Method and device for growth of mercurous iodide single crystal

A technology of mercurous iodide and mercurous iodide is applied in the field of material engineering, and can solve the problems that it is difficult to obtain a single crystal with practical value and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

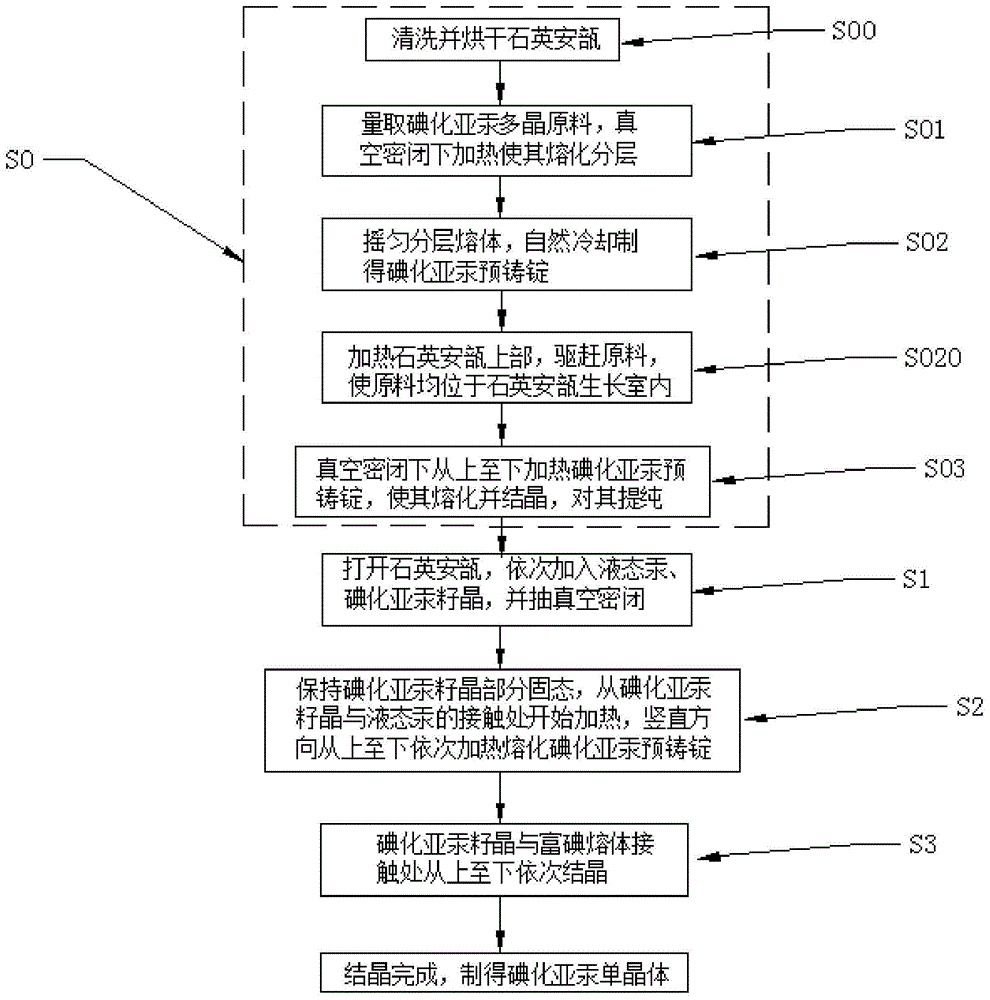

Method used

Image

Examples

Embodiment 1

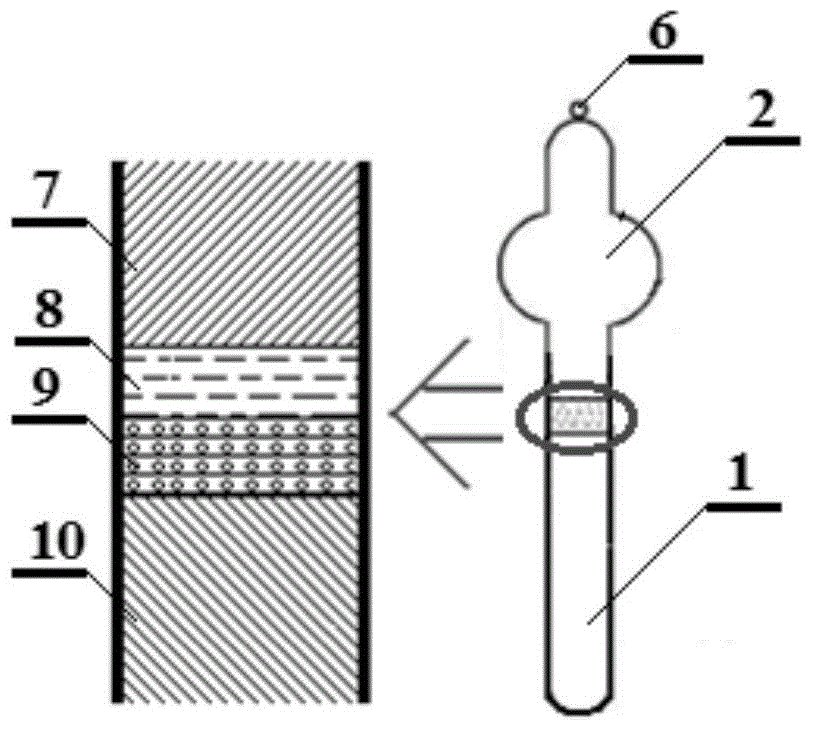

[0048] In this example, using image 3 The quartz ampoule shown includes a growth chamber 1, a material storage chamber 2, a second suction pipe 4, and a first suction pipe 5. The growth chamber 1 has an inner diameter of 10mm and a length of 220mm, and has two suction pipes. The inner diameter of the constriction of the exhaust pipe 4 is 12 mm.

[0049] S00: Clean the quartz ampoule with deionized water and dry it;

[0050] S01: Measure 120g of mercurous iodide polycrystalline raw material, put it into a quartz ampoule, and evacuate to 2×10 -3 Seal and make hook 6 after Pa, vertically place the quartz ampoule that calomel iodide polycrystalline raw material is housed in a vertical tube furnace and be heated to 310° C., and be incubated for 30 minutes;

[0051] S02: After all the calomel iodide polycrystalline raw materials are melted, the quartz ampoule is taken out, shaken well, placed vertically outside the furnace to cool to room temperature, and the calomel iodide preca...

Embodiment 2

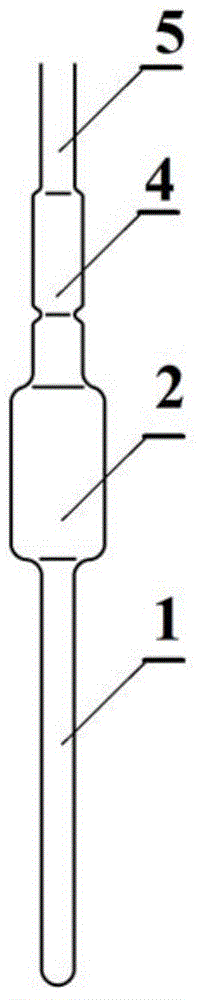

[0057] In this example, using Figure 4 The quartz ampoule shown includes a growth chamber 1, a material storage chamber 2, a third suction pipe 3, a second suction pipe 4, and a first suction pipe 5. The growth chamber 1 has an inner diameter of 10 mm and a length of 240 mm. The inner diameter of the second exhaust pipe 4 is 12 mm.

[0058] S00: Clean the quartz ampoule with deionized water and dry it;

[0059] S01: Measure 120g of mercurous iodide polycrystalline raw material, put it into a quartz ampoule, and evacuate to 2×10 -3 Seal and make hook 6 after Pa, vertically place the quartz ampoule that calomel iodide polycrystalline raw material is housed in a vertical tube furnace and be heated to 370° C., and be incubated for 30 minutes;

[0060] S02: After all the calomel iodide polycrystalline raw materials are melted, the quartz ampoule is taken out, shaken well, placed vertically outside the furnace to cool to room temperature, and the calomel iodide precast ingot 10 i...

Embodiment 3

[0069] In this example, using image 3 The quartz ampoule shown includes a growth chamber 1, a material storage chamber 2, a second suction pipe 4, and a first suction pipe 5. The growth chamber 1 has an inner diameter of 10mm and a length of 220mm, and has two suction pipes. The inner diameter of the constriction of the exhaust pipe 4 is 12 mm.

[0070] S00: Clean the quartz ampoule with deionized water and dry it;

[0071] S01: Measure 120g of mercurous iodide polycrystalline raw material, put it into a quartz ampoule, and evacuate to 2×10 -3 Seal and make hook 6 after Pa, vertically place the quartz ampoule that calomel iodide polycrystalline raw material is housed in a vertical tube furnace and be heated to 370° C., and be incubated for 30 minutes;

[0072] S02: After all the calomel iodide polycrystalline raw materials are melted, the quartz ampoule is taken out, shaken well, placed vertically outside the furnace to cool to room temperature, and the calomel iodide preca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com