Method for preparing high-purity chalcogenide glass for optical fiber

A high-purity sulfur and glass technology, applied in glass manufacturing equipment, glass molding, glass furnace equipment, etc., can solve the problems that cannot be completely removed, fail to reach the theoretical minimum loss value, limit the application of high-purity chalcogenide glass, and achieve High purity, effect of guaranteed purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

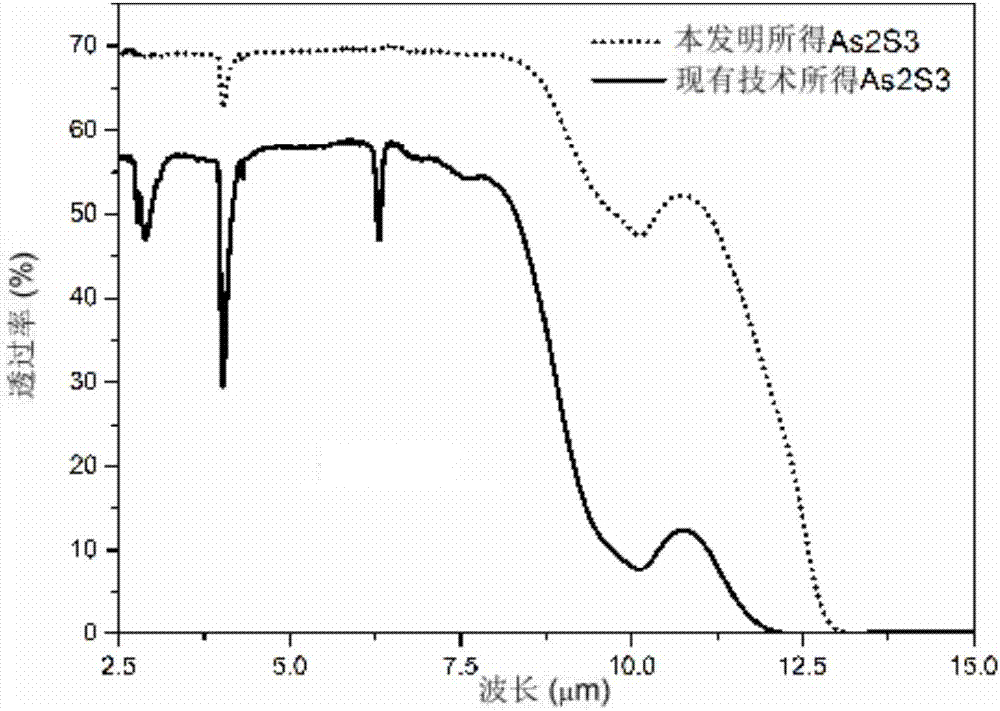

[0049] In Example 1, the elemental raw materials used for preparing chalcogenide glass are As and S, respectively, and the high-purity chalcogenide glass to be prepared is As 2 S 3 Glass rod, As 2 S 3 The diameter of the glass rod is 10 mm.

[0050] Specifically, the medium and high-purity chalcogenide glass As in Example 1 2 S 3 The preparation method comprises the following steps:

[0051] Step 1, select seven quartz ampoules, a quartz glass tube 8 and seven porous quartz filters 9 that are all lower than 1ppm in hydroxyl content; the inner diameter of the quartz glass tube is 10mm, so that the inner diameter of the quartz glass tube is equal to 2 S 3 The diameters of the glass rods are matched; the seven quartz ampoules include the first quartz ampoule 1, the second quartz ampoule 2, the third quartz ampoule 3, the fourth quartz ampoule 4, the fifth quartz ampoule 5, the sixth quartz ampoule Quartz ampoule bottle 6 and the seventh quartz ampoule bottle 7; the second ...

Embodiment 2

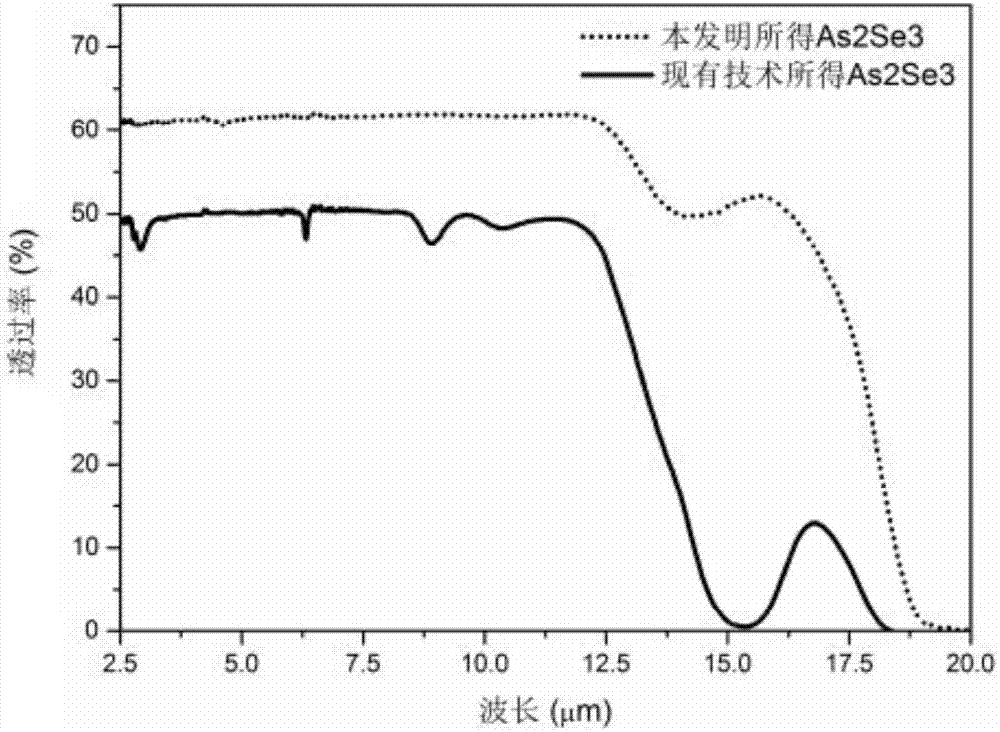

[0077] In the second embodiment, the raw materials used for preparing chalcogenide glass are As and Se respectively, and the high-purity chalcogenide glass to be prepared is As 2 Se 3 Glass rod, As 2 Se 3 The diameter of the glass rod is 15 mm.

[0078] Specifically, the high-purity chalcogenide glass As in the second embodiment 2 Se 3 The preparation method comprises the following steps:

[0079] Step 1, select for use seven quartz ampoules, a quartz glass tube 8 and seven porous quartz filters 9 that are all lower than 1ppm in hydroxyl content; the inner diameter of the quartz glass tube 8 is 15mm, so that the inner diameter of the quartz glass tube is the same as the one to be prepared. As 2 Se 3 The diameters of the glass rods are matched; the seven quartz ampoules include the first quartz ampoule 1, the second quartz ampoule 2, the third quartz ampoule 3, the fourth quartz ampoule 4, the fifth quartz ampoule 5, the sixth quartz ampoule Quartz ampoule bottle 6 and ...

Embodiment 3

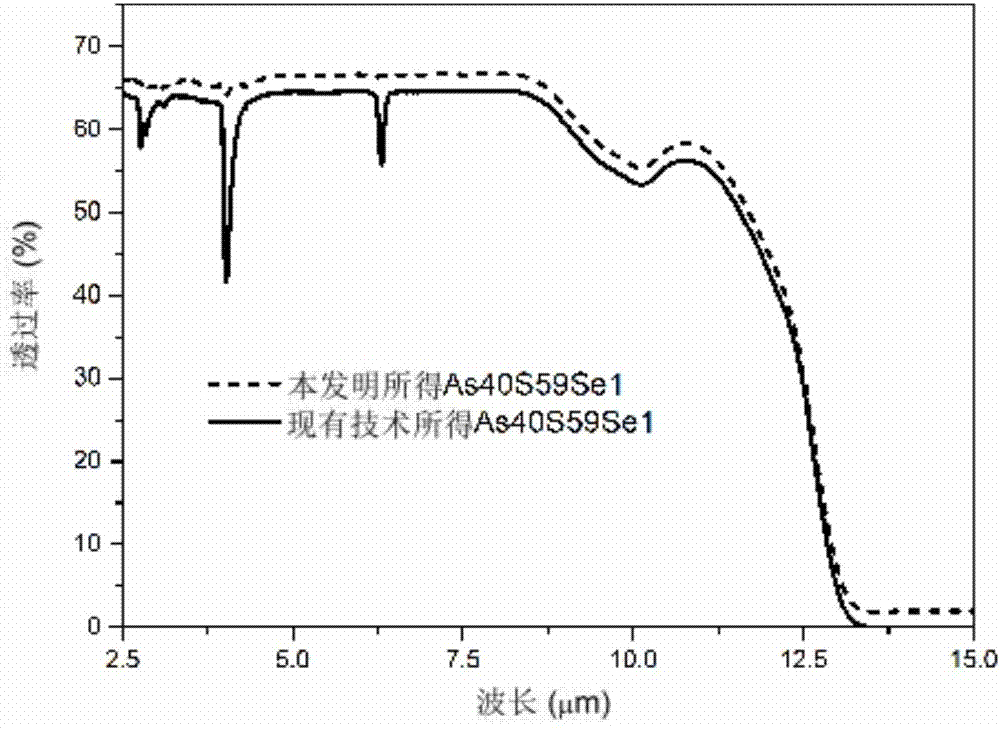

[0105] In the third embodiment, the raw materials used for preparing chalcogenide glass are As, S and Se respectively, and the high-purity chalcogenide glass to be prepared is As 40 S 59 Se 1 Glass rod, As 40 S 59 Se 1 The diameter of the glass rod is 20 mm.

[0106] Specifically, the high-purity chalcogenide glass As in Example 3 40 S 59 Se 1 The preparation method comprises the following steps:

[0107] Step 1, select seven quartz ampoules, a quartz glass tube 8 and seven porous quartz filters 9 that are all lower than 1ppm in hydroxyl content; the inner diameter of the quartz glass tube is 20mm, so that the inner diameter of the quartz glass tube and the 40 S 59 Se 1 The diameters of the glass rods are matched; the seven quartz ampoules include the first quartz ampoule 1, the second quartz ampoule 2, the third quartz ampoule 3, the fourth quartz ampoule 4, the fifth quartz ampoule 5, the sixth quartz ampoule Quartz ampoule bottle 6 and the seventh quartz ampoule ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com