Eddy current suppression structure and preparation method thereof

A technology of eddy current suppression and thickness direction, which is applied in the field of eddy current suppression structure and its preparation, can solve the problems of stress discontinuity and low radiation efficiency of magnetoelectric antennas, and achieve the goal of solving stress discontinuity, improving soft magnetic characteristics, and increasing radiation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

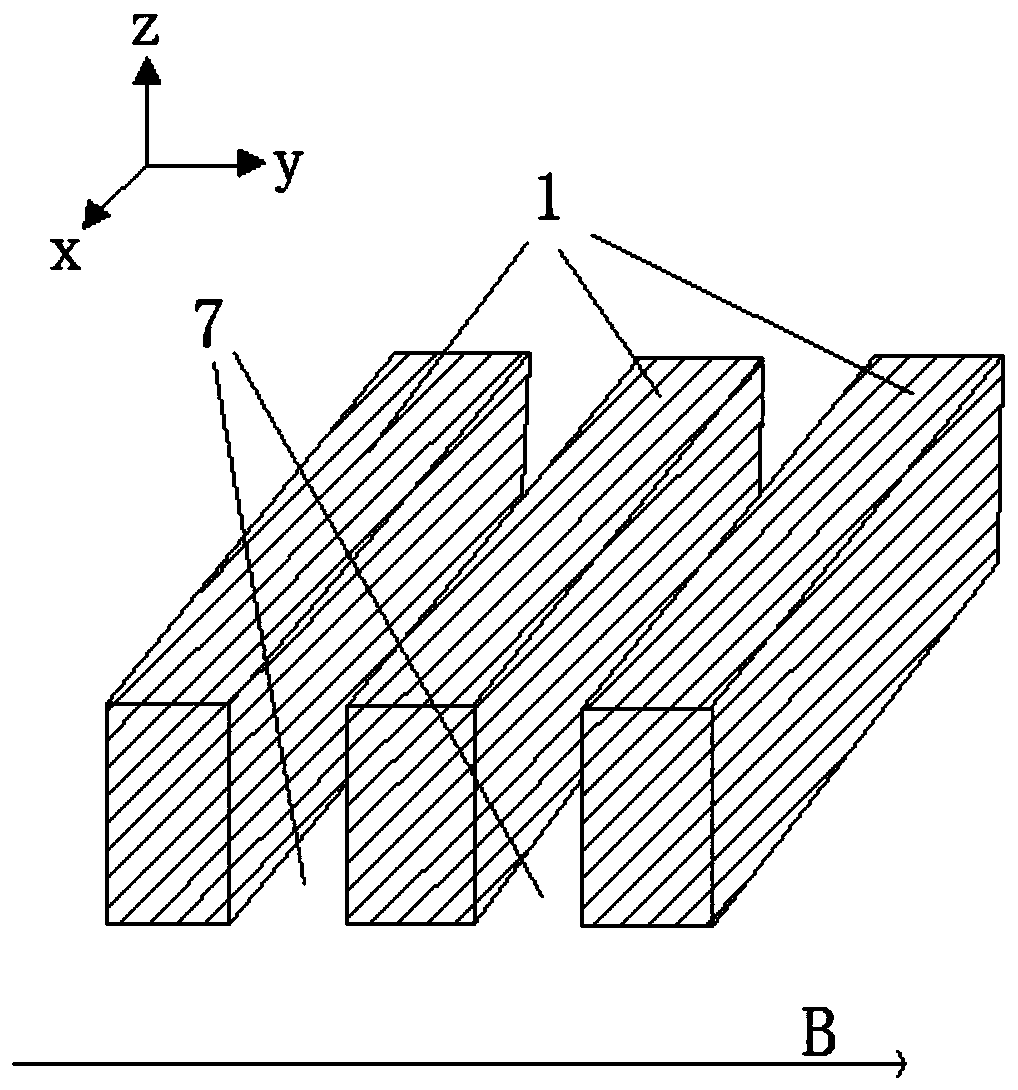

[0046] like Figure 3-11 , as the basic solution of the present invention, an eddy current suppression structure includes a magnetostrictive layer 1 and an insulating dielectric layer, the insulating dielectric layer is arranged in the magnetostrictive layer 1 for breaking eddy currents to suppress Eddy current losses in bulk acoustic wave magnetoelectric antennas.

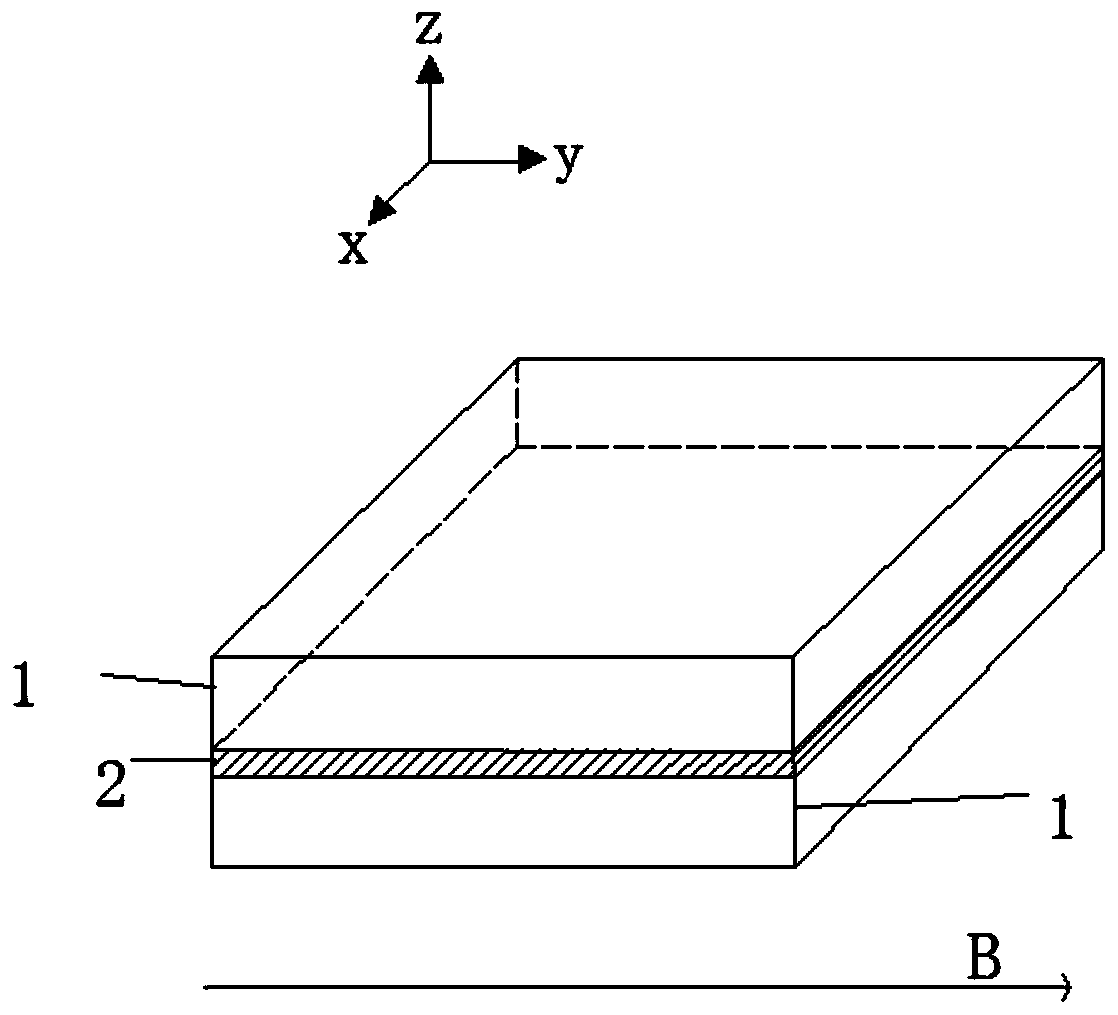

[0047] like image 3 As a further solution of this embodiment, at least one layer of the first insulating dielectric layer 2 is disposed in the magnetostrictive layer 1 along its thickness direction.

[0048] As a further solution of this embodiment, the first insulating dielectric layer 2 has three layers parallel to each other, the thickness of each first insulating dielectric layer 2 is 5-100 nm, and the material of the magnetostrictive layer 1 is FeGaB film, the total thickness of the FeGaB film is 1 μm, the electrical conductivity range of the first insulating dielectric layer 2 is 0-100S / m, and the first i...

Embodiment 2

[0052] like Figure 3-11 , as the basic solution of the present invention, an eddy current suppression structure includes a magnetostrictive layer 1 and an insulating dielectric layer, the insulating dielectric layer is arranged in the magnetostrictive layer 1 for breaking eddy currents to suppress Eddy current losses in bulk acoustic wave magnetoelectric antennas.

[0053] like Figure 4 As a further solution of this embodiment, at least one layer of the second insulating dielectric layer 3 is arranged in the magnetostrictive layer 1 along its width direction.

[0054] As a further solution of this embodiment, the second insulating dielectric layer 3 has three layers and are parallel to each other, the thickness of each second insulating dielectric layer 3 is 5-30nm, and the material of the magnetostrictive layer 1 is FeGaB film, the total thickness of the FeGaB film is 1 μm, the electrical conductivity range of the second insulating dielectric layer 3 is 0-100S / m, and the ...

Embodiment 3

[0058] like Figure 3-11 , as the basic solution of the present invention, an eddy current suppression structure includes a magnetostrictive layer 1 and an insulating dielectric layer, the insulating dielectric layer is arranged in the magnetostrictive layer 1 for breaking eddy currents to suppress Eddy current losses in bulk acoustic wave magnetoelectric antennas.

[0059] like Figure 5 and 6 As a further solution of this embodiment, at least one layer of first insulating dielectric layer 2 is arranged in the magnetostrictive layer 1 along its thickness direction, and at least one layer of second insulating medium layer 2 is arranged in the magnetostrictive layer 1 along its width direction. The insulating medium layer 3, the first insulating medium layer 2 and the second insulating medium layer 3 are arranged at intervals across each other.

[0060] like Figure 5 and 6 , as a further solution of this embodiment, the first insulating dielectric layer 2 has three layers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com