A preparation method of copper-based multi-component high-temperature difficult-to-deform alloy wire for engine

A multi-element alloy, hard-to-deform technology, applied in the field of preparation of copper-based multi-element high-temperature hard-to-deform alloy wire for engines, to achieve the effects of improved component uniformity, high brazing temperature, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

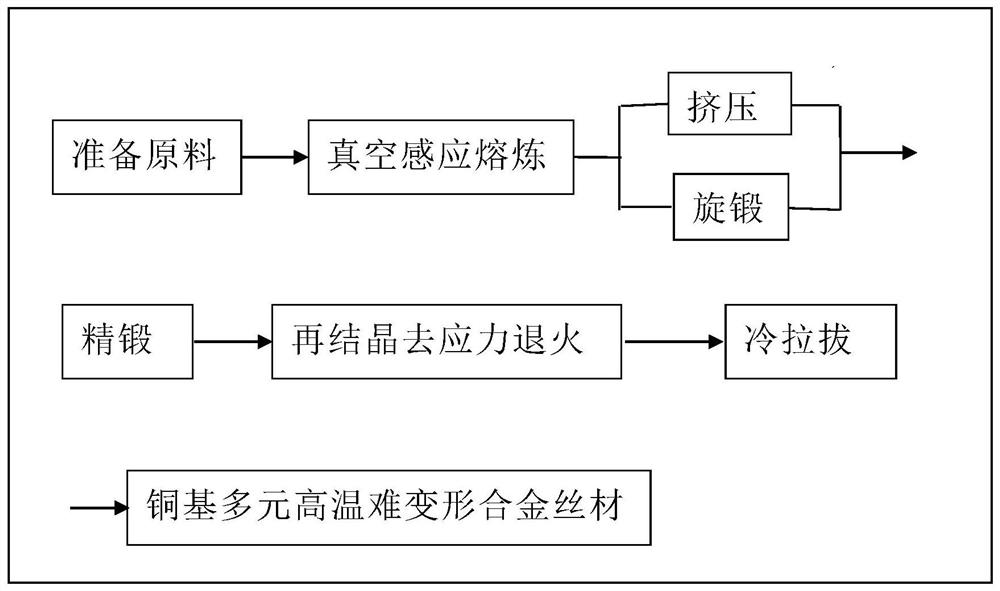

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

[0029] Step 1. Prepare the raw materials of each component according to the following mass percentages: Ni 10.0%, Mn 15.0%, Ag 5.0%, Si 0.4%, B 0.1%, and the balance is Cu; the raw material of B is NiB master alloy, The raw materials of other components are metal simple substances; the Mn simple substance raw materials are coated with Ag;

[0030] Step 2. Put the elemental metal and NiB intermediate alloy in the raw materials of each component prepared in step 1 into the magnesia crucible of the vacuum induction melting furnace, and put the simple substance of Mn coated with Ag prepared in step 1 into the vacuum induction melting furnace. In the top hopper of the melting furnace, the vacuum induction melting furnace is then vacuumed to a vacuum degree of 10 -3 Heating at MPa to make the raw materials in the magnesia crucible completely melted, adding the Ag-coated Mn elemental raw material from the top hopper into the mag...

Embodiment 2

[0035] This embodiment includes the following steps:

[0036] Step 1. Prepare the raw materials of each component according to the following mass percentages: Ni 11.0%, Mn 17.0%, Ag 6.0%, Si 0.8%, B 0.2%, and the balance is Cu; the raw material of B is NiB master alloy, The raw materials of other components are metal simple substances; the Mn simple substance raw materials are coated with Ag;

[0037] Step 2. Put the elemental metal and NiB intermediate alloy in the raw materials of each component prepared in step 1 into the magnesia crucible of the vacuum induction melting furnace, and put the simple substance of Mn coated with Ag prepared in step 1 into the vacuum induction melting furnace. In the top hopper of the melting furnace, the vacuum induction melting furnace is then vacuumed to a vacuum degree of 10 -2 Heating the temperature at MPa to completely melt the raw materials in the magnesia crucible, adding the Ag-coated Mn elemental raw material from the top hopper int...

Embodiment 3

[0042] This embodiment includes the following steps:

[0043] Step 1. Prepare the raw materials of each component according to the following mass percentages: Ni 10.5%, Mn 16.0%, Ag 5.5%, Si 0.6%, B 0.15%, and the balance is Cu; the raw material of B is NiB master alloy, The raw materials of other components are metal simple substances; the Mn simple substance raw materials are coated with Ag;

[0044] Step 2. Put the elemental metal and NiB intermediate alloy in the raw materials of each component prepared in step 1 into the magnesia crucible of the vacuum induction melting furnace, and put the simple substance of Mn coated with Ag prepared in step 1 into the vacuum induction melting furnace. In the top hopper of the melting furnace, the vacuum induction melting furnace is then vacuumed to a vacuum degree of 10 -2 Heating the temperature at MPa to completely melt the raw materials in the magnesia crucible, adding the Ag-coated Mn elemental raw material from the top hopper in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com