Purification method for preparing high-purity infrared chalcogenide glass, and apparatus thereof

A technology of chalcogenide glass and purification method is applied in the purification field of preparing high-purity infrared chalcogenide glass, which can solve the problems of inevitable introduction of impurities, limited quality improvement of chalcogenide glass, complicated process, etc., and achieve excellent infrared optical transmission performance. , The effect of reducing the volatilization of raw materials and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

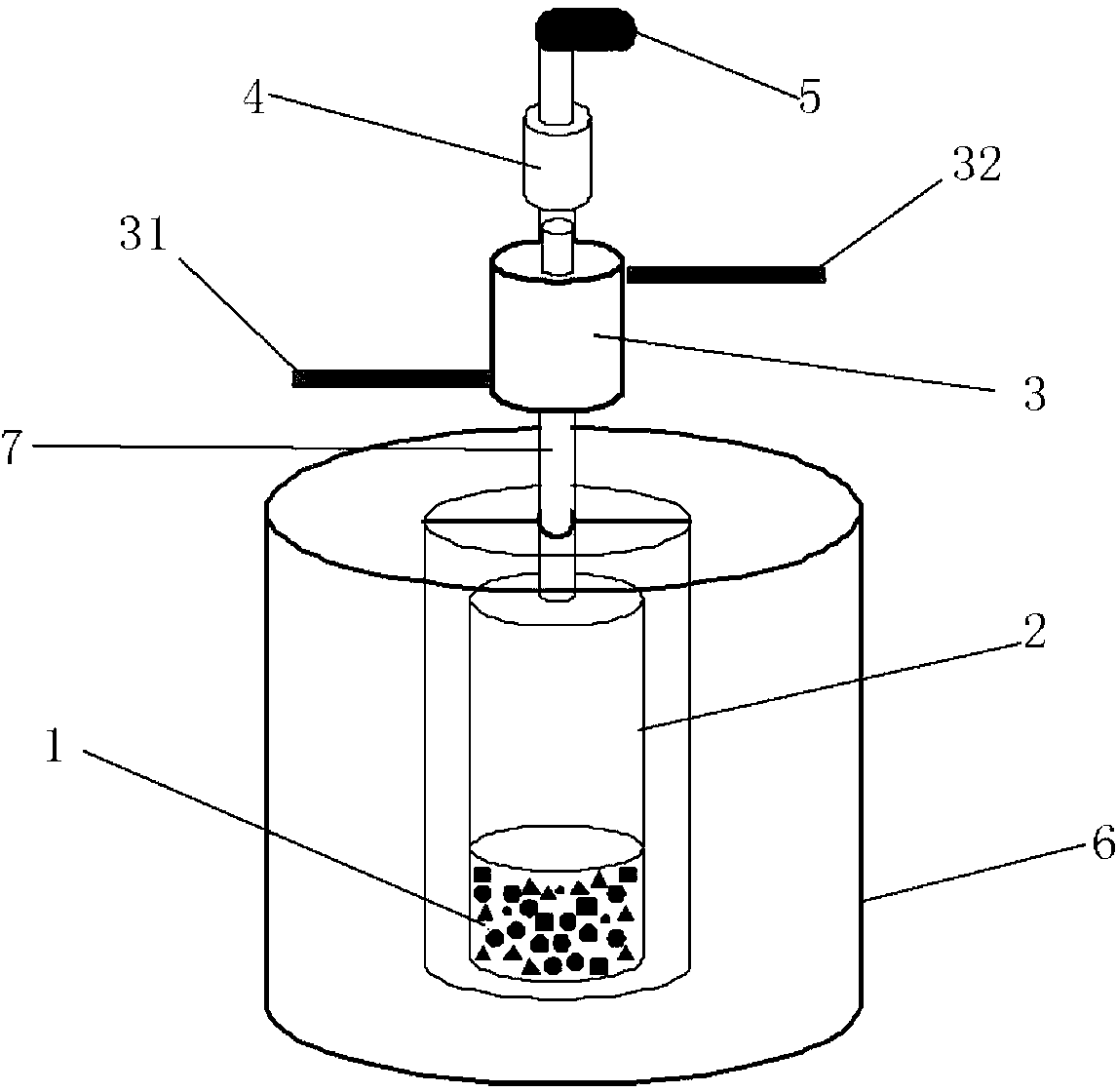

[0036] figure 1 It is a structural schematic diagram of the purification device of the present invention; as figure 1 As shown, the purification device of the present invention comprises a purification furnace 6, a quartz ampoule bottle 2, a cooling device 3, a connector 4 and a vacuum pump 5, wherein:

[0037] Quartz ampoule 2, used to accommodate the mixture 1 composed of chalcogenide glass raw material and oxygen scavenger;

[0038] The purification furnace 6 is used to heat the mixture 1 in the quartz ampoule;

[0039] The cooling device 3 is located at the part where the upper end of the quartz ampoule bottle 2 protrudes from the purification furnace 6 to solidify the volatile substances;

[0040] Connector 4, connects quartz ampoule bottle 2 and vacuum pump 5;

[0041] The vacuum pump 5 vacuumizes the quartz ampoule bottle 2 to provide the required vacuum environment for the mixture 1;

[0042] Wherein, the part where the upper end of the quartz ampoule 2 protrudes f...

Embodiment 2

[0045] Purification method of the present invention is specifically as follows: preparation chemical formula is Ge 28 Se 60 Sb 12 Glass raw materials, that is, weigh 50g of raw materials according to the precise proportion of germanium, selenium and antimony in the proportion of 28mol%, 60mol% and 12mol%, respectively, and weigh aluminum and gallium in the mass ratio of 200ppm as oxygen scavenger. In an environment full of an inert atmosphere, the above-mentioned weighed elemental raw materials Ge, Sb, Se and oxygen scavenger are fully mixed and then placed in the quartz ampoule 2, and the quartz ampoule 2 and the vacuum pump 5 are connected together with a connector 4, Vacuum down to 4×10 -4About Pa, put the quartz ampoule 2 into the purification furnace 6 at 300°C, wherein the upper part of the quartz ampoule 2 outside the purification furnace 6 uses a cooling device 3 to solidify the volatile material here, and after purification and heating for 5h, The evacuated quartz ...

Embodiment 3

[0048] Another embodiment of the purification method of the present invention is specifically as follows: the preparation chemical formula is Ge 20 Se 65 Sb 15 Glass raw materials, that is, weigh 50g of raw materials according to the precise ratio of 20mol%, 65mol% and 15mol% of germanium, selenium, and antimony, respectively, and weigh aluminum and magnesium as oxygen scavengers at a mass ratio of 200ppm. Mix the above-mentioned elemental raw materials Ge, Sb, Se and oxygen scavenger fully in the environment of the atmosphere and place them in the quartz ampoule bottle, connect the quartz ampoule bottle 2 and the vacuum pump 5 with the connector 4, and evacuate to 5 ×10 -4 About Pa, put the quartz ampoule bottle 2 into the purification furnace 6 at 280°C, wherein the upper part of the quartz ampoule bottle 2 outside the purification furnace uses a cooling device 3 to solidify the volatile material here, and after purification and heating for 5h, put the The evacuated quart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com