Preparation device of gallium-containing chalcogenide glass having high melting point and high boiling point, and preparation method thereof

A technology of chalcogenide glass and preparation equipment, which is applied in the preparation equipment and field of high melting and boiling point chalcogenide glass, which can solve the problems of pressure cracking, pressure deformation, and low Ga vapor pressure parameter value, and achieve the effect of low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

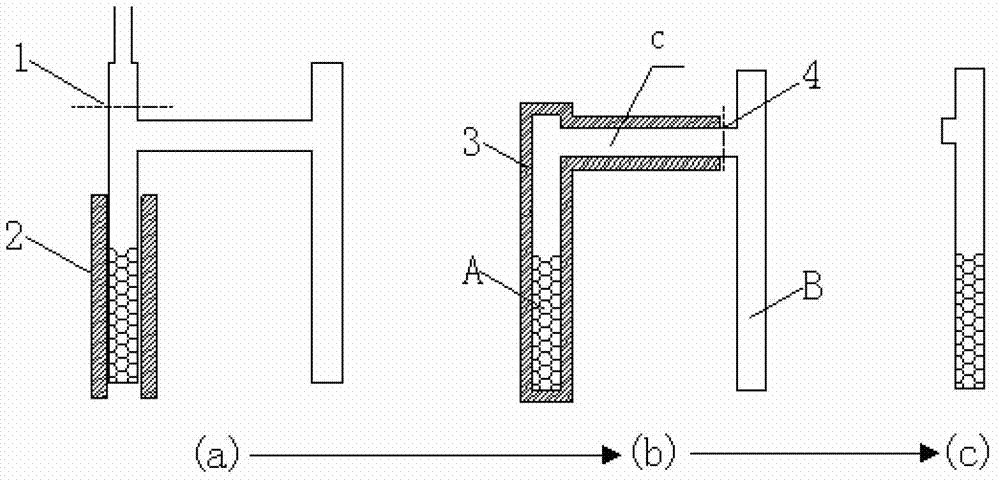

[0015] Embodiment 1: A preparation device for gallium-containing high melting and boiling point chalcogenide glass, comprising an electric heating furnace 2, a rapid heating furnace 3 and an H-type quartz ampoule, the electric heating furnace 2 has a temperature control device, and the H-type quartz ampoule includes a glass The raw material tube A and the purified glass tube B, the glass raw material tube A and the purified glass tube B are connected through the connecting pipe C, the upper end of the glass raw material tube A is open, the upper end of the glass raw material tube A is connected to a vacuum pump, and the electric heating furnace 2 is used to heat the glass raw material A tube, the rapid heating furnace 3 is used to heat the glass feedstock tube A and connecting tube C at the same time.

[0016] Preparation of high-purity Ge 15 Te 75 Ga 10 Chalcogenide glass, the specific steps are as follows:

[0017] 1) According to the ratio of 15mol%, 75mol%, and 10mol% o...

Embodiment 2

[0024] Preparation of high-purity Ge 23 Se 65 Ga 12 Chalcogenide glass, the specific steps are as follows:

[0025] 1) The raw materials are 20g of germanium, selenium, and gallium in proportions of 23mol%, 65mol%, and 12mol%, respectively. At the same time, 0.005g of magnesium bars are put in according to the mass percentage of 0.025wt%, and TeCl is put into it according to the mass percentage of 0.025wt%. 4 0.005 g, put into pre-dehydroxylated glass feedstock tube A;

[0026] 2) Seal the nozzle of the glass raw material tube A with the vacuum pump to evacuate, and at the same time heat the glass raw material to 110 with the electric heating furnace 2 o C, to remove the glass raw material and water molecules in the H-type quartz ampoule, when the vacuum in the H-type quartz ampoule reaches 2×10 -3 When the Pa is below, use a hydrogen-oxygen flame to seal at position 1 of the glass raw material tube A;

[0027] 3) Use the rapid heating furnace 3 to heat the glass raw...

Embodiment 3

[0030] Preparation of high-purity Ge 15 Ga 10 Te 72 Se 3 Chalcogenide glass, the specific steps are as follows:

[0031] 1) According to the ratio of 15mol%, 10mol%, 72mol% and 3mol% of germanium, gallium, tellurium and selenium as raw materials, 20g of magnesium bar is put into 0.025wt% by mass percentage, and 0.025wt% by mass percentage into TeCl 4 0.005 g, put into pre-dehydroxylated glass feedstock tube A;

[0032] 2) Seal the nozzle of the glass raw material tube A with the vacuum pump and vacuumize it, and heat the glass raw material to 130°C at the same time with the electric heating furnace 2 o C, to remove the glass raw material and water molecules in the H-type quartz ampoule, when the vacuum in the H-type quartz ampoule reaches 2×10 -3 When the Pa is below, use a hydrogen-oxygen flame to seal at position 1 of the glass raw material tube A;

[0033] 3) Use the rapid heating furnace 3 to heat the glass raw material pipe A and the connecting pipe C at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com