Cadmium zinc telluride single crystal furnace and growth process of cadmium zinc telluride single crystals

A technology of cadmium zinc telluride and single crystal furnace, applied in single crystal growth, single crystal growth, crystal growth and other directions, can solve the problem of single crystal lattice structure integrity, unsatisfactory diameter size, low single crystal yield, tellurium zinc Cadmium single crystal has problems such as poor economic benefits, and achieves the effect of complete lattice structure, uniform composition and less inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

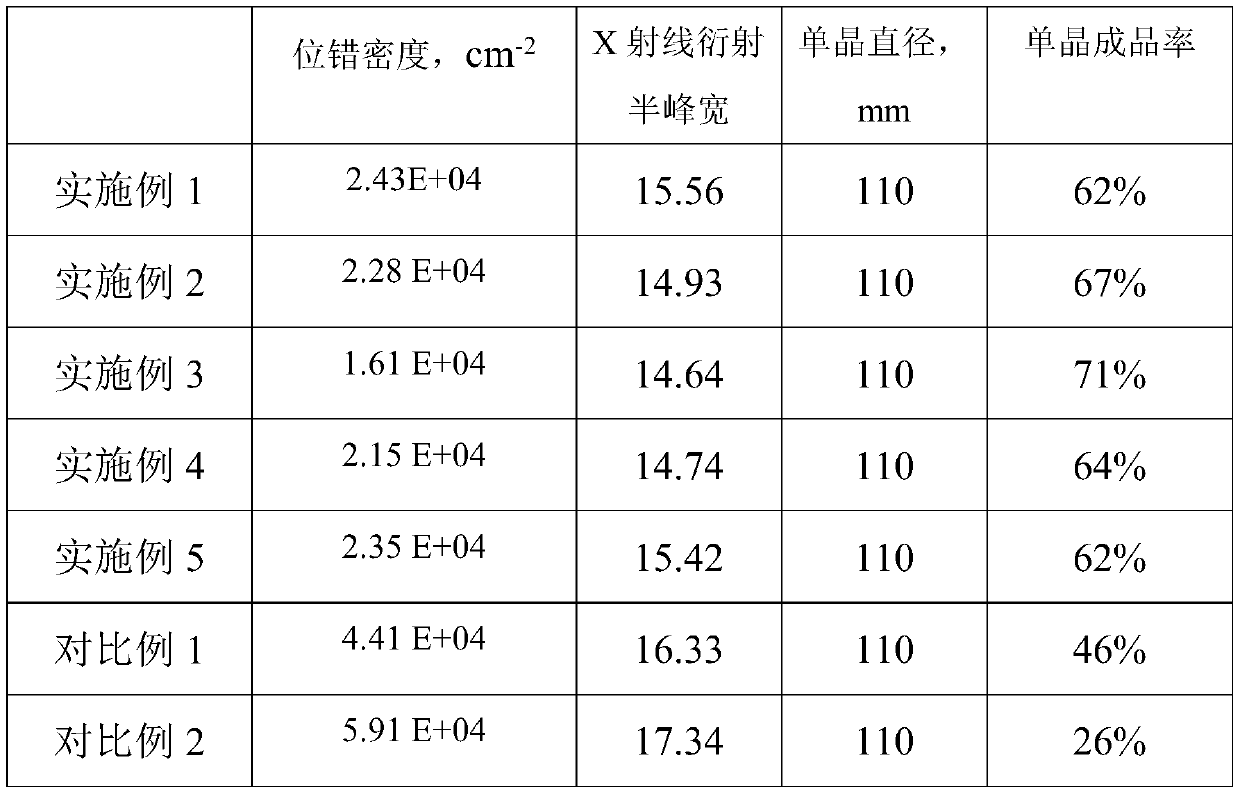

Embodiment 1

[0030] A growth process of cadmium zinc telluride single crystal includes the following steps:

[0031] A. Seed processing: select Cd with orientation cut 1-x Zn x 85g Te seed crystals, where x is 0.1, are mechanically polished by a cylindrical grinder, soaked in a 4% bromine-methanol solution by volume for 2 minutes, and then rinsed with methanol;

[0032] B. Loading: use Cd 1-x Zn x Te polycrystalline material 4kg, where x is 0.04, the seed crystal washed with methanol in step A and the Cd 1-x Zn x Te polycrystalline material is put into the boron nitride crucible 3 from top to bottom, then the boron nitride crucible 3 is put into the quartz ampoule 2 and evacuated, when the vacuum degree in the quartz ampoule 2 reaches 5.0×10 -5 After Pa is above, use a hydrogen-oxygen flame torch to seal and weld the quartz ampoule 2 to complete the sealing of the quartz ampoule 2;

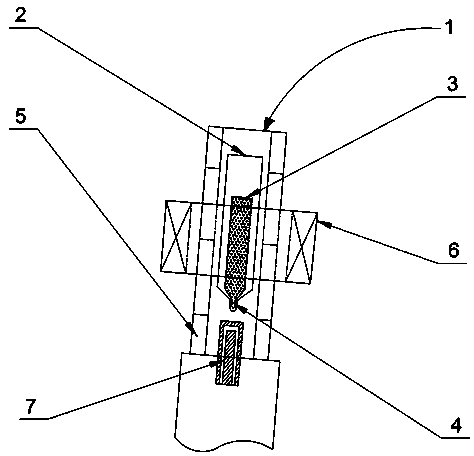

[0033] C. Furnace installation: Put the sealed quartz ampoule 2 into the furnace body 1. The furnace body 1 is inc...

Embodiment 2

[0039] Compared with Example 1, the only difference is that the furnace body 1 is inclined by 5° with respect to the vertical direction.

Embodiment 3

[0041] Compared with Example 1, the only difference is that the furnace body 1 is inclined by 8° with respect to the vertical direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com