Lad containing sulfide glass and its preparationm method

A sulfide and glass technology, applied in the field of lead-containing sulfide glass and its preparation, can solve the problems of weak bond strength, limitation, poor thermomechanical properties, etc., and achieve the effects of high mechanical strength, short processing cycle and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

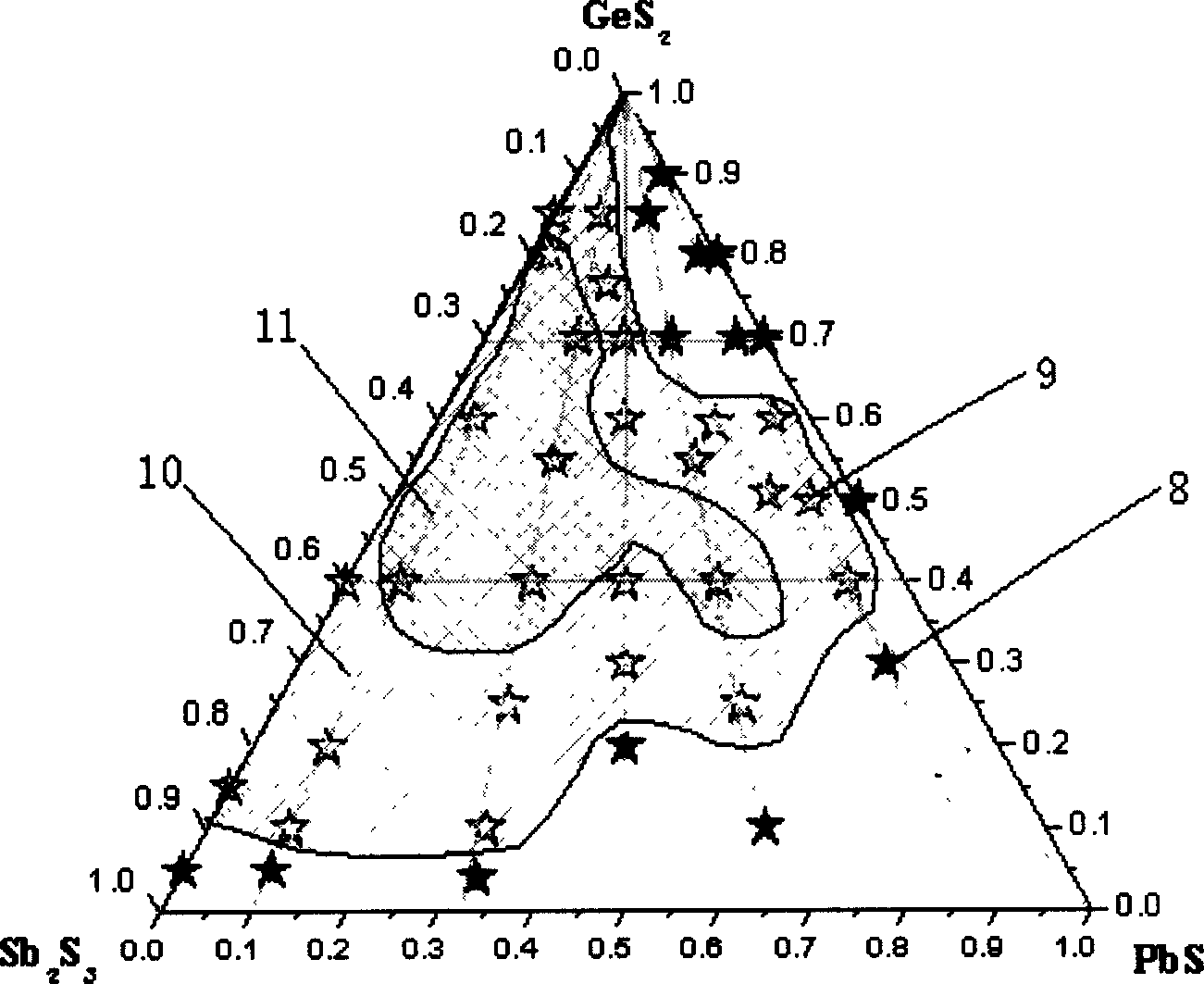

[0032] Formulation design:

[0033] Using the quaternary system of germanium, antimony, sulfur and lead, the components are designed as follows:

[0034] GeS 2

[0035] Raw material purification:

[0036] Sulfur is purified by distillation to remove moisture and other impurities in the sulfur. Put the quartz tube filled with commercial sulfur (99.999%) into the furnace, heat it while vacuuming, and raise the temperature to 170°C. At this temperature, the water quickly escapes, and the sulfur vapor recrystallizes in the cooling part, thereby being purified. The oxide layer on the surface of the high-purity raw material lead (99.999%) is rubbed off with sandpaper, and then the surface is washed with alcohol. The oxide layer on the surface of the high-purity raw material germanium (99.999%) is eliminated by the oxygen scavenger Mg. Based on the weight of the batch, the amount of Mg added is 250ppm. During the melting process, Mg can be preferentially combined with...

Embodiment 2~9

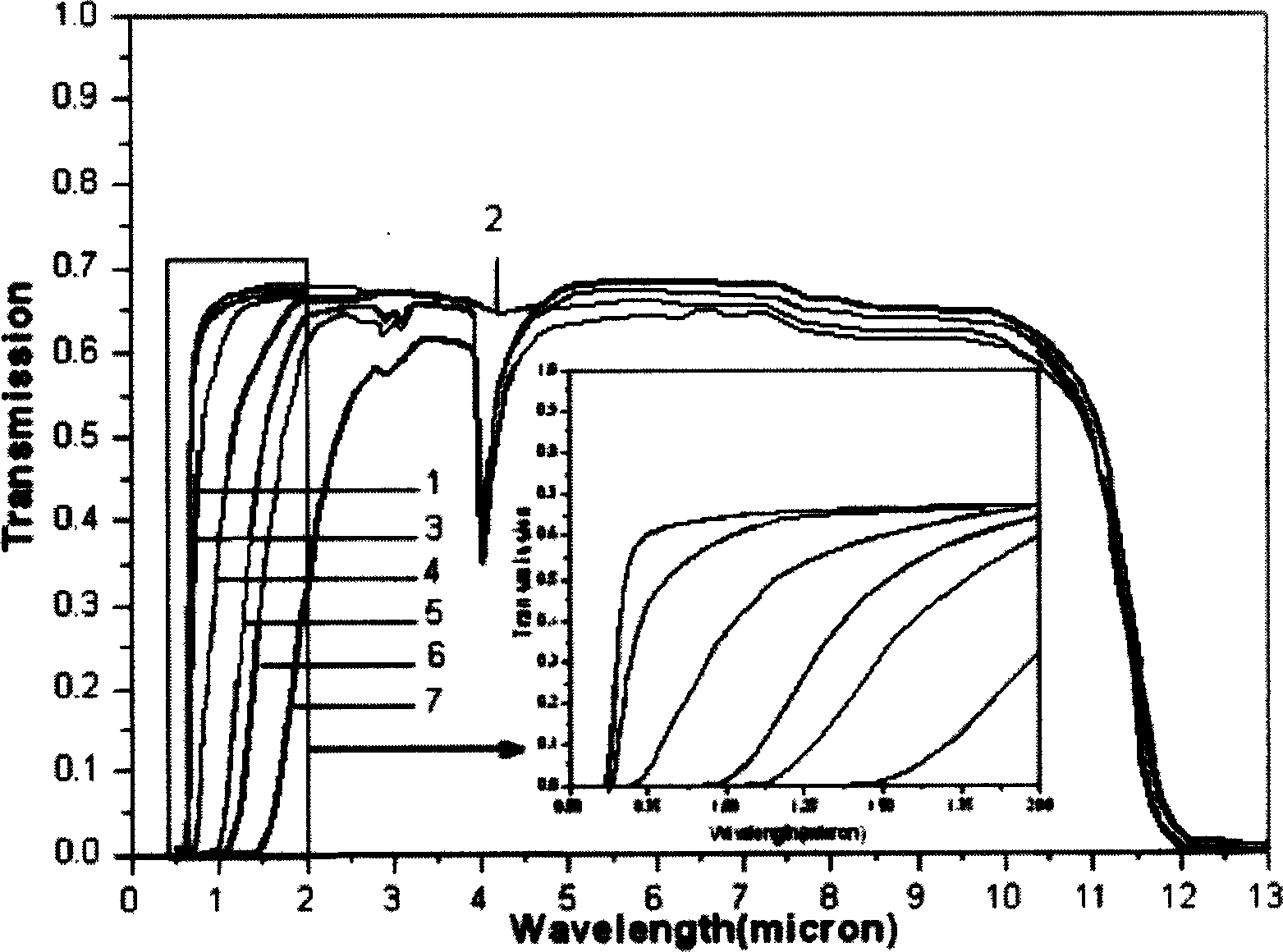

[0053] In each of the following examples, the glass preparation method is the same as Example 1, and the different glass compositions and performance test results used are listed in Table 3 and Table 4 respectively.

[0054] Example

[0055]

[0056] in:

Embodiment 2

[0057] The glass melting process condition of embodiment 2 is as follows:

[0058] Melting temperature is 900°C, heat preservation for 12 hours;

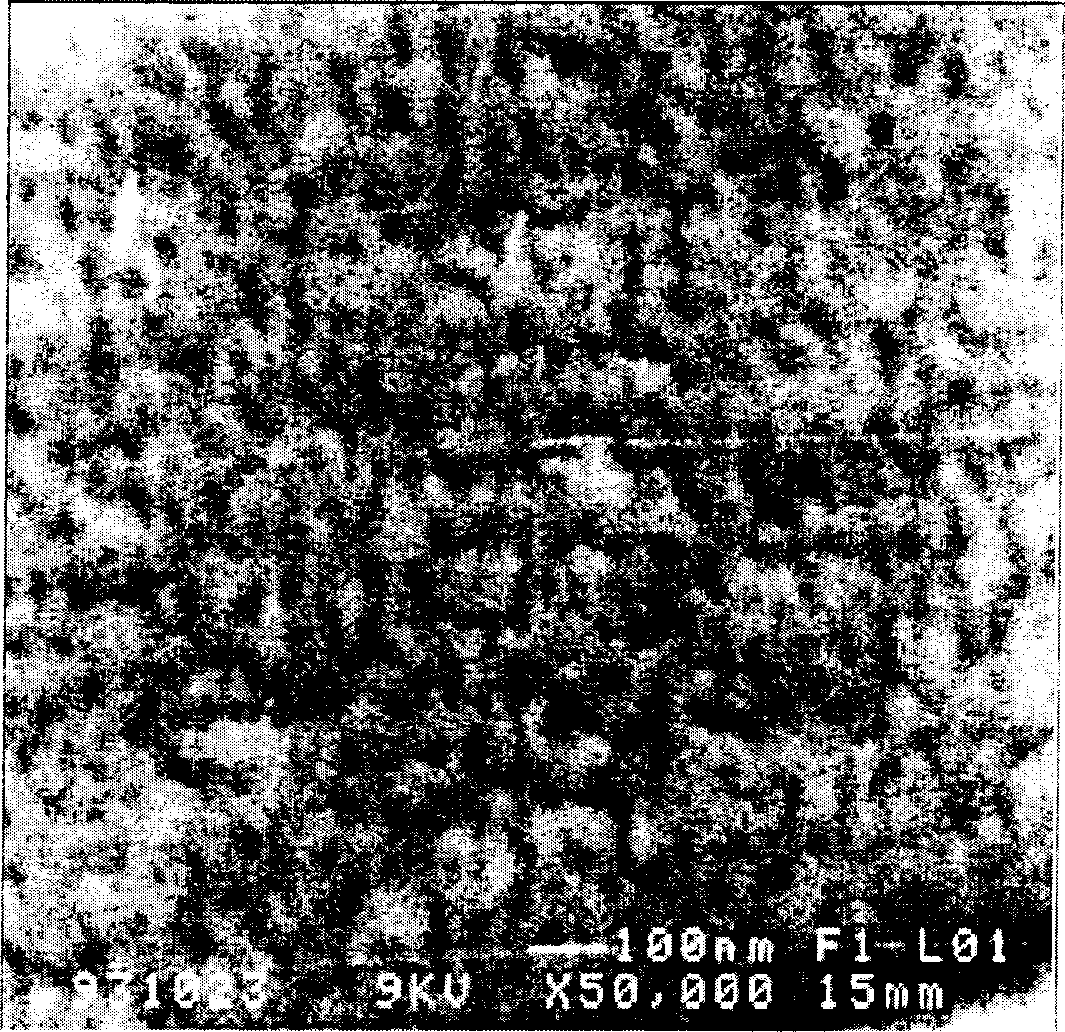

[0059] The processing conditions of step microcrystallization heat treatment step are as follows:

[0060] Put the cooled glass sample back into the muffle furnace and heat it to 350°C for 350 hours. After the heat preservation is over, the muffle furnace is closed, and the glass sample is cooled to 20°C along with the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com