Preparation method of bromine-lead-cesium monocrystal by horizontal moving zone melting

A technology of horizontal movement, bromine lead cesium, which is applied in the field of melting preparation of horizontal movement zone of bromine lead cesium single crystal, can solve the problems of large phase transformation stress and easy cracking, and achieves low thermal stress, small mechanical vibration, and few cracks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

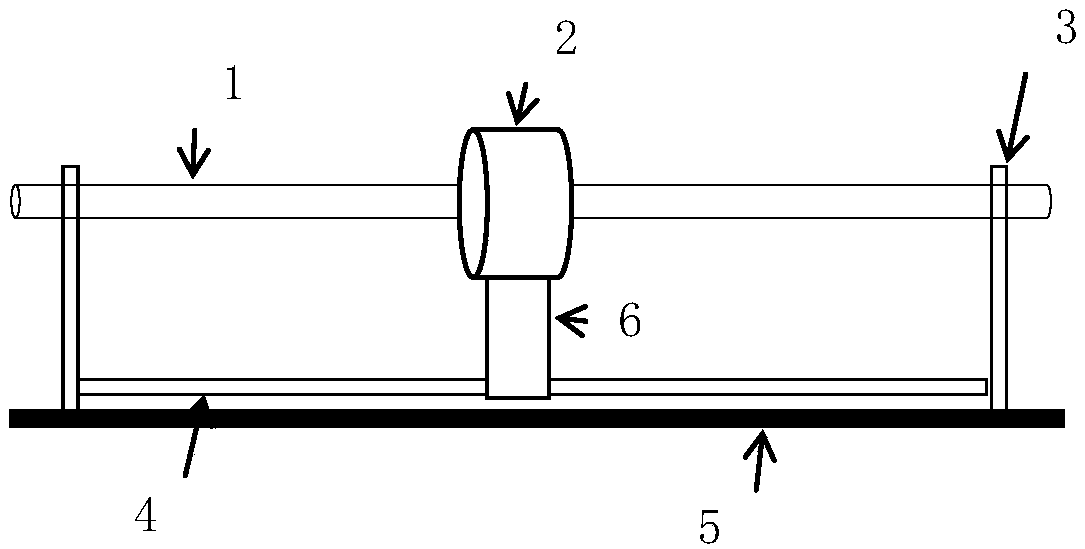

Method used

Image

Examples

Embodiment 1

[0033] (1) Ampoule preparation

[0034] Ampoule wash.

[0035] (a) Soak in concentrated nitric acid with a mass fraction of 68wt% for 48h, then clean the soaked ampoule with deionized water above 10MΩ;

[0036] (b) Soak in acetone solution for 48h, then clean the soaked ampoule with deionized water above 10MΩ;

[0037] (c) Clean the ampoule ultrasonically with deionized water above 10 MΩ.

[0038] Ampoule coated with carbon. The ampoule after cleaning is dried, and a layer of carbon film is coated on the inner wall. Its carbon plating process adopts nitrogen gas with a purity of 99.999% at a rate of 110mL / s at 1150°C as a carrier gas, and then maintains the original speed to continue to feed the carrier gas at a speed of 60mL / s with a purity of 99.999% after stabilization. The methane continued for 20 minutes, and then the temperature of the carbon coating device was lowered to room temperature to obtain a carbon coated ampoule. After the carbon plating is completed, take...

Embodiment 2

[0044] (1) Ampoule preparation

[0045] Ampoule wash.

[0046] (a) Soak in concentrated nitric acid with a mass fraction of 68wt% for 48h, then clean the soaked ampoule with deionized water above 10MΩ;

[0047] (b) Soak in acetone solution for 48h, then clean the soaked ampoule with deionized water above 10MΩ;

[0048] (c) Clean the ampoule ultrasonically with deionized water above 10 MΩ.

[0049] Ampoule coated with carbon. The ampoule after cleaning is dried, and a layer of carbon film is coated on the inner wall. Its carbon plating process adopts nitrogen gas with a purity of 99.999% at a rate of 110mL / s at 1150°C as a carrier gas, and then maintains the original speed to continue to feed the carrier gas at a speed of 60mL / s with a purity of 99.999% after stabilization. The methane continued for 20 minutes, and then the temperature of the carbon coating device was lowered to room temperature to obtain a carbon coated ampoule. After the carbon plating is completed, take...

Embodiment 3

[0055] (1) Ampoule preparation

[0056] Ampoule wash.

[0057] (a) Soak in concentrated nitric acid with a mass fraction of 68wt% for 48h, then clean the soaked ampoule with deionized water above 10MΩ;

[0058] (b) Soak in acetone solution for 48h, then clean the soaked ampoule with deionized water above 10MΩ;

[0059] (c) Clean the ampoule ultrasonically with deionized water above 10 MΩ.

[0060] Ampoule coated with carbon. The ampoule after cleaning is dried, and a layer of carbon film is coated on the inner wall. Its carbon plating process adopts nitrogen gas with a purity of 99.999% at a rate of 80mL / s at 1150°C as a carrier gas. After stabilization, the original speed is maintained to continue to feed the carrier gas, and the purity is 99.999% at a rate of 40mL / s. The methane continued for 20 minutes, and then the temperature of the carbon coating device was lowered to room temperature to obtain a carbon coated ampoule. After the carbon plating is completed, take out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com