Chalcohalide glass and preparation method thereof

A technology of sulfur halide glass and glass, which is applied in the field of sulfur halide glass and its preparation, to achieve the effects of improved light transmission, environmental friendliness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 0.3Ga 2 S 3 -0.5Sb 2 S 3 -0.2CsI glass preparation

[0029] Prepare a glass mixture with Ga, Sb, S with a purity ≥99.999% and CsI with a purity ≥99.9% in proportion, put the glass mixture into a clean quartz ampoule with a hydroxyl content of less than 5ppm, and vacuum until the vacuum degree is less than 10 -2 Pa, the quartz ampoule was sealed with an oxyhydrogen flame. Put the sealed quartz ampoule containing the glass mixture into a swing furnace, raise the temperature to 900°C and keep it warm for 12 hours, take it out and quench it in water; Rate cooling to room temperature, that is, get 0.3Ga 2 S 3 -0.5Sb 2 S 3 -0.2CsI glass.

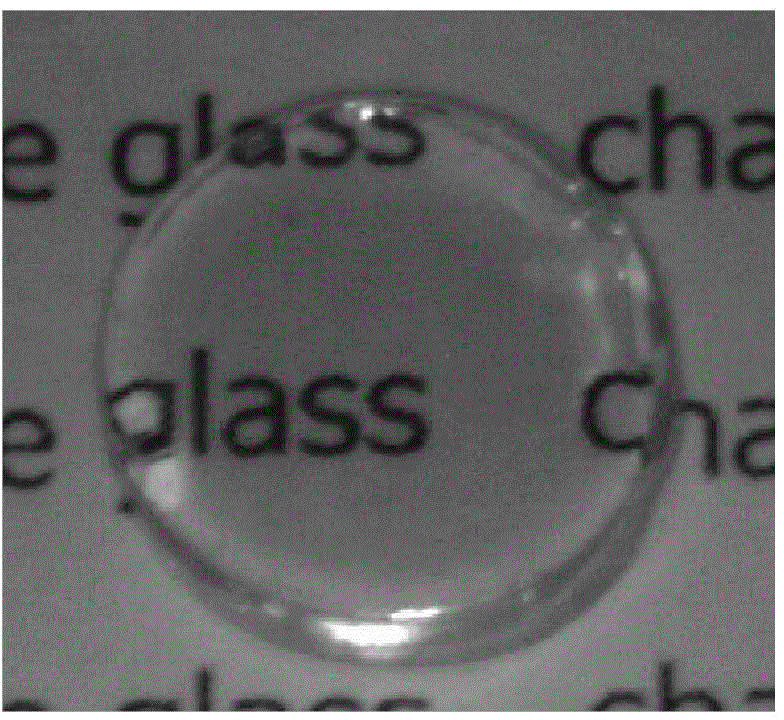

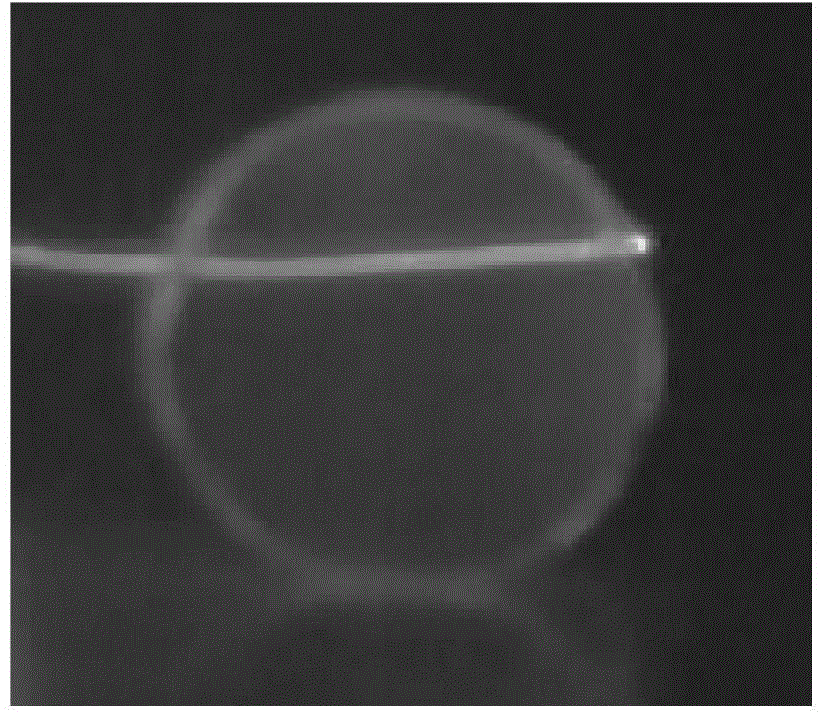

[0030] figure 1 with figure 2 These are the photos of the glass of this embodiment taken by an ordinary visible light camera and an infrared camera with a working wavelength of 7.5-13 μm. Through the glass of this embodiment, the characters and iron wires placed behind the glass can be clearly seen respectively.

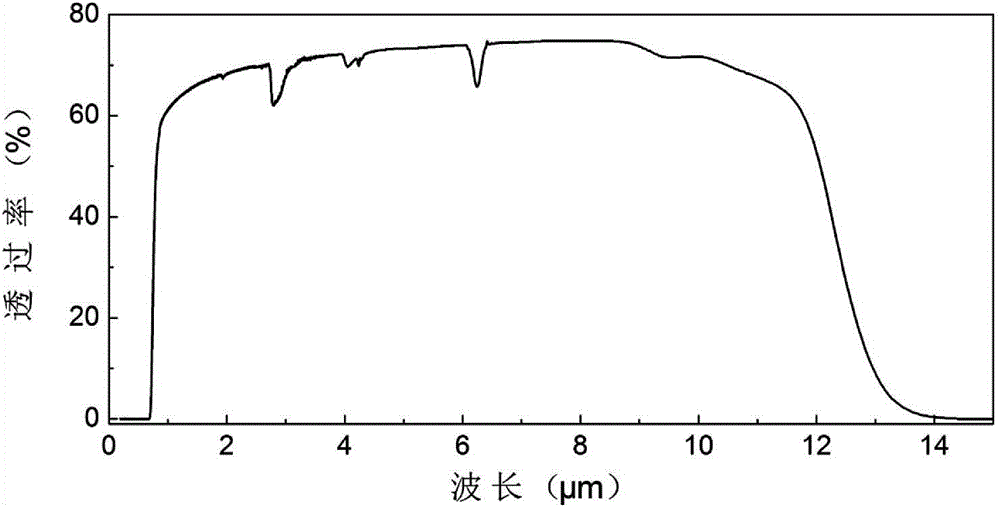

[0031] The de...

Embodiment 2

[0034] 0.3Ga 2 S 3 -0.3Sb 2 S 3 -0.4CsBr glass preparation

[0035] Prepare glass mixture with Ga, Sb, S with purity ≥99.999% and CsBr with purity ≥99.9% in proportion, put the glass mixture into a clean quartz ampoule with hydroxyl content less than 5ppm, and vacuum until the vacuum degree is less than 10 -2 Pa, the quartz ampoule was sealed with an oxyhydrogen flame. Put the sealed quartz ampoule containing the glass mixture into a swing furnace, raise the temperature to 875°C and keep it warm for 18 hours, take it out and quench it in water; Rate cooling to room temperature, that is, get 0.3Ga 2 S 3 -0.3Sb 2 S 3 -0.4CsBr glass.

[0036]The density of the glass was tested by the Archimedes method; the glass transition temperature of the glass was tested by the TAQ2000 differential scanning calorimeter, and the heating rate was 10°C / min; the hardness of the double-sided polished glass sheet was tested by the INSTRON Wilson-Wolpert Tukon 2100B hardness tester Microha...

Embodiment 3

[0039] 0.3Ga 2 S 3 -0.1Sb 2 S 3 -0.6CsCl glass preparation

[0040] Prepare Ga, Sb, S with a purity of ≥99.999% and CsCl with a purity of ≥99.9% to prepare a glass mixture in proportion, put the glass mixture into a clean quartz ampoule with a hydroxyl content of less than 5ppm, and vacuum until the vacuum degree is less than 10 -2 Pa, the quartz ampoule was sealed with an oxyhydrogen flame. Put the sealed quartz ampoule containing the glass mixture into a swing furnace, raise the temperature to 850°C and keep it warm for 24 hours, take it out and quench it in water; Rate cooling to room temperature, that is, get 0.3Ga 2 S 3 -0.1Sb 2 S 3 -0.6CsCl glass.

[0041] The density of the glass was tested by the Archimedes method; the glass transition temperature of the glass was tested by the TAQ2000 differential scanning calorimeter, and the heating rate was 10°C / min; the hardness of the double-sided polished glass sheet was tested by the INSTRON Wilson-Wolpert Tukon 2100B ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com