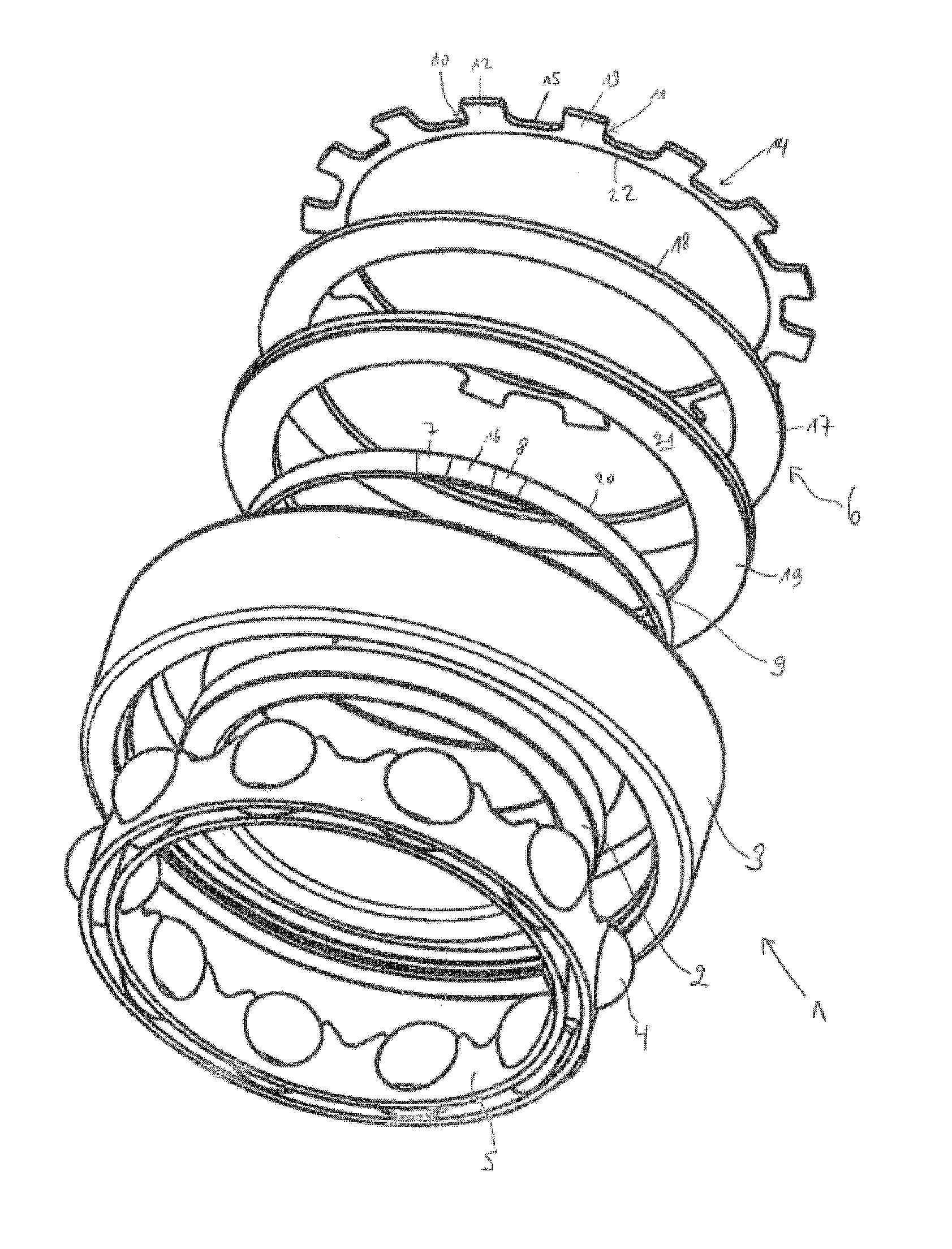

Bearing having a power generation unit

InactiveUS20120175983A1Suppress eddy currentImprove efficiencyBearing assemblyBall bearingsEngineeringFilling factor

Owner:SCHAEFFLER TECH AG & CO KG

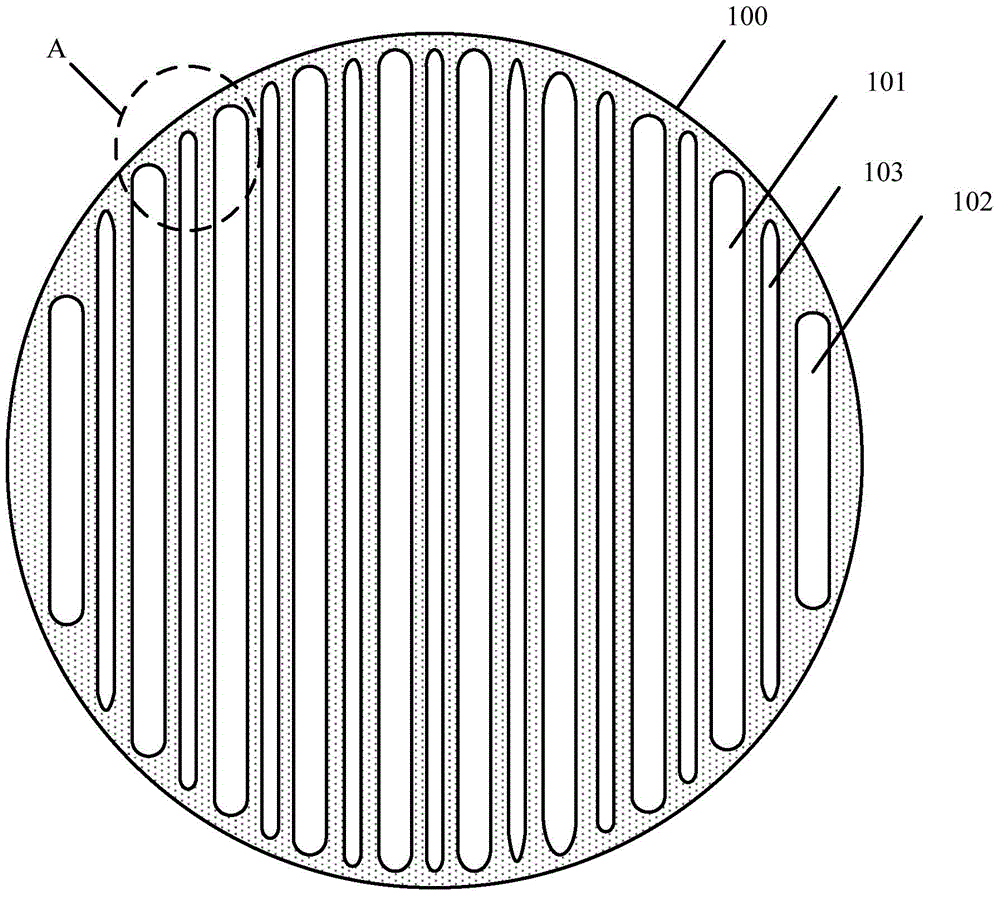

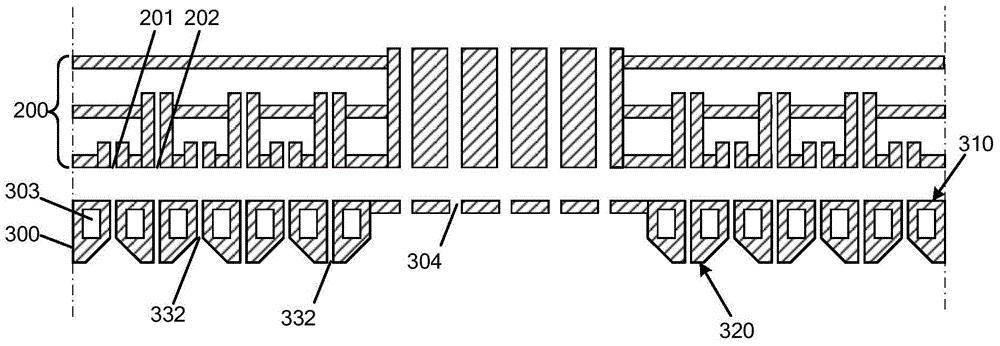

Electro-cardiograph Sensor Mat

The invention relates to an electrocardiograph sensor mat (100), the mat (100) comprising a multitude of electrodes (104) for acquiring cardiac signals and a plug (200), wherein the electrodes (104) are connected to the plug (200) by electric wires (102), wherein the wires (102) are segmented by switches (202), wherein the switches (202) are switchable between a closed state and an open state, wherein in the closed state the electrodes (104) are electrically connected to the plug (200) and wherein in the open state the electrodes (104) are electrically isolated from the plug (200).

Owner:KONINKLJIJKE PHILIPS NV

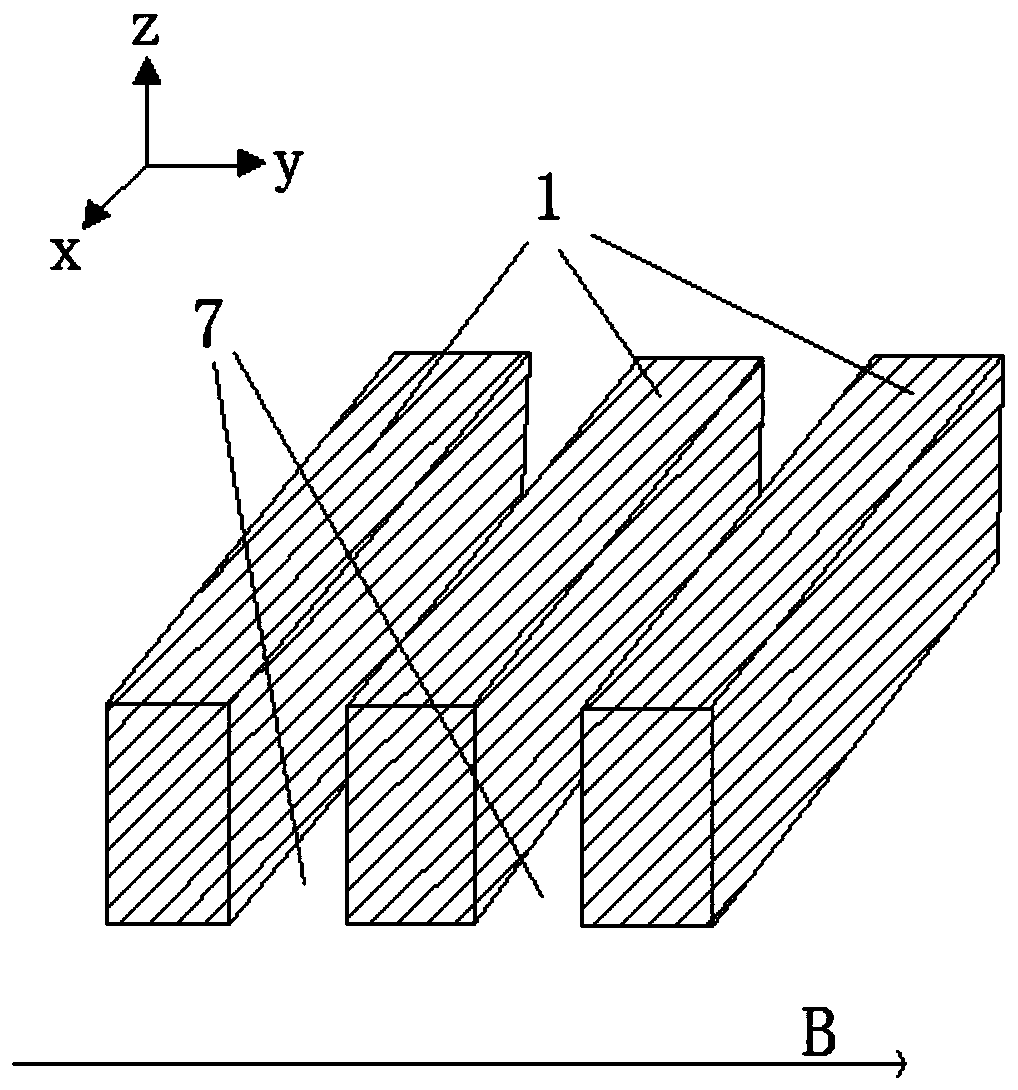

Eddy current suppression structure and preparation method thereof

PendingCN110970716AExcellent soft magnetic propertiesLow coercivityVacuum evaporation coatingSputtering coatingAcoustic waveEddy current

The invention relates to an eddy current suppression structure, and the structure comprises a magnetostriction layer and an insulating dielectric layer, wherein the insulating dielectric layer is arranged in the magnetostriction layer and is used for breaking eddy current so as to suppress eddy current loss of a bulk acoustic wave magnetoelectric antenna. According to the invention, the insulatingdielectric layer is inserted into the magnetostriction layer to reduce eddy current loss, so that the radiation efficiency of the bulk acoustic wave magnetoelectric antenna is improved, and the problems of discontinuous stress and low radiation efficiency of the magnetoelectric antenna caused by the air gap interval magnetostriction layer in the prior art are solved. The insulating dielectric layer is used as the spacer layer, so the soft magnetic characteristic of the magnetostriction layer can be improved, the coercive force of the magnetostriction layer is effectively reduced, and the sensitivity of the radiation region is improved. Through simulation analysis, the eddy current loss can be effectively reduced by more than 65%, and the radiation efficiency of the magnetoelectric antennais greatly improved.

Owner:SICHUAN BAW ME MICRO&NANO TECH CO LTD

Yarn cooler

Owner:TMT MACHINERY INC

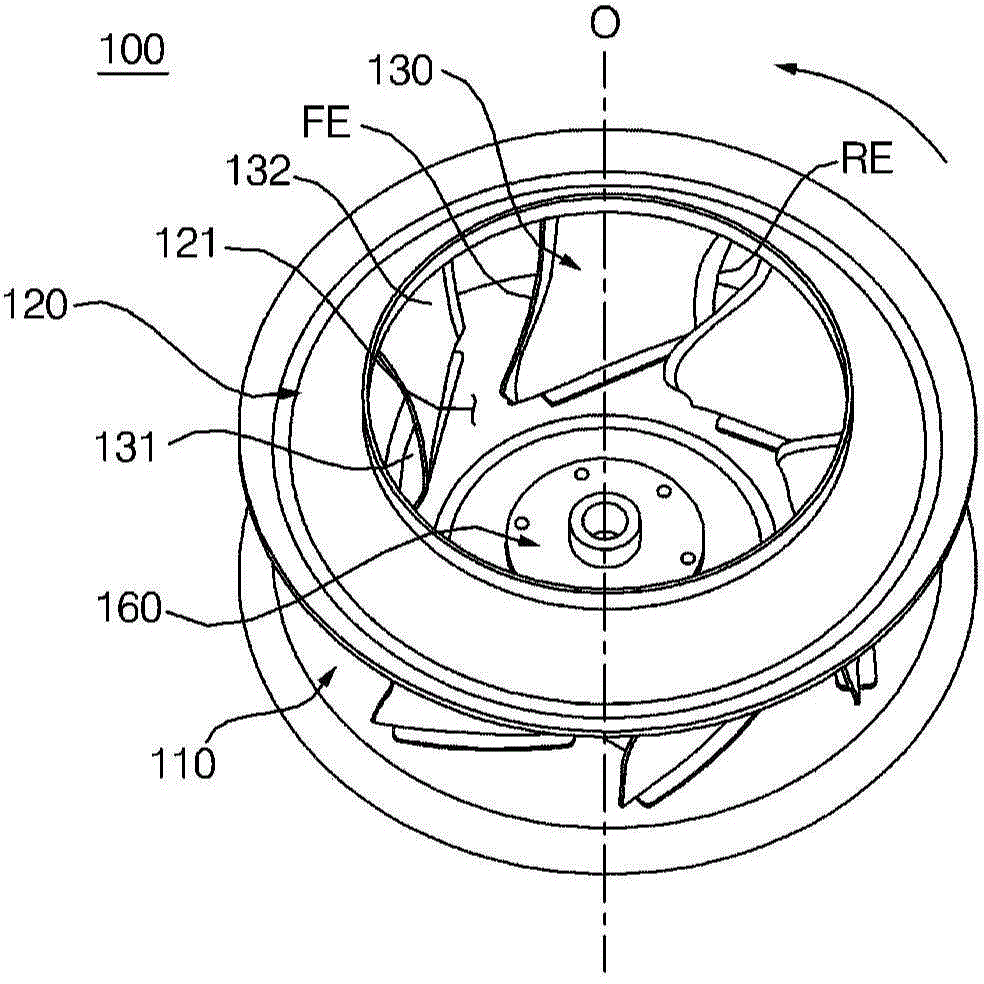

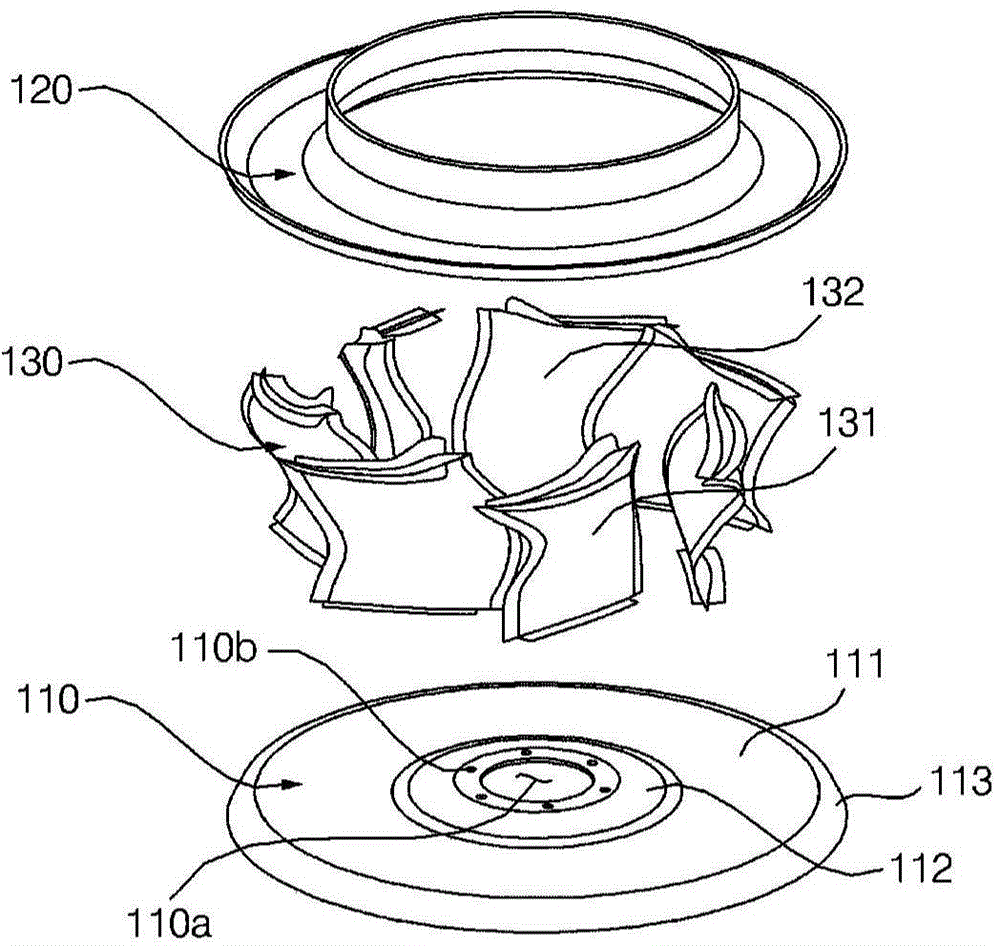

Centrifugal fan

InactiveCN105134658AImprove efficiencyReduce noisePump componentsRadial flow pumpsAirflowEngineering

Centrifugal fan including a main plate (110) rotating about an axis of rotation, a shroud (120) having an inlet port (121) for introduction of air, and a plurality of blades (130) circumferentially arranged between the main plate and the shroud so as to form a flow of air by accelerating air introduced through the inlet port, each having a pressure surface (131) formed such that a portion thereof (RC) near to the shroud is convex in a direction away from the axis of rotation and a portion thereof (CRC) near to the main plate is concave toward the axis of rotation, wherein the shroud has an inside surface formed as a curved surface, the curved surface has a diffusion section (DS) extending radially, the main plate has a curved surface (113) extending radially, and a curved surface of the shroud in the diffusion section at least partially overlaps with the curved surface formed in the main plate when viewed in a direction of the axis of rotation.

Owner:LG ELECTRONICS INC

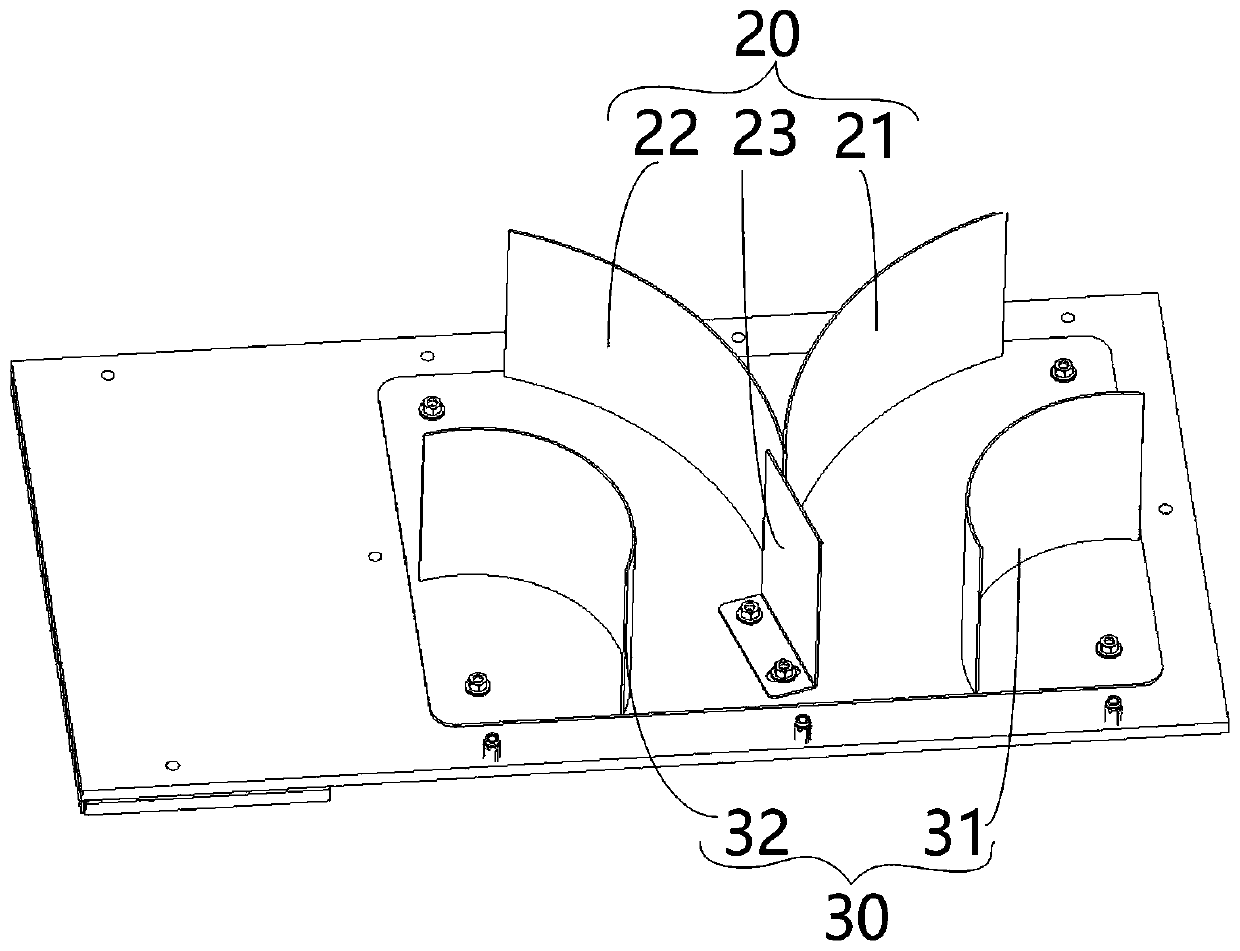

Air supply structure and air conditioning unit

PendingCN110901673AUniform air supplySuppress eddy currentRailway heating/coolingAir conditioningMechanics

The invention provides an air supply structure and an air conditioning unit. The air supply structure comprises an air supply shell, a first flow guide plate assembly and a second flow guide plate assembly. An air inlet is formed in the air supply shell in the vertical direction, and a first air outlet and a second air outlet are formed in the two opposite sides of the air supply shell in the horizontal direction correspondingly. The first flow guide plate assembly is arranged at the position, opposite to the air inlet and away from the air inlet, in the air supply shell. The second flow guideplate assembly is arranged at the position opposite to the air inlet and close to the air inlet, in the air supply shell. According to the technical scheme, the second flow guide plate assembly and the first flow guide plate assembly are matched, air inlet of the air inlet can be divided, airflow is divided into two layers, laminar flow is strengthened, vortexes are restrained, dynamic pressure is converted into static pressure, uniform air supply of the first air outlet and the second air outlet is achieved, flow resistance losses are reduced, and noise is lowered.

Owner:GREE ELECTRIC APPLIANCES INC

Slag blocking ball for converter

The invention discloses a slag blocking ball for a converter. The slag blocking ball comprises a ball matrix (1) and a handle (3), wherein the handle is connected with the ball matrix; the surface of the ball matrix (1) is coated with a gas generating layer (2), which is 10cm to 20cm thick, in an enwrapping manner. According to the slag blocking ball for the converter, by adopting a method of coating the surface of the ball matrix of the slag blocking ball with a circle of substance which can generate gas at a high temperature, the effects of decreasing the occurrence rate of the stranding phenomenon of the slag blocking ball and suppressing the phenomenon that slag is entrapped by a tapping vortex are achieved.

Owner:SHANDONG IRON & STEEL CO LTD

Semiconductor device

ActiveUS7928539B2Increased complexitySuppress eddy currentSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceElectrical conductor

Owner:RENESAS ELECTRONICS CORP

Throttle valve

InactiveUS20060027209A1Suppress eddy currentSmall air eddyEngine controllersMachines/enginesEngineeringThrottle

A valve body or a throttle valve is disclosed that is capable of changing the amount of intake air into an engine according to a gradient angle of a valve body rotatably supported in an intake air passage. The valve body includes at least one first end surface and at least one second end surface formed on an outer circumferential surface thereof. Air eddies occurring from air flow contact with the first and second end surfaces are shifted to each other.

Owner:NISSAN MOTOR CO LTD

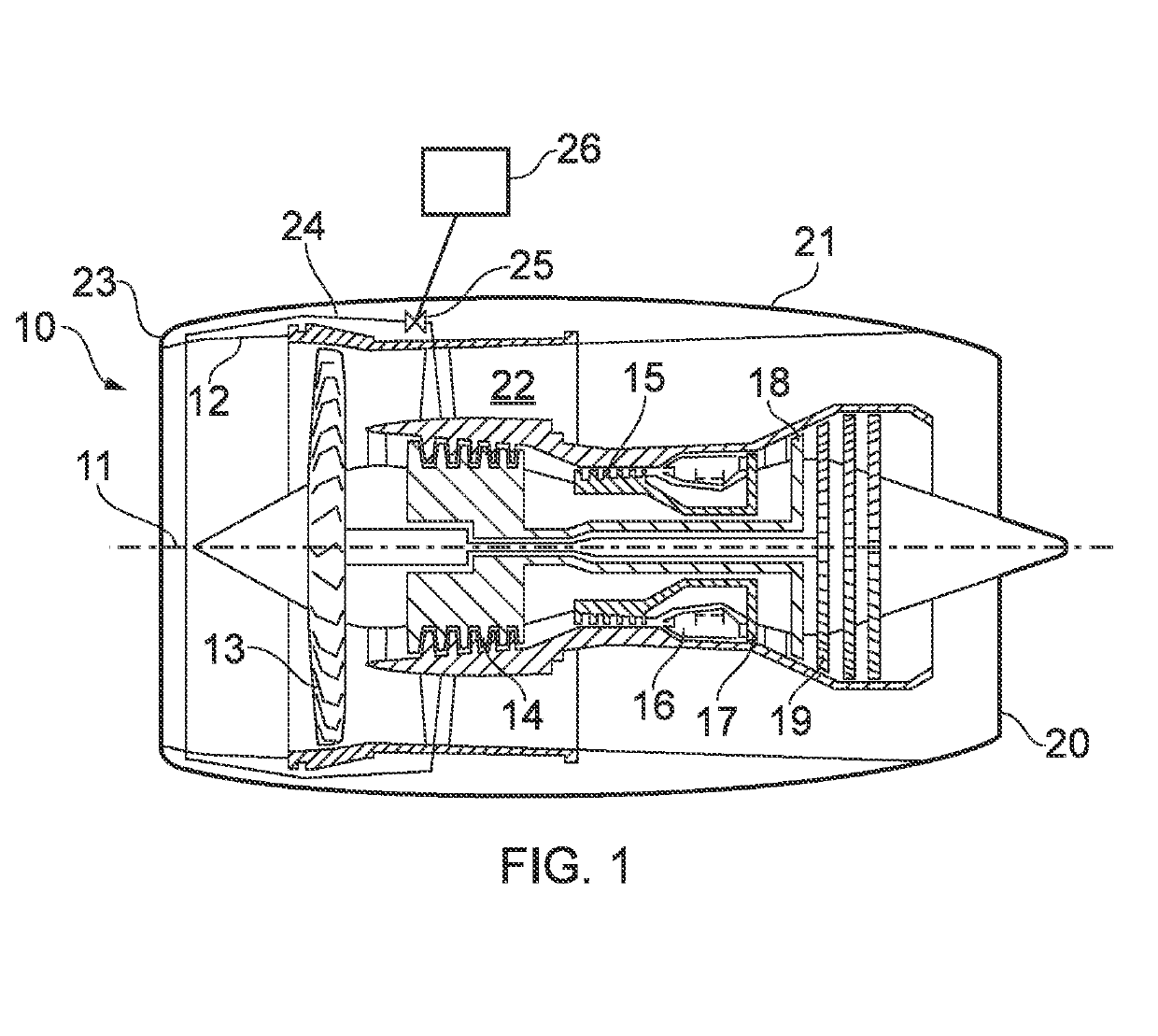

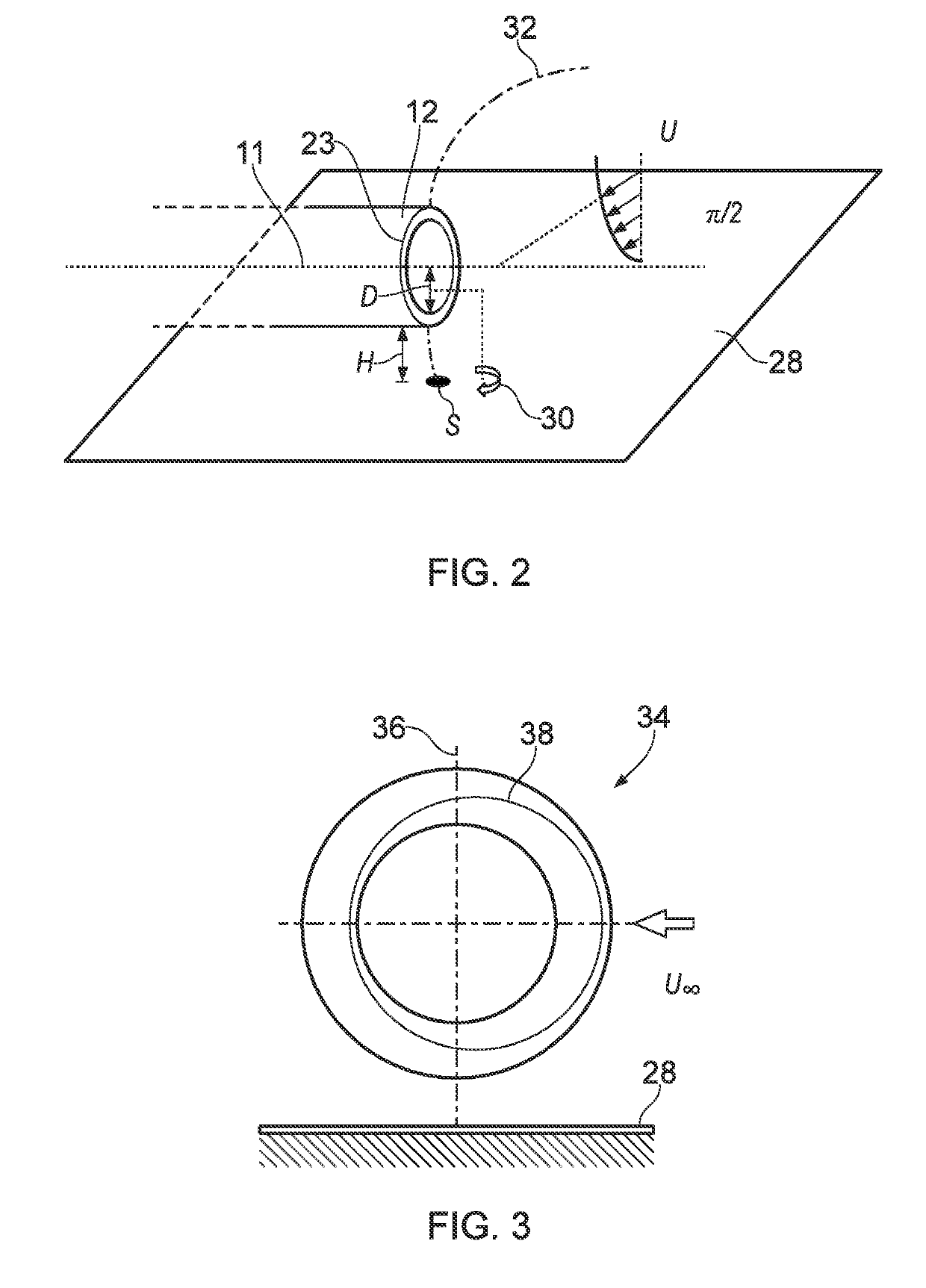

Gas turbine engine vortex suppressor

InactiveUS20190112978A1Suppress eddy currentGas turbine plantsEngine controlLeading edgeNon symmetric

An intake (12) for a gas turbine engine (10) has an annular lip structure (23) extending about a central axis (11) and defining an intake opening. The annular lip structure (23) has a leading edge (38) located between a radially inwardly facing portion of the intake and a radially outwardly facing portion of the intake (12). The annular lip structure (23) has upper, lower and opposing side regions on either side of the central axis (11). The annular lip structure (23) comprises a formation (40; 42; 48) on the radially inwardly facing portion arranged to create a non-symmetric flow field over the opposing side regions of the annular lip structure (23). The formation (40; 42; 48) may be actively controlled in response to ground vortex conditions.

Owner:ROLLS ROYCE PLC

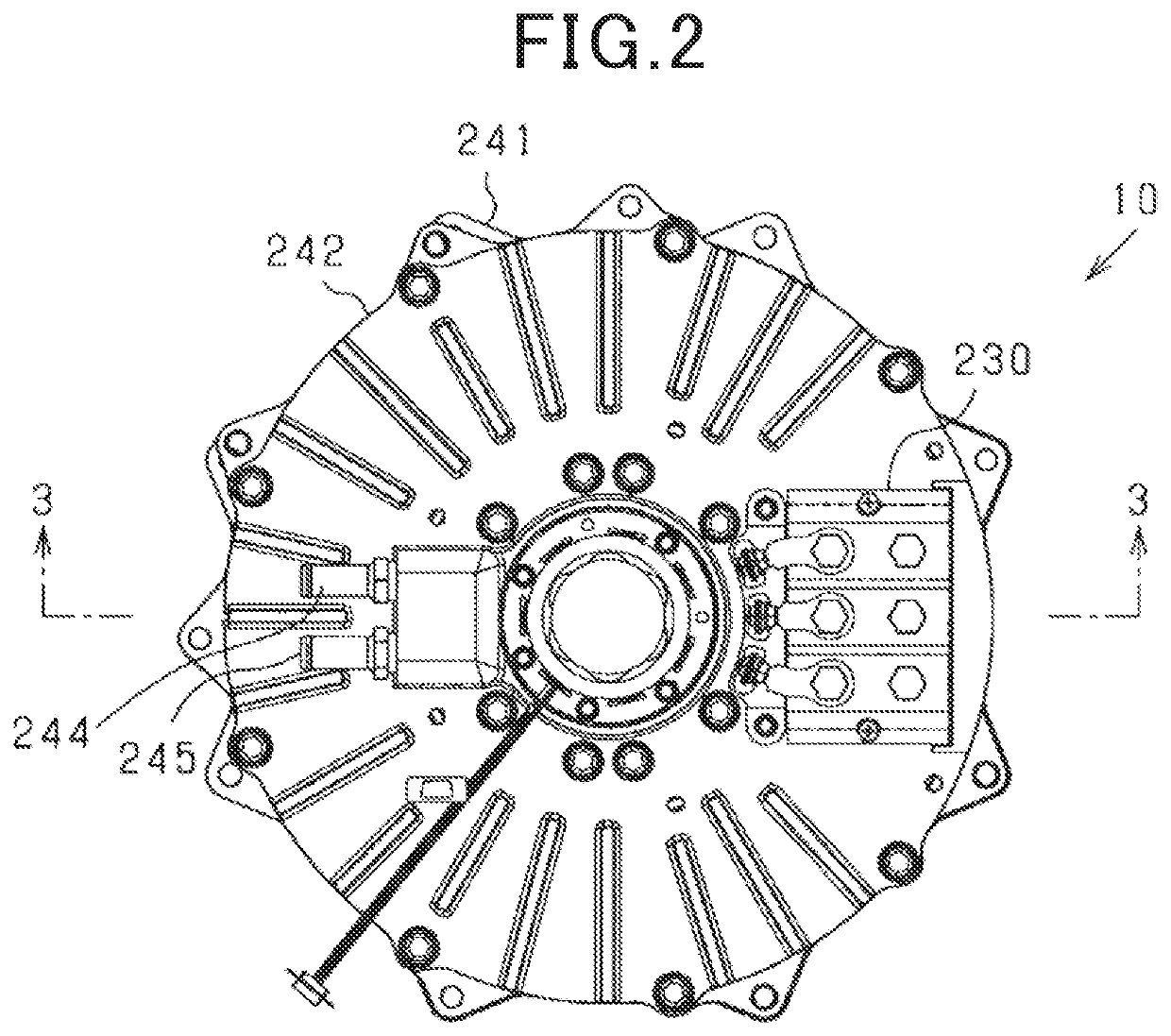

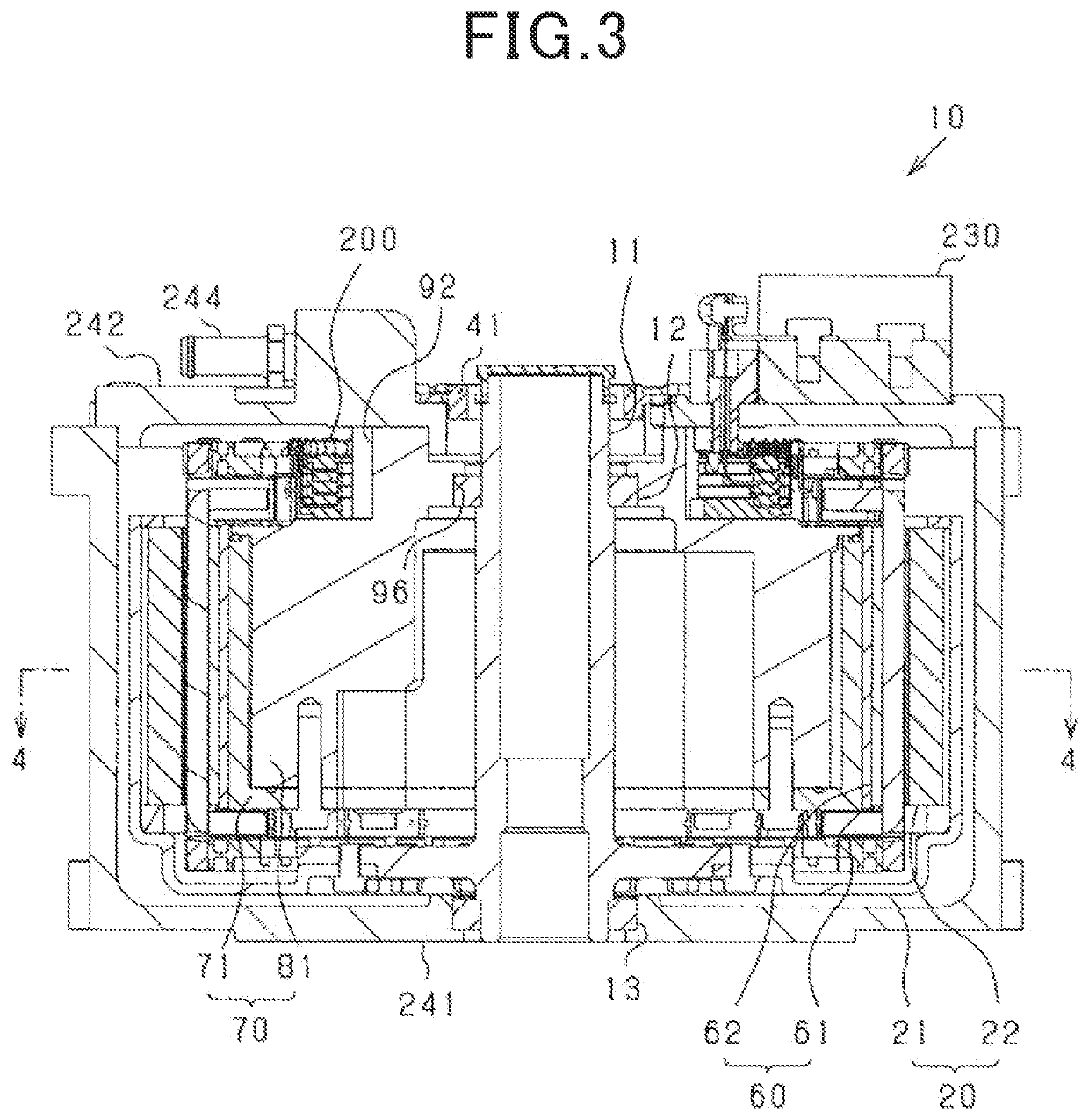

Rotating electric machine and method of manufacturing rotating electric machine

PendingUS20220271596A1Suppress eddy currentElectrical potential differenceWindings insulation shape/form/constructionPrevention/reducing eddy-current losses in winding headsElectrical conductorElectric machine

In a rotating electric machine that includes an armature with an armature coil, the armature coil is formed by winding an electrical conductor wire. The electrical conductor wire includes a plurality of element wires in a bundled state and an insulating coat covering the bundled element wires. Each of the element wires includes an electrical conductor through which electric current flows, and a fusing layer that covers a surface of the electrical conductor. In the bundled state of the element wires, the fusing layers of the element wires are in contact with and fused to one another. Between adjacent parts of the electrical conductor wire wound to form the armature coil, there are formed gaps due to differences in straightness between different parts of the electrical conductor wire. The gaps are filled with a filler.

Owner:DENSO CORP

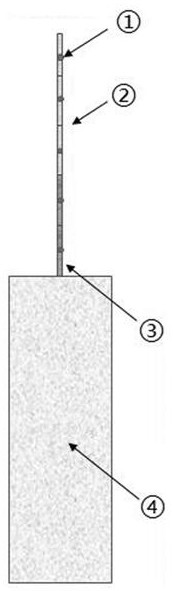

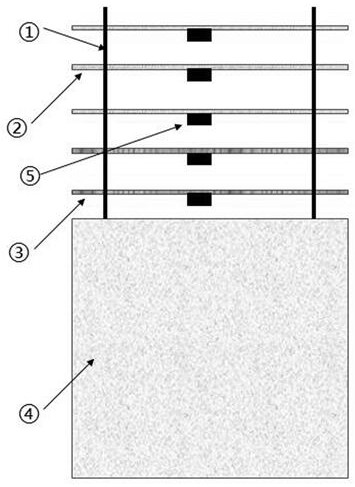

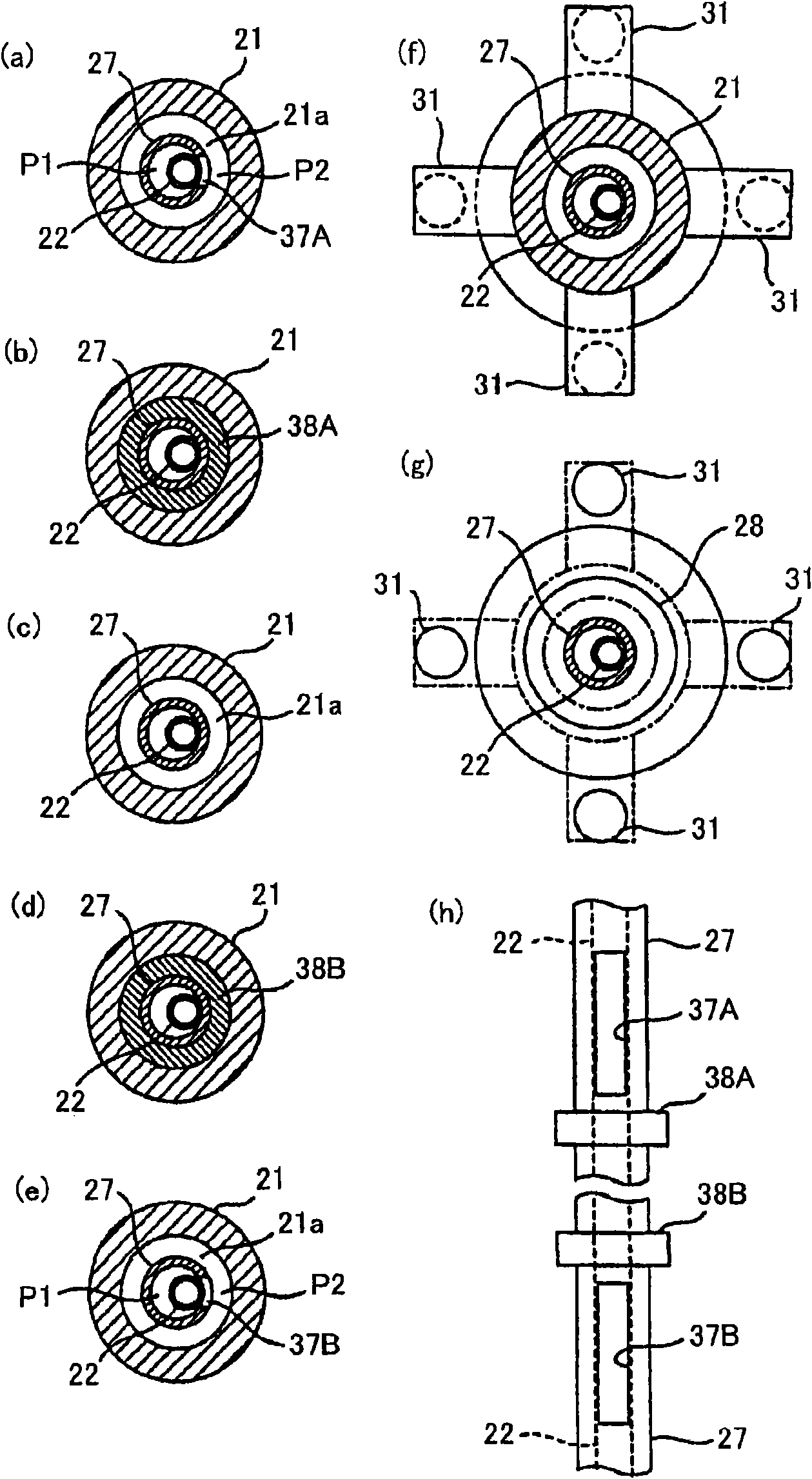

Structure for suppressing flow vibration of instrumentation guide tube

InactiveCN101632133AFlow Vibration SuppressionLow costNuclear energy generationNuclear monitoringEngineeringGuide tube

A structure for suppressing flow vibration of an instrumentation guide tube, the structure being constructed such that an upper hole (37A) and a lower hole (37B) are formed at two upper and lower positions in a side face of the guide tube (27) and that a thimble tube (22) is pressed against the inner peripheral surface of the guide tube (27) by a difference between pressures of a cooling material in the inside and outside of the upper and lower hole (37A, 37B). Further, the structure desirably has an upper pressure regulation hole and lower pressure regulation hole formed at two upper and lower positions in a side face of an upper reactor core support column (21). The upper and lower pressure regulation holes allow a cooling material, having flown from the upper end of the guide tube into the guide tube, to flow from the inside to the outside of the guide tube through a gap between the thimble tube and the upper hole, flow from the inside to the outside of the upper reactor core support column through the upper pressure regulating hole, flow from the lower end of the guide tube into the guide tube, flow from the inside to the outside of the guide tube through a gap between the thimble tube and the lower hole, and then flow from the inside to the outside of the upper core reactor support column through the lower pressure regulating hole.

Owner:MITSUBISHI HEAVY IND LTD

Outdoor unit for air conditioner

ActiveCN1768237ASuppress eddy currentReduce noisePump componentsLighting and heating apparatusBell mouthAxial length

The invention discloses an outdoor unit of an air conditioner, which has an axial flow fan and a bell mouth. The axial fan is configured by arranging blades at predetermined intervals along the outer circumference of a hub, each of which is formed such that a contour line of a rear edge portion thereof with respect to a rotation direction is recessed toward a front edge thereof. The bell mouth is arranged on the blowing side of the axial flow fan. An axial blower is provided in the outdoor unit. The bell mouth and the axial fan are arranged in the axial blower such that the ratio X / L is in the range of 0.2 to 0.8, where X is the point on the contour line of the trailing edge of the blade. The distance between the most inwardly recessed part in the direction of rotation and the air outflow surface of the bell mouth, L is the axial length of the bell mouth.

Owner:TOSHIBA CARRIER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com