High-purity chalcogenide phase change alloy target and preparation method for same

A phase change alloy, high-purity sulfur technology, applied in electrical components and other directions, can solve the problems of difficult to control target deviation and distribution uniformity, unfavorable large-scale production, complex operation process, etc., to reduce target costs and equipment. requirements, the effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

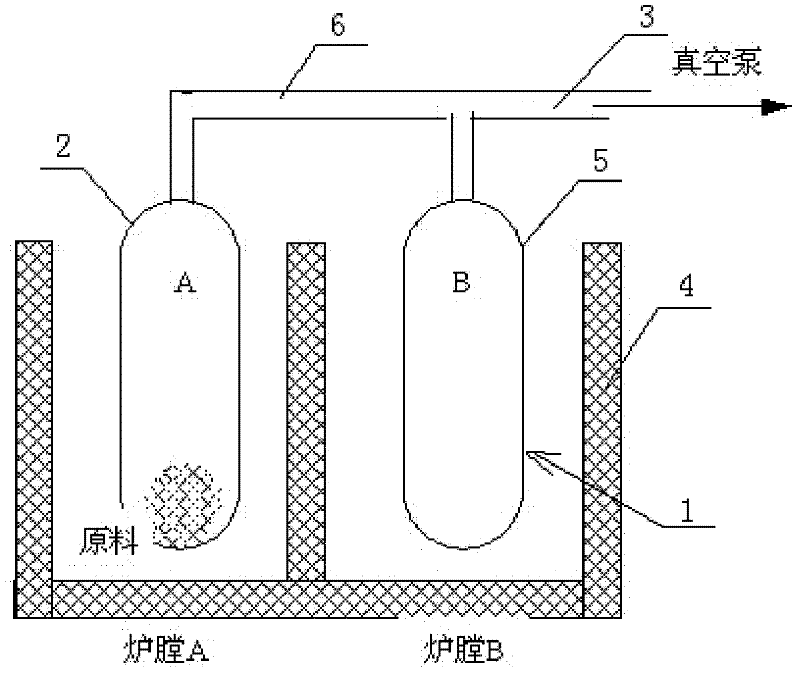

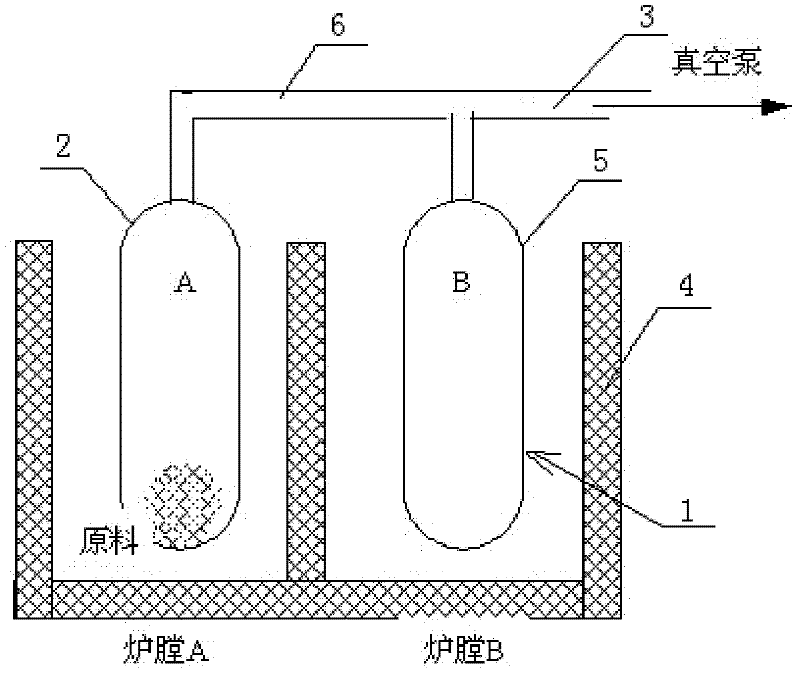

[0027] The present invention is a high-purity chalcogenide phase-change alloy target, a high-purity chalcogenide phase-change alloy target, mainly composed of the following components and their weight percentages: germanium Ge 0-20%; antimony Sb 20-40% %; Tellurium Te 50-70%, the sum of the weight percentages of the mixture composed of the above raw materials is 100%, and then add 0.1wt% magnesium strips to the mixture (the mass of magnesium strips is 0.1% of the mass of the mixture) and 300ppm TeCl 4 . (TeCl 4 The concentration in the mixture is 300ppm), the specific preparation process is as follows:

[0028] 1. Ingredients

[0029] Mix target raw materials germanium Ge, antimony Sb and tellurium Te with a purity of 99.99% according to the following weight percentages: germanium 0-20%; antimony 20-40%; tellurium 50-70%, and the weight of the mixture obtained after mixing The sum of the percentages is 100%, then add magnesium strips and TeCl to the mixture 4 , wherein th...

Embodiment 2

[0039] A high-purity chalcogenide phase-change alloy target is the same as in Example 1, the difference is that the raw materials of the target are formulated according to the following specific proportions, the weight percentage of Ge is 14.14%, the weight percentage of Sb is 23.72%, Te The weight percentage is 62.14%, the sum of the weight percentages of each raw material is 100%, and the atomic ratio Ge:Sb:Te=2:2:5.

[0040] The temperature of the hot end of the double-pipe distillation furnace 4 is controlled at 650°C, and the temperature at the cold end is controlled at 20°C; the temperature of the swing furnace is slowly raised to 850°C, and the swing is melted for 25 hours, taken out and cooled, and kept in an annealing furnace at 100°C for 12 hours. Slowly cool down to room temperature to obtain alloy target samples;

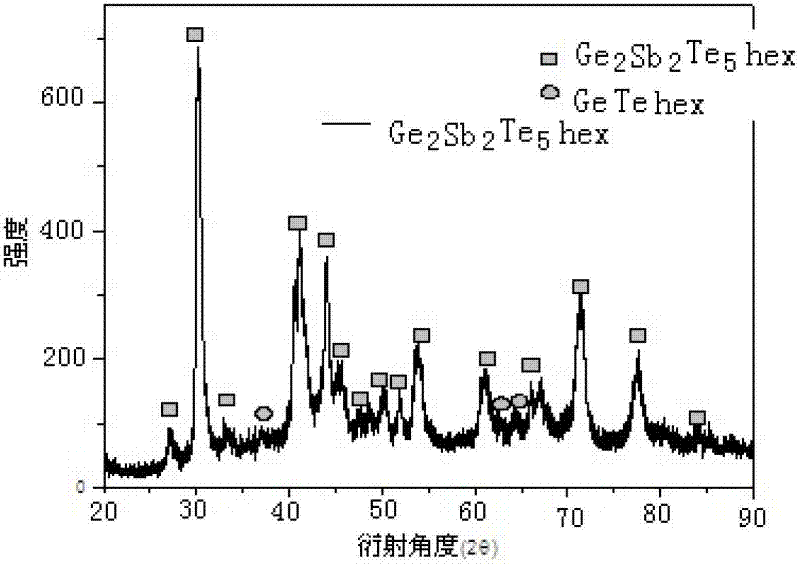

[0041] Tested by X-ray Energy Spectroscopy (EDS), Ge 2 Sb 2 Te 5 The composition of the alloy target is (weight ratio) Ge: 13.66%, Sb: 24.18%, Te: 62...

Embodiment 3

[0043] A high-purity chalcogenide phase-change alloy target is basically the same as in Example 1, the difference is that the raw materials of the target are formulated according to the following proportions: Ge is 8.78% by weight, Sb is 29.46% by weight, Te The weight percentage of each raw material is 61.76%, the sum of the weight percentages of each raw material is 100%, and the atomic ratio Ge:Sb:Te=1:2:4.

[0044] The temperature of the hot end of the double-pipe distillation furnace 4 is controlled at 650°C, and the temperature at the cold end is controlled at 100°C; the temperature of the swing furnace is slowly raised to 900°C, and the swing is melted for 30 hours, taken out and cooled, and kept in an annealing furnace at 150°C for 12 hours. Slowly cool down to room temperature to obtain alloy target samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com