Annealing and crucible releasing method after crystal growth and crystal preparation method

A technology of crystal growth and crystal growth furnace, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of difficulty in removing the conical part of the crystal, damage to the inner wall of the crucible, contamination of crystal slices, etc. The effect of reducing error density defects, improving quality and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

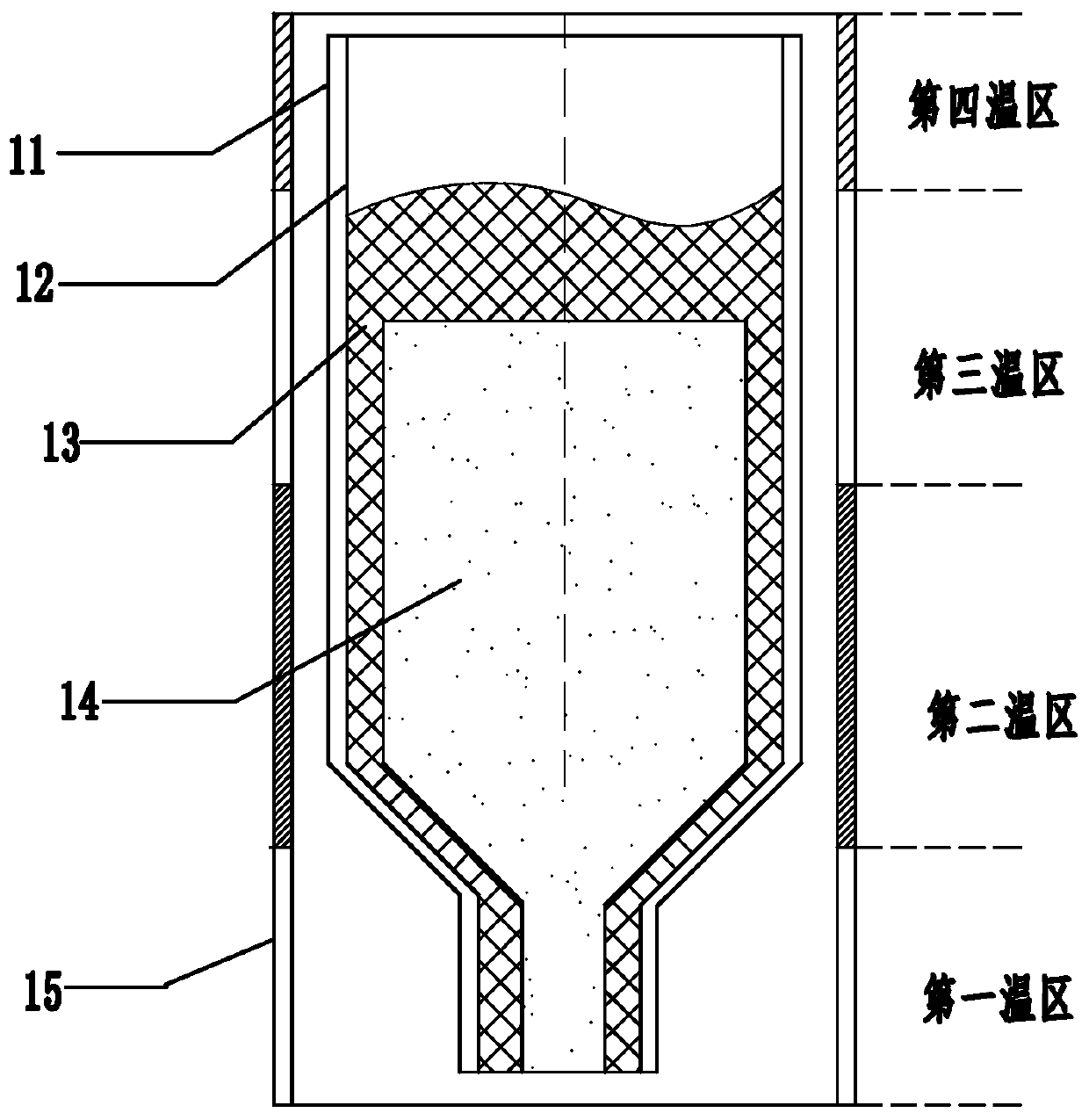

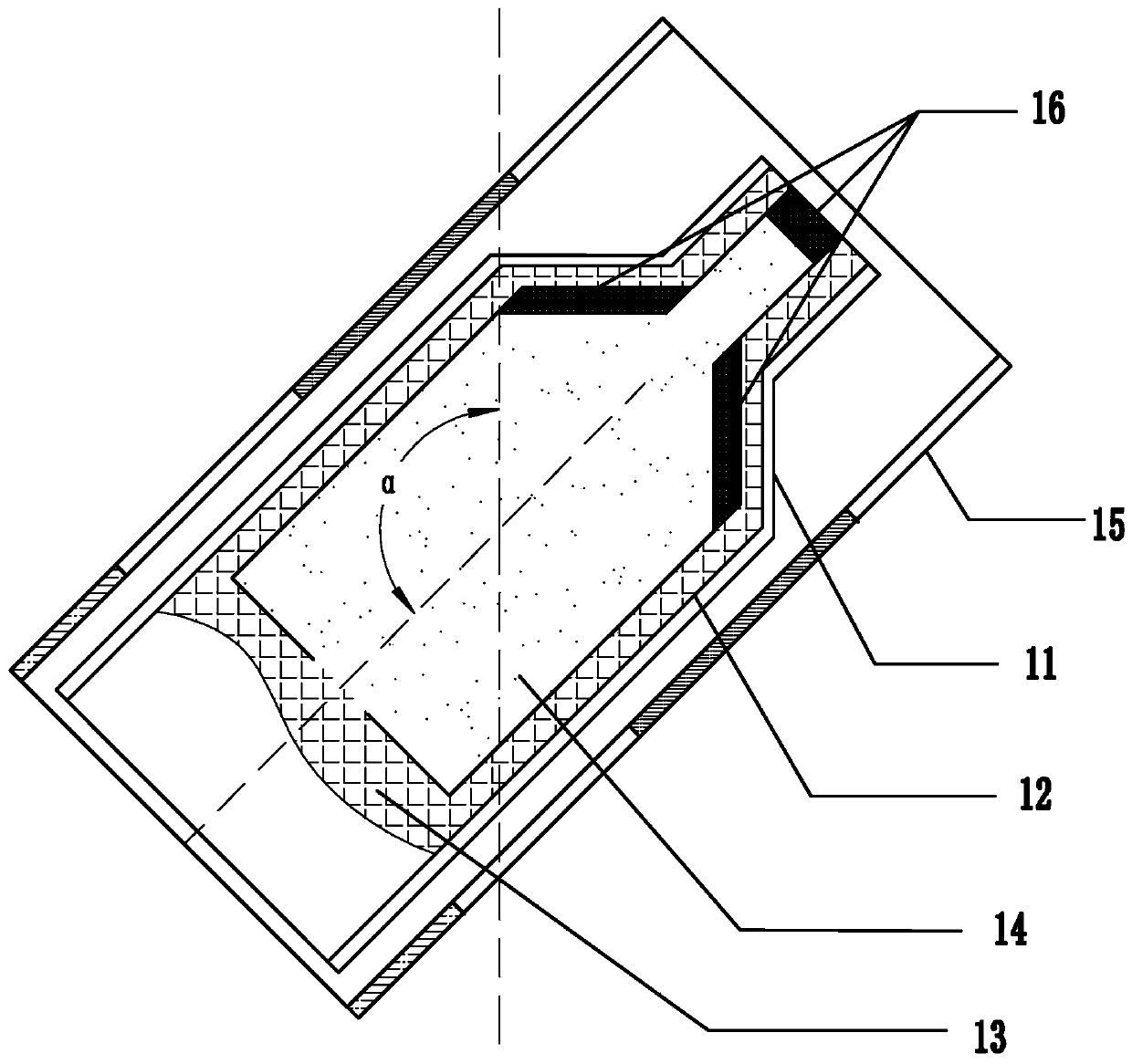

[0037] combine Figure 1~4 , taking the preparation of indium phosphide single crystal as an example to illustrate. This embodiment provides a method for crystal preparation, comprising the following steps:

[0038] S1: Clean the quartz ampoule 11, the quartz cap, and the PBN crucible 12 in the following manner:

[0039] First use organic solvent to scrub and rinse with deionized water, then soak and clean with acid or aqua regia, and finally rinse with deionized water and dry for later use;

[0040] S2: vacuum annealing the quartz ampoule 11, the quartz cap and the PBN crucible 12;

[0041] S3: Put the PBN crucible 12 in the quartz ampoule 11, put the required raw materials into the PBN crucible 12, and then vacuumize the quartz ampoule 11. When the vacuum degree reaches the design requirement, cover the quartz cap and place the quartz ampoule Bottle 11 was sealed; the vacuum was kept at 4*10 -4 ~8*10 -3 Between mmHg, the preferred vacuum is 10 -4 mmHg, the sealing and ...

Embodiment 2

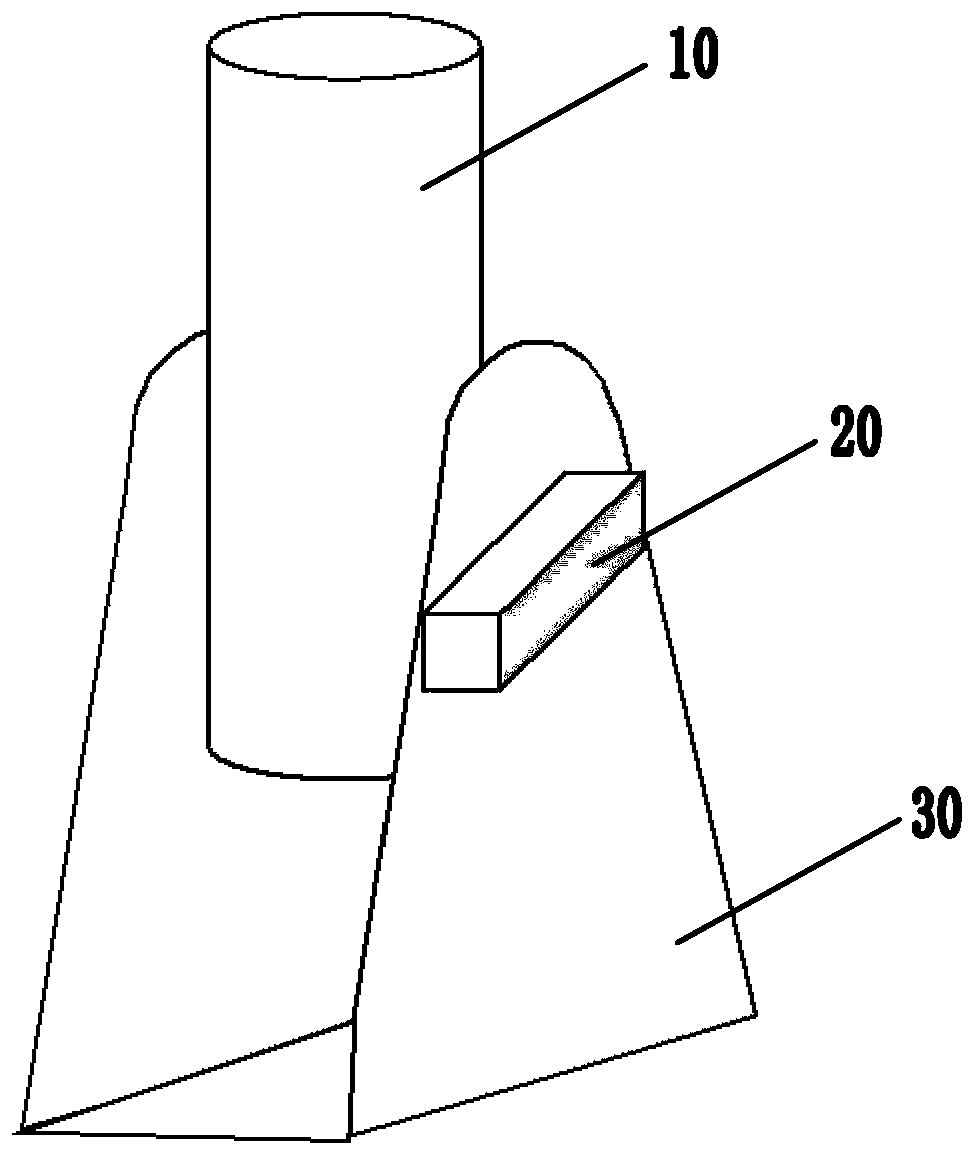

[0060] Combined with the above-mentioned embodiment one and image 3 , 4 As shown, the present embodiment provides a crystal growth device, including a crystal growth furnace 10, an angle adjustment device 20 for adjusting the inclination angle of the crystal growth furnace 10, and a base 30; the crystal growth furnace 10 has a rotating shaft, and the crystal growth furnace 10 passes through the The rotating shaft is installed on the base 30, and is movably connected with the base 30; the angle adjusting device 20 is installed on the base 30, and the driving end of the angle adjusting device 20 is connected to the rotating shaft of the crystal growth furnace 10; the angle adjusting device 20 drives the rotating shaft to rotate to Adjust the inclination angle of the crystal growth furnace 10 ; preferably, the angle adjustment device 20 includes a driving motor, and the driving end of the driving motor is connected to the rotating shaft of the crystal growth furnace 10 .

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com