PBN crucible oxidation pretreatment device and method and application thereof

A pretreatment device and pretreatment technology, applied in chemical instruments and methods, self-solidification method, single crystal growth, etc., can solve problems such as crystal side wall pits and cracks, quartz ampoule expansion, affecting crystal quality, etc., to prevent Effects of heating device and PBN crucible damage, reduction of heterogeneous nucleation phenomenon, and easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a PBN crucible oxidation pretreatment device.

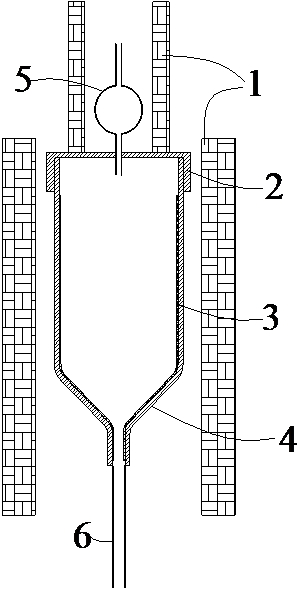

[0041] Such as figure 1 As shown, the device includes: a quartz ampoule 4 containing a PBN crucible 3 , the PBN crucible 3 is placed in the quartz ampoule 4 , and the outer wall of the PBN crucible 3 is bonded to the inner wall of the quartz ampoule 4 . The top opening of the quartz ampoule 4 is provided with a suitable quartz sealing cover 2 at the top opening. The quartz sealing cover 2 is detachable, and the quartz sealing cover 2 is provided with an air inlet. The bottom of the ampoule 4 is provided with an air outlet, the bottom of the PBN crucible 3 is a seed crystal end, and the seed crystal end is open, and the opening of the seed crystal end communicates with the air outlet at the bottom of the quartz ampoule 4, and the quartz ampoule 4 and Oxygen in the PBN crucible 3 can be discharged from the air outlet. The air inlet and the air outlet are connected to the air inlet pipe 5 and the ai...

Embodiment 2

[0043] This embodiment provides a PBN crucible oxidation pretreatment method, the treatment method is as follows:

[0044] (1) Provide a PBN crucible oxidation pretreatment device described in Example 1;

[0045](2) First, put the PBN crucible 3 in an acid solution for ultrasonic cleaning for 2 hours. In the acid solution, HF acid: deionized water = 2:1, then use deionized water to rinse the acid solution on the surface of the PBN crucible 3, and finally The washed PBN crucible 3 is soaked in ethanol for 10 minutes and then dehydrated, and the cleaned PBN crucible 3 is placed on a clean workbench to naturally dry the ethanol and water on its surface. Put the PBN crucible 3 whose surface has been dried in the quartz ampoule 4, control the heating device 1, heat up to 200°C and bake for 1 hour, and dry the moisture on the surface of the crucible;

[0046] (3) Use the quartz sealing cap 2 to seal the opening of the quartz ampoule 4, close the air inlet pipe 5 and the air outlet ...

Embodiment 3

[0050] This embodiment provides a method of using embodiment 2 to process the obtained PBN crucible 3 in gallium arsenide single crystal

[0051] For the application of the growth process, in this embodiment, bulk gallium arsenide polycrystalline material is used to fill the PBN crucible 3 to produce 10 kg of gallium arsenide single crystal material with a diameter of 4 inches, and the total length of the equal diameter part is 200 mm.

[0052] The single crystal growth process of this embodiment is as follows: use the PBN crucible 3 pretreated in this embodiment to charge, and hold 10Kg of gallium arsenide polycrystalline material in total, place the PBN crucible 3 containing the polycrystalline material in a quartz ampoule 4, pump Vacuum treatment until the pressure in the quartz ampoule 4 is lower than 10 -2 After Pa, the quartz tube is welded and sealed with an oxyhydrogen flame. Put the sealed quartz ampoule 4 containing the PBN crucible 4 and the polycrystalline materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com