Quartz rod production method

A production method and technology of quartz rods, which are applied in glass forming, glass forming, glass remolding and other directions, can solve the problems of poor temperature resistance of quartz rods, limitation of quartz rods, pollution of quartz glass, etc., and achieve surface quality. Good, good temperature resistance, low hydroxyl content

Active Publication Date: 2007-05-23

久智光电子材料科技有限公司 +1

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantages of this method are: ① due to the use of tungsten mesh materials as heaters and crucibles, the quartz glass is polluted, resulting in low purity of the quartz rod; The content is about 150ppm, and the low hydroxyl group cannot be achieved, resulting in poor temperature resistance of the quartz rod; ③ Due to the gaps between the raw materials and the bubble inclusions in the raw materials cannot be removed in time, resulting in many bubbles and color lines in the appearance of the quartz rod

The disadvantages of this method are: ①Using a hydrogen-oxygen flame as a heat source has a high hydroxyl content in the quartz rod, which is greater than about 200ppm, and the quartz rod with a high hydroxyl content has poor temperature resistance; The surface quality is polluted, and there are appearance defects such as bubbles, gas lines, and grooves, which make the quartz rods produced by this method also limited in application.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0037] The specific implementation manner of the present invention will be described in more detail below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

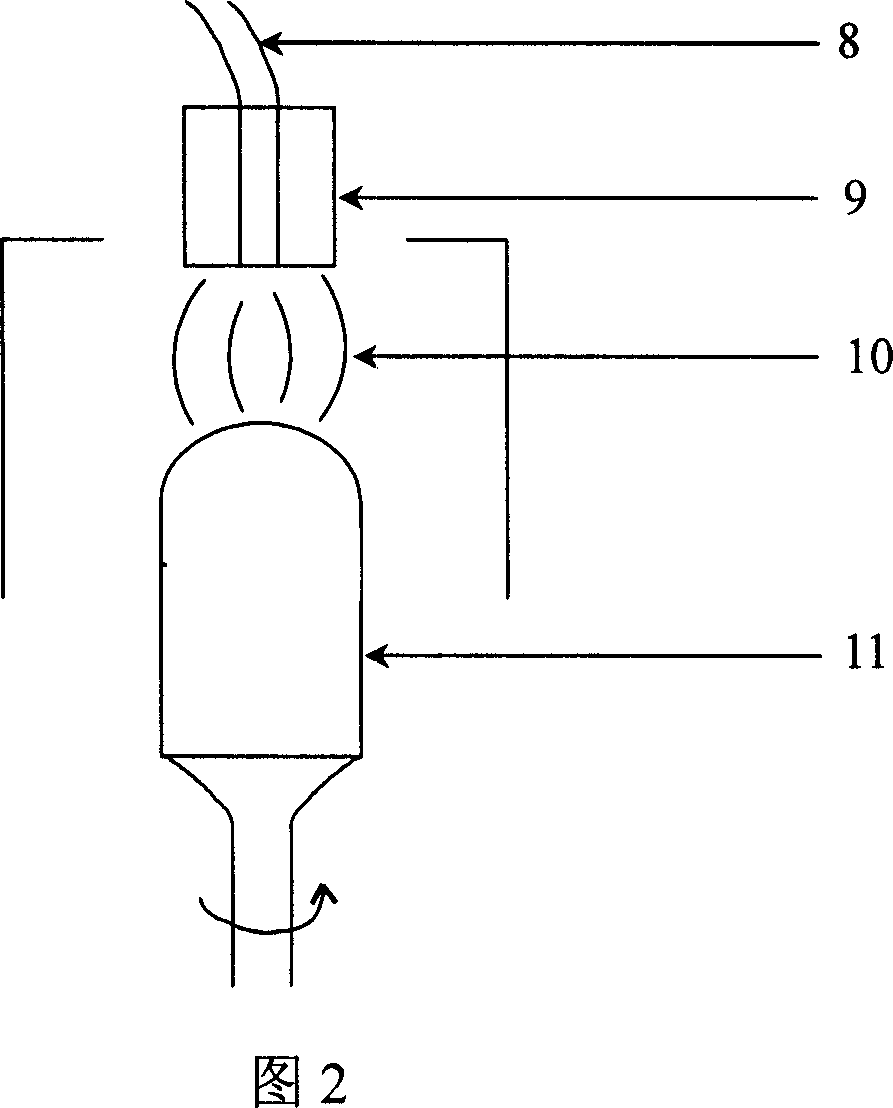

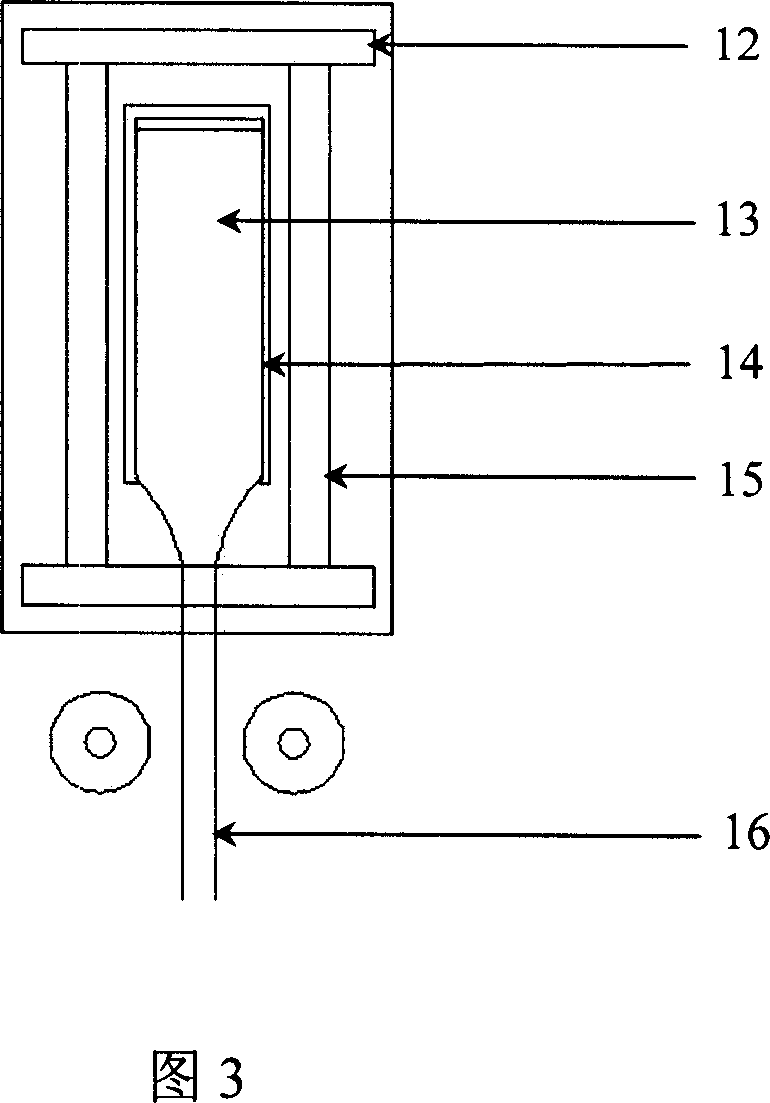

There's provided a way to produce quartz sticks: smelting the quartz sand to prepare hollow quartz columns by plasms body flame; by mechanical cold work to prepare quartz ampoule with thick walls; producing the quartz sticks by intermediate frequency heating quadric-forming technology absence of contact. The quartz ampoule with thick walls is hanged in the intermediate frequency stove so as to cause underpressure in the quartz ampoule then the producers can melt and shrink the ampoule as well as producing the quartz sticks at the same time. The quartz sticks in the invention has high purity, low hydroxyl radical content, high measurement precision, high appearance quality without flaws which can be used in high technology domain.

Description

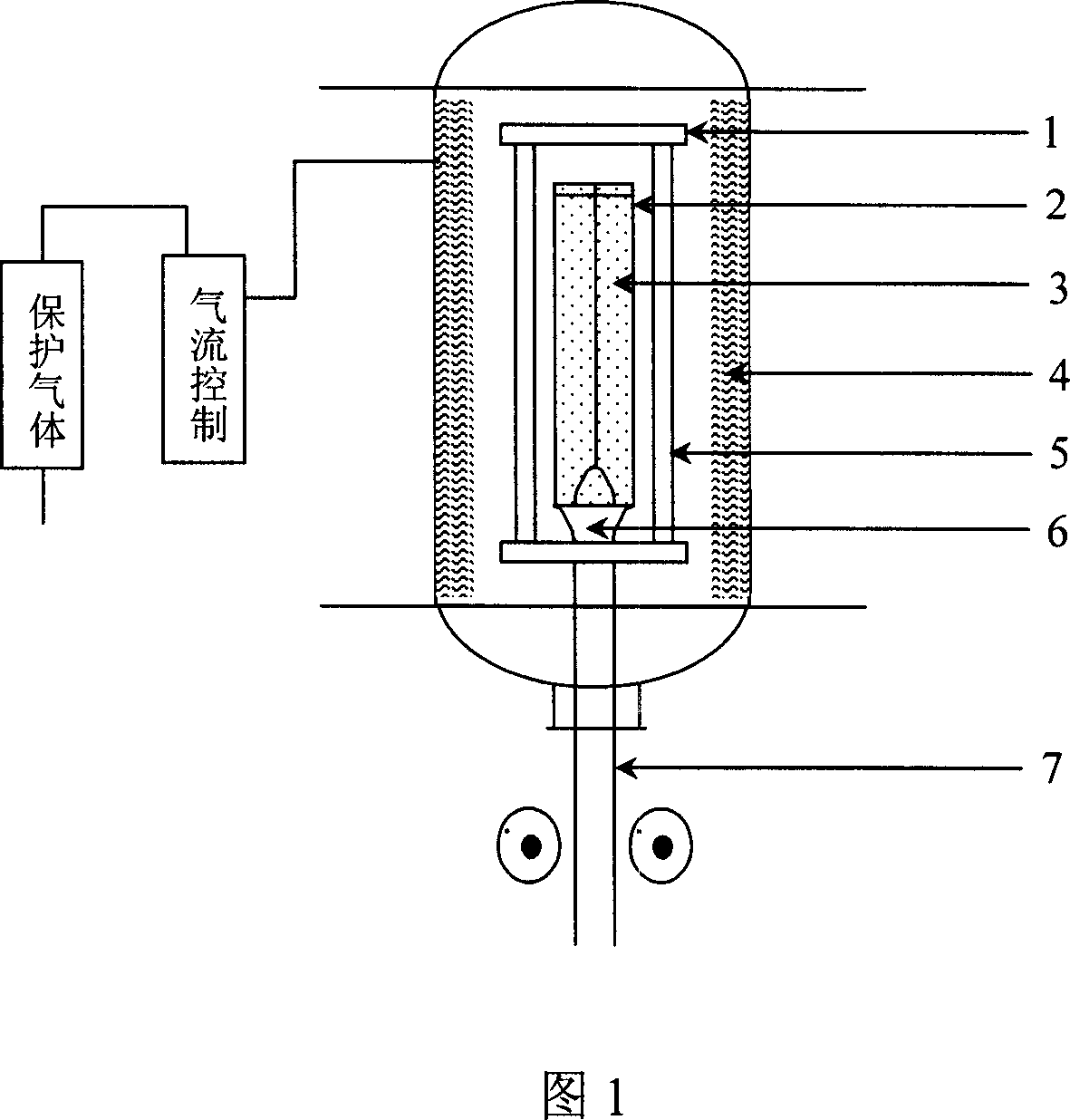

technical field [0001] The invention relates to a production method of quartz products, in particular to a production method of quartz rods. Background technique [0002] At present, there are mainly two existing technologies for producing quartz rods: continuous melting one-step method and hydrogen-oxygen flame two-step method. Among them, the continuous melting one-step process is characterized by drawing quartz rods while melting quartz powder in a continuous melting furnace. As shown in Figure 1, first put the quartz sand into the crucible in the continuous melting furnace through the silo, pass the protective gas into the furnace, and then heat it. The heating temperature is 1900°C-2000°C. After heating to the molten state of the quartz sand, start The material is drawn through the mouth of the furnace to draw quartz rods. During the process of drawing the quartz rods, quartz sand is added to the continuous melting furnace while drawing the rods to continuously draw th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B20/00C03B15/14

CPCC03B17/04C03B23/04

Inventor 张锦杨兴华李文彦张晓风

Owner 久智光电子材料科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com