Method for plating carbon film on ampoule internal wall for CdZnTe crystal growth and apparatus thereof

A technology of quartz ampoule and crystal growth, which is applied in gaseous chemical plating, metal material coating process, coating, etc., and can solve problems such as diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: The method for coating the inner wall of the quartz ampoule with a carbon film of the present invention is realized through its special device, that is, a vacuum coating device.

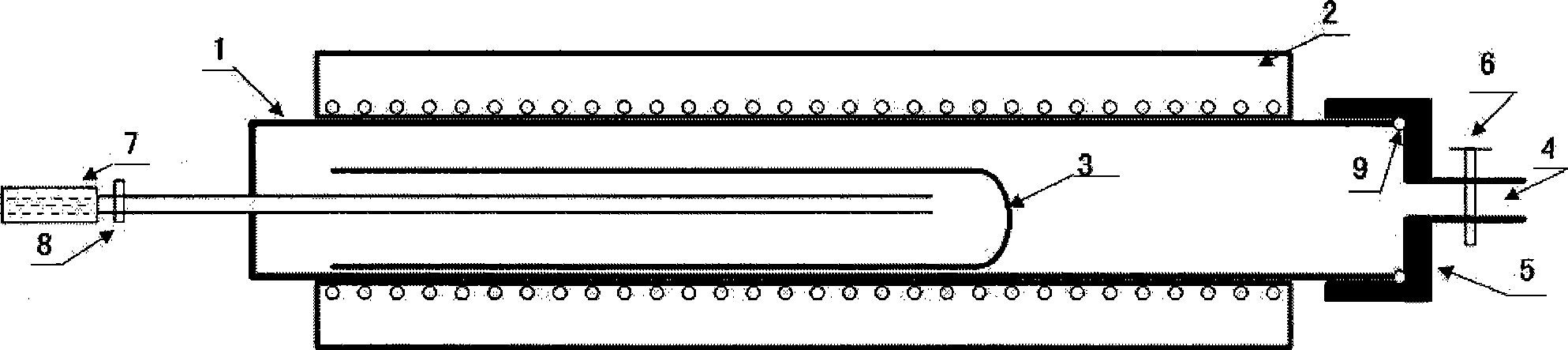

[0014] Referring to Fig. 1, the vacuum coating device used among the present invention comprises quartz furnace tube 1, heating furnace 2, quartz ampoule 3, vacuum system 4, stainless steel pipe joint 5, vacuum valve 6, ethanol storage bottle 7, regulating valve 8, sealing ring 9; the quartz furnace tube 1 is placed in the heating furnace 2 embedded with the electric heating wire, and a quartz ampoule 3 to be carbon-plated is arranged in the cavity of the quartz furnace; one end of the quartz furnace tube 1 is provided with a sealing ring 9 is connected to a stainless steel joint 5, a round hole is opened in the center of the stainless steel joint and a short tube is connected to the vacuum system 4; a vacuum valve 6 is installed on the connecting pipe of the vacuum system 4 to ad...

Embodiment 2

[0019] Embodiment 2: In this embodiment, the same vacuum coating device as in Embodiment 1 above is used.

[0020] The process steps of the coating method in this embodiment are exactly the same as those in Embodiment 1 above. The difference is that some process parameters have been changed. Its different process parameters are: (1) The vacuum degree in the quartz furnace tube is 10 -2 Pa; (2) The heating temperature of the heating furnace during coating is 1050°C, and keep baking for 10 minutes; (3) Control the flow rate of absolute ethanol into the quartz ampoule to be 0.5ml / min. Finally, a quartz ampoule whose inner wall is coated with a carbon film is obtained.

Embodiment 3

[0021] Embodiment 3: In this embodiment, the same vacuum coating device as in Embodiment 1 above is used.

[0022] The process steps of the coating method in this embodiment are exactly the same as those in Embodiment 1 above. The difference is that some process parameters have been changed. Its different process parameters are: (1) The vacuum degree in the quartz furnace tube is 10 -1 Pa; (2) The heating temperature of the heating furnace during coating is 980°C, and keep baking for 30 minutes; (3) Control the flow rate of absolute ethanol into the quartz ampoule to be 1.5ml / min. Finally, a quartz ampoule whose inner wall is coated with a carbon film is obtained.

[0023] Using the carbon-coated quartz ampoule obtained in the embodiment of the present invention, the experiment of CdZnTe crystal growth effect is carried out. After loading the CdZnTe raw material, the crystal after pure high-temperature synthetic growth has an extremely low carbon content; it shows that the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com