Apparatus for vertical pulling growth of CdZnTe monocrystals, and method thereof

A vertical pulling, cadmium zinc telluride technology, applied in chemical instruments and methods, self-melt pulling method, single crystal growth and other directions, can solve the problem of reducing the yield of single wafers, the surface of the melt is too large, and increasing the cost of device manufacturing and other problems, to achieve the effect of reducing tellurium precipitation or inclusion, improving component uniformity, and reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

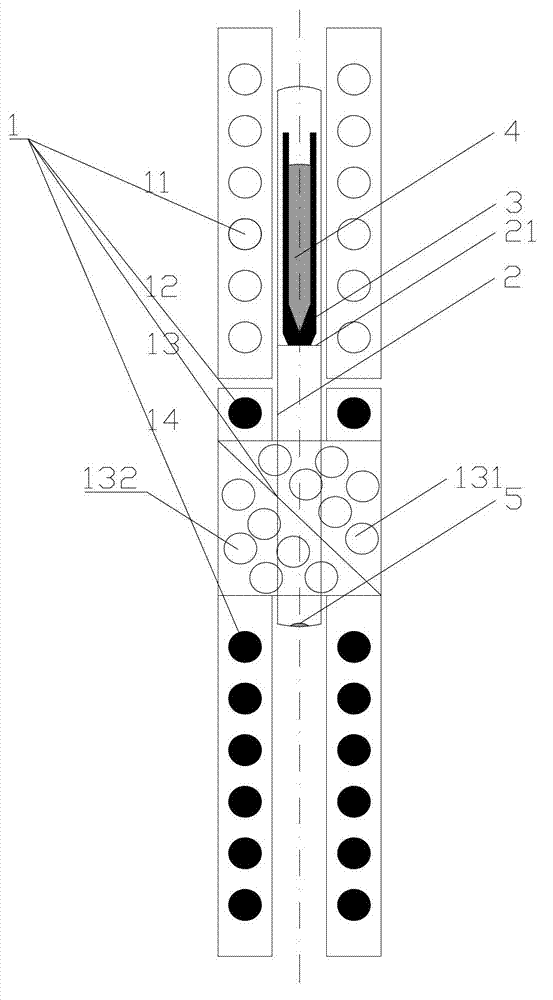

[0024] The process of preparing a CdZnTe single crystal using the device and method for vertically pulling a CdZnTe single crystal of the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

[0025] figure 1 It is a schematic structural diagram of a device for vertically pulling a CdZnTe single crystal according to the present invention. As can be seen from the figure, the device for vertically pulling CdZnTe single crystal of the present invention comprises a tubular furnace body 1, a quartz ampoule 2 and a graphite boat 3: the tubular furnace body 1 comprises a rotatable synthesis furnace 11, A buffer furnace 12 for temperature compensation, an inclined plane furnace 13 for controlling the solid-liquid interface, and a cadmium source furnace 14 for controlling the temperature of the cadmium source; a quartz ampoule 2 is placed in the furnace body 1, and there is a baffle plate 21 with a hole in the middle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com