Filter with hole in its filtering part

A filter and inlet part technology, applied in the field of fuel injection devices, can solve problems such as increased pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

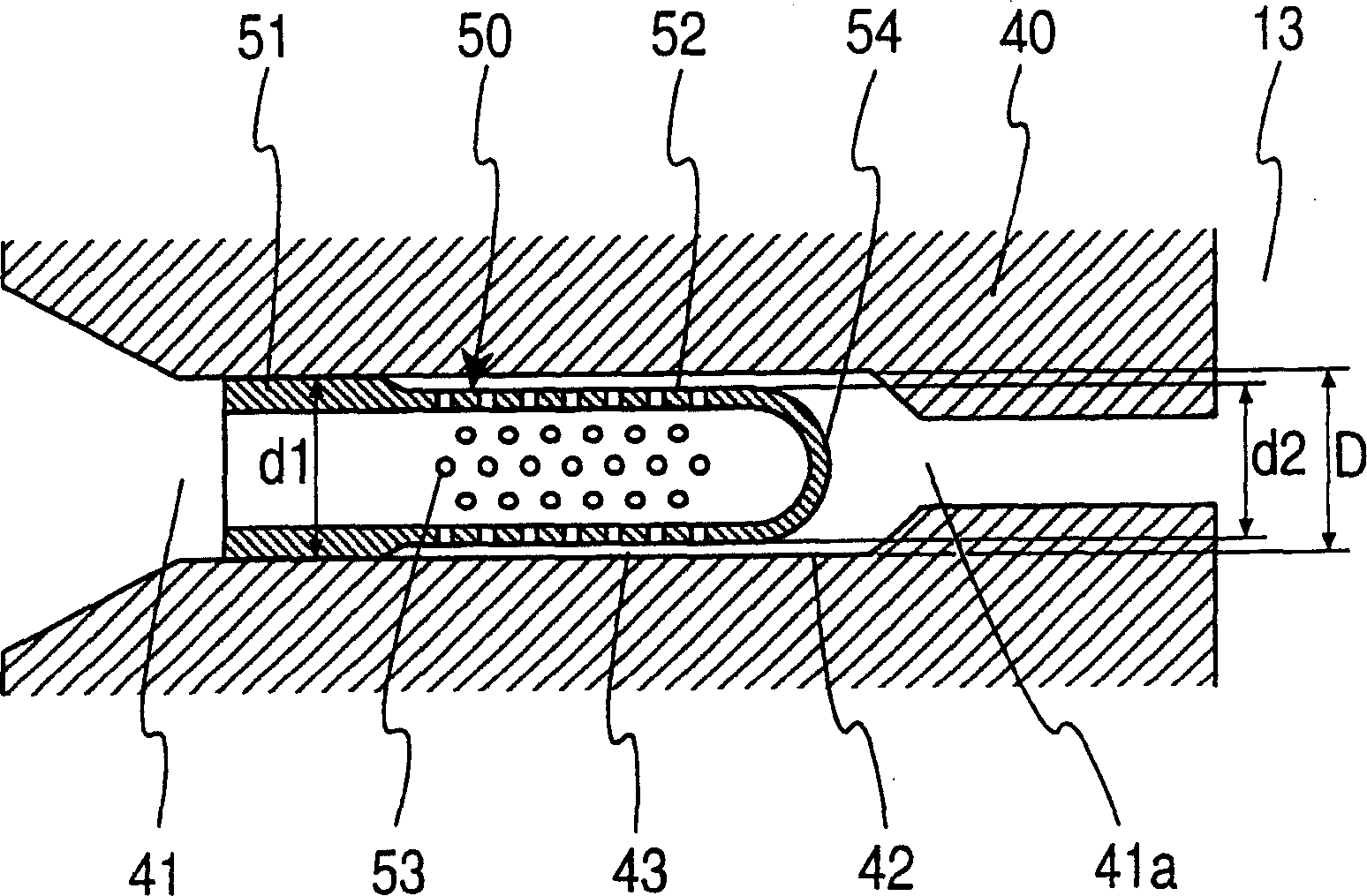

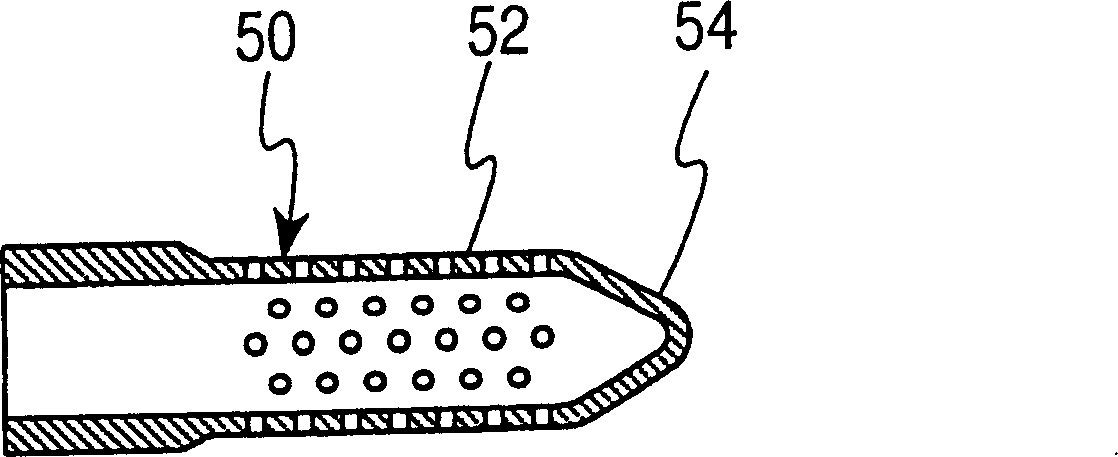

[0023] refer to figure 1 , a filter of the present invention is indicated by reference numeral 50 and applied to a fuel injector 1 used in a common rail fuel injection system of a diesel engine. The injector 1 includes a body portion 10 having a housing 11 , a nozzle portion 20 and an electromagnetic drive portion 30 . The injector 1 is arranged on a cylinder head of an engine, and is used for introducing fuel into corresponding cylinders.

[0024] The housing 11 is substantially cylindrical, and a fuel introduction port 40 protrudes from the outer peripheral surface of the housing 11 in a side direction and is integrally formed as a fuel introduction passage body. A fuel introduction passage 41 is formed in the fuel introduction port 40, and a filter 50 is provided in the fuel introduction passage. The fuel introduction port 40 is connected to a common rail (not shown).

[0025] In the nozzle portion 20, a retainer 24 is fixed to the bottom end of the casing 11, and an end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com