Alloy thermoelectric semiconductor material and fabrication method thereof

A technology of thermoelectric semiconductors and bulk materials, applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of reduced lattice thermal conductivity and difficulty in achieving a large-scale leap in carrier concentration, etc. , to achieve the effects of reduced formation, reduced carrier concentration, and optimized carrier concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

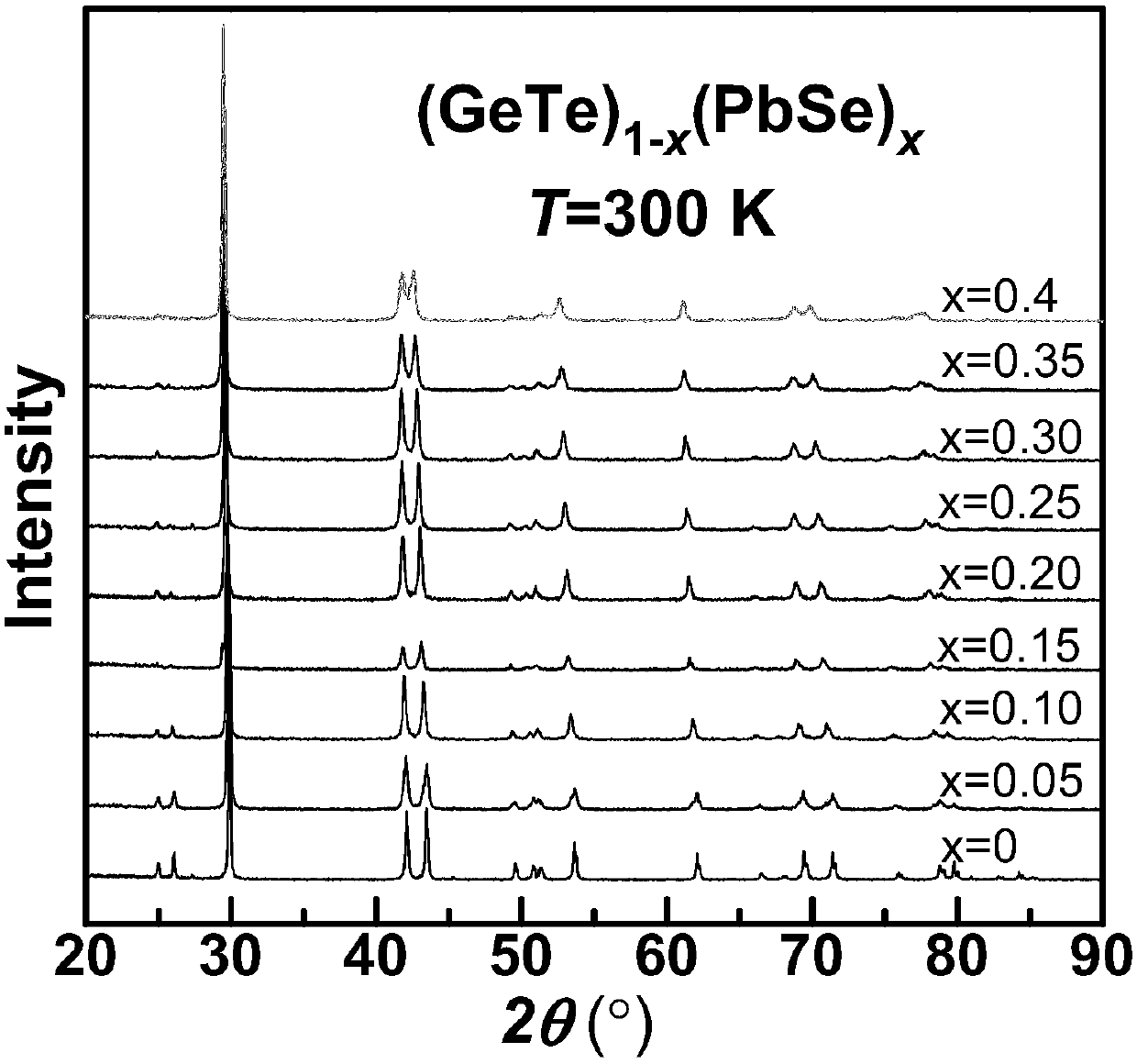

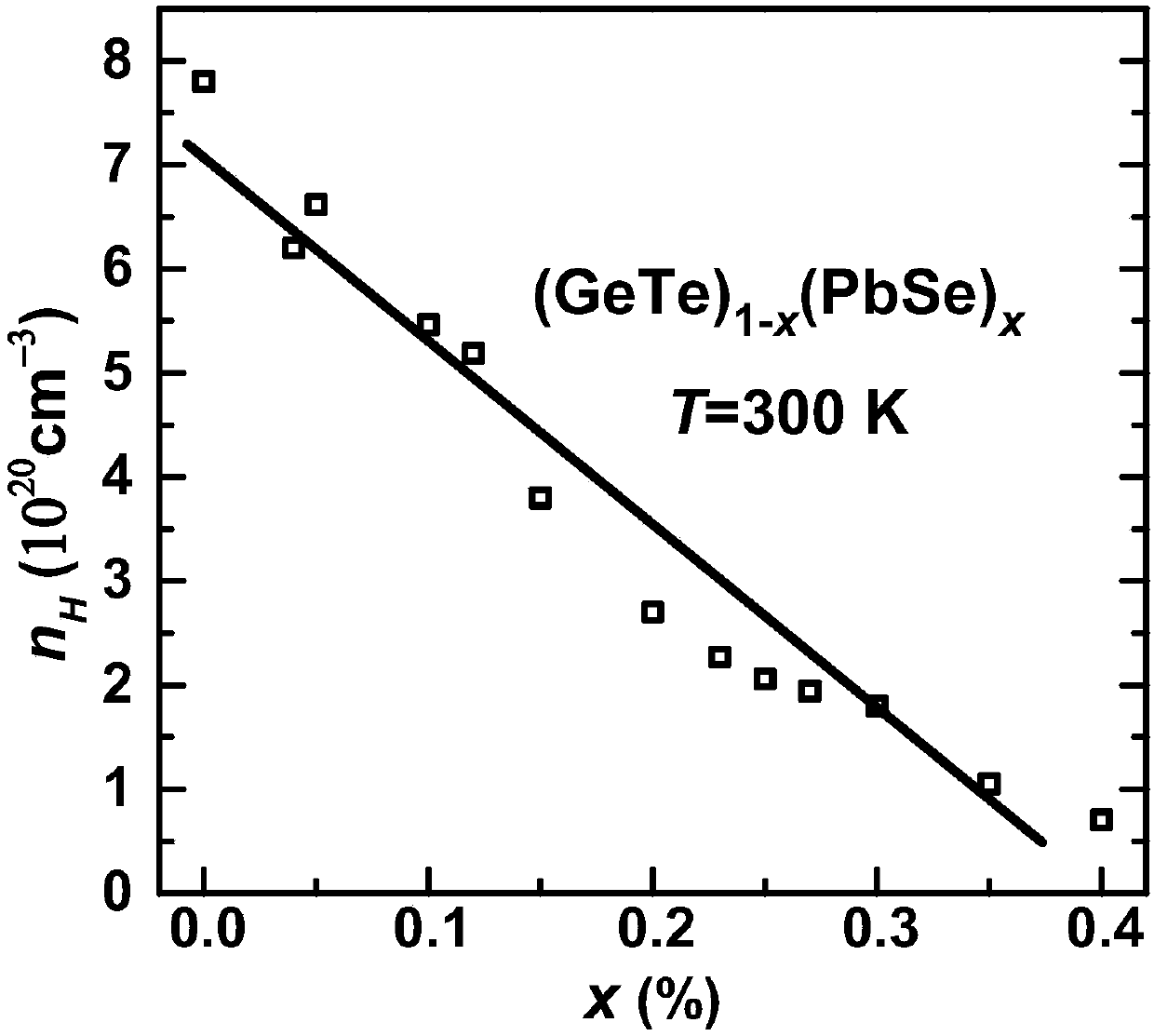

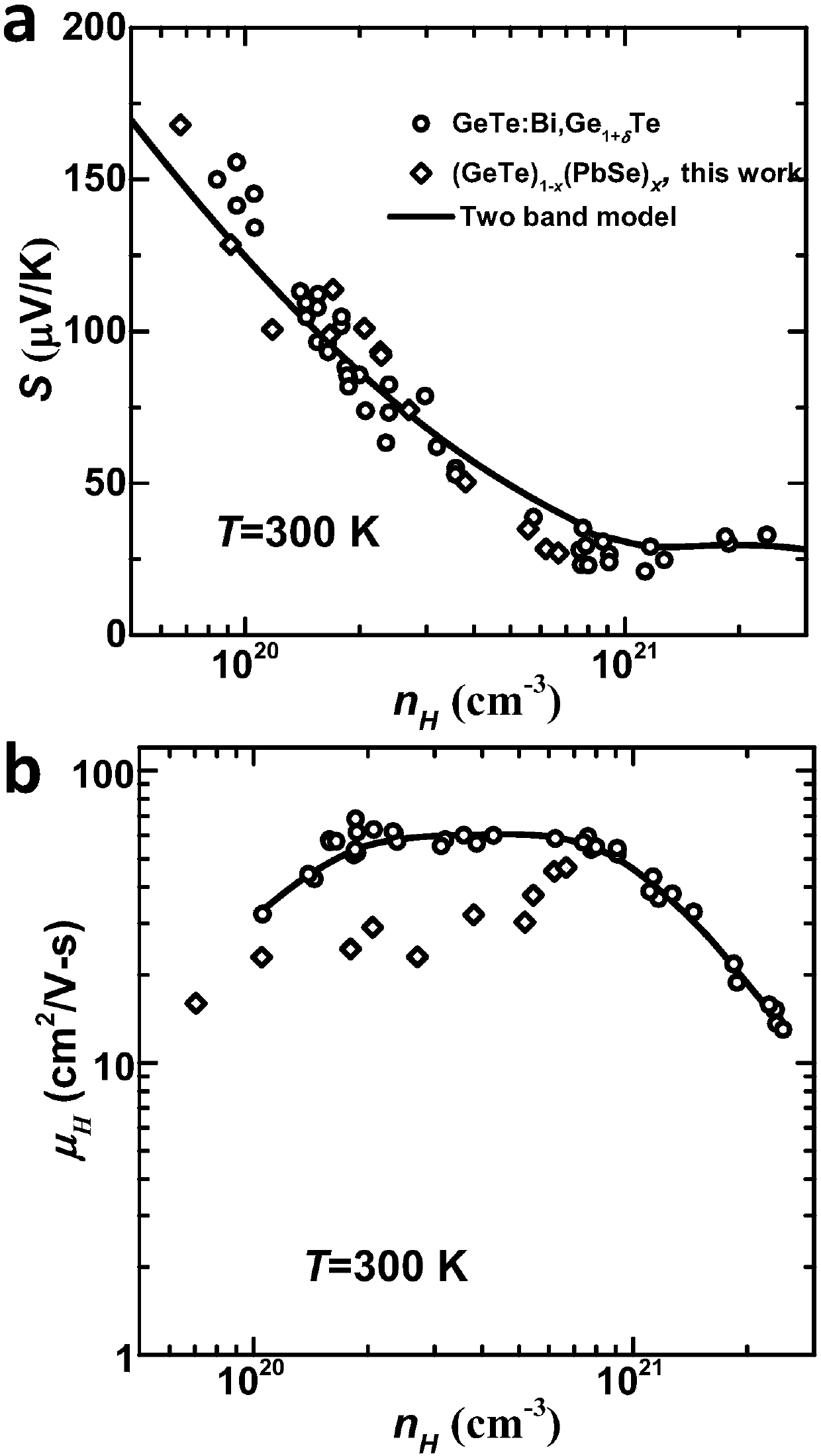

[0043] A kind of GeTe matrix alloy semiconductor thermoelectric material, its chemical formula is (GeTe) 1-x (PbSe) x, 01-x (PbSe) x Block material:

[0044] (1) According to different x values, the chemical formula is (GeTe) 1-x (PbSe) x The stoichiometric ratio of (x=0~0.4) Weigh the elemental raw materials germanium Ge, tellurium Te, lead Pb, selenium Se with a purity greater than 99.99%, place the raw materials in a quartz ampoule, and seal the quartz ampoule under vacuum.

[0045] (2) Hang the quartz tube containing the raw materials in a high-temperature well-type furnace, slowly raise the temperature to 900-1000°C at a rate of 150-200°C per hour, and keep it warm for 6-12 hours, and then quickly quench and cool to obtain the first ingot ; In this step of this embodiment, the temperature is slowly raised to 950° C. at a rate of 200° C. per hour, and kept at 950° C. for 6 hours.

[0046] (3) heat-treat the first ingot after high-temperature melting and quenching obta...

Embodiment 2

[0051] The preparation method of this embodiment is specifically:

[0052] A method for preparing a high-performance GeTe-based alloy thermoelectric semiconductor material, comprising the following steps:

[0053] (1) Vacuum packaging: The elemental elements Ge, Te, Pb and Se with a purity greater than 99.99% are dosed according to the stoichiometric ratio, and loaded into quartz ampoules in order of density from small to large, and then packaged after vacuuming for 30 minutes with a mechanical pump ;

[0054] (2) Melting and quenching: Put the quartz ampoule containing the raw material into the pit furnace and heat slowly, and raise the temperature of the quartz ampoule from room temperature to 900°C at a rate of 150°C per hour and keep it warm for 12 hours to make the raw material react in a molten state. This is followed by quenching in cold water to obtain the first ingot.

[0055] (3) Annealing and quenching: put the first ingot in the quartz ampoule into the well furna...

Embodiment 3

[0059] The preparation method of this embodiment is specifically:

[0060] A method for preparing a high-performance GeTe-based alloy thermoelectric semiconductor material, comprising the following steps:

[0061] (1) Vacuum packaging: The elemental elements Ge, Te, Pb and Se with a purity greater than 99.99% are dosed according to the stoichiometric ratio, and loaded into quartz ampoules in order of density from small to large, and then packaged after vacuuming for 30 minutes with a mechanical pump ;

[0062] (2) Melting quenching: Put the quartz ampoule containing the raw material into the pit furnace and heat it slowly, raise the temperature of the quartz ampoule from room temperature to 1000°C at a rate of 200°C per hour and keep it warm for 6 hours to make the raw material react in a molten state, This is followed by quenching in cold water to obtain the first ingot.

[0063] (3) Annealing and quenching: put the first ingot in the quartz ampoule into the pit furnace and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com